TOC

TOC

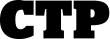

Minutes before Ricardo Lopez and the Customs by Lopez crew headed off for their SEMA 2021 unveil, Kevin “Fuelish Media” Aguilar snapped our Mar. ’22 cover image of “Monik,” this stunning ’56 Chevy!

Rodney Bauman, Tommy Lee Byrd, Ron Ceridono, Michael Christensen, Ron Covell, Grant Cox, Dominic Damato, John Drummond, Fuelish Media, Eric Geisert, Joe Greeves, John Jackson, Barry Kluczyk, Scotty Lachenauer, Ryan Manson, Josh Mishler, Todd Ryden, Jason Scudellari, Chris Shelton, Tim Sutton, Chuck Vranas, Michael Yamada – Writers and Photographers

ClassicTruckPerformance.com

ModernRodding.com

AllChevyPerformance.com

InTheGarageMedia.com

Mark Dewey National Sales Manager

Patrick Walsh Sales Representative

Travis Weeks Sales Representative

ads@inthegaragemedia.com

inthegaragemedia.com “Online Store”

For bulk back issues of 10 copies or more, contact store@inthegaragemedia.com

PRINTED IN THE USA.

The Classic Truck Performance trademark is a registered trademark of In The Garage Media.

Still Hammerin’

Still Hammerin’

s I sit here writing this—late, as usual—I’m once again fighting the “what ifs” that constantly like to party in my head. This time, the occasion is the future of our hobby, or, more importantly, how far are we willing to go to keep it and the “prehistoric” vehicles we love alive and running?

Not to intentionally be the doom-and-gloom pessimist I’m famous for, but this particular thought party always seems to rage after filling up at the pump, receiving a registration renewal notice in the mail, or simply trying to purchase any performance parts.

While the price of gasoline in this fine state of California has “slightly” come down since surpassing the $5 mark not too long ago, I don’t see it ever going back anywhere near reasonable pricing—at least not here. I was astonished when E85, normally significantly cheaper than regular petroleum fuel, creeped up right behind the cost of unleaded over the holidays (it’s since come down a little, but not what it was before all this madness began). With 2035 approaching quicker than I’m willing admit, and the EV mandate looming over our heads, what does the future of fossil fuels really hold in store for us?

Parts Dept.

Parts Dept.

Feature

Feature

Photography BY THE AUTHOR

Photography BY THE AUTHORost builders know that balancing between work and family life is a hard struggle. This goes especially for those who own their own shops as it takes many personal sacrifices to create a successful business. Working late hours to finish projects to help grow your name can take a toll, and if you’re lucky you have a family who will stand by your side in order to turn dreams into realities.

Ricardo Lopez is a third-generation automotive builder who took knowledge from his family in Mexico to create his own shop called Customs by Lopez. Based out of Compton, California, Ricardo was able to prove that it doesn’t matter where you come from as long as you have persistence and dedication to your craft. With help from his wife, Monica, Ricardo was able to get his business off the ground. With lots of hard work he was able to grow the shop, and people have taken notice. Over the last few years, Ricardo built a few rides for the annual SEMA Show where the big boys bring their best stuff to impress the world.

Now on a roll with the shop, Ricardo thought it was time to repay his wife for all the hard times spent in the past. About seven years ago he was able to pick up this ’56 Chevy and in 2020 he decided it was time to build it for his wife to enjoy. To up the challenge, he decided to finish it for SEMA, which is always a huge challenge. Long hours after regular workdays are the norm when building vehicles to be at the show, but that’s what separates the men from the boys.

Tech

Tech

Photography by THE AUTHOR

Photography by THE AUTHORremember, back in the day, Volare clips were all the rage for the early F-100s. Matter of fact, there were quite a few “specialists” within a 50-mile radius of where I lived. Today, however, with the advancement of the aftermarket IFS kits, not to mention the wide variety of available aftermarket chassis, it doesn’t make a whole lot of sense resorting to the older torsion bar clips.

That said, there is somewhat of a current trend in clip borrowing for the ’76-up F-100s: the ’03-11 Ford Crown Victoria bolt-in front suspension crossmember. Occasionally, you can spot these a mile away without having to peer under the truck, as the increase track width puts the front wheels at the fender’s edge if the right negative-offset wheel isn’t used. For the most part, however, the cast-aluminum cradle is an easy way to update that old split I-beam front suspension.

