Tech

Tech Photography by Mike Chase

Photography by Mike Chasehen Pete and Leslie Richmond sat down with the Cotati Speed Shop crew to determine how to get their 1968 C10 to sit right, look good, handle well, and stop even better, the one thing they knew was that they were going with a company that offered a “full system.” They knew that mixing and matching components had the risk of incompatibility. It was also decided that they wanted a system that would allow for full adjustability when it came to the stance as well as the handling of the truck. Stock coil springs and non-adjustable tube shocks wouldn’t cut it nor would the stock trailing arm setup out back.

Last month, we followed along with the Cotati crew as they installed a QA1 front suspension kit from Speedway Motors on the Richmond C10, so it should come as no surprise that when it came to addressing the rear suspension, the guys went with more of the same.

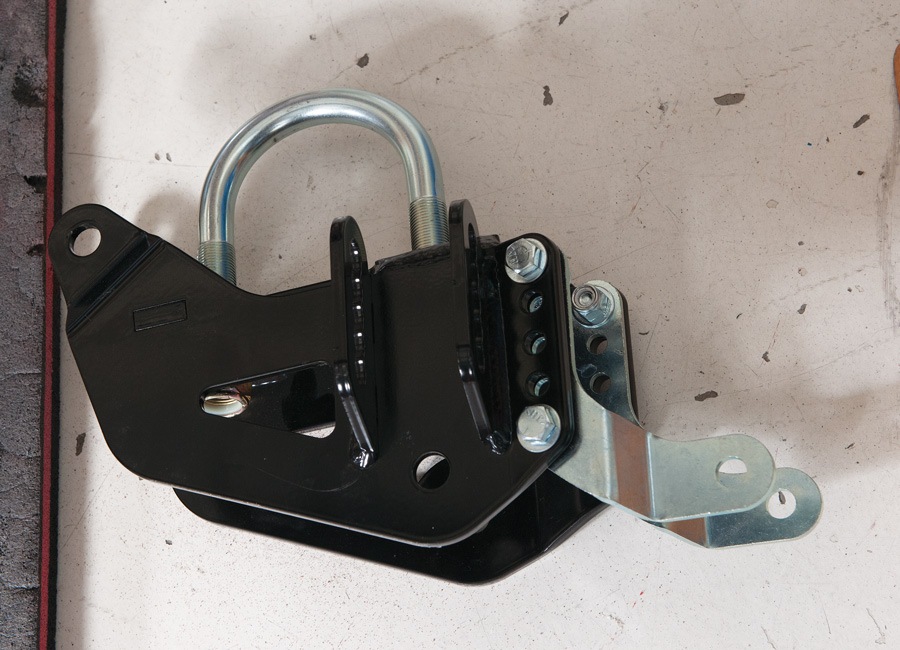

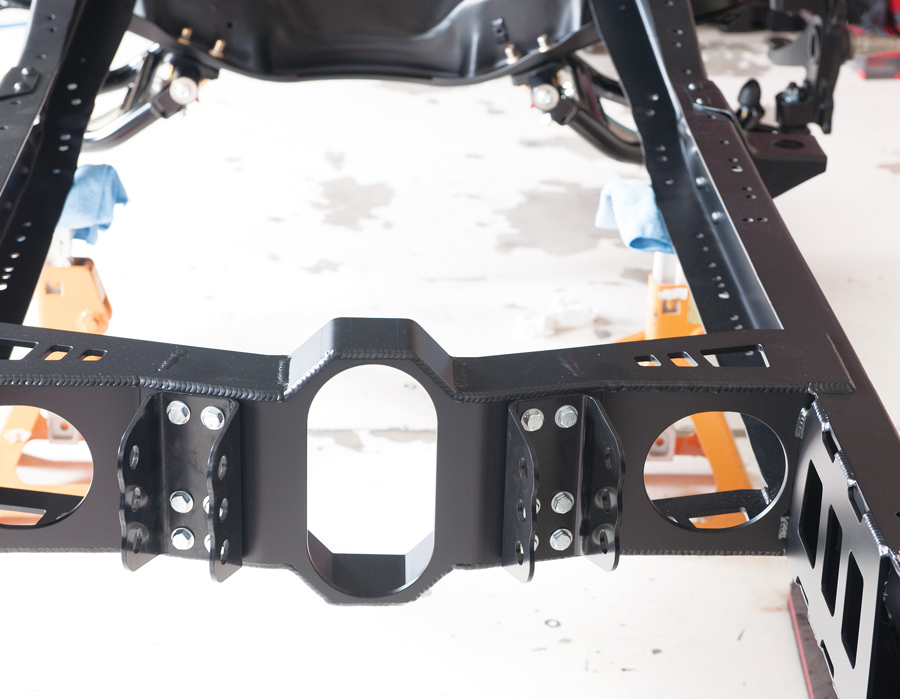

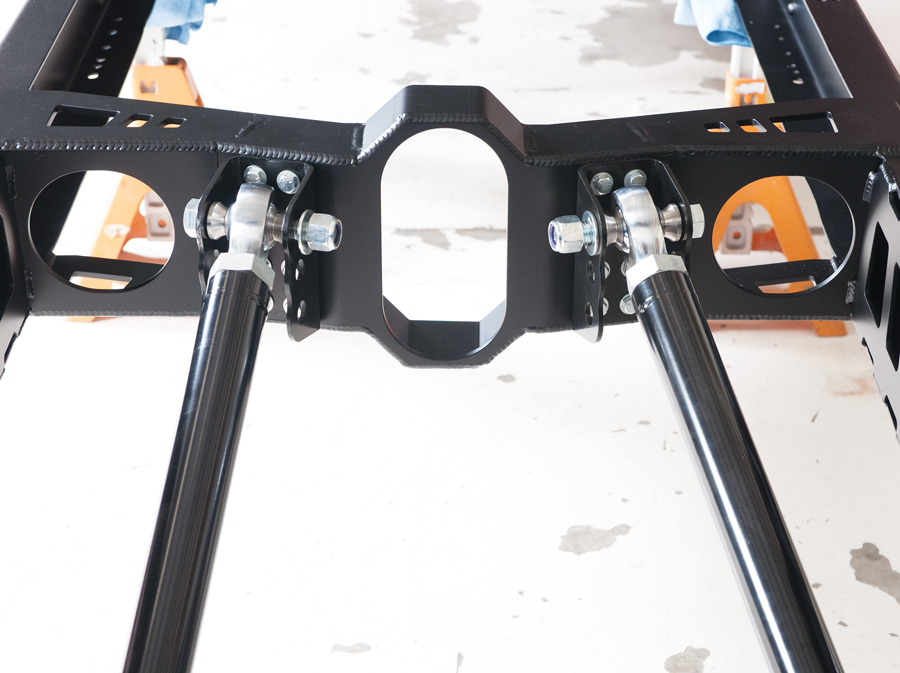

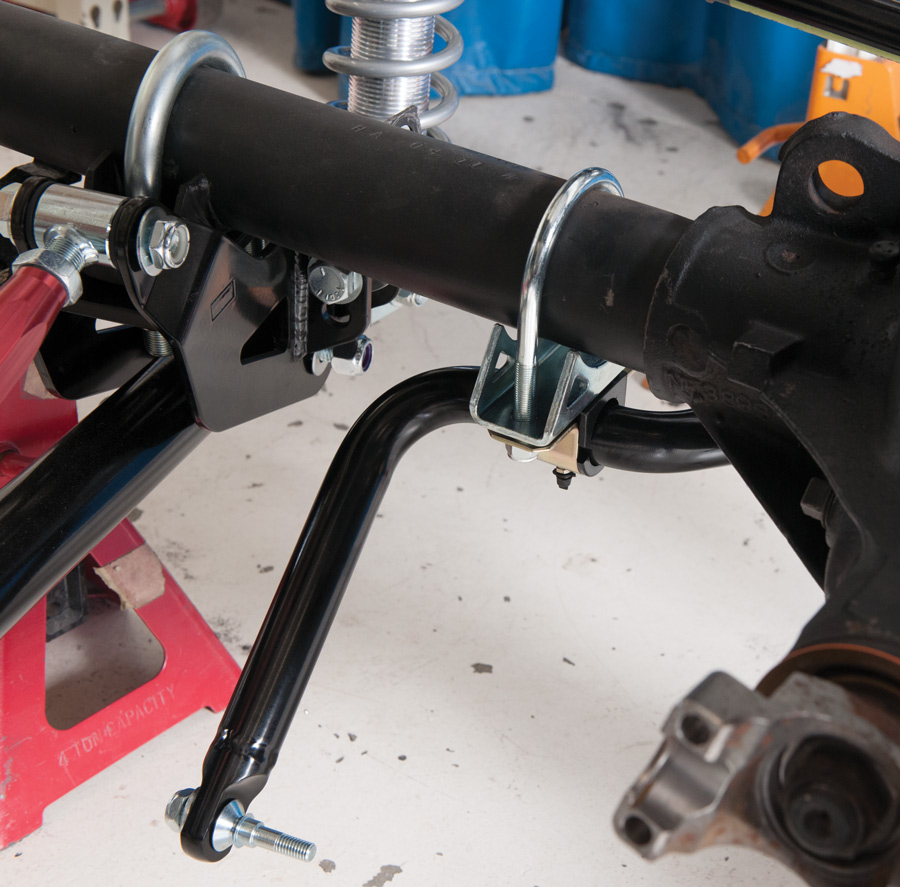

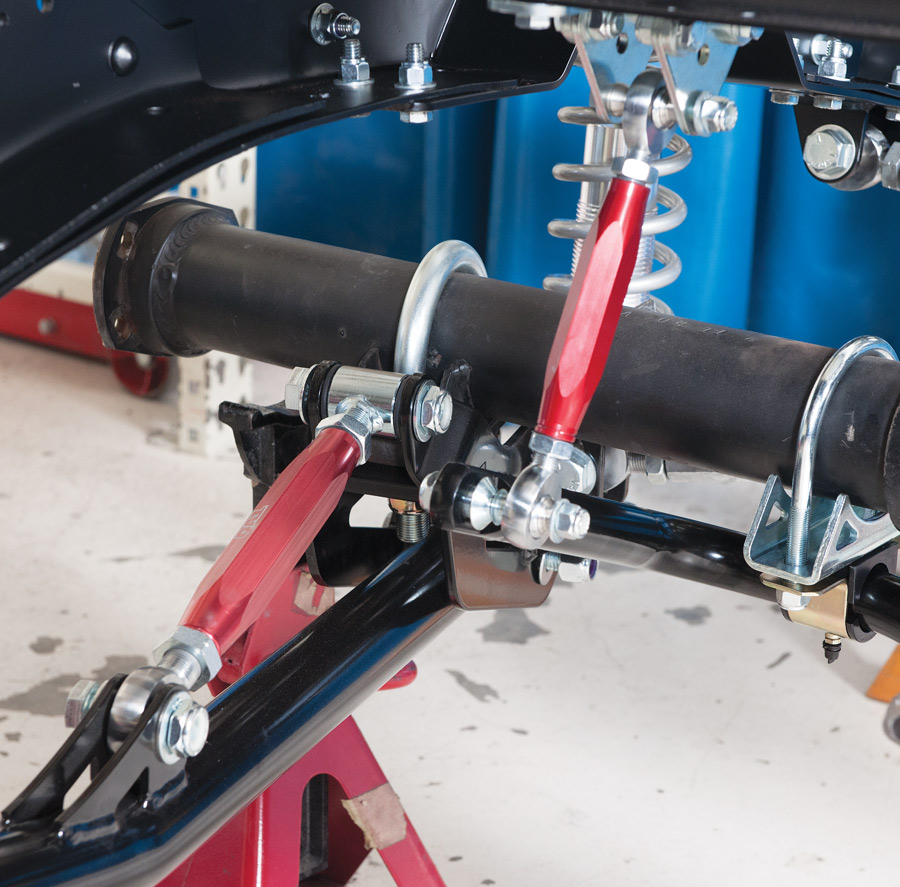

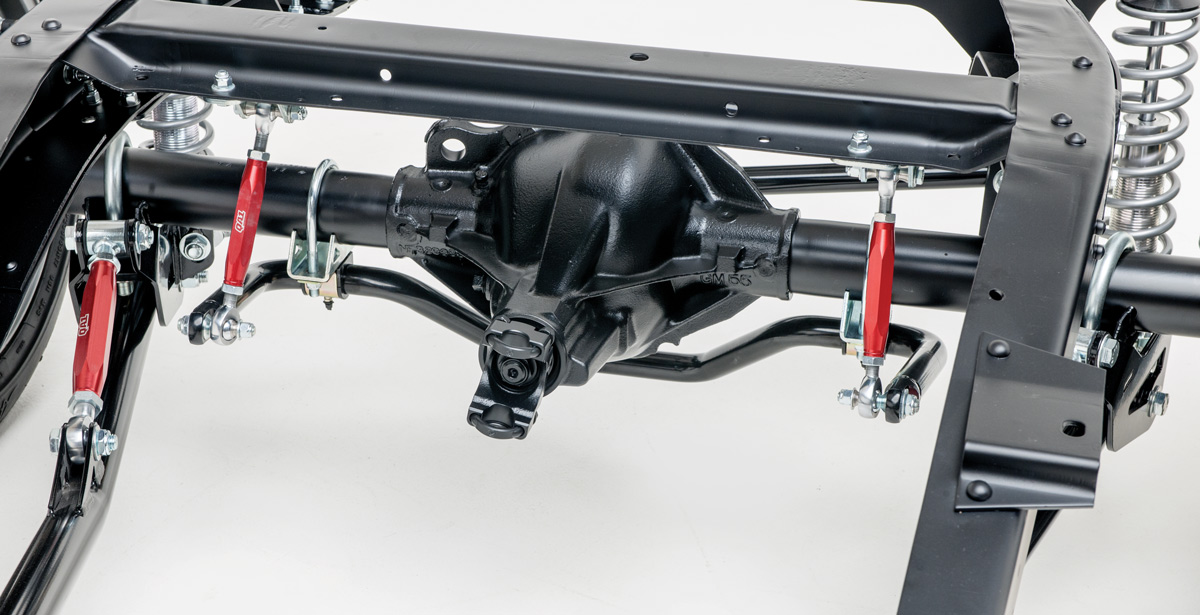

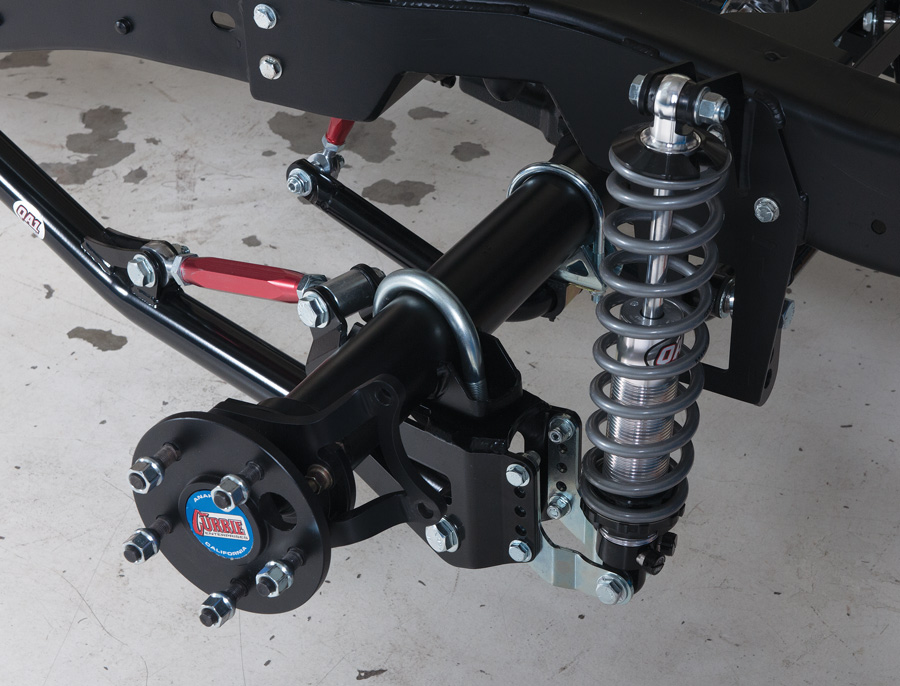

QA1’s Tubular Truck Arm Kit is the perfect complement to their front tubular control arm coilover shock setup. With double-adjustable 200-pound coilover shocks, fully adjustable tubular trailing arms, adjustable sway bar, and extended Panhard bar, the limits are endless when it comes to setting up the suspension exactly as desired. The upper coilover shock mounts on the bolt-in C-notch bracket, relocates the shocks to the outside of the frame, closer to the wheel, providing more cornering stability and increased real estate for a rear-mounted fuel tank. Tubular truck arms built from seven-gauge DOM steel replace the stamped factory trailing arms with integrated pinion angle adjustment, eliminating the need for angled shims. The adjustable truck arms also allow for wheelbase adjustments to get that rear wheel perfectly centered in the wheelwell, a common problem with lowered trucks. A full-length, adjustable Panhard bar with multiple mounting locations keeps the rearend centered while also correcting roll center geometry on a lowered truck.

