In the Shop

In the Shop

Photography BY THE AUTHOR

Photography BY THE AUTHORf you are a fan of 1967-1972 C10 trucks but have been desiring a higher level of performance than a stock chassis has to offer, we are here to tell you the wait is over. As an Art Morrsion dealer who has worked closely with the AME team over the years, we were thrilled to hear they had the first C10 chassis assembled. We hopped in the old shop truck and tore up to the AME manufacturing facility in Fife, Washington, to see it firsthand.

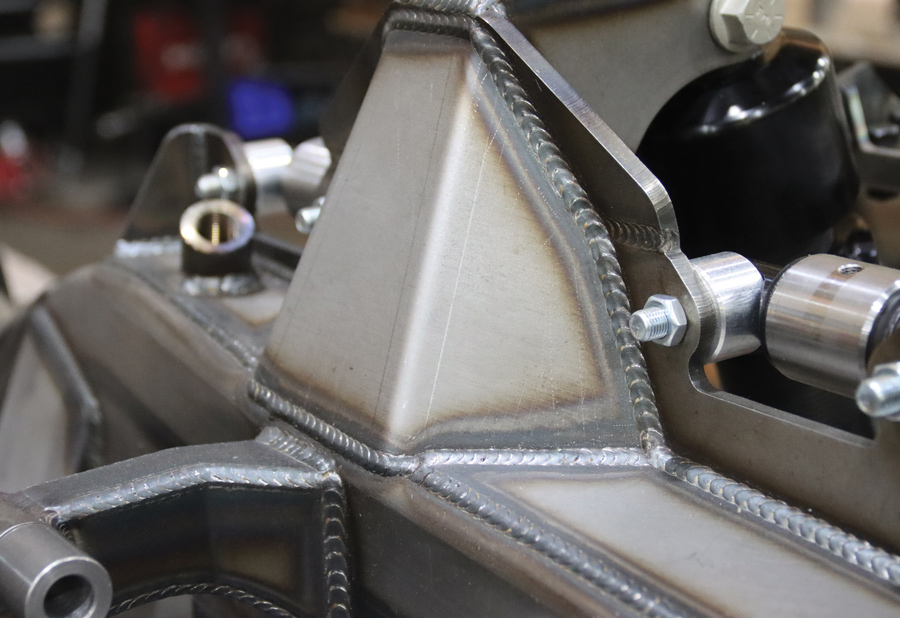

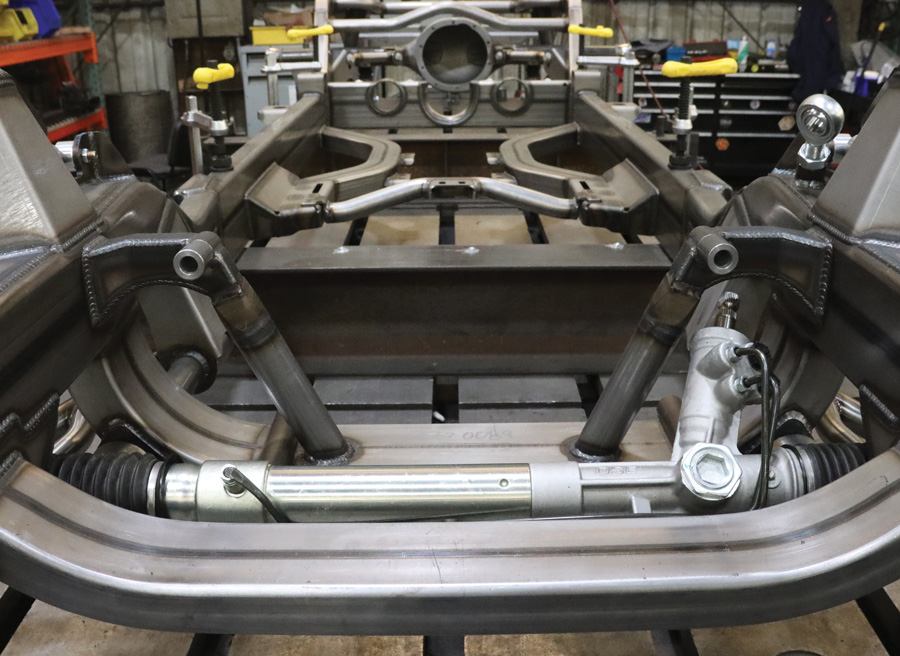

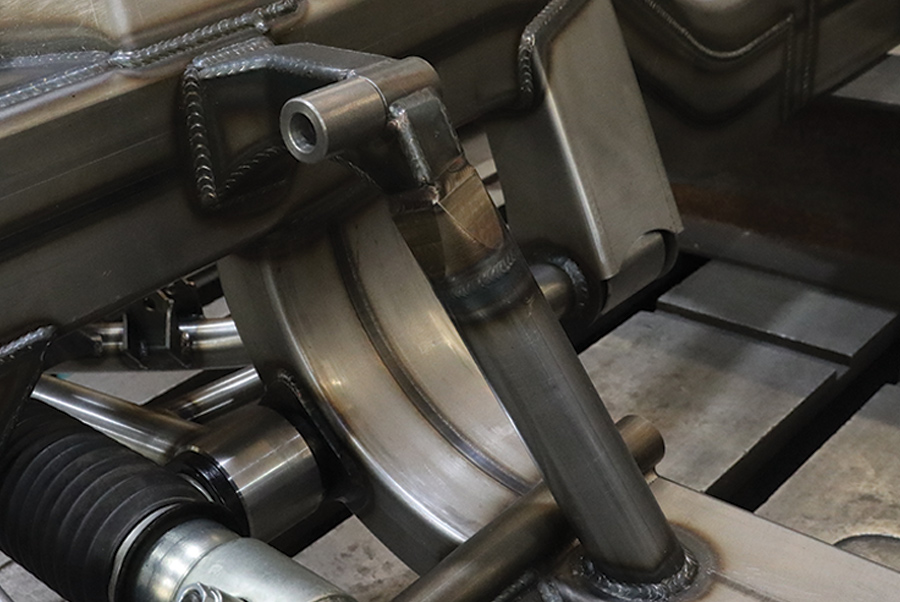

AME chassis are aesthetically beautiful, largely due to their ability to perform mandrel bends in multiple directions. The result is a gorgeous, flowing aesthetic to their chassis that also delivers excellent strength. AME’s new 1967-1972 C10 chassis continues this theme but with a number of new upgrades. The beefy 2×6-inch frame features FEA-optimized chassis braces to stiffen the platform. The front suspension is a new design with large CNC fixtured and TIG-welded tubular steel control arms with CNC-machined upper mounts. Wilwood provides the heavy-duty forged aluminum spindles with an integrated modular bearing assembly and ball joints that are serviceable. In summary, the new front suspension is heavy duty and provides excellent performance both on the street and the track.

We are really looking forward to installing one of these chassis under a C10 truck in the near future. As with all AME chassis the level of comfort, performance, and quality you experience makes the investment well worth it. Just look at the quality of the welds on these chassis, it’s hard to cover them up with a car body as they alone look like pieces of art.

The C10 chassis is available to order now. If you are curious, or have questions, please contact the team at MetalWorks at metalworksclassics.com/art-morrison/.