TOC

TOC

378 E. Orangethorpe Ave. Placentia, California 92870

#ClassicPerform

Wes Allison, Rodney Bauman, Tommy Lee Byrd, Ron Ceridono, Michael Christensen, Ron Covell, Grant Cox, Dominic Damato, John Drummond, Fuelish Media, Eric Geisert, John Gilbert, Joe Greeves, Barry Kluczyk, Scotty Lachenauer, Don Lindfors, Ryan Manson, Josh Mishler, NotStock Photography, Todd Ryden, Jason Scudellari, Chris Shelton, Tim Sutton, Chuck Vranas, Michael Yamada – Writers and Photographers

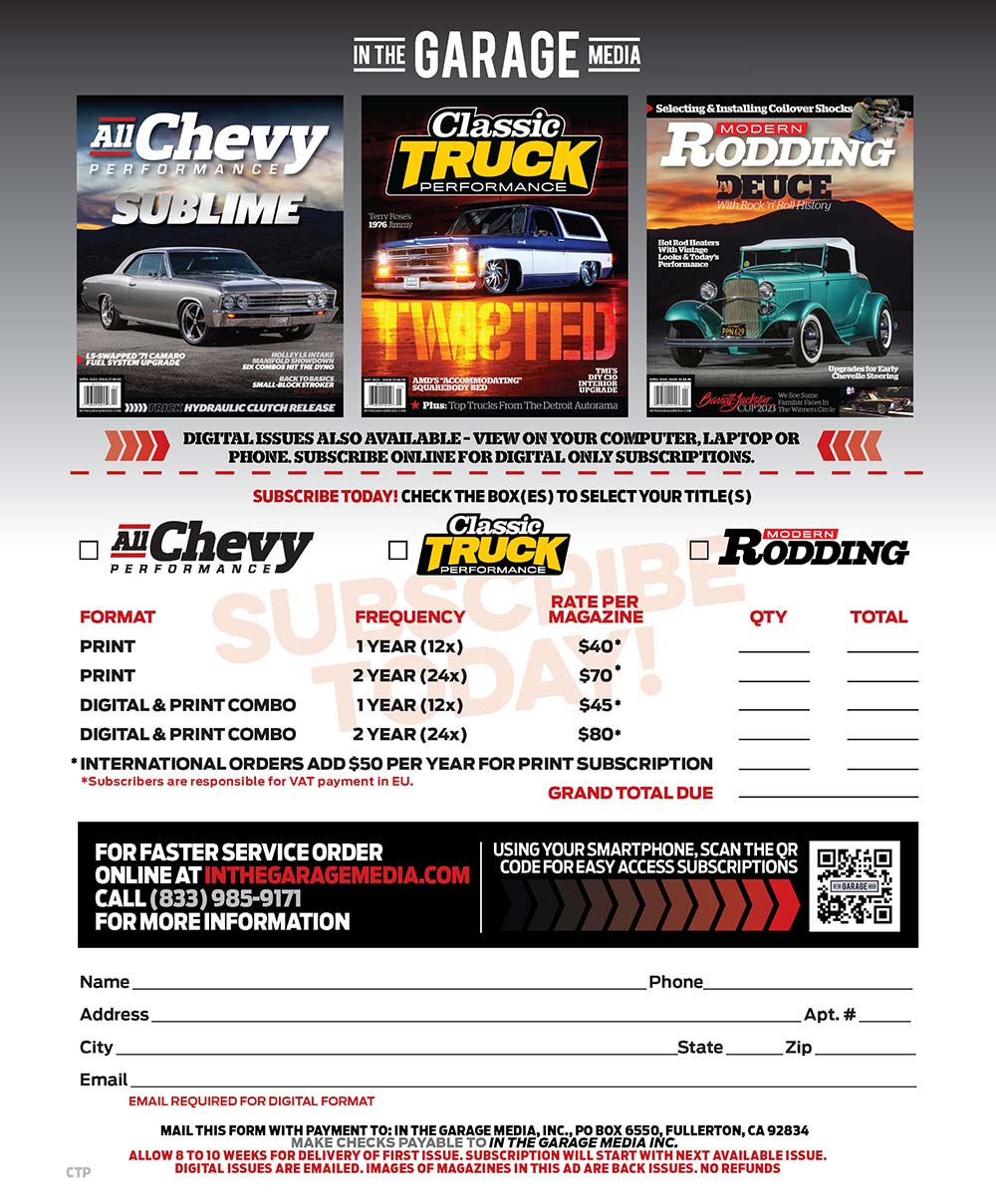

ClassicTruckPerformance.com

AllChevyPerformance.com

ModernRodding.com

InTheGarageMedia.com

Travis Weeks Advertising Sales Manager

Mark Dewey National Sales Manager

Patrick Walsh Sales Representative

ads@inthegaragemedia.com

inthegaragemedia.com “Online Store”

For bulk back issues of 10 copies or more, contact store@inthegaragemedia.com

Editorial contributions are welcomed but editors recommend that contributors query first. Contribution inquiries should first be emailed to info@inthegaragemedia.com. Do not mail via USPS as we assume no responsibility for loss or damage thereto. IN THE GARAGE MEDIA, INC. reserves the right to use material at its discretion, and we reserve the right to edit material to meet our requirements. Upon publication, payment will be made at our current rate, and that said, payment will cover author’s and contributor’s rights of the contribution. Contributors’ act of emailing contribution shall constitute and express warranty that material is original and no infringement on the rights of others.

PRINTED IN THE USA.

CTP RESELLERS

Cleveland, OH

(216) 281-8777

Still Hammerin’

Still Hammerin’InTheGarageMedia.com

here are plenty of “trigger” topics in the world of classic trucks, but the one that seems to always raise the most controversy is the act of converting longbeds to shortbeds. And though I totally understand and empathize with the longbed lovers, I think some numbers need to be put out there to (hopefully) put things in a different and (hopefully) better perspective.