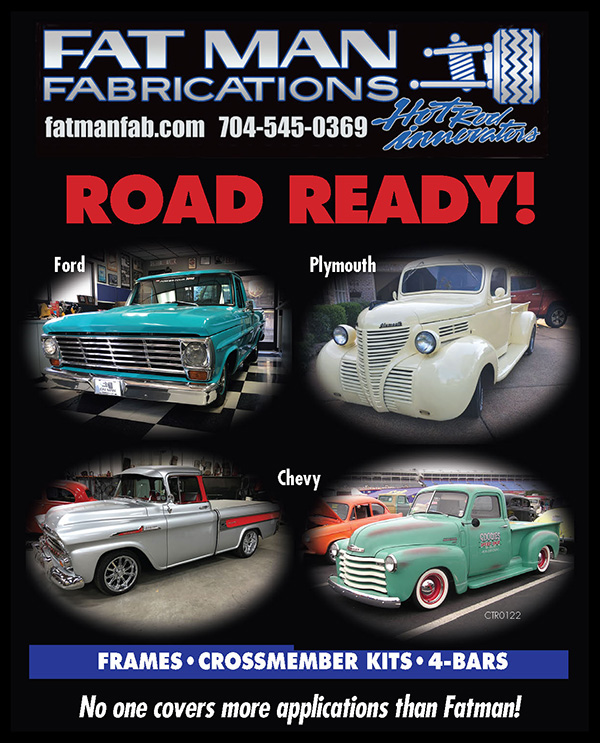

With the late-model clip you get a decent package deal: disc brakes, rack-and-pinion steering, the ability to install a modern engine/trans (including the Coyote) with ease. The only slight drawback other than the track width (which our friends at Fatman Fabrications offer an improved geometry control arm kit for!) is the standard coilover-shock configuration. But there is a cure for that as well—and it’s without a doubt one of the most affordable and easy-to-accomplish upgrades you can do to your Crown Vic–equipped F-100 … and get amazing performance results.

Feature

Feature

PHOTOGRAPHY BY THE AUTHOR

PHOTOGRAPHY BY THE AUTHORrowing up, there was always that one driveway in your neighborhood where all the cool cars could be found regardless of whether they were being wrenched on, tuned to perfection, or detailed to get them ready for the weekend. The only way this could get better is if you lived within earshot of your local dragstrip. Well, for Clay Stevens of Cordova, Maryland, the experience led him down a performance path starting in his teens. The ’49 Chevy Advance Design pickup laid out across our pages is a stellar example of what can be accomplished when melding traditional good looks with a ferocious driveline, thus making it competitive on the quarter-mile.

Tech

Tech

Photography BY The Author

Photography BY The Authorhen we think of Classic Truck Performance the first thing that comes to mind is the engine. These days that usually seems to involve Coyote or LS swaps. Other performance enhancements center around suspension or complete chassis upgrades and bigger brakes. Transmissions seem to be forgotten in many cases unless an entire modern drivetrain is being transplanted.

When our classic trucks were new, they were designed as work vehicles and as such engine and transmission choices were geared toward that end. Automatics weren’t all that common and in the case of GM, offerings were originally the two-speed powerglides, later replaced by the Turbo 350 and 400. Fords were blessed with three-speed autos, but none of these transmissions, and the accompanying rearend gear ratios, were designed for the way we use classic trucks today. As personal transportation, performance vehicles, and weekend cruisers, these old gearing options don’t cut it with today’s faster speeds that seem to be the norm. On the manual transmission side, things weren’t much better with three- and four-speed “truck” transmissions. Heavy gears and slow shifting do not make for a lot of fun when driving a three-pedal truck for pleasure.

Our project ’76 F-100 was ordered as a farm truck where it spent most of its life. It had an unusual combination of a 302 small-block Ford engine with a BorgWarner T-18 four-speed, popularly called the “Granny Low” trans. First gear is an absurdly low 6.32:1 ratio, good for crawling up the side of a mountain with a heavy load. It also means you go about 10 feet before needing to shift the big gap to Second. When put behind big-block FE engines or the mighty 460, most owners just choose to use the torque and start off in Second gear, but that isn’t really an option with the 302. Something had to change to make this truck more enjoyable.

Feature

Feature

Photography By THE AUTHOR

Photography By THE AUTHORhat do you do when you’re torn between buying a brand-new truck for its reliability or going with an old truck for its classic, timeless appeal? Well, if you’re anything like Jon Blumenthal, a general contractor from Encinitas, California, you get the best of both in one single pickup package.

During one of his regular eBay browsing sessions, Jon ran into this ’68 Dodge W100 (4WD) Power Wagon for sale in Texas that literally stopped him mid scroll. He admits that he wasn’t looking for a Dodge truck specifically, but once he saw the amount of original patina it had and that the truck was actually in decent enough shape physically and not a rusted-through scrap heap, he threw a bid on it—and won.

That’s not to say the Dodge wasn’t without its issues when it landed at Jon’s house, as he was sure to fill us in. “The truck was a total death trap when it first arrived,” he admits. “There was a big hole in the floor where the transfer case was, it had drum brakes all around and no power steering to turn the 36-inch tires it had on it. I just didn’t feel comfortable driving it more than 40 mph due to all the violent rattling and shaking going on.”

Tech

Tech

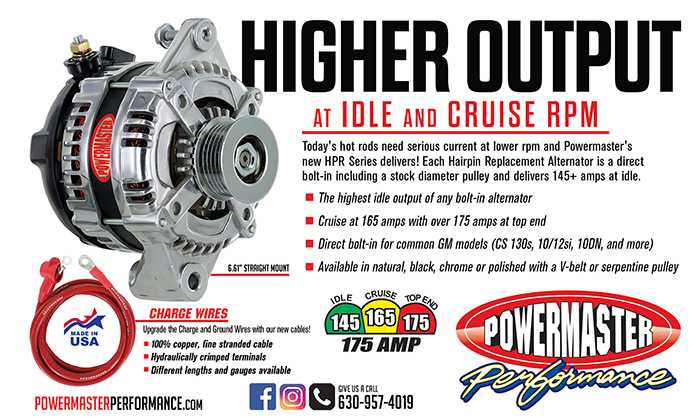

1. There’s a lot to consider when updating your charging system, from current requirements to wiring and pulley sizes.

BY Todd Ryden Photography BY THE AUTHOR

Photography BY THE AUTHOR

hoosing and installing an alternator sounds easy enough, right? In the old days you simply bolted in the new (or rebuilt!) unit, connected the wires, and tightened the belt to where it had an inch or two of deflection and done. Alas, those days are long gone, along with a factory “high-output,” 50-amp alternator.

