Tech

Tech

BY Ron Ceridono

BY Ron Ceridonohere are few things that are more annoying than an engine that overheats. Living in fear of steam boiling out from under the hood of your truck and then seeing the green river of death pouring out from underneath your cherished truck is a sure way to ruin the day.

Overheating an engine comes with consequences, some minor, like cleaning up the mess that burping out coolant can make, to catastrophic engine damage that can cost a small fortune. And while overheating is a concern, the first question to ask on the subject is how hot is hot? Due to the composition of today’s fuels, 180 degrees is considered the minimum operating temperature for efficient combustion even for vintage engines on the street. Most experts agree that 190 degrees is a safe operating temperature for modern engines and for contemporary fuel-injected crate engines, 195 to 220 degrees is considered the norm.

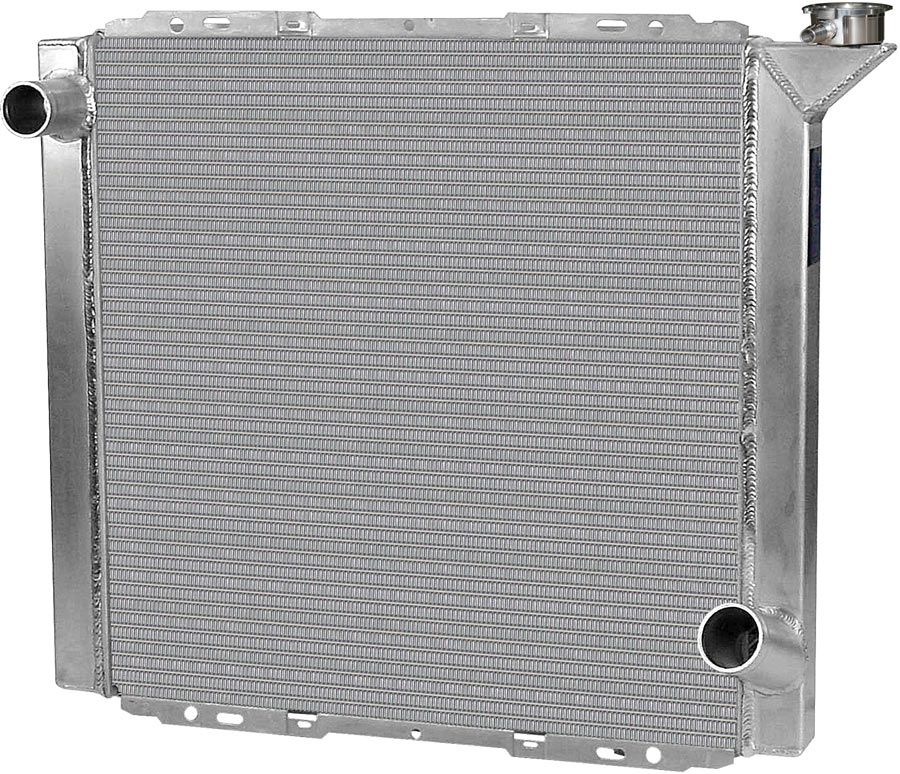

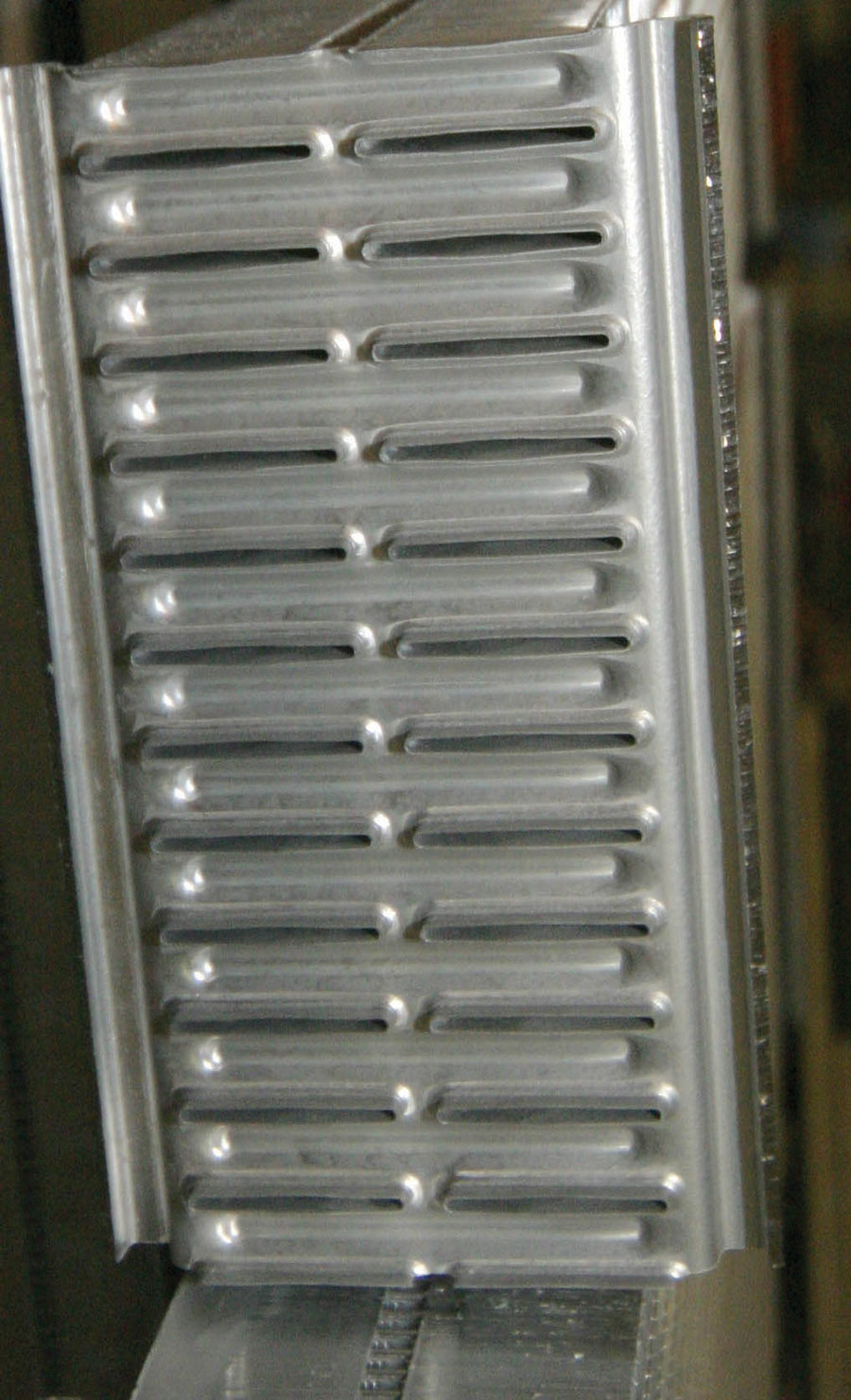

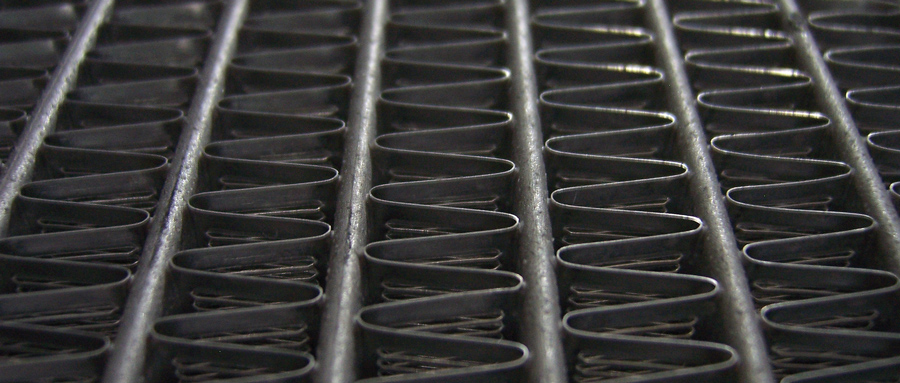

Any discussion about cooling has to start with the radiator. Simply put, radiators dissipate heat by air passing by the tubes and fins that make up the radiator core. Generally there is a 25- to 50-degree drop in water temperature between the radiator’s inlet and outlet; of course the more powerful the engine is the more challenging cooling becomes. In performance applications it’s always wise to fit the largest radiator that will fit the space available and consult the tech team at Afco Racing Products.

