Tech

TechInTheGarageMedia.com

BY STEVE MAGNANTE PHOTOGRAPHY BY THE AUTHOR

PHOTOGRAPHY BY THE AUTHOR

PHOTOGRAPHY BY THE AUTHOR

PHOTOGRAPHY BY THE AUTHORSolving the Rusty Bed Blues

Golden Star Classic Auto Parts’ Squarebody Sheetmetal Cure

P

ickup trucks are hot these days. If collector car auction results are any indicator, trucks have equaled cars in desirability—and value. But rust doesn’t care. The same corrosive meanies who gobble up a Chevelle, Mustang, or Charger quarter-panel love pickup truck cabs, doors, and beds. In this story, let’s watch as Wheelwright, Massachusetts HVAC guru—and 1985 Chevy K10 pickup truck owner—Brian Rochette replaces the faltering stock bed and doors with fresh replacements from Golden Star Classic Auto Parts.

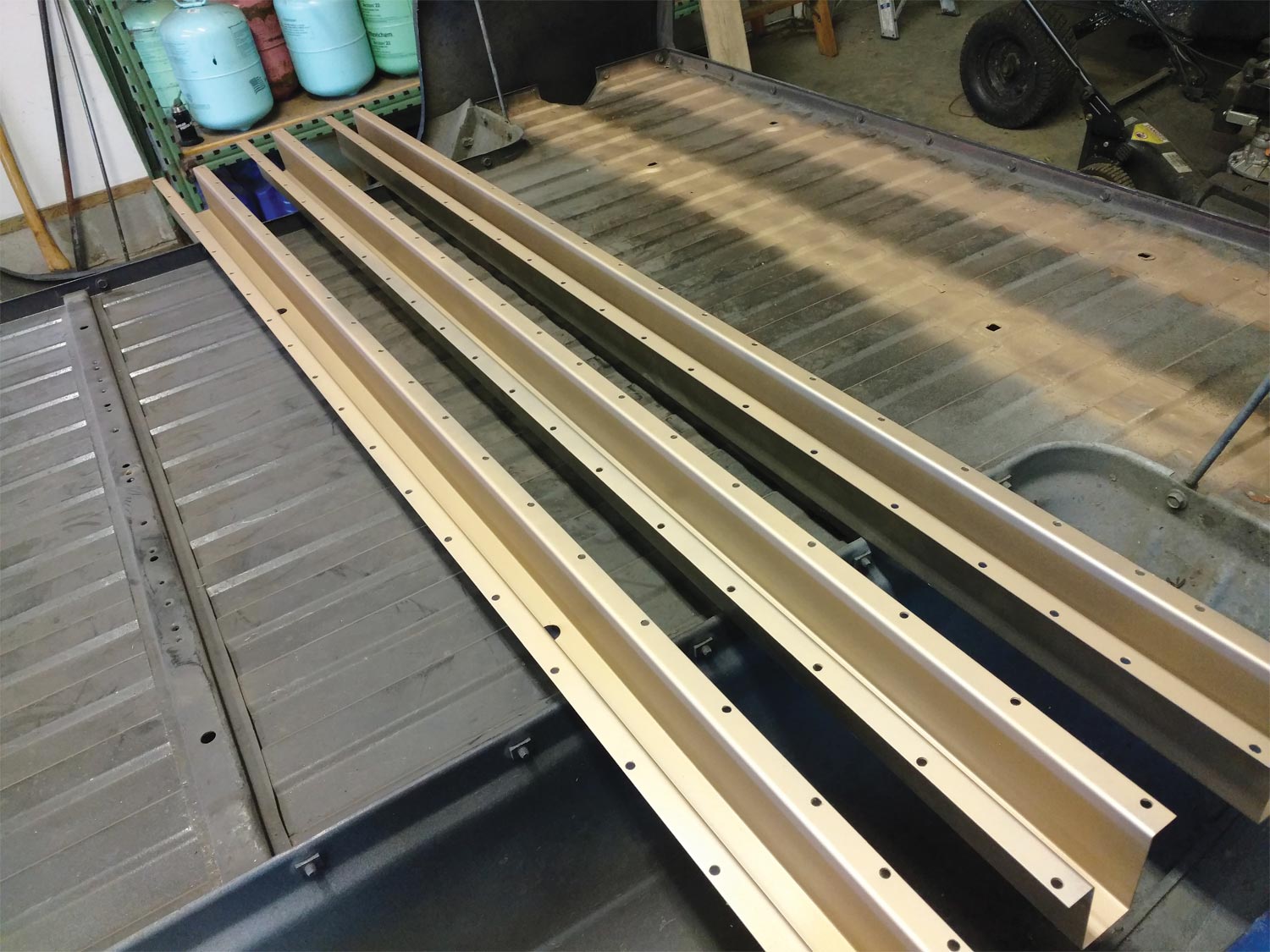

Like the best gift ever from K10 Santa, all the parts to cure the rust problem arrived on a pallet.

