Tech

Tech

InTheGarageMedia.com

Photography BY Taylor Kempkes

Photography BY Taylor Kempkes Videography BY RYAN FOSS PRODUCTIONS

Videography BY RYAN FOSS PRODUCTIONS

he Chevy OBS truck series, known in 1988 as the GMT400 platform when introduced, was all new from the ground up. The series ran through a successful decade of hard-working trucks, along with Tahoes and Suburbans, and today are sought after by truck enthusiasts.

We’re lucky enough to have a two-wheel drive Tahoe that serves as a daily driver and remains mostly stock. But, at 25 years old, there are plenty of worn-out pieces that need replacing to keep the rig riding and driving as nice, and safely, as one would expect. One area that was overdue for some maintenance and attention was the front suspension.

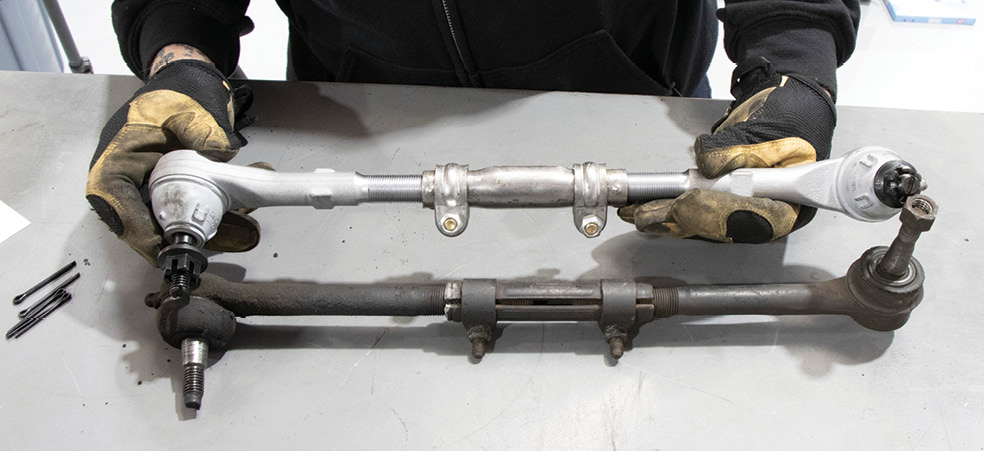

The parts we needed to rebuild our ’98 Tahoe’s suspension were easy to look up and select. We ended up choosing Duralast’s complete control arm assemblies as a huge time saver rather than rebuild our factory units. They do offer direct-fit bushings and ball joints in their Gold series line that are engineered to be improved, stronger-than-factory replacements, which is what we chose to update the steering linkage. Lastly, a new set of monotube shocks were selected for the front and rear.

By the end of the day, the Tahoe was dropped back on the ground with its new suspension. The first drive felt tighter, nicer, and just better. Once we get the alignment done and dialed in, we’ll be ready for miles of smooth, trouble-free cruising.