Today, you likely need at least twice as much output to power the growing list of electronic controls on a modern-built classic truck. We’re talking about electric fans, fuel pumps, HVAC systems, EFI, and more modern amenities. With increased output requirements also comes more pressure on your wiring connections, cables, and grounds, not to mention belt and pulley choices.

It’s important to note that the alternator is producing the electricity your vehicle needs while it is running not the battery. The battery’s main function is to act as a reserve storage of electricity that is primarily used to get the engine started. Once running, the alternator is tasked with maintaining the battery at its full capacity as well as powering everything on the vehicle that requires voltage. If you’re using more than the alternator is capable of producing, well, you’ll be on the side of the road eventually, or as a best case, sitting in a parking lot waiting for a jump.

Feature

Feature

PHOTOGRAPHY BY THE AUTHOR

PHOTOGRAPHY BY THE AUTHORhe idea of doing whatever it takes to get the job done correctly should always be the goal, but often the cost in time, money, and material has a project truck driving down a different road. Perfection doesn’t come cheap and it’s certainly not quick, but, in hindsight, the results always seem to be worth the extra effort. It was with that “no-compromise” philosophy that Canadian Joe Massaro began the creation of his ultimate ’56 F-100.

Tech

TechInTheGarageMedia.com

1. Here’s the scan of the whole truck before any modifications were made.

Part 2: Sectioning the Cowl

BY Ron Covell Photography BY THE AUTHOR, Michael Christensen & Gary George

Photography BY THE AUTHOR, Michael Christensen & Gary George

hile we often enjoy seeing adventurous experimentations with truck styling, this is something that is easily overdone. Sometimes the more subtle modifications produce a better result.

Last month we introduced Jason Souza’s F-100 project

being built at Gary’s Rods and Restorations in Northern California and showed the work done on the floor and firewall. This time we’re going to look at a subtle modification being done to lower the roof—not by chopping but by sectioning the cowl.

Feature

Feature Photography By Ray Ambler/RA Photos

Photography By Ray Ambler/RA Photoshen we started this fine publication of ours, we titled it as such—Classic Truck Performance—with the intent on strongly promoting the performance aspect of all things classic truck. While that has and will remain the crux of our monthly content, we would be completely remiss if we didn’t on occasion acknowledge the roots of this fine hobby of ours. With that said, we present you Seth Doulton’s ’58 Chevrolet Apache deluxe frame-off restoration!

IN THE SHOP

IN THE SHOP

Photography By THE AUTHOR

Photography By THE AUTHORhere have been dozens of Hollywood-produced movies where someone living in the East packs up all their belongings in an old truck and heads out West to make it big. Rarely do you ever hear of that kind of thing actually working out, but for Paul Bosserman it’s looking pretty good.

After growing up in Virginia and having had a successful stairway-building business when he was younger, Paul’s passion for hot rods eventually got the better of him. When he was a kid his dad had a channeled Ford coupe, and Paul’s first car was a ’57 Chevy hardtop, but he was trained in metallurgy and in fabrication shops on how to manipulate steel in various forms. With the economic crash of 2008 his type of work was hard to find, but he was able to hook up with a sports car restoration shop that built Pebble Beach Concourse–level vehicles (allowing him to hone his fab skill even further).

He’d also run across a ’38 Chevy (a former six-wheel coal delivery dump truck) that he bought sight-unseen for $500. It was only a cab and frame but, when he went to retrieve it, they had to cut away the bushes that had grown up against the house to find the hood and front fenders, and the original ’38 registration was still with the truck. After Paul installed a 350/700-R4 trans combo he made the truck driveable.