1. “With a little help from his friends,” Brian Rochette drove the truck out from under the punky bed.

2. Packing a BluePrint Engines 427 small-block stroker with a Holley Sniper throttle body EFI unit, this K10 is a low 13-second sleeper. The Muncie SM465 four-speed transmission and 2.73:1 corporate 10-bolt rear axle have been totally reliable. Axle hop is tamed by Edelbrock Performer IAS gas shocks with 46mm pistons. Borrowing a page from the early days of the big-block Camaro, GM staggered the C10/K10 shocks for maximum jounce/rebound control.

3. Like most New England–based vehicles, rust hides everywhere. Though the bed floor was surprisingly clean, the transverse support/mounting crossmembers were shot. Though a reproduction is offered by Golden Star Classic Auto Parts, our story was photographed in the midst of the COVID-19 pandemic and supplies of the bed floor (PN PB16-736) were on back order. So Rochette improvised. By the time you read this, Golden Star’s warehouses should be fully stocked.

4. The K10 (and C10) bed floor has six crossmembers. The three larger ones locate the bed to the frame and must be solid or the bed will sag and flop. The three smaller ones (one of which is closest to the camera) provide floor strength and were in good shape.

5. With open ends, the U-channel crossmembers can retain moisture and rot from the inside out. A combination of power and hand tools separated the spot-welds, holding them to the bed floor.

6. Because (so far) nobody reproduces these vital crossmembers, Rochette’s pal Dave Dowgielewicz (a skilled metalworker with access to the metal brake at Forgione Engineering in Lowell, Massachusetts) measured the originals and cloned them out of 12-gauge sheet steel.

7. Here Dowgielewicz uses a pneumatic punch to put holes in the flanges so the new crossmembers can be plug welded to the underside of the bed floor. SEM weld-through spray primer (PN 40783) was applied to the inner and outer surfaces to prevent future corrosion.

8. The original bed floor was stripped clean before the new crossmembers were welded in place.

9. The new crossmembers stand ready to support the bed and cargo. The trio of smaller crossmembers was solid (to the right of the replacement item) and required no attention.

10. Rochette and helper Ray Stanley show off the revitalized bed floor mounting crossmembers. Thankfully the wheelhouses were in great shape for reuse. Again, Golden Star offers brand-new bed floors—and wheelhouses—if yours are beyond repair.

11. The outer bed walls were another story. Though smooth looking from 20 feet, close inspection revealed the usual flakes, bubbles, holes, and plastic filler applied by a previous owner.

12. This author has prowled hundreds of wrecking yards but was surprised to learn the bedsides were not welded in place. Rather, a handful of threaded fasteners hold them in place. Honestly, I’d never seen a GM (or Ford or Dodge/Ram) pickup bed in the junkyard with a wall removed like this. I thought they were all welded together—otherwise boneyard scavengers would have made stripped beds like this a common sight—which they are not. Live and learn.

13. The bolt-together bed construction makes panel replacement a breeze. Fingers point to the flanges and boltholes that align and hold it all together.

14. The Golden Star bedsides are much more than outer skins. They’re double-wall items and virtual blueprint copies of GM items. No welding is required. The passenger side item (PN PB07-81R) is available with—or without—the fuel filler door opening needed for trucks equipped with the auxiliary fuel tank. The driver-side bed side (PN PB07-79L) comes with the standard fuel filler door opening.

15. The bedsides were bolted to the original floor with a thick bead of seam sealer filling the gaps to eliminate crevices where moisture can foster rust. Golden Star also offers smaller, localized patch panels and reproduction body and underbody panels for popular Ford, Bronco, Dodge, and Ram trucks, not to mention VW and most American muscle and ponycars. Check out their website for a huge assortment of useful repair and restoration items.

16. Rochette test-fits the taillamp unit prior to painting to match the cab. Golden Star bed panels come coated in semi-matte primer that’s safe to paint over, following a light scuff to help paint adhesion.

17. Rochette’s cab was in good condition (though Golden Star offers cab floors, corners, firewalls, and many other items) but the doors had the usual New England lower edge bubbling. Knowing it was probably the tip of a “rustberg,” a set of new reproduction doors set things straight. The passenger side is PN DO16-77R.

18. Rochette test-fit the driver side door (PN DO16-77L) before painting. The inner and outer skins are welded together just like new old stock items. The window tracks, risers, glass, door handles, and latches transfer easily. If needed, Golden Star offers manual and power window riser and track assemblies for Chevy trucks and many other popular applications.

19. Rochette was happily surprised to discover that the factory-installed door hinge shims were not needed with the Golden Star doors. He said, “The character lines are precise and matched the front fenders and cab edges as good as the original sheetmetal.”

20. The lighter shade of primer on the doors will be resprayed to match the new bedsides prior to painting so there aren’t any subtle shade differences in the dark blue metallic topcoat.

SOURCE

SOURCE