Tech

TechInTheGarageMedia.com

Photography BY THE AUTHOR

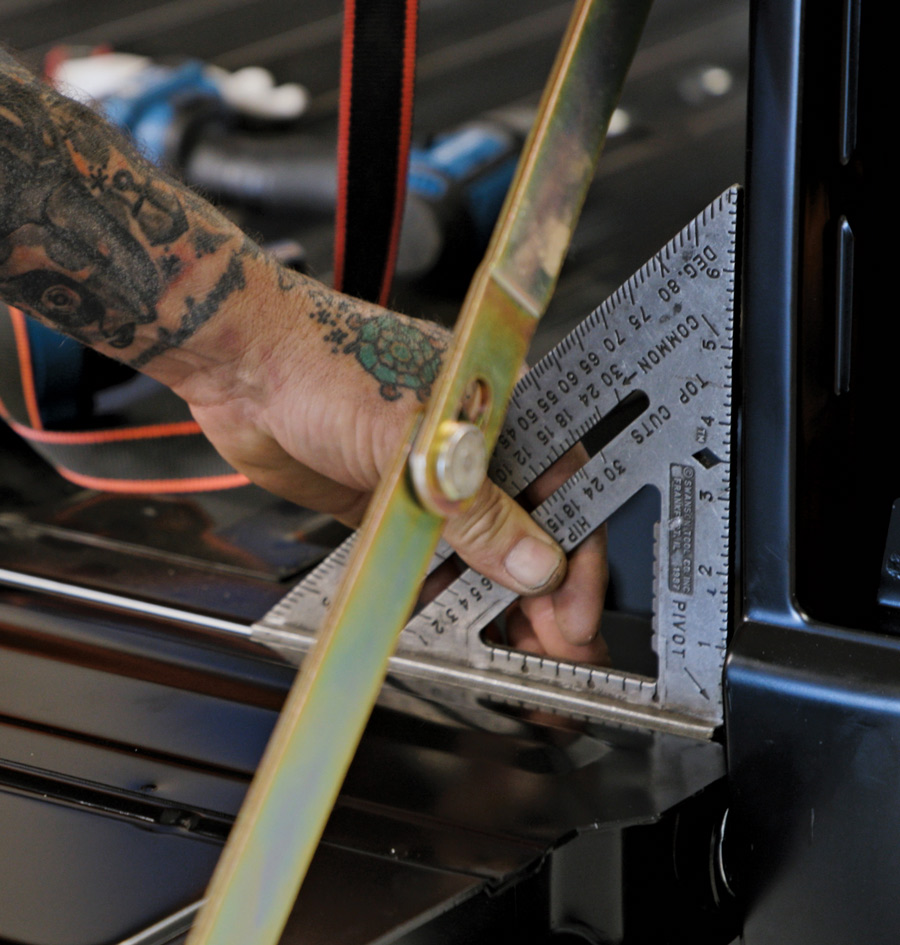

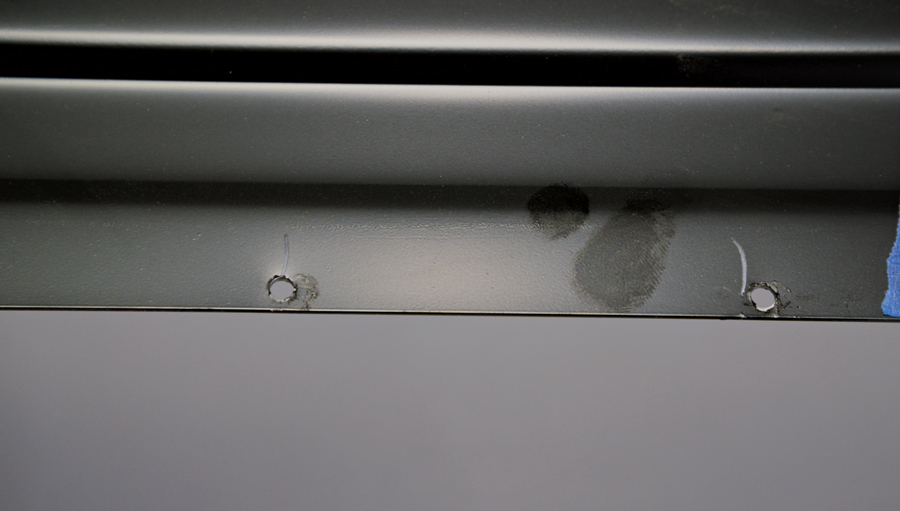

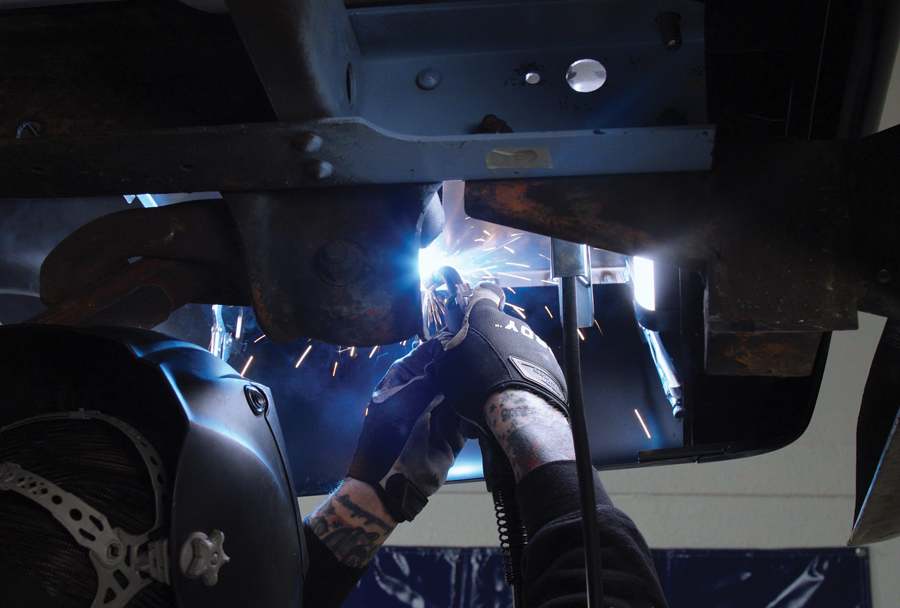

Photography BY THE AUTHORith our longbed-to-shortbed conversion on our ’69 Ford F-100 a wrap as far as the chassis goes, it’s time to turn our attention to the part that will really bring to life the transformation, the shortbed sheetmetal assembly. In the past there was no easy way to convert the longbed sheetmetal down to shortbed specs. Slicing a full 16-inch section out of the front bedsides and floor, as well as an additional 4-inch section out back, makes for a ton of cutting and welding, not to mention the grinding and sanding involved to get the sheetmetal smooth enough for body and paint. A challenge on the double-walled smooth bedsides to be sure, but grinding the two seams nice and smooth on the corrugated steel floor would be something akin to Chinese water torture. For most homebuilders this put the conversion out of reach as far as skill set or budget resources allowed. But thanks to the recent introduction of reproduction steel bedsides from Golden Star Classic Auto Parts, converting that longbed Ford down to a shortbox Fleetside is a simple matter of swapping a few sheetmetal components.

While this might sound labor intensive, assembling the bed and welding the panels together for our project F-100 was accomplished in less than a day. Compared to modifying all the panels that are required to be sliced and diced to take the longbed sheetmetal down to shortbed specs, this process is not only much faster, but will result in a product that is ready to send straight to the paint shop, with minimal bodywork required. Spending a little more money up front, while saving a massive amount of time, labor, and money on the back end, makes assembling a new shortbed out of Golden Star sheetmetal a much more sensible approach.