Tech

Tech

Images By THE AUTHOR

Images By THE AUTHOR’ve been a professional repair and refinish technician for over half my life. I love my career, and how cars and what they represent are intertwined with family memories from a very early age. My family is from western Canada, south-central British Columbia to be exact, and we grew up around cars. My uncle Herb Pinske’s antique auto wreckers, A&H Used Auto Parts, sold cars and parts from the 1920s up to the 1970s, with a vast array of makes and models. My brother, Blaine Tetz, and I grew up around these cars and learned life lessons along the way.

My Cousin Wayne Pinske was here in Tennessee for a visit earlier in the year and we were reminiscing about childhood memories, cars, tall tales, and family get-togethers. We (possibly over adult beverages …) hatched a crazy plan to drag my youngest cousin Allan’s truck (that he got from his dad) down to my shop to throw a quick paintjob on it and have a family get-together. Ultimately, that plan escalated over the summer and ended up in a weeklong event that started with Cousin Allan’s ’56 F-100 making the 2,400-mile/36-hour journey on an open car hauler with his brother, Wayne, their nephew, Brandon, and Shane Dacosta (Brandon’s brother-in-law) on board.

My brother, Blaine, and Wayne’s son Steve flew in and met us in Nashville just in time to attend the Triple Crown of Rodding, which is an amazing car show! Once we saw the sights, had a nice visit, and got reacquainted, we got down to business.

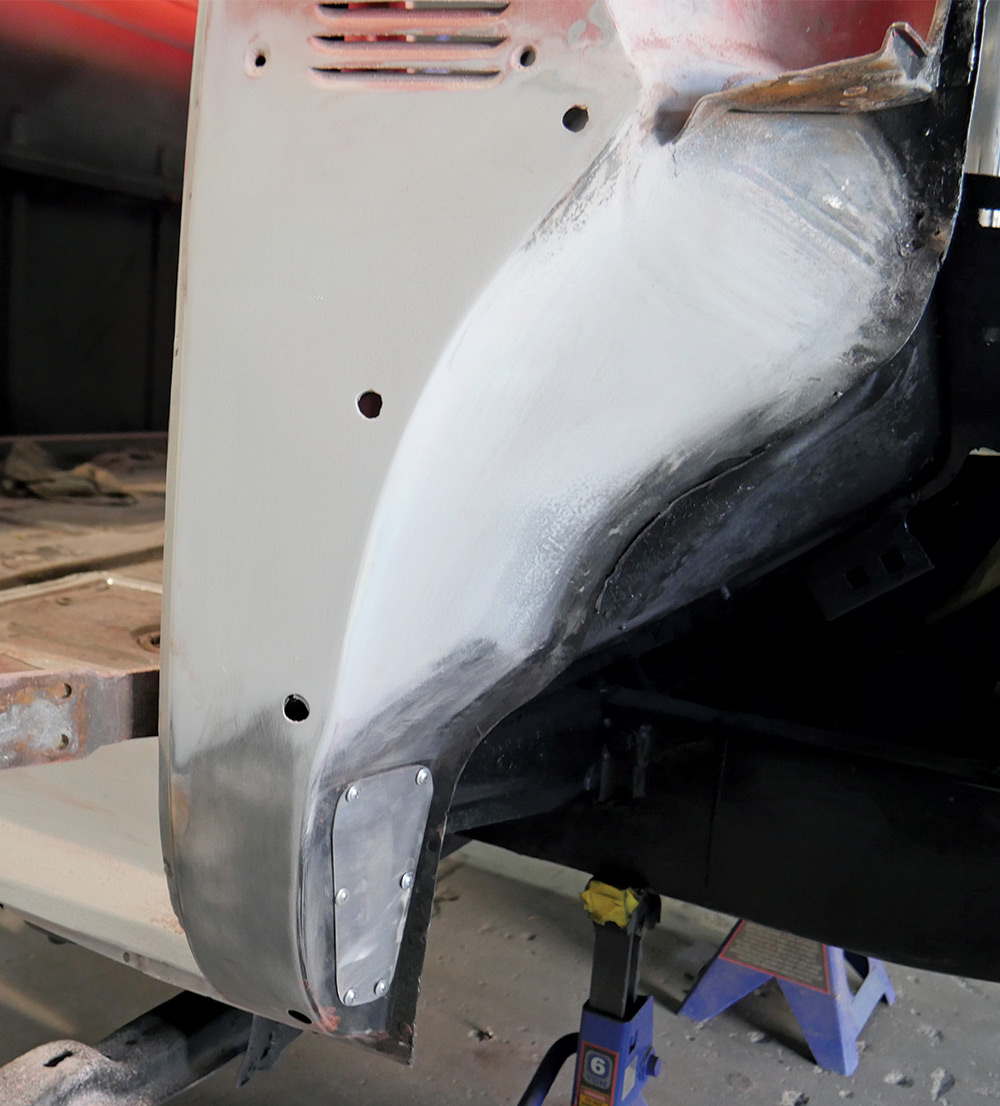

We had a six-day deadline, so it was GO-TIME! What makes it a little easier is that we used all-new Auto Metal Direct (AMD) fenders, bedsides, braces, and patch panels to complete the repairs and get us beautiful parts that, aside from cab corners and rust repairs, only needed to be scuffed and painted for installation on the truck. This is a snapshot of a once-in-a-lifetime build thrash. It was an adventure that got our family back together again after decades apart and kicked out an outstanding F-100 refurb at the end of a six-day/500-hour week!

33. Everyone was a little shell-shocked and exhausted for reassembly … we still put in 12- to 14-hour days with seven bodies, which makes a total of just under 500 labor hours all accumulated. We installed a new rear glass, new weather-seals (PN X580-4556-1), and a few other chrome goodies to freshen things up.

SOURCES

SOURCES