Based on my research, much of which comes from the wonderful 67-72ChevyTrucks.com forum, GM’s production numbers paint a rather interesting picture. Kicking off the second-gen C10 era in 1967, there were less than 44,000 SWB Fleetsides produced (with an additional 45,000 and change Stepsides!). However, for the first-year longbed Fleetside, consumers had a whopping 166,000 options to choose from, with another 20,000 long-steps available! Now, I won’t break down the production numbers for the remaining five years of C10 productions, but let’s just say, overall, we, the truck-buying public, were offered just under 1.5 million longbeds (both Fleetside and Stepside), while there were only 480,000 shortbeds (both varieties) available. That’s but a third if my math is correct!

Parts Dept.

Parts Dept.

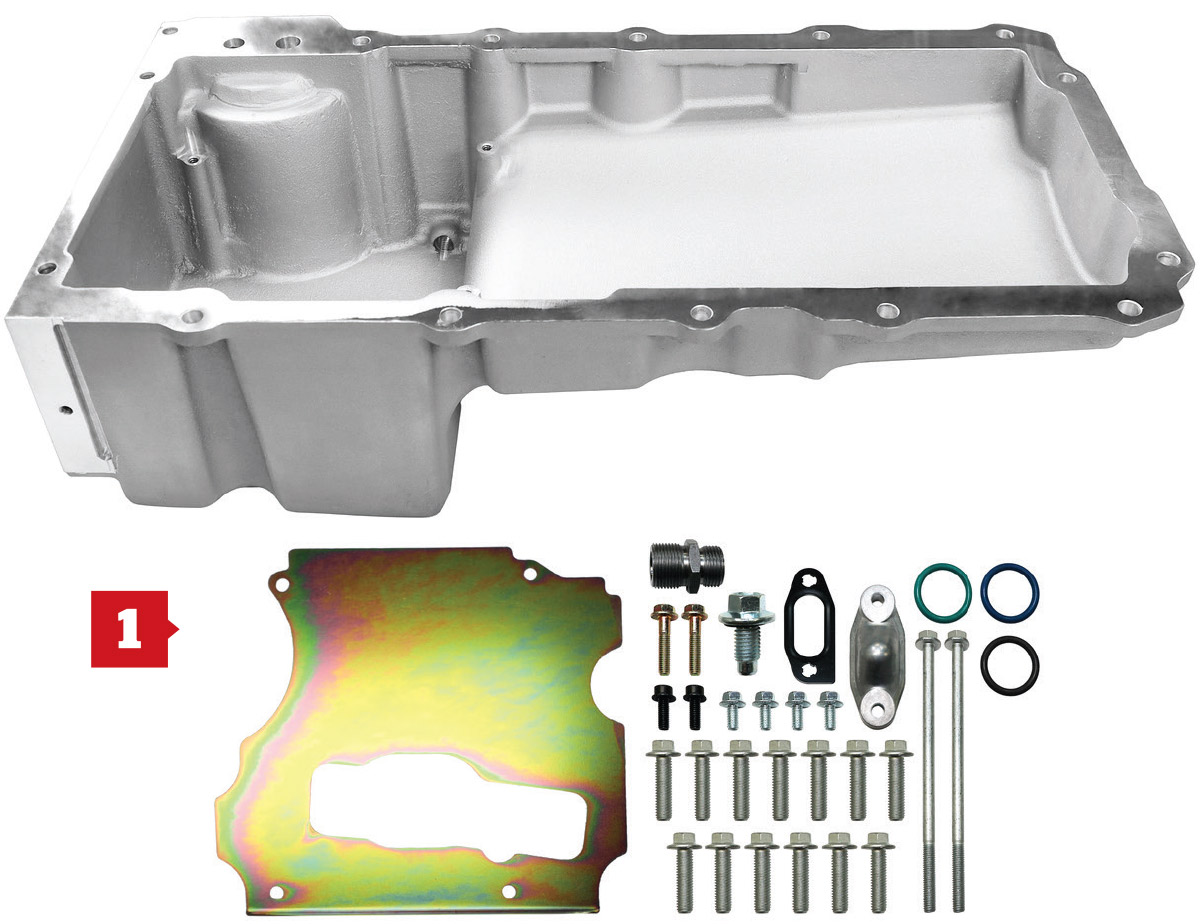

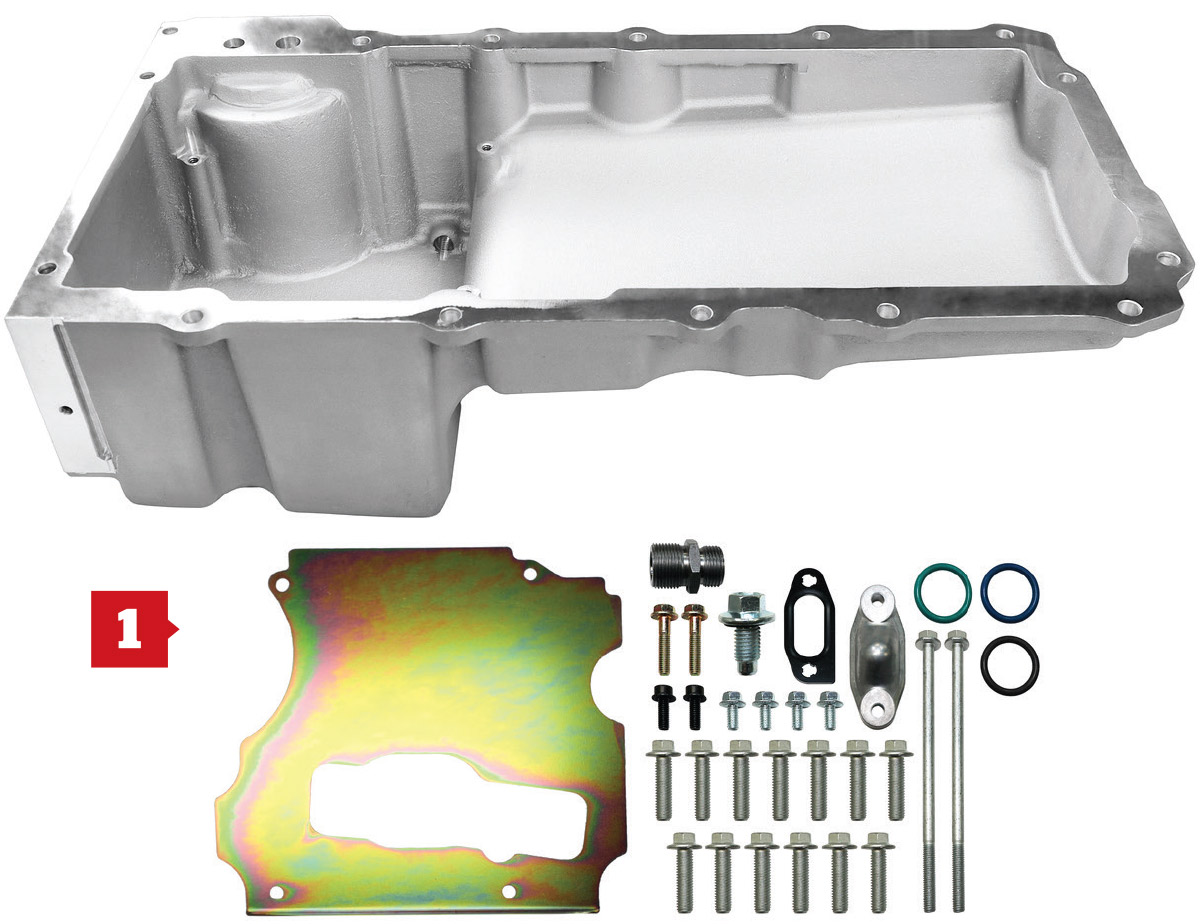

The Standard Profile Oil Pan is reminiscent of the iconic fourth-generation F-body oil pan. Engineered for compatibility with numerous GM applications from 1955-87, it offers excellent fitment on first-generation F-body and first-generation X-body cars, among others.

Providing additional clearance on the front portion, the Medium Profile Oil Pan is ideal for GM G-body platforms, favored for LS swaps. It fits most 1955-87 GM muscle cars and trucks.

With increased exterior clearance at the front sump, the Ultra Low Profile Oil Pan is tailored for tight-fitting chassis, including Fox-body Mustangs. Its internal clearance supports up to a 4-inch crankshaft stroke. Each oil pan is meticulously crafted to OEM specifications, ensuring seamless integration. Key features include OEM oil filter mounting, oil cooler port provision, OEM engine NVH suppression, and proper structural rigidity. Additionally, the pans come complete with essential components such as a sump baffle, pick-up tube, sump plug, oil filter stud, and oil passage cover.

