In the Shop

In the Shop

Photography BY THE AUTHOR

Photography BY THE AUTHORhere’s nothing more refreshing than getting back on the open road after what seems to be an eternity of standing on the sidelines. Our latest road trip brought us to the seaside community of Portland, Maine, to check out the latest happenings straight from the shop floor at Back Bay Customs. Co-owned by Adam Clayman and Paul White, Back Bay Customs has been in business well over 20 years. The shop recently relocated to a larger 10,000-square-foot building, allowing them to expand their services and capabilities even further.

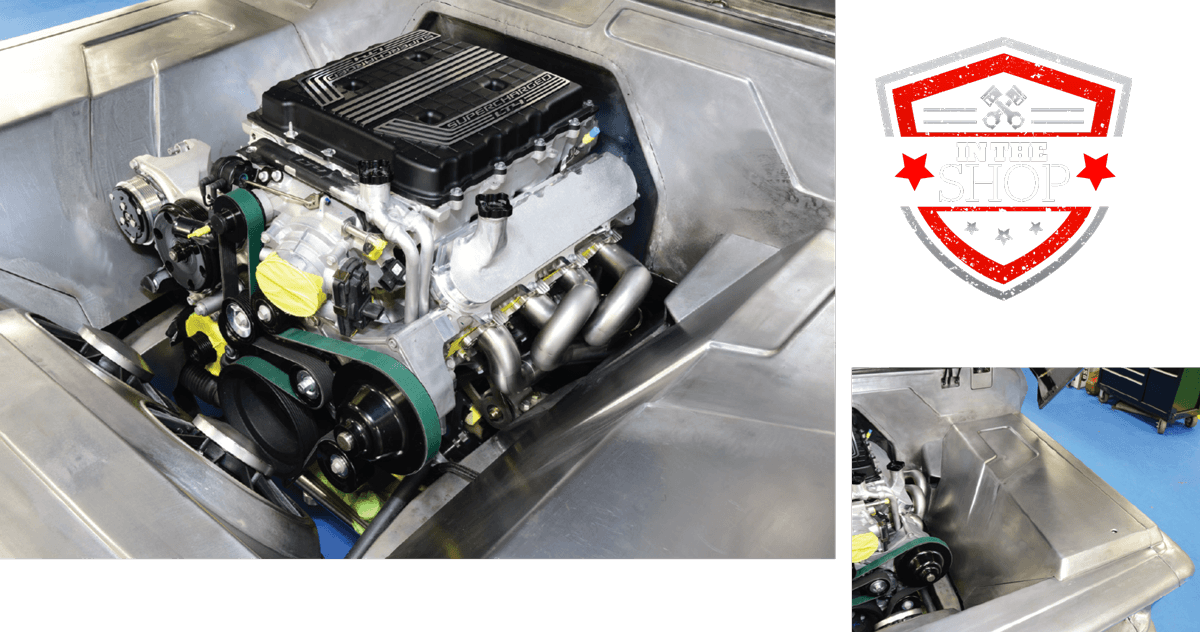

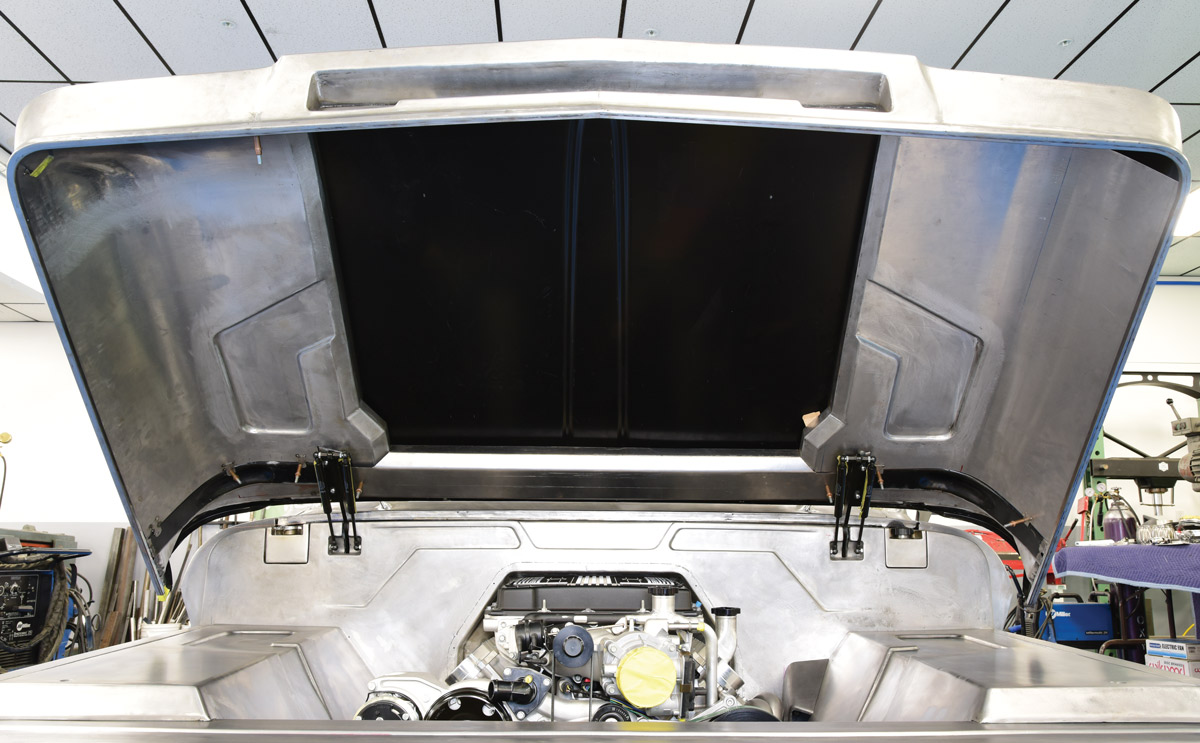

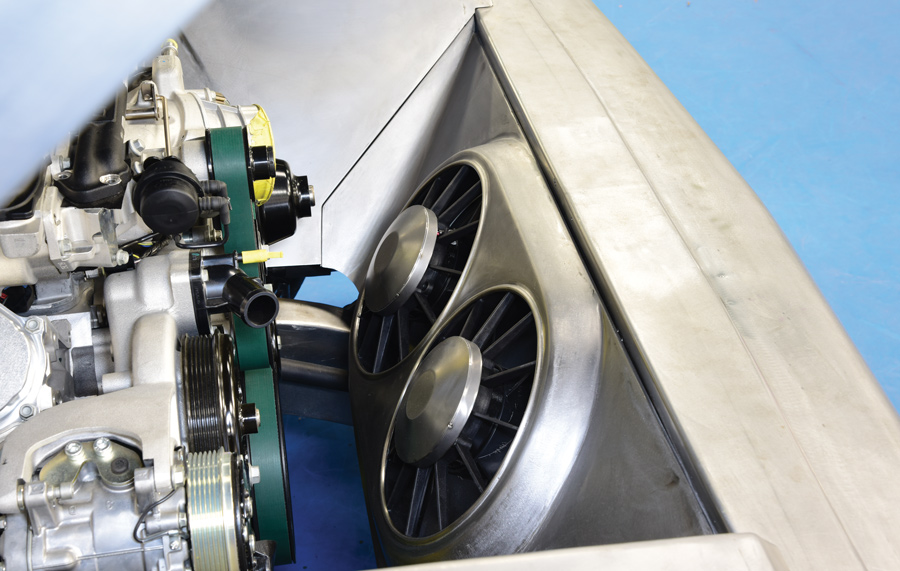

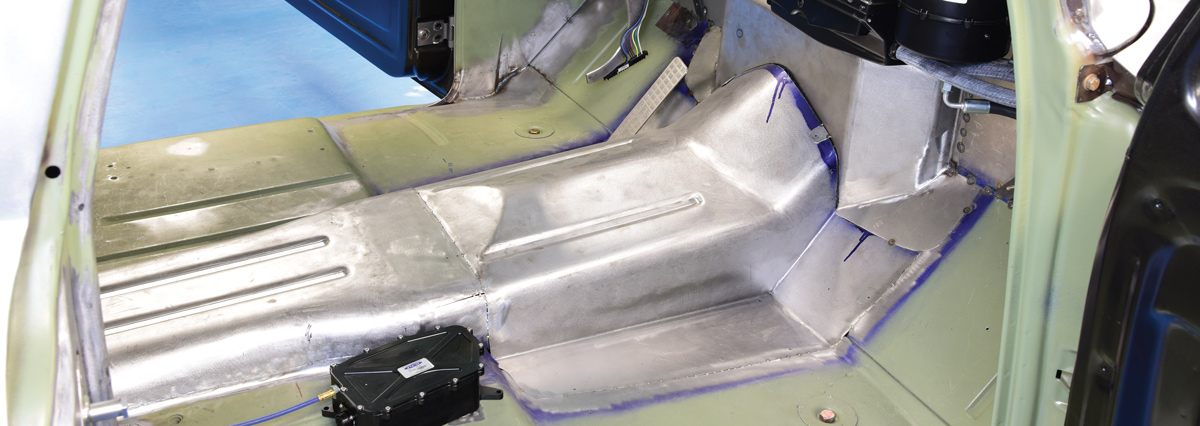

