Tech

Tech

Images BY CTP Staff

Images BY CTP Staffn the July ’24 editorial in Classic Truck Performance magazine, editor Rob Fortier covered the controversy concerning the conversion of a longbed C10 pickup into a shortbed. As always Rob looked at both sides of the issue while pointing out that General Motors sold far more longbed trucks than shortbeds, something like three times as many between 1967 and 1972. That fact is a good argument for cutting a longbed down to size.

Like many things, how pickup trucks are viewed today is far different from the ’60s and ’70s. Back then pickup trucks were simple, rugged utilitarian vehicles so it stands to reason that so many buyers opted for longbeds due to their increased carrying capacity. As a result, after years of service, many longbed trucks have the telltale signs of leading a rough life.

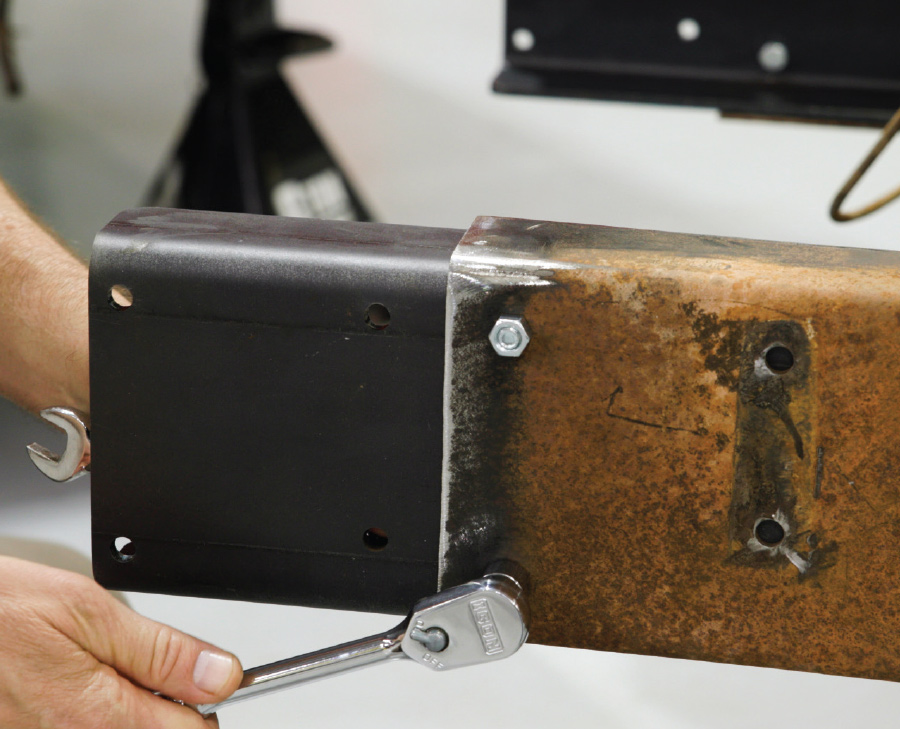

Although longbed Chevy and GMC trucks have their followers, there’s no question that the shortbed versions are more popular with classic truck fans. Of course supply and demand being what it is, the more sought-after shortbed trucks bring higher prices when compared to longbeds, but that lower initial investment can be an advantage in some instances, particularly when an affordable Classic Performance Products (CPP) frame shortening kit (PN 6372LBCSK) is considered.

Once the frame is shortened by removing a section under the cab, it is put back together with laser-cut C-channel reinforcements that are bolted in place (CPP does recommend welding as well to ensure long-term structural rigidity). Included in the kit are step-by-step instructions on how to modify the frame and all the necessary hardware.

Now that the chassis modifications are complete, next time we’ll wrap up our short story by showing how to assemble a new short Fleetside pickup box.

SOURCE

SOURCE