FiTech’s LS Oil Pans are compatible with a range of LS-swapped applications, including F-body models, G-body platforms, Mustangs, and C10 trucks. The pans are designed to accommodate standard off-the-shelf oil filters and utilize OEM LS3 dipsticks and dipstick tubes for seamless installation.

Feature

Feature

Images by NotStock Photography

Images by NotStock Photographyack in 1983, Wendell Bentley, a mechanic at a local sawmill in Fredonia, Arizona, bought himself a brand-new Chevy C10, which he used as a work truck right up until his retirement. When his grandson, Josh, turned 15, Grandpa Wendell gave the truck to his parents, with the intention of it being Josh’s high school driver—which it was, and continued to be clear through college … and it also traveled to a handful of states in the process, eventually ending up parked at his sister’s house in Illinois while he finished up his cerebrovascular and endovascular neurosurgery fellowship in Seattle.

Tech

Tech

Images by THE AUTHOR

Images by THE AUTHORhen a pickup project’s cab and chassis remain separated long enough, we might (OK, I might) lose sight of a detail or two. Our ’55 Chevy second-series project has been seen this way in tech before. If by chance you missed it, we started with a wreck.

Because this old truck first belonged to its current owner’s father, it’s a sentimental build. In this instance we wouldn’t want to completely erase the truck’s personality. Granted, it’s receiving the mandatory stance-enhancement but apart from that, it’ll be a dolled-up stocker, pretty much.

When the project’s twisted Unisteel cab was first lifted, its twisted-to-match foundation went straight to the frame shop. Still bearing some scars, it did at least roll out true. As an extra-added plus, the frame retains its digits, just as an Oakland assembly plant worker stamped ’em in late 1955.