Ad Index

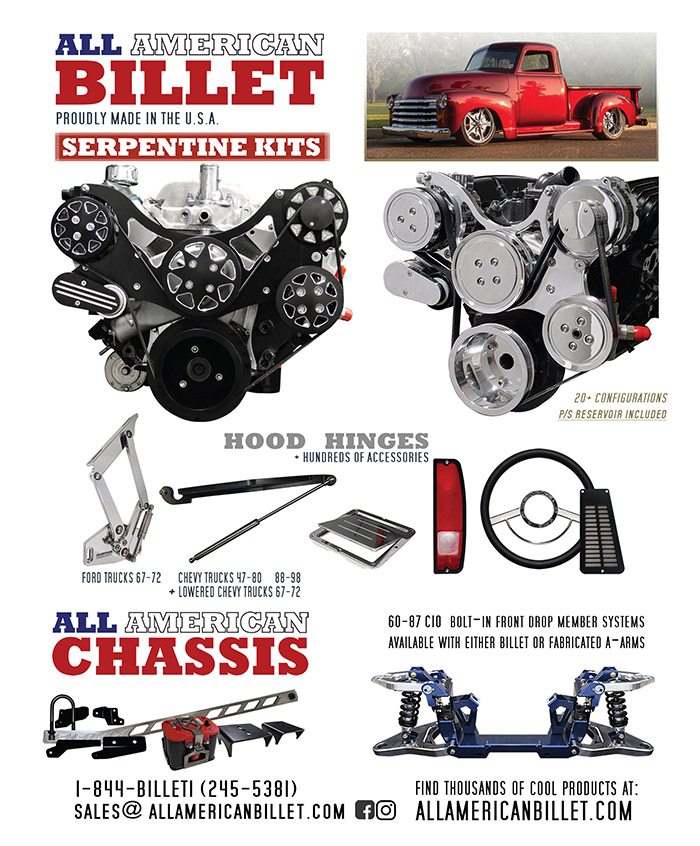

- All American Billet19

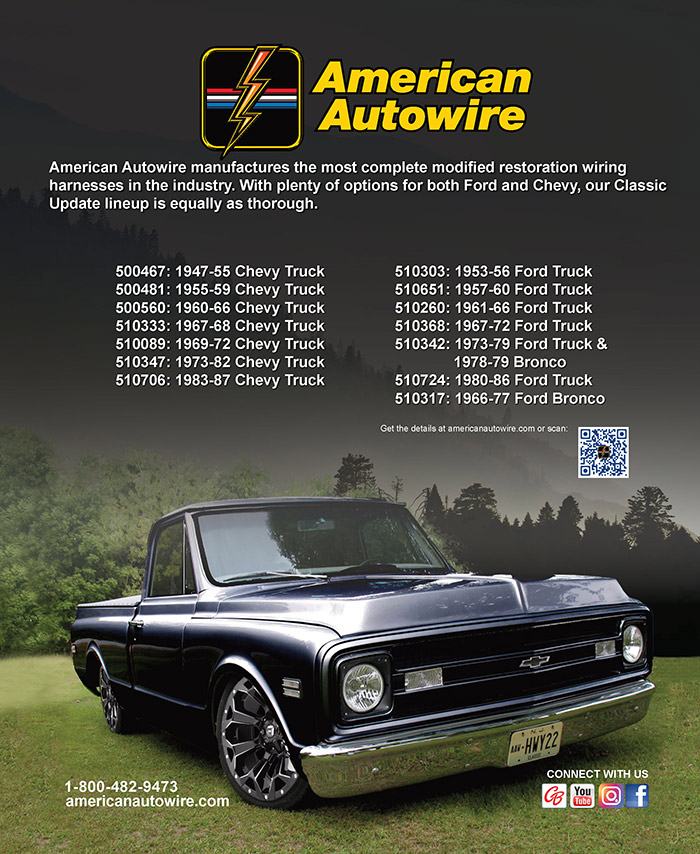

- American Autowire61

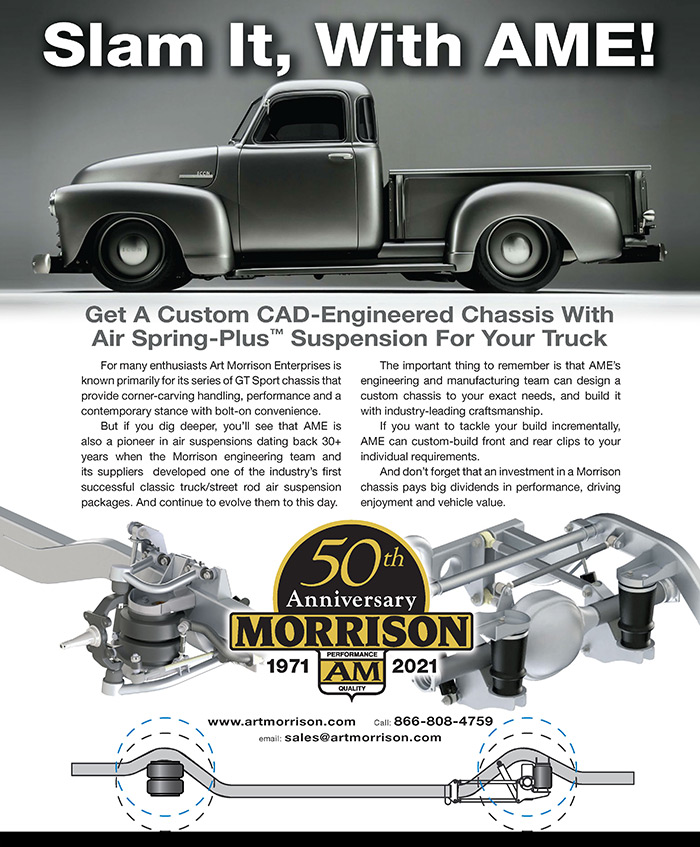

- ART MORRISON ENTERPRISES23

- AUTO METAL DIRECT27

- Automotive Racing Products43

- BEDWOOD AND PARTS63

- BOWLER PERFORMANCE TRANSMISSIONS95