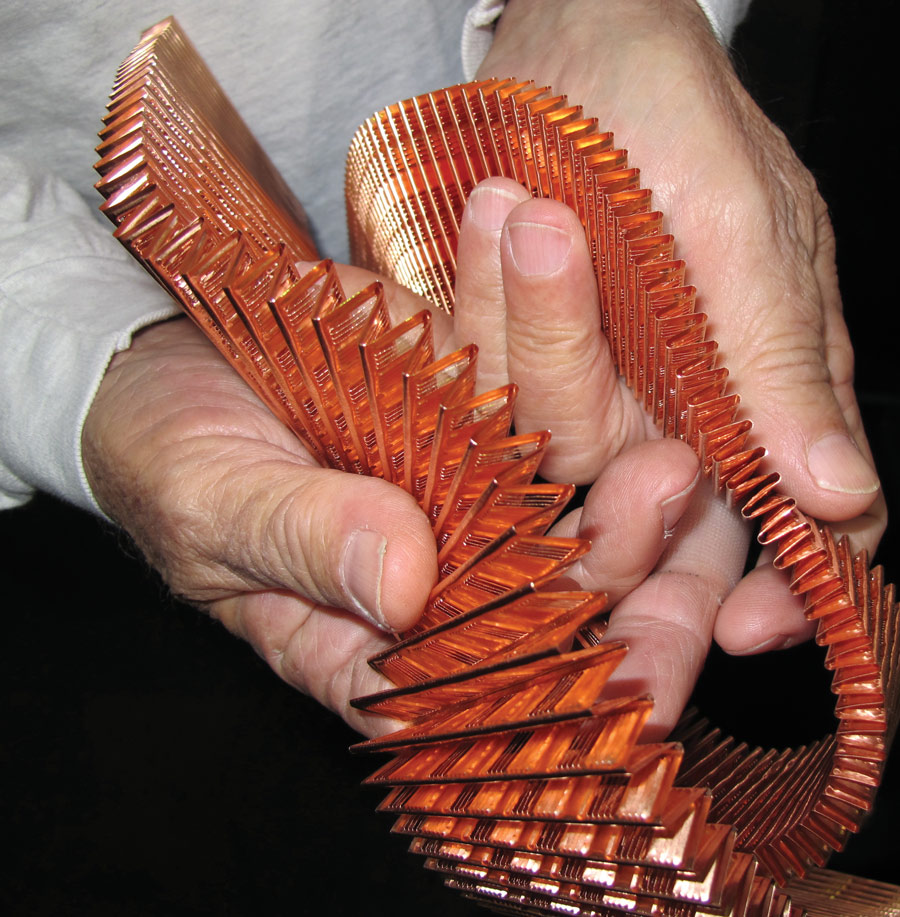

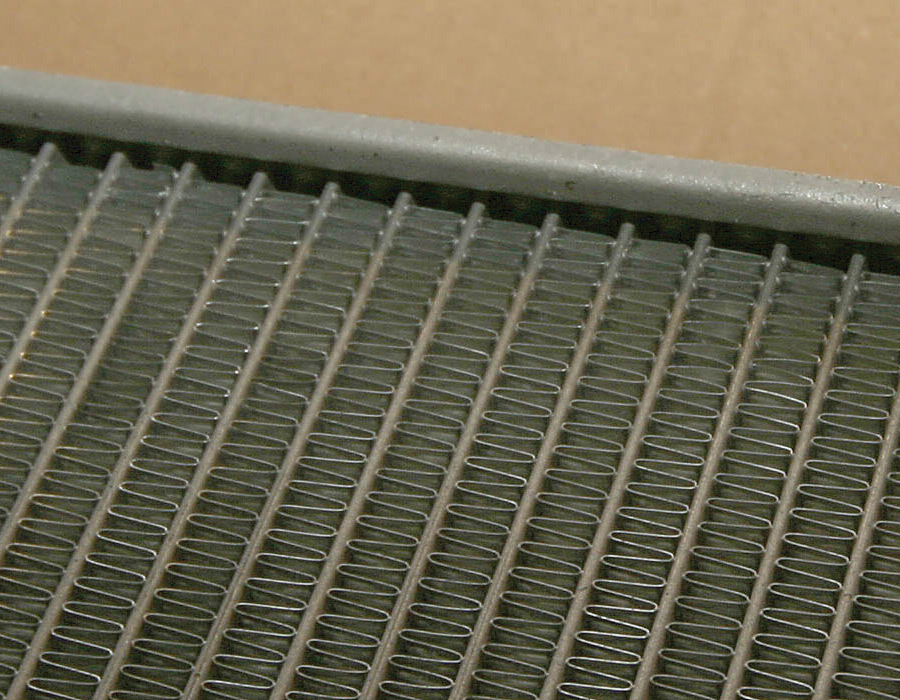

The radiator core’s fin count is critical—increasing fin count will increase the capacity to cool, up to a point. If the fin spacing is too close airflow may be restricted, which will reduce cooling capacity. Afco has found the “sweet spot” for the most effective airflow, and as a result the best cooling is 15 or 16 fins per inch.

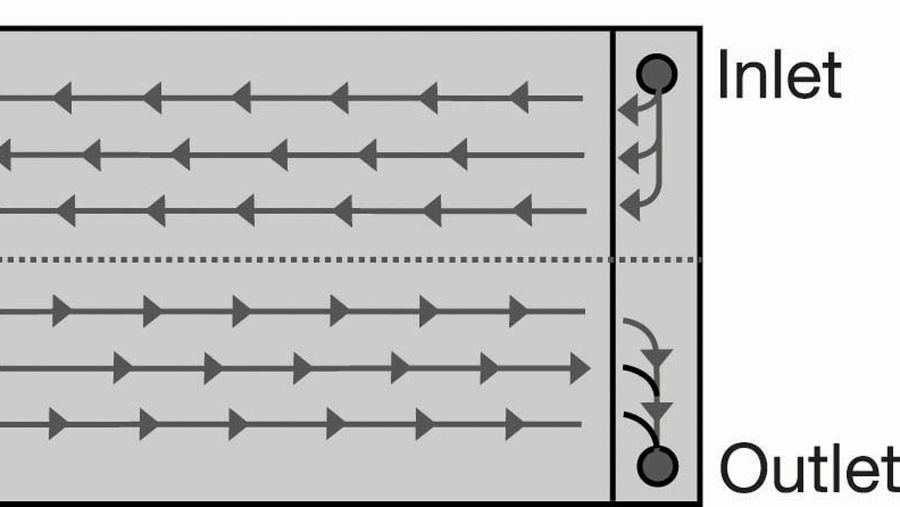

As hood heights became lower, OEMs went to wider crossflow radiators as a means to get longer tubes in a radiator with less height.