Event

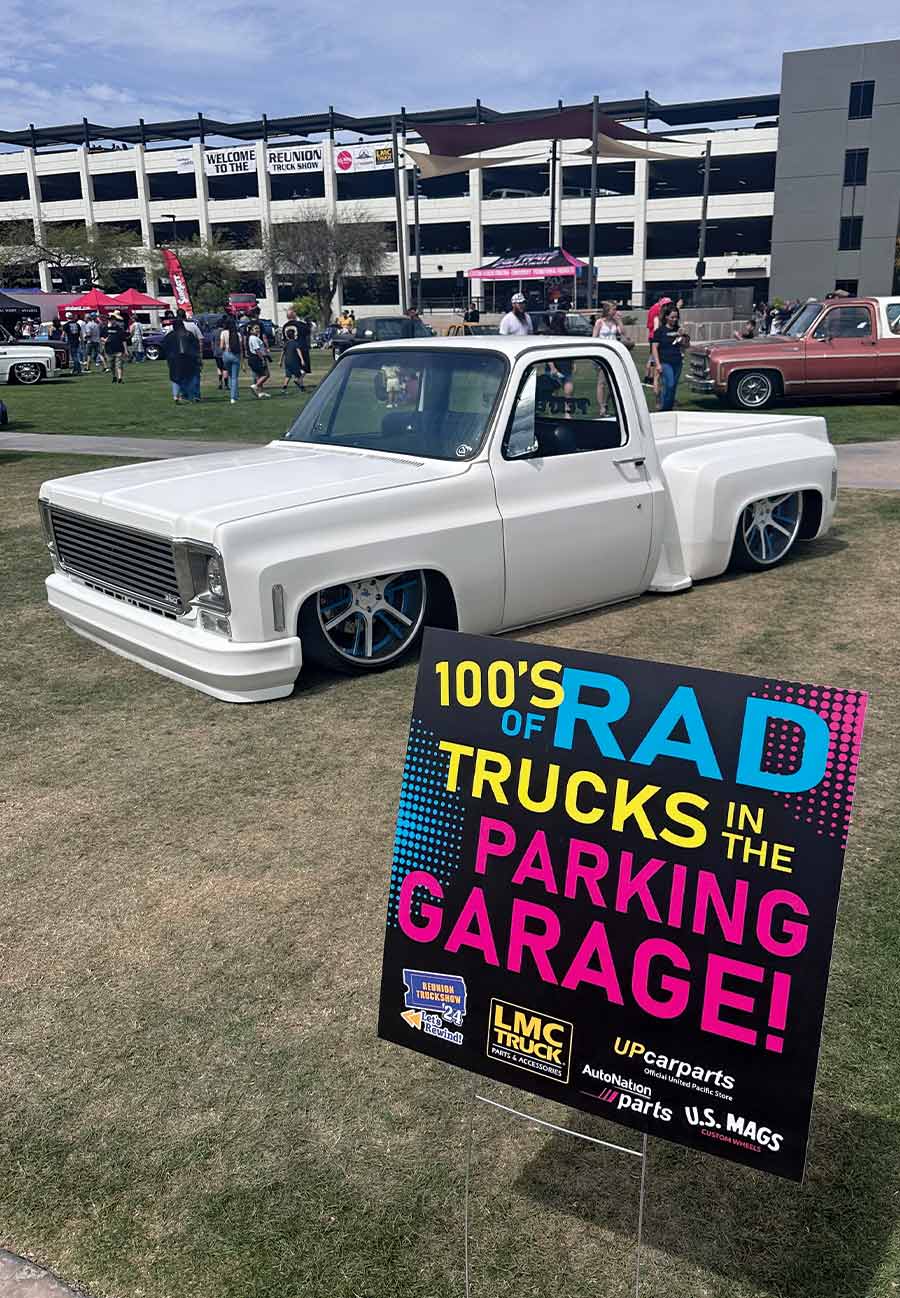

EventNumber Three for the Tallest Truck Show in the World is Outta the Park … Literally!

Images by the author

Images by the authorust as we’re unwinding from the short winter indoor show season, I find myself kicking spring off in what I consider the classic truck mecca—Arizona—for the 3rd annual Reunion Truck Show … and what an amazing way to usher in the warmer months of 2024 hanging out with some of my favorite and closest friends in beautiful downtown Chandler?!

For the second year in a row, we kicked off the Reunion on Friday evening at QuartHaus with the official Classic Truck Performance pre-party, where our gracious host, Reunion founder (and of “C10 Talk”) Ronnie Wetch and Sam Castronova organized an evening of trucks, brews, good food, and lots a genuine BS’n to properly warm everyone up for the following day’s festivities. Thanks to the QuartHaus staff for taking care of the crowd—and especially thanks to Sonny’s BBQ for smoking up and serving some delicious proteins!

Feature

Feature

Images by NotStock Photography

Images by NotStock Photographyp until 1960, General Motors had names for each series of trucks—Art Deco, Advance Design, Task Force—even the second generation C10s received in-house birth names (unbeknownst to me, the ’67-72s were called the “Action Line,” though I believe from there on out it was/is all consumer-given monikers but I could be wrong … wouldn’t be the first time!). Nevertheless, the first-gen C10 in any form is without a doubt one of my favorites … OG restored, full custom, post-NAPCO 4×4, and especially in hot rod patina form like Walker Zeigler’s ’65 Fleetside!

Tech

Tech

I-Beams for IFS

IMAGES BY CTP Staff

IMAGES BY CTP Staffn 1948 Ford introduced their first generation of 1/2-ton pickups, the F-1. They were revolutionary in so far as they were no longer based on passenger car frames and suspension components like all Ford’s light-duty trucks that had come before. The second generation of the F-series trucks were produced from 1953-56. This series of trucks had been redesigned once again, the 1/2-ton versions were now identified as F-100s and 3/4-ton trucks were now F-250s. The third generation of Ford pickups from 1957-60 were treated to another face-lift. While several updates had been made to the chassis at this point, the same basic design could be traced back to the ’48 F-1; at both ends were solid axles with parallel semielliptic leaf springs—simple but effective.

The fourth generation of the F-series trucks were produced from 1961-66. Up to this point annual sheetmetal and trim changes were made for a fresh look, but the chassis remained much the same as those that had come before, that is until a big change was made midway in 1965. A completely new chassis was introduced that included Ford’s infamous twin I-beam front suspension. This layout used two I-beam axles, each anchored to the frame on one side of the frame with the wheel on the opposite side of the truck. The idea was the long individual axles would allow each wheel to act independently while maintaining the strength of a conventional single I-beam.

Feature

FeatureInTheGarageMedia.com

Images BY THE AUTHOR

Images BY THE AUTHORhrough the decades there was only one place to get hop-up parts for your ride: at the local speed shop. It was a place where hot rodders would gather on a regular basis to check out the latest performance parts available to squeeze every bit of horsepower out of an engine, giving it the greatest edge on the street or track. One of the most iconic tools a speed shop ever had was the rolling advertisement a lettered-up truck could provide to promote their own unique brand. Regardless of whether it was just parked out in front of the shop on a daily basis, used in deliveries, or as a push-truck at the drags, dry lakes, or the salt, nothing else could duplicate its impact. The slammed ’69 Dodge D200 Sweptline laid out across our pages belonging to Paul and Raquel Barber of Milton, Ontario, Canada, is a perfect example of its breed to support their business.