- BROTHERS TRUCK PARTS100

- CHEVS OF THE 40’S81

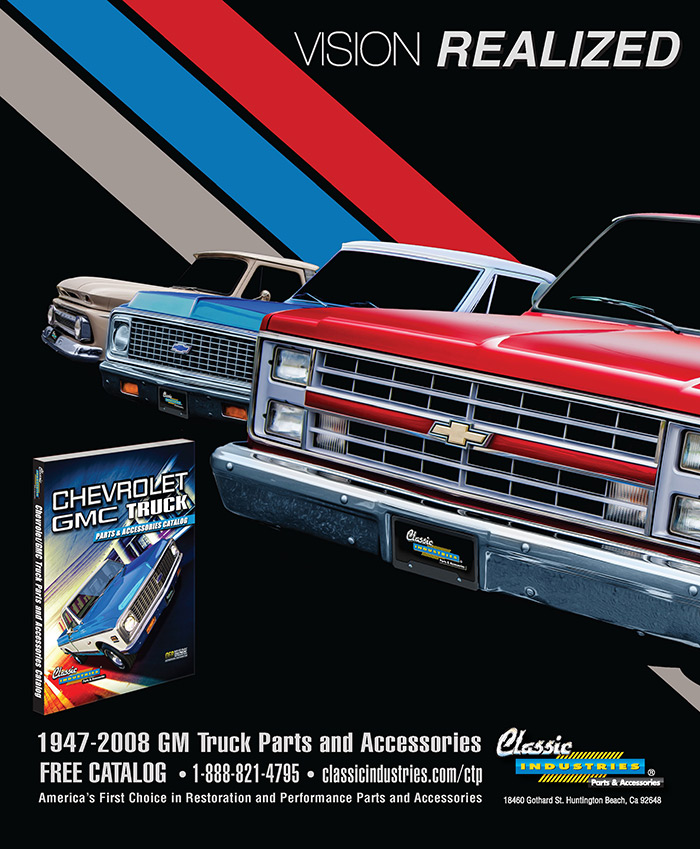

- CLASSIC INDUSTRIES35

- CLASSIC INSTRUMENTS56

- CLASSIC PERFORMANCE PRODUCTS4-5; 95

- DAKOTA DIGITAL99

- DESIGN ENGINEERING81

- EATON Detroit Spring89

- FAT MAN FABRICATION89

- FITECH EFI17

- FLAT OUT ENGINEERING89

- FRONTIER SHOP SUPPLIES71