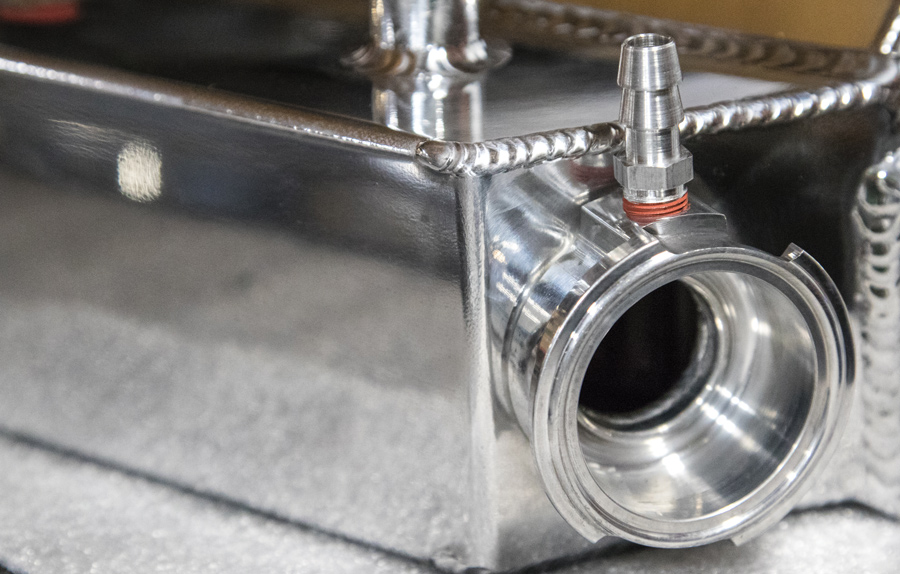

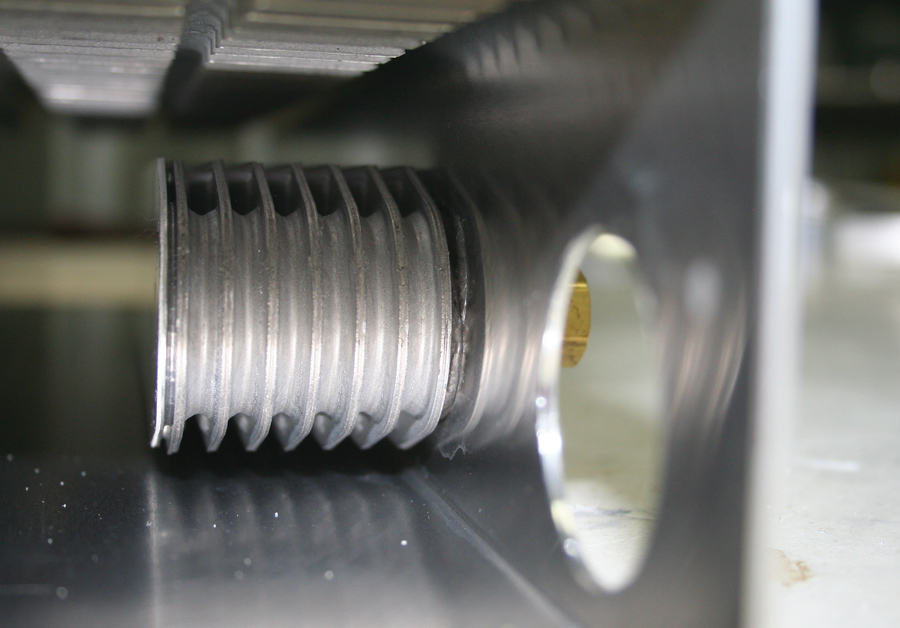

Another variation on core configuration is the multi-pass style. Water flows into the core in one direction, then is redirected by baffles in the tank(s) to flow back through the core a second, or in some cases a third, time.