Tech

TechInTheGarageMedia.com

IMAGES BY THE AUTHOR

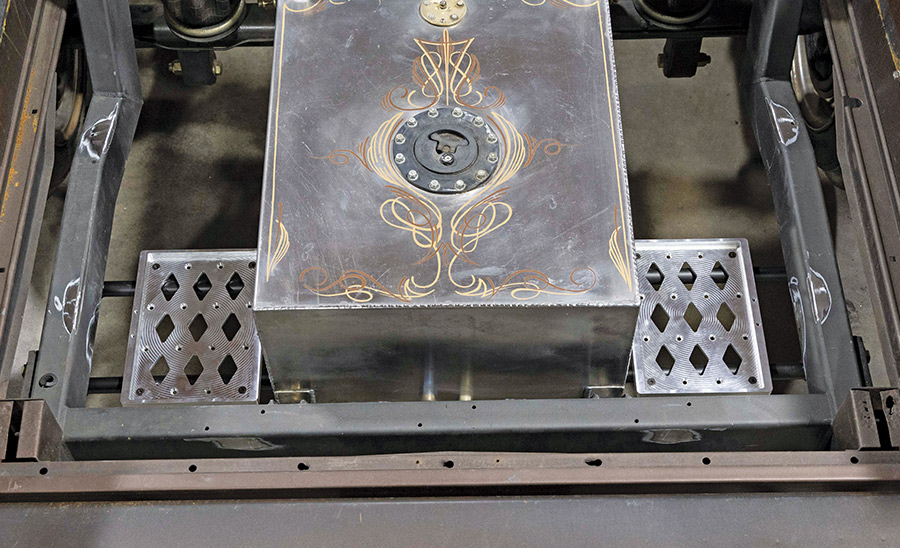

IMAGES BY THE AUTHORn the last installment of our Speedway Motors C10 build, we gathered up a derelict ’68 C10 shortbox and dragged it back to our shop. What was left of the old truck was carefully taken apart and the chassis was blasted and treated to a fresh coat of epoxy and black urethane. Now it’s time for the fun part to begin with the install of our G-Comp rear suspension, a rebuild of the front suspension with some new parts for a lowered stance, and an upgrade to the brakes.

Though our truck wasn’t much to look at, the chassis was exceptionally straight and rust-free. The glaring exception was a rear crossmember that had been crudely torched at some point in this truck’s eventful past. We were eager to get rid of this eyesore, so we elected to start at the rear. We selected the Speedway Motors G-Comp C10 Coilover Truck Arm Rear Suspension kit for its bolt-on installation, improved geometry, and adjustability over the stock suspension, not to mention the addition of coilovers. The fact that the kit included a fresh new crossmember direct from our fab shop that would replace the hacked stocker was icing on the cake.

![]() Feature

Feature

BY Fuelish Media

BY Fuelish Mediaou hear the term “back in the day” thrown around a lot, but for those who grew up in the pre-Internet era, things were A LOT different—especially for those who were into building custom vehicles of any kind. Charlie Taylor of Fountain Valley, California, can definitely attest to this, as he got his start working in the wireless trenches as a teenager. That’s not a nod to WiFi or Bluetooth, he just grew up, like a good number of us, without the convenience of asking Google’s advice for every little thing. “I learned the ropes of teardown at a wrecking yard when I was 15,” Charlie says. “You had to try a lot harder to make things happen back then, that’s for sure.”

It’s this “old school” mentality that shaped the way Charlie approached any new project as he started to get older. “I’ve always loved cars, and once I got more experience with them, I gravitated toward ’60s/’70s Chevys,” he adds. Having grown up in the ’80s mini-truck scene in Southern California, Charlie developed a taste for a lowered stance, larger wheels, and nice paint. Also having built a ’64 Impala wagon after his days at the truck runs, he was just itching to get back into a pickup—something within his wheelhouse.

Tech

Tech

Images BY Taylor Kempkes

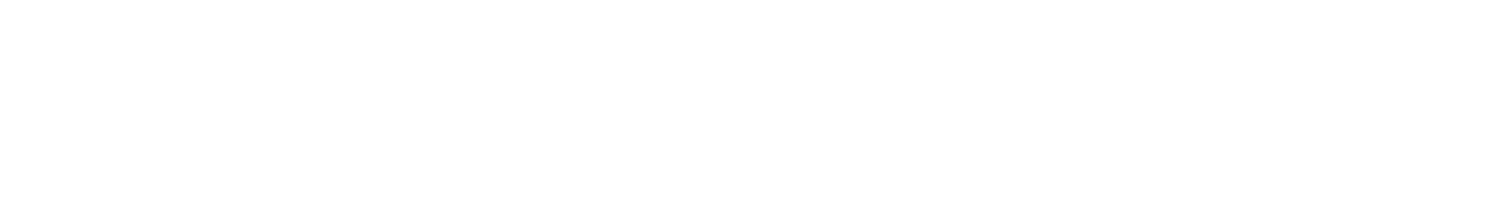

Images BY Taylor Kempkesor as long as I’ve been around cars and motorcycles, you’d think that my specific knowledge of and skillset with wiring would be rather advanced. Nope. Don’t get me wrong, I understand basic electronics and have even wired a couple full vehicles, but there are specifics about automotive electrical systems (even the older ones) that are not in my realm of expertise—if there is such a thing to begin with?!

Among the numerous items on the laundry list of to-dos that Old Anvil Speed Shop is handling on my ’48 Chevy, wiring was not one of them … until I walked in the shop one day and Paul says to me, “We’re installing dual batteries—we need a pair of Group 34 AGMs.” Even though I’d just installed a brand-new battery in the stock location (under the passenger-side floorboard), I didn’t want to question Paul, but ultimately I had to ask “why?”

Event

Event

Images by THE AUTHOR

Images by THE AUTHORoad trips are fun, and it’s even more fun behind the wheel of an old truck. One of the coolest parts of the classic truck world is that most of us build these trucks to be driven. That’s why you see so many modern engine swaps, weathered paintjobs, and minimal interiors—the goal is to drive it and have a good time not to win a trophy. So, when the announcement was made that a truck-specific road trip was happening, we wanted to check it out.

It’s called the GM Tailgate Tour presented by Snowden Custom Seats and it’s a five-day event that takes the scenic route from Nashville to Sevierville, Tennessee, by way of Tupelo, Mississippi; Birmingham, Alabama; and Chattanooga, Tennessee. This inaugural event had lots of great destinations and an unbelievable route through some of the coolest backroads in the Southeast. We caught a glimpse of the event as the group made its day four stop at Camp Jordan Arena just outside Chattanooga. Before the trucks gathered at Camp Jordan, the participants had time to check out some of the sights around Chattanooga, including Rock City, the Towing and Recovery Museum, and the Coker Museum.