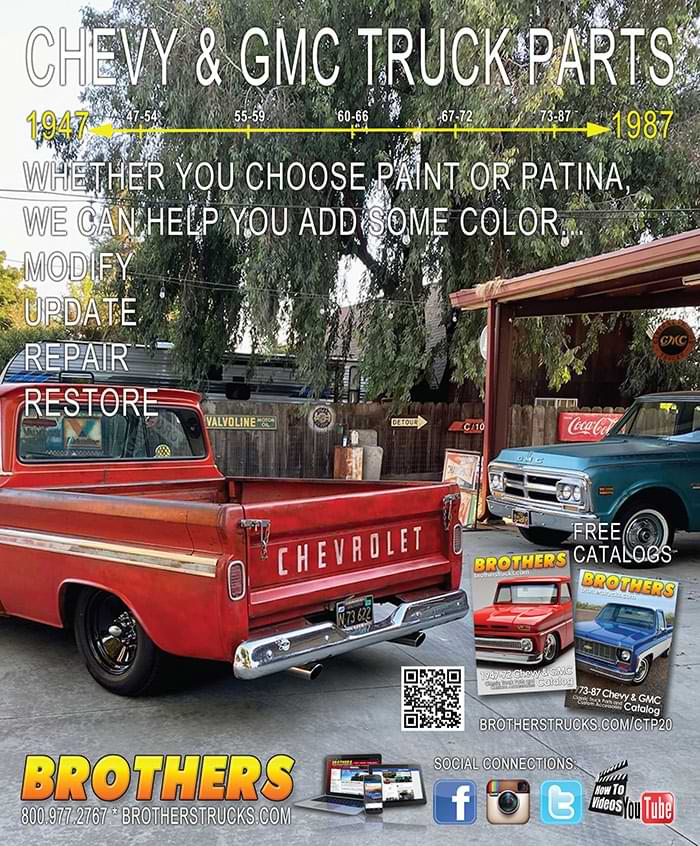

- Golden Star Classic Auto Parts6

- Granatelli Motor Sports71

- Heidts Suspension Systems79

- HEINZMAN STREET ROD SHOP97

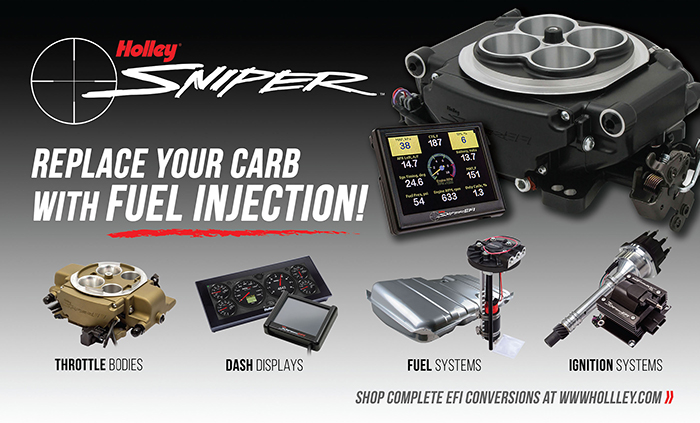

- Holley Performance Products57

- JOHN’S INDUSTRIES97

- KUGEL KOMPONENTS95

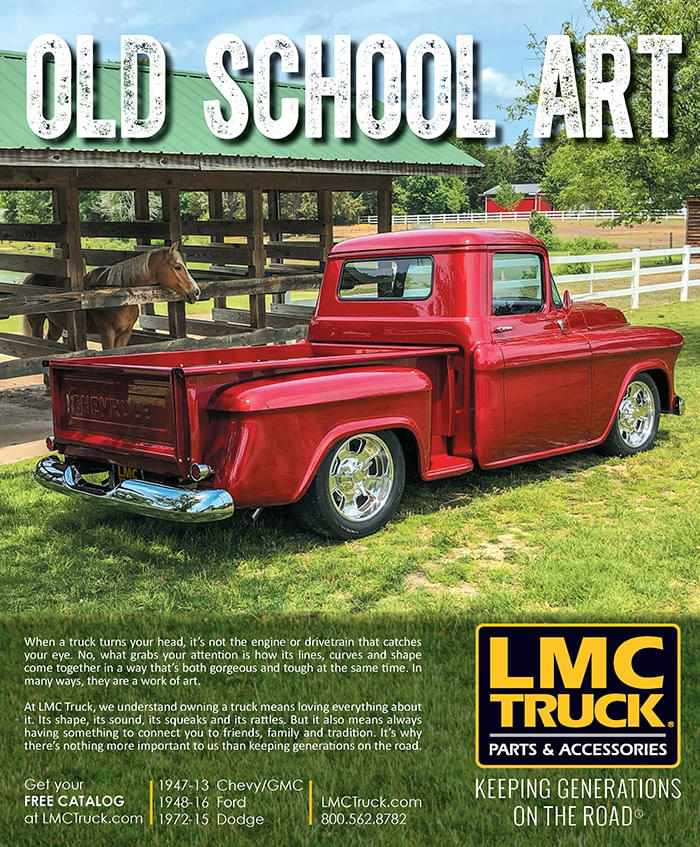

- LMC TRUCK25