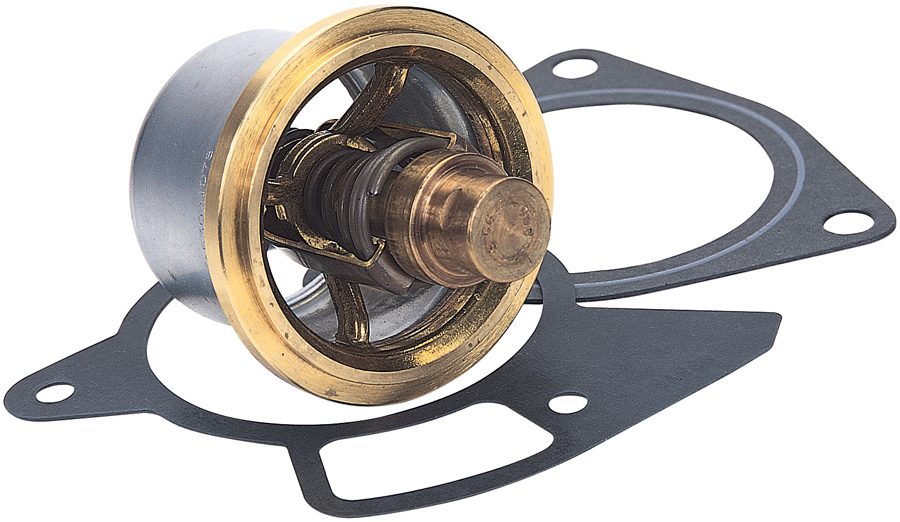

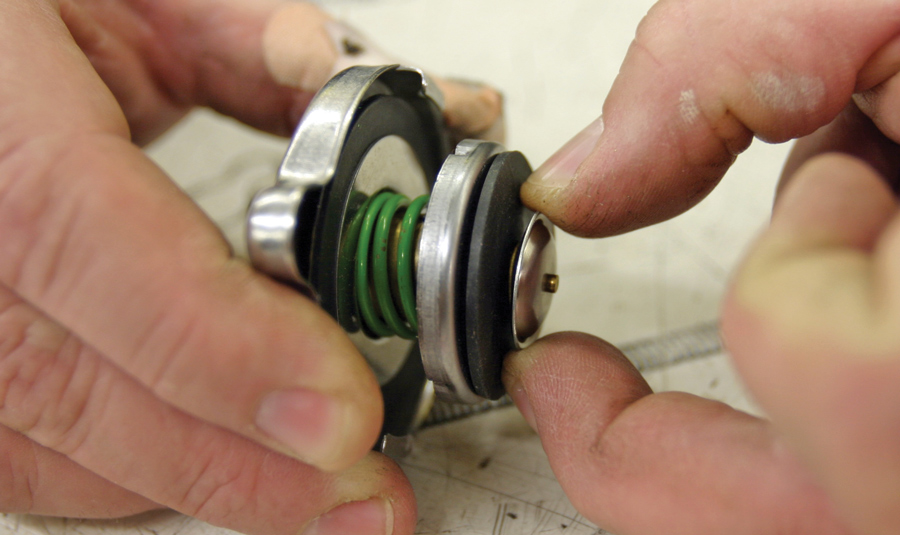

There are two types of thermostats that are common, the poppet valve style and the sleeve style. The poppet style is either open or closed and opens against the flow of coolant from the water pump, which can cause problems at high rpm and high pressure in the cooling system. The sleeve style is a non-linear design that opens gradually. Unlike a poppet design, the sleeve-stye thermostat equalizes the system pressures above and below the thermostat’s moving valve. Therefore the thermostat is pressure balanced and will respond to system temperatures regardless of the pressure in the system.

Like many things that seem simple there’s more to a modern radiator cap than meets the eye. Along with a spring that keeps a preset amount of pressure in the cooling system, radiator caps also have a vacuum valve. When an engine is shut off the coolant stops flowing through the radiator, however the coolant continues to absorb heat from the heads and block and as a result the temperature in the system increases. As the coolant expands the pressure often increases to the point where the radiator cap’s rating is exceeded and liquid is released through the radiator’s overflow. When the system cools and the coolant contracts air (or liquid) is drawn back into the radiator through the vacuum valve.