Feature

Feature Images BY THE AUTHOR

Images BY THE AUTHOR

s the years pass, there’s always one ride that totally instills itself into your memory banks for decades with its own unique style, powerful enough to make you want to channel its influences into a future build. It’s almost as if time stands still, securing its historic roots till tapped once again to bring it back to life. The ’56 Ford F-100 laid out across our pages owned by Paul Close of Tolland, Connecticut, is one such subject paying homage to days past. In fact, its early ’60s custom vibe was inspired by a prize-winning ’57 Ford Fairlane built by John North (and later owned by singer Gene Pitney) known as the “White Pearl.”

Ad Index

- AFFORDABLE STREET RODS67

- ALL AMERICAN BILLET17

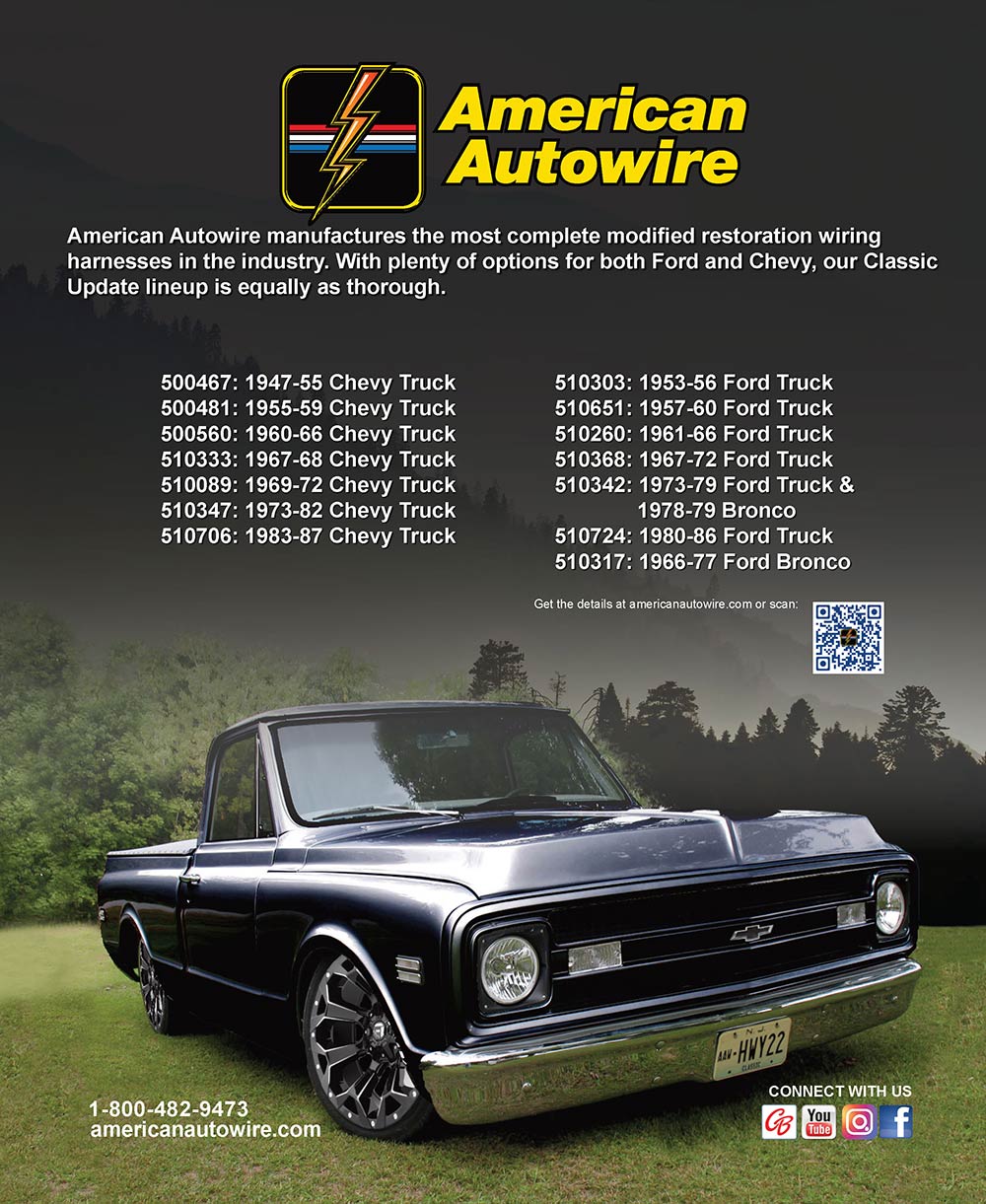

- AMERICAN AUTOWIRE19

- ART MORRISON ENTERPRISES47

- AUTO METAL DIRECT27

- AUTOMETER PRODUCTS29

- AUTOMOTIVE RACING PRODUCTS21

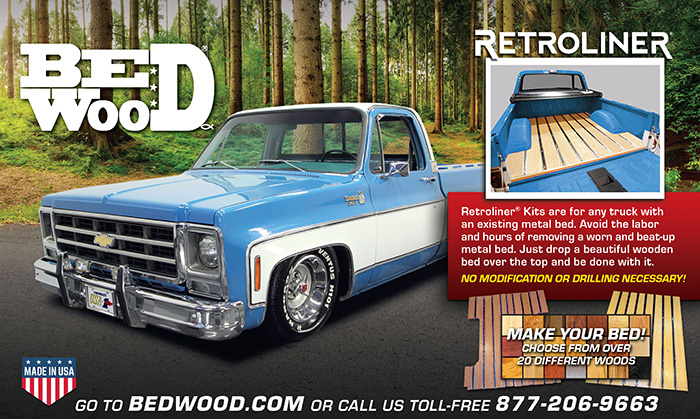

- BEDWOOD AND PARTS67

- BOESE ENGINEERING97

- BOLING BROTHERS EARLY IRON79

- BORGESON UNIVERSAL CO.37

- CHEVS OF THE 40’S71

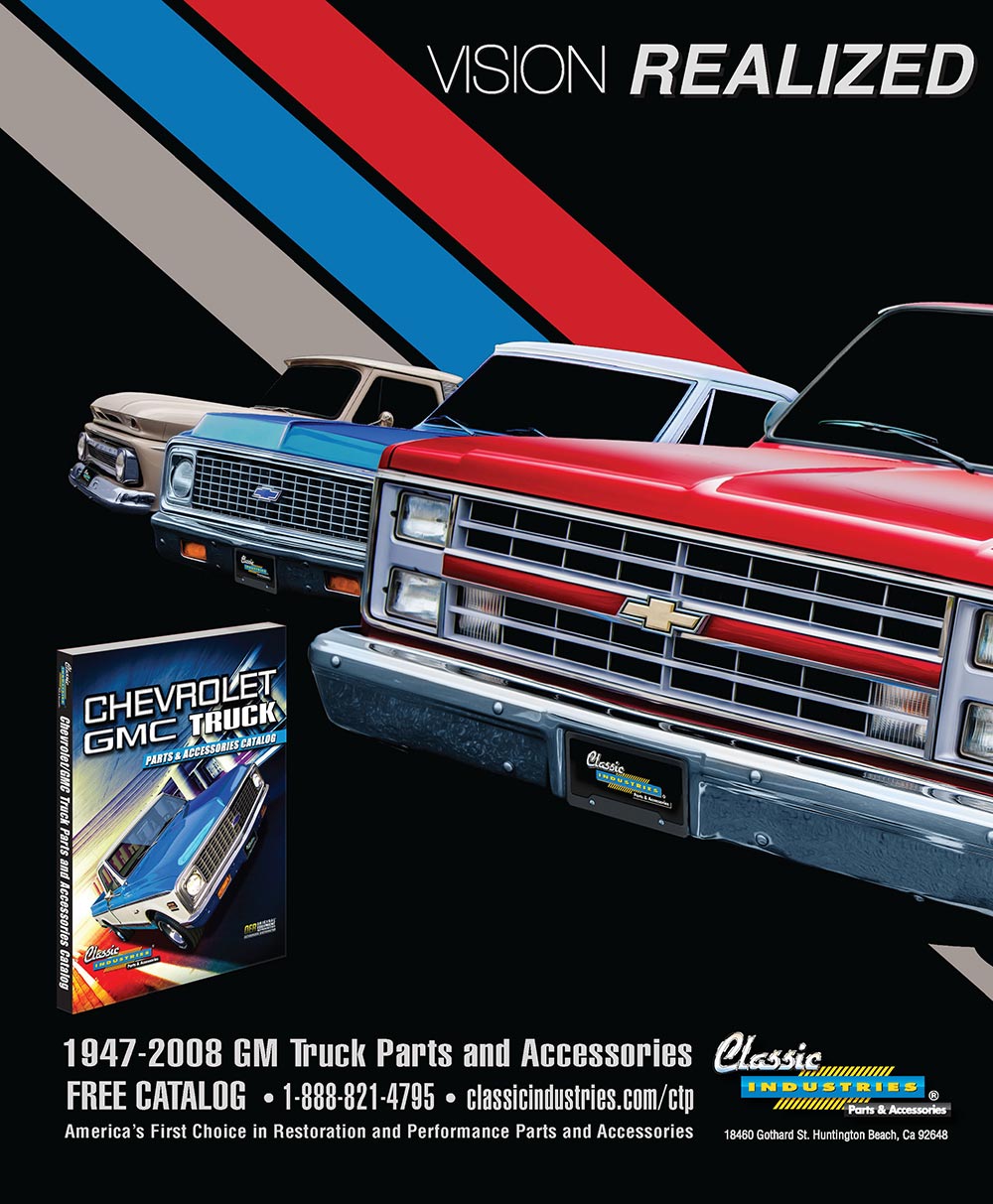

- CLASSIC INDUSTRIES35

- CLASSIC PERFORMANCE PRODUCTS4-5, 93

- CLEANTOOLS40

- DAKOTA DIGITAL99

- EATON DETROIT SPRING, INC.89

- FITECH EFI69

- FLAT OUT ENGINEERING89

- FRONTIER SHOP SUPPLIES81

- GEARSTAR PERFORMANCE TRANSMISSIONS89

- GOLDEN STAR CLASSIC AUTO PARTS7

- GRANATELLI MOTOR SPORTS, INC. 85

- HEIDTS SUSPENSION SYSTEMS81