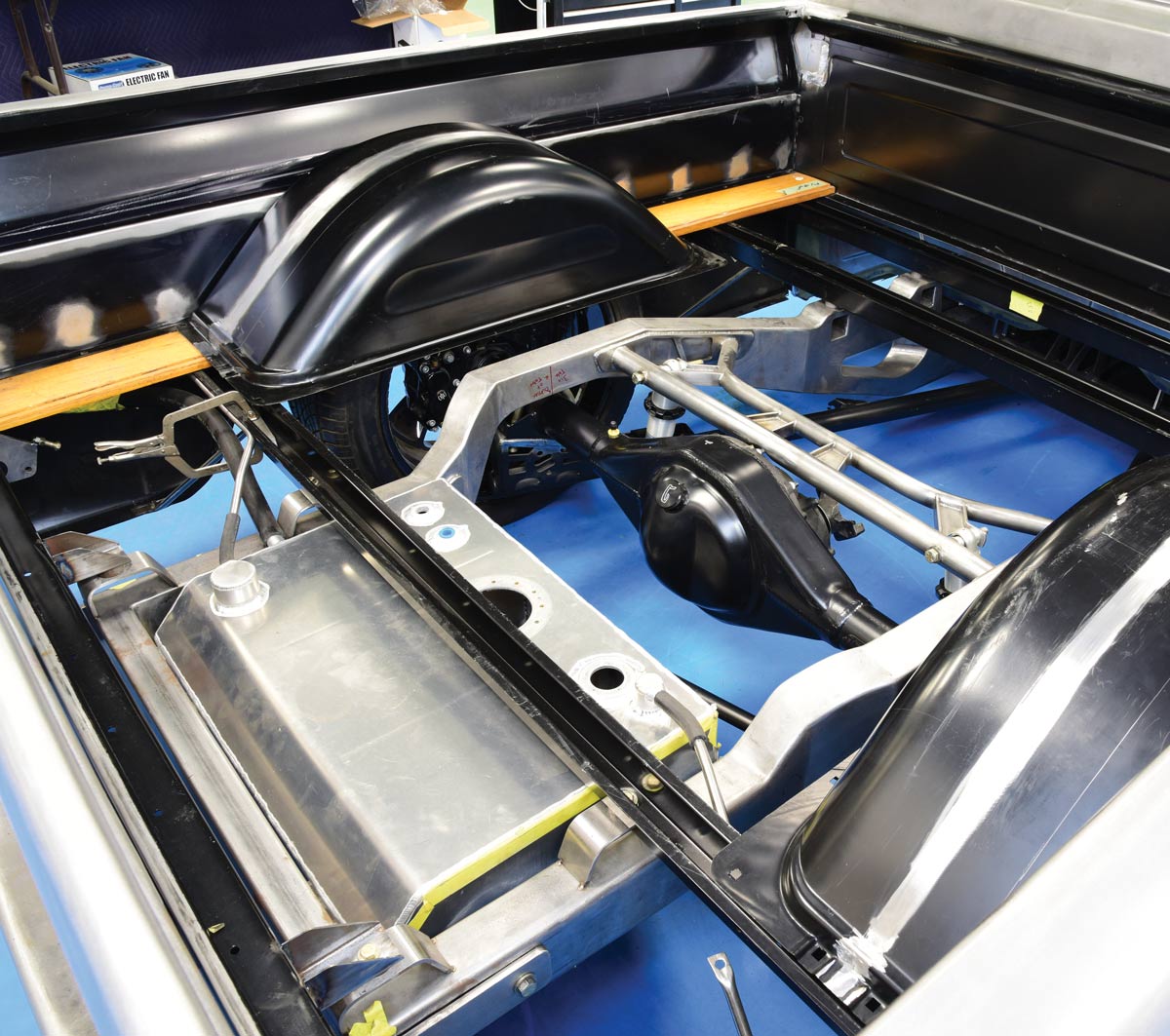

Walking the shop floor with Clayman, there were a number of projects underway, including an LS driveline swap on a 1972 Nova, 1934 Chevy roadster reaching completion, rarely seen 440 Chrysler V-8 powered Jensen Interceptor, and a bare-metal 1966 Chevy C10 owned by customer Chris Castro, which was a knockout.

SOURCE

SOURCE