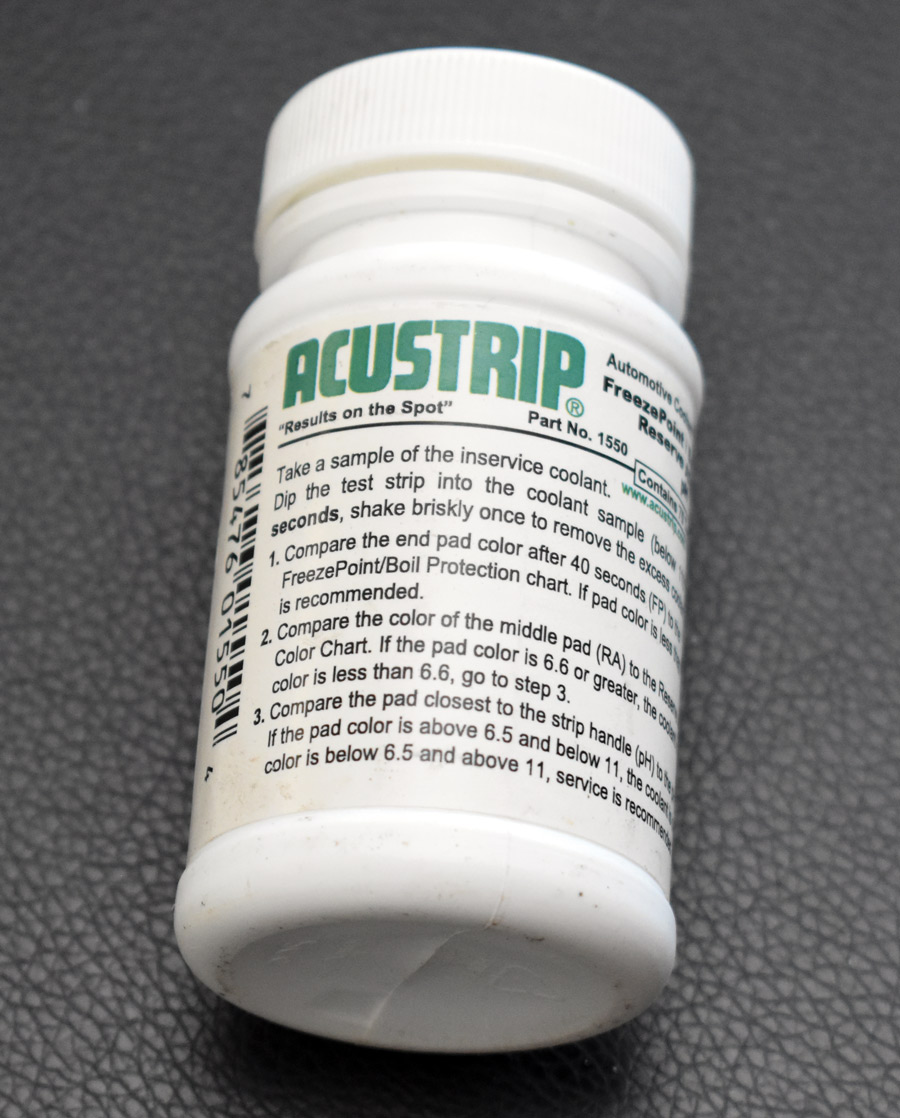

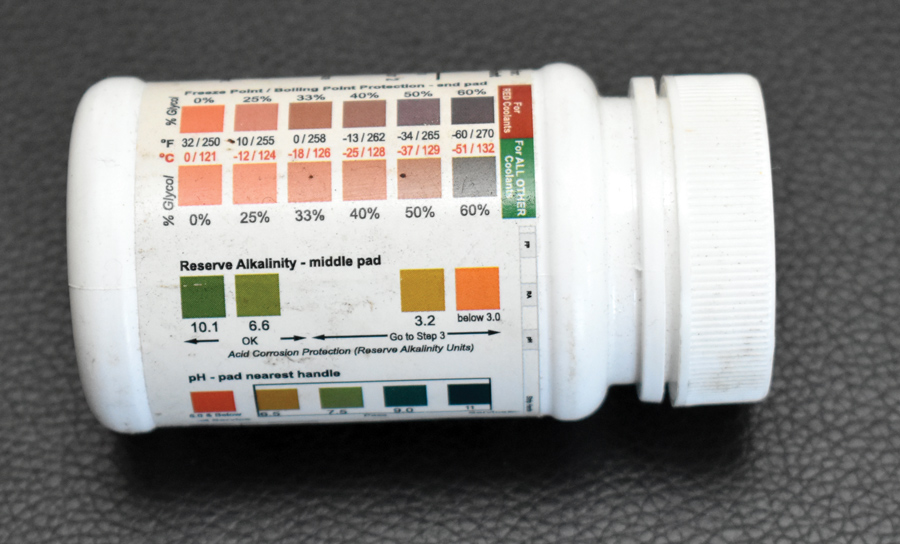

In addition, quality coolant contains corrosion inhibitors. Ironically the concern with the coolant used isn’t due to the antifreeze, it’s the water mixed with it. Tap water contains harmful minerals that can lead to corrosion, and there is some debate over using distilled water. The best choice is deionized water and the easiest way to get that is to use Afco High Performance Coolant; it’s pre-mixed with a 50/50 mix of antifreeze and deionized water.

Afco warns that radiator damage and inadequate cooling can result from improper filling and purging of the cooling system. Improperly purged systems can result in air pockets that allow coolant to expand, violently creating steam, which causes surges in water pressure that overcome the pressure cap rating. In turn, inadequate cooling (because all internal surfaces are not in contact with coolant) and radiator damage (tube or tank bulging) can result.

Chemical Electrolysis: This is caused by dissimilar metals in the cooling system, such as cast iron, aluminum, steel, copper, brass, and others that can actually create electrical current.

Stray Voltage: Since the coolant will conduct electricity, stray voltage will travel through it to find a ground. And because an aluminum radiator is the softest metal in the system it is the most vulnerable to damage. To prevent this from happening make sure the engine and frame are properly grounded. Make sure all accessories are properly grounded and remember painted and powdercoated surfaces do not make a good ground—metal surfaces must be bare.

Corrosion Erosion: When the antifreeze turns bad or electrolysis occurs it leeches off very small particles of metals, rust, and aluminum oxide into the coolant. Tests show these particles are like having liquid sandpaper flowing through your cooling system, which in turn erodes the aluminum components even more. The best preventative is to change coolant.

When it comes to keeping your cool, Afco has all the bases covered. They offer replacement aluminum radiators with OEM dimensions and custom radiators for virtually any application in downflow, crossflow, or multi-pass designs. Radiators come in satin finish, black, or, for that extra bit of bling, with polished tanks.