- LOKAR5; 53

- NATIONAL STREET ROD ASSOCIATION47

- OLD AIR PRODUCTS73

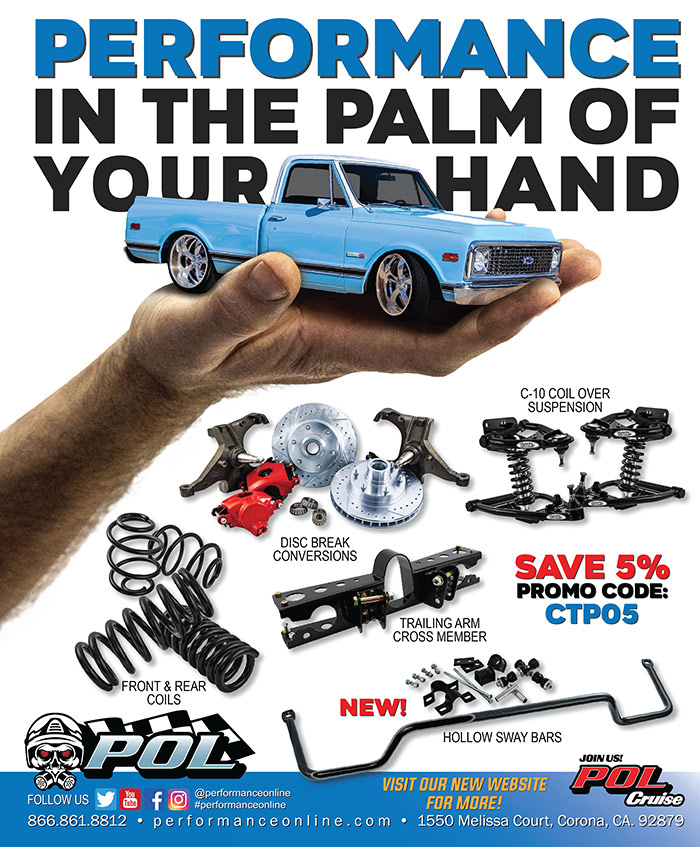

- PERFORMANCE ONLINE37

- PHOENIX MACHINE PRODUCTS97

- POWERMASTER PERFORMANCE73

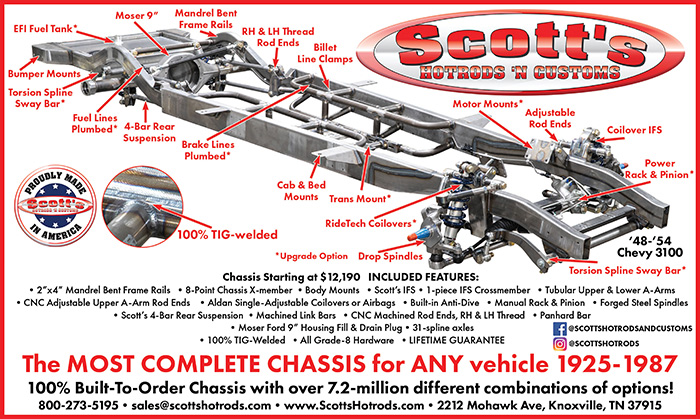

- SCOTT’S HOTRODS63

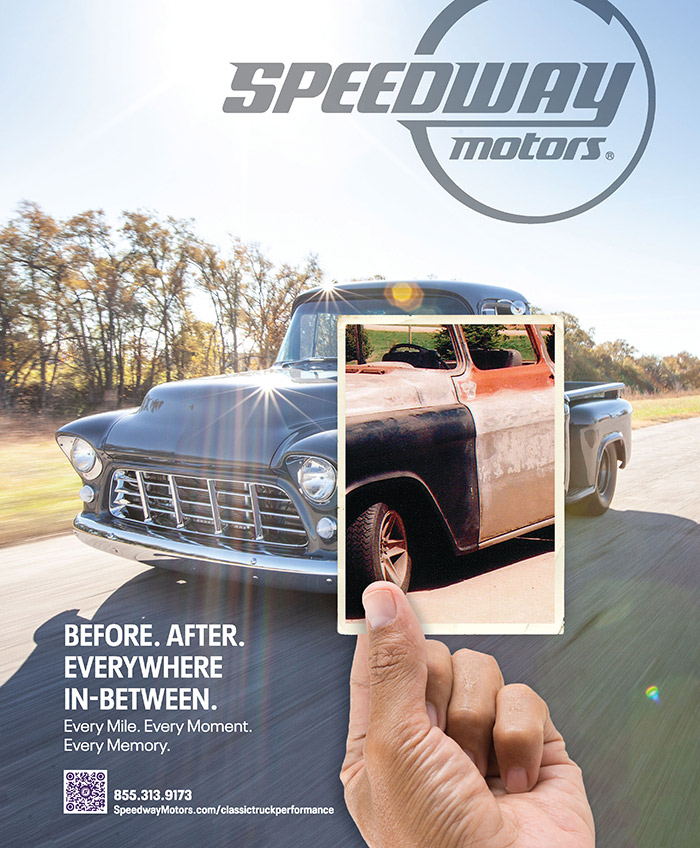

- SPEEDWAY MOTORS29

- Strange Engineering65