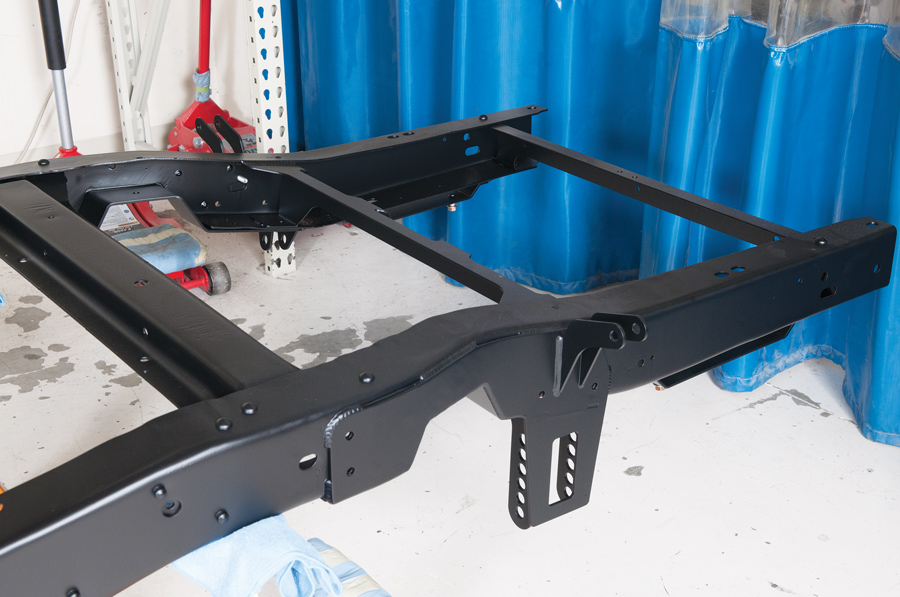

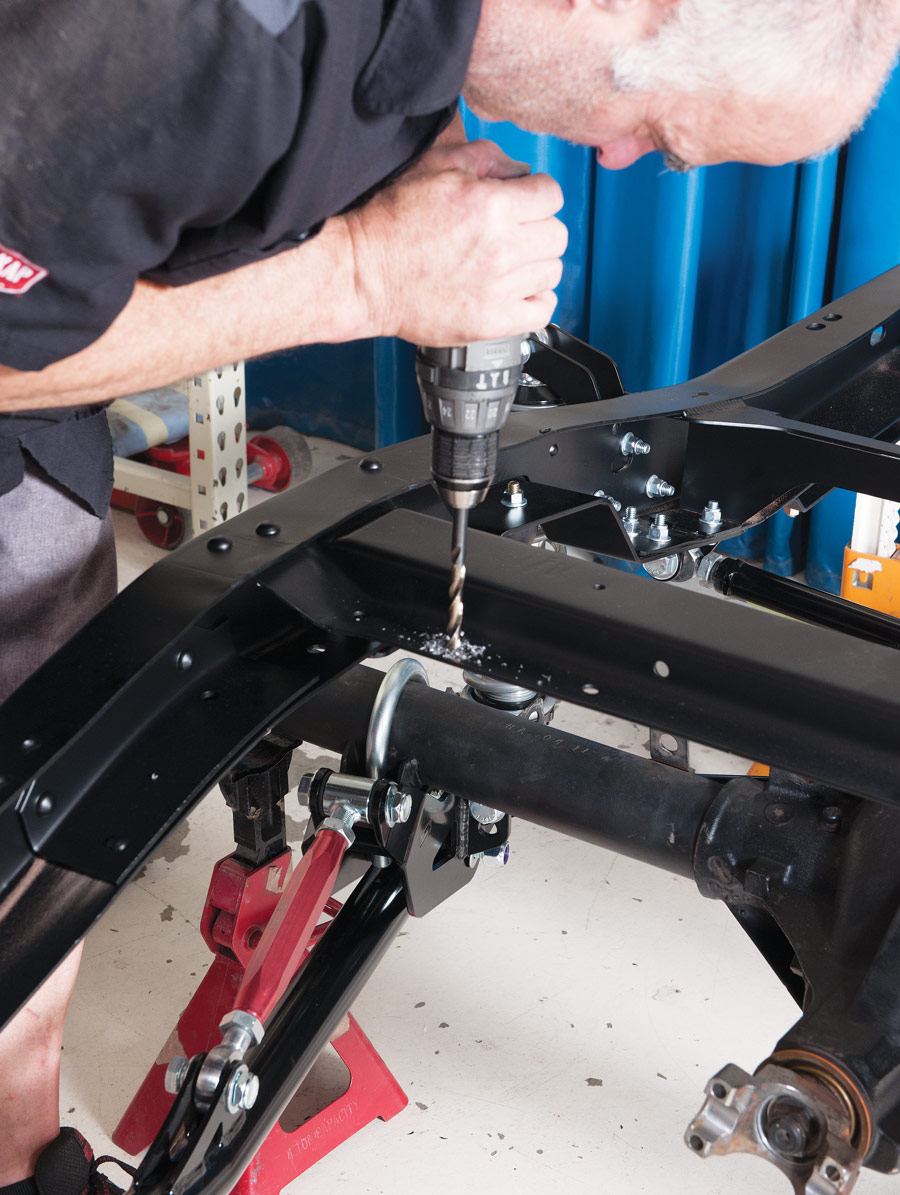

Installation of the QA1 kit begins with the removal of a number of crossmembers, as well as a handful of stock brackets. Thankfully, the Cotati crew did the dirty work before we arrived, going so far as sending the chassis out for blasting and powdercoating after they installed the new QA1 C-notch and shock brackets. We showed up just in time to catch the guys as they started bolting in all the new componentry.

SOURCES

SOURCES(707) 981-7069