- HEINZMAN STREET ROD SHOP97

- HEMMINGS59

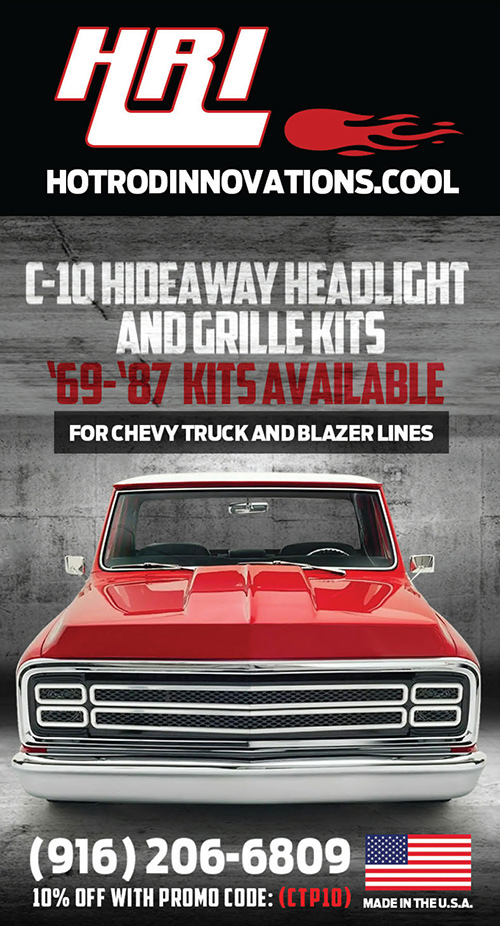

- HOT ROD INNOVATIONS97

- KUGEL KOMPONENTS97

- LMC TRUCK100

- LOKAR2, 55

- NATIONAL STREET ROD ASSOCIATION57

- NEW PORT ENGINEERING87

- OLD AIR PRODUCTS69

- PAINT OVER RUST PRODUCTS, LLC79

- PERTRONIX11

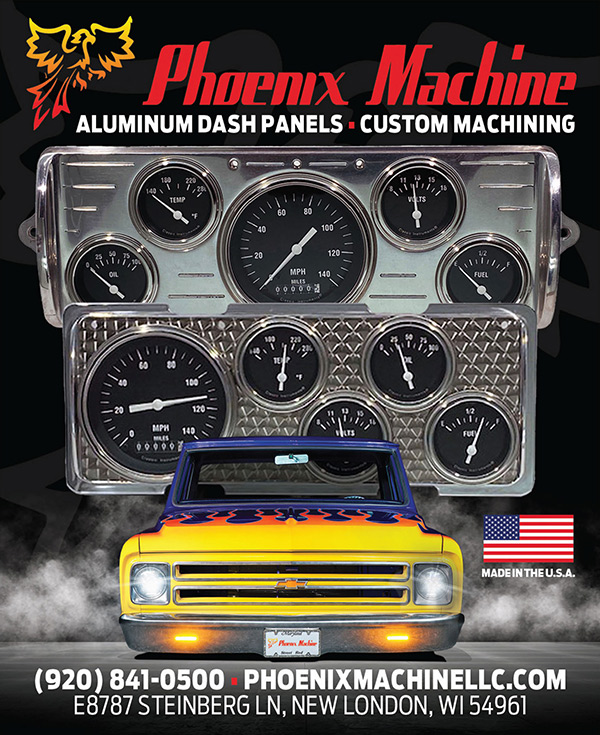

- PHOENIX MACHINE PRODUCTS87

- POWERMASTER PERFORMANCE71

- PPG INDUSTRIES9

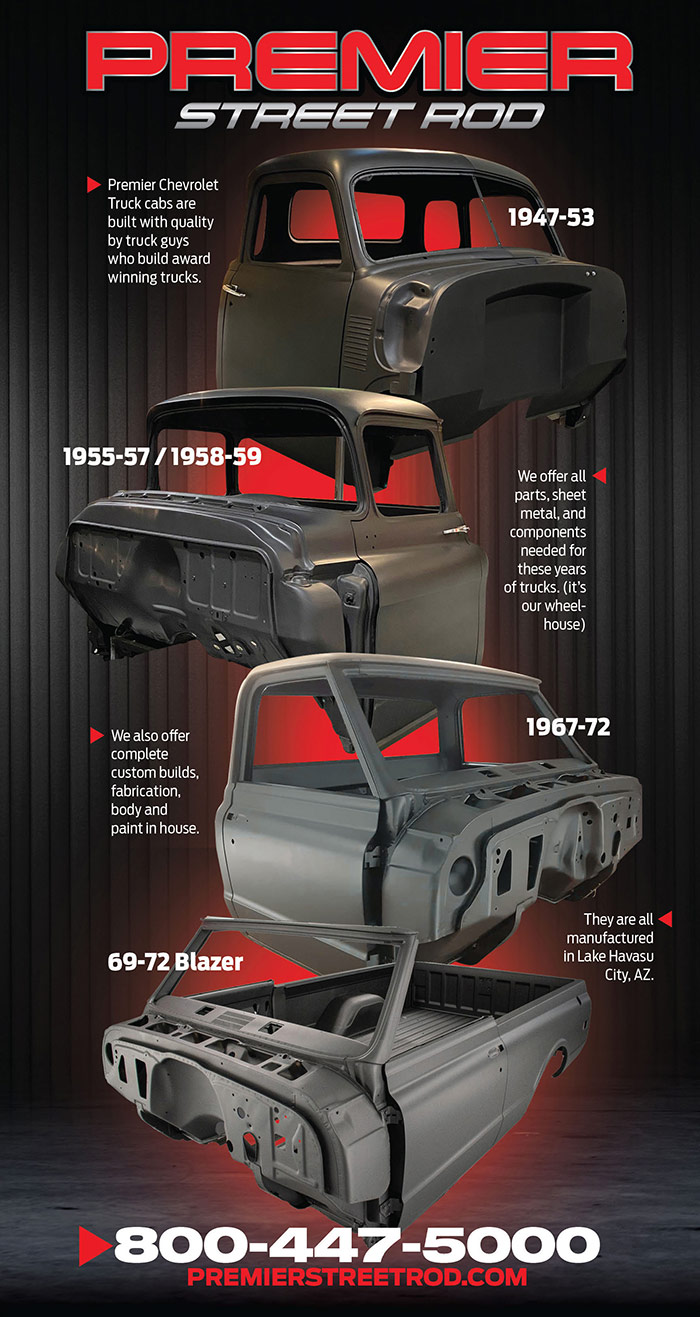

- PREMIER STREET ROD53

- PRO’S PICK87

- ROADSTER SHOP31

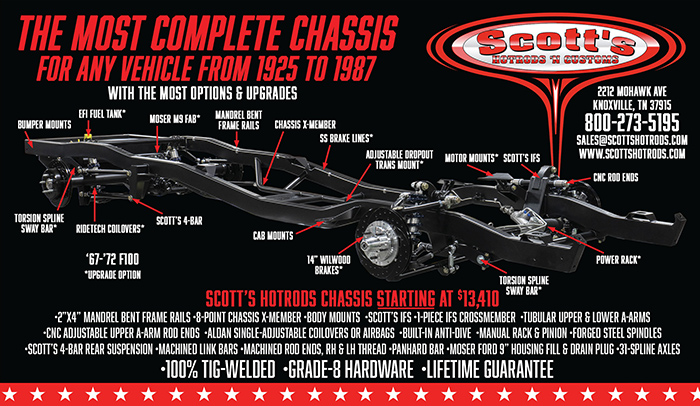

- SCOTT’S HOTRODS85

- SPARETIME BILLET93

- SPEEDWAY MOTORS39

- THERMO-TEC AUTOMOTIVE89

- TMI PRODUCTS87

- TRIPLE CROWN OF RODDING, LLC25

- VINTAGE AIR6

- WILWOOD ENGINEERING49

BY

BY