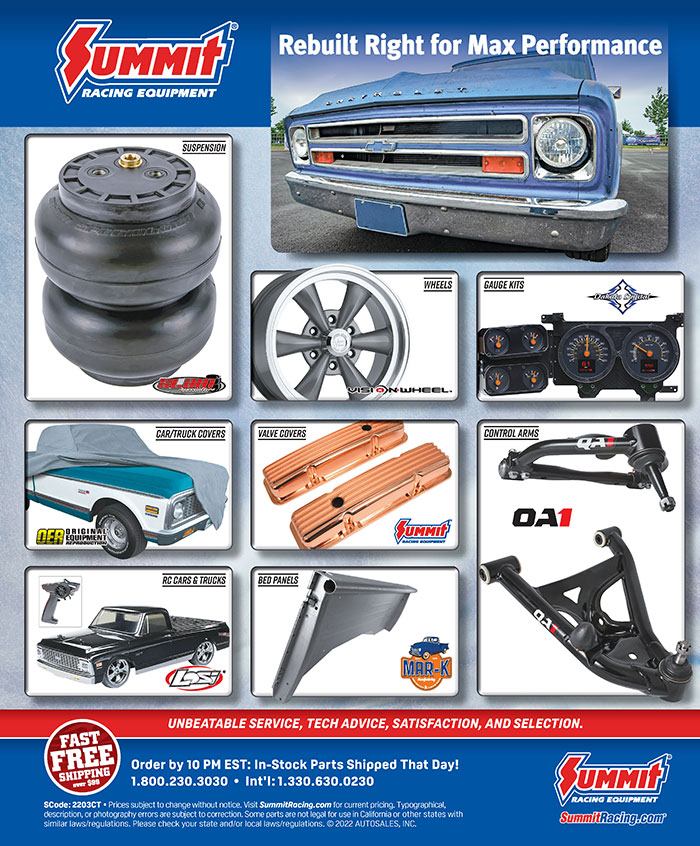

- Summit Racing Equipment11

- THERMO-TEC AUTOMOTIVE89

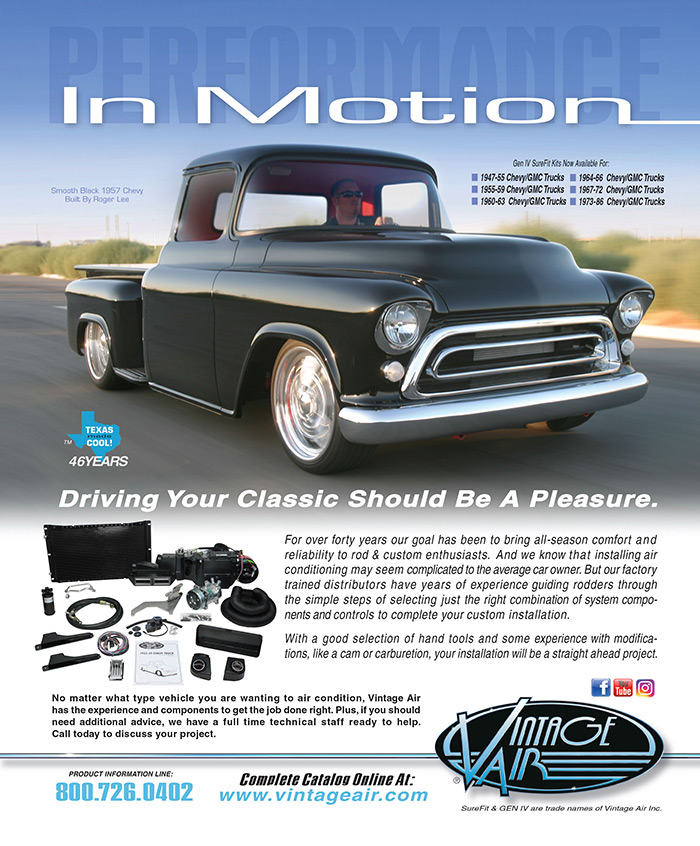

- VINTAGE AIR9

- Wentz Motor Company97

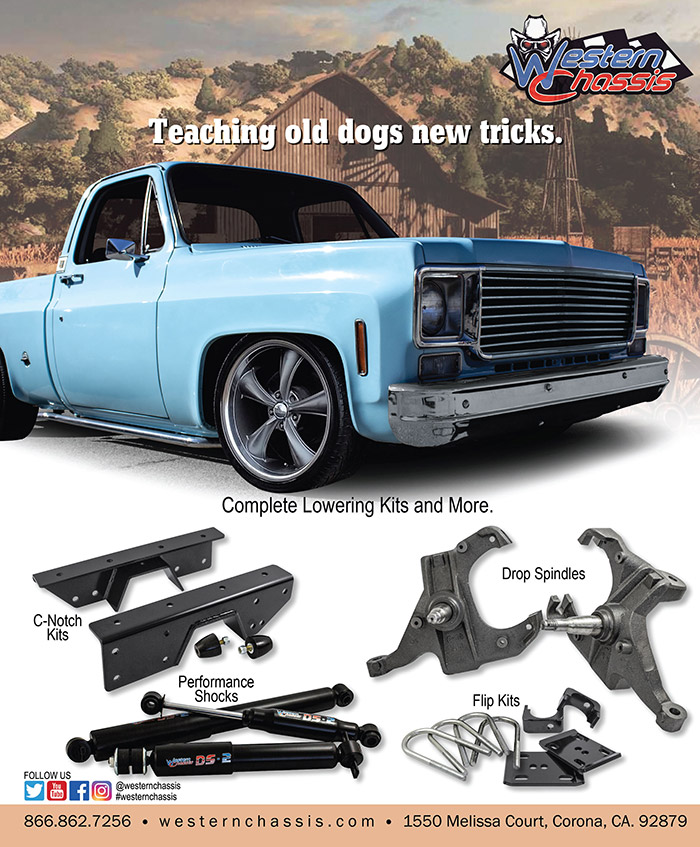

- WESTERN CHASSIS55

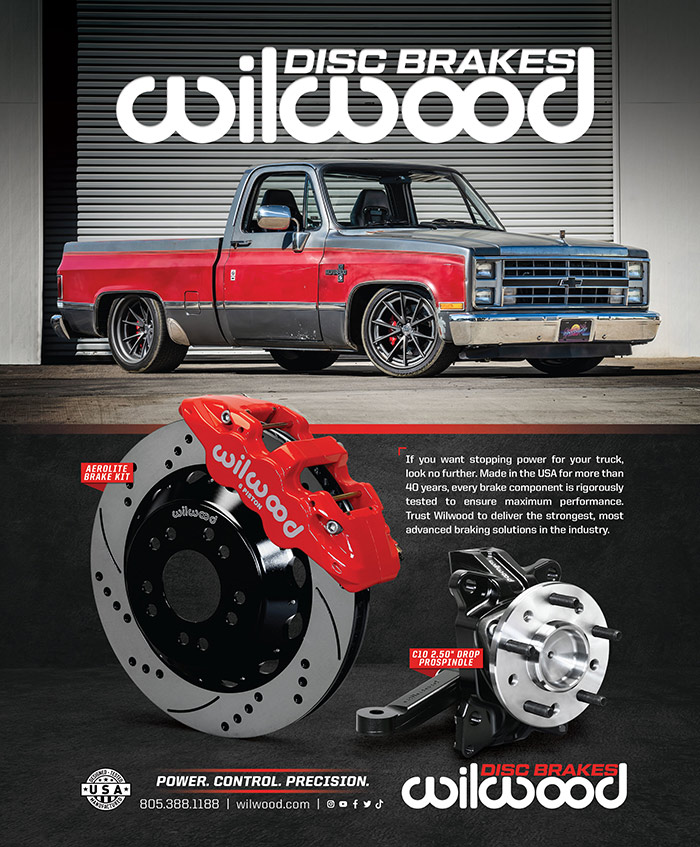

- WILWOOD ENGINEERING45

- WINTERS PERFORMANCE79

BY

BY