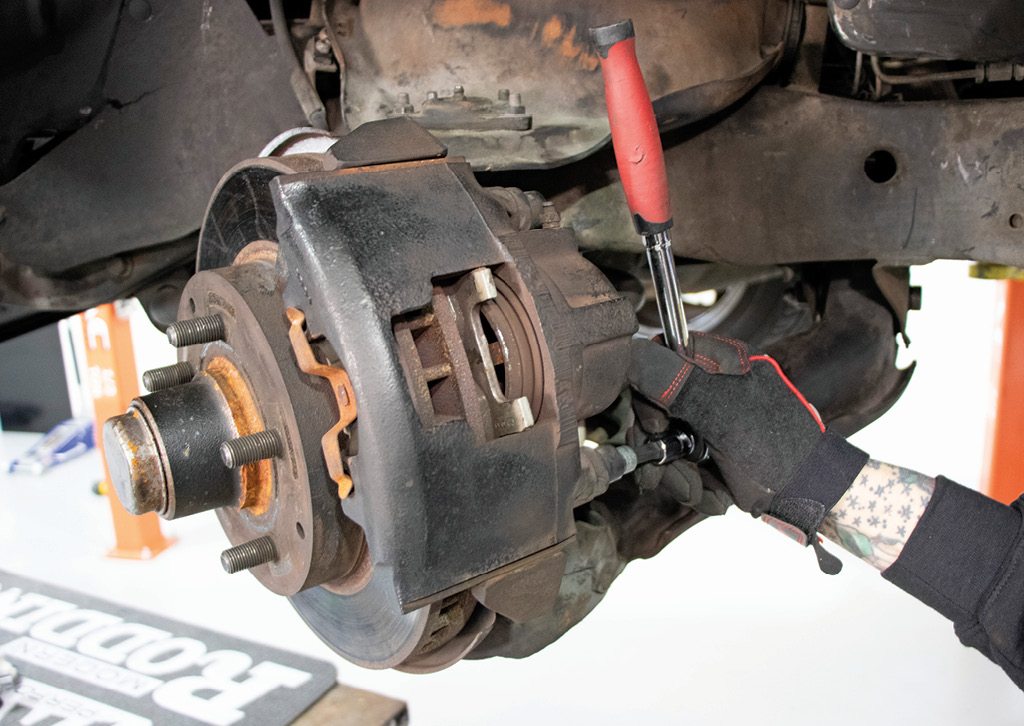

2-3. With the OBS safely raised off the floor, we went to work on the frontend by removing the calipers followed by the brake hose mount from the control arm.

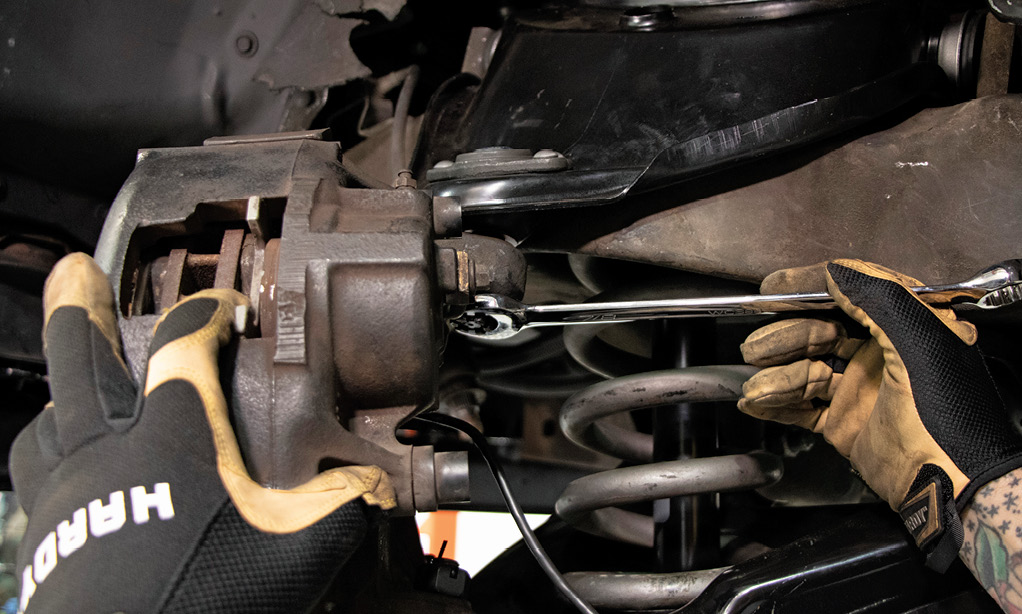

7-8. A few taps on the spindle separated it from the ball joint, but you will likely need a picklefork to get the job done. At this point you’ll need to have a floor jack to support the lower control arm to help safely remove the coil spring. We usually pull the spindle from the lower control arm, followed by the upper connection.

SOURCE

SOURCE