Droppin’ It Ol’

School

School

Western Chassis Revisits its Roots With the Traditional 1988-1998 C1500/OBS Super C-Notch & Flip Kit

BY ROB FORTIER | Photography by the Author

When I started my career back in 1993, the GM C1500 Series 1/2-ton pickups were all the rage. The “sport truck” fad contributed to the success of two rather large magazines that, albeit no longer with us, devoted themselves to the pastel-colored, sometimes tweed-interiored, small-diameter wheeled trucks that many, including myself, would fade away like disco once the trend of big-wheeled ’n’ bagged pickups took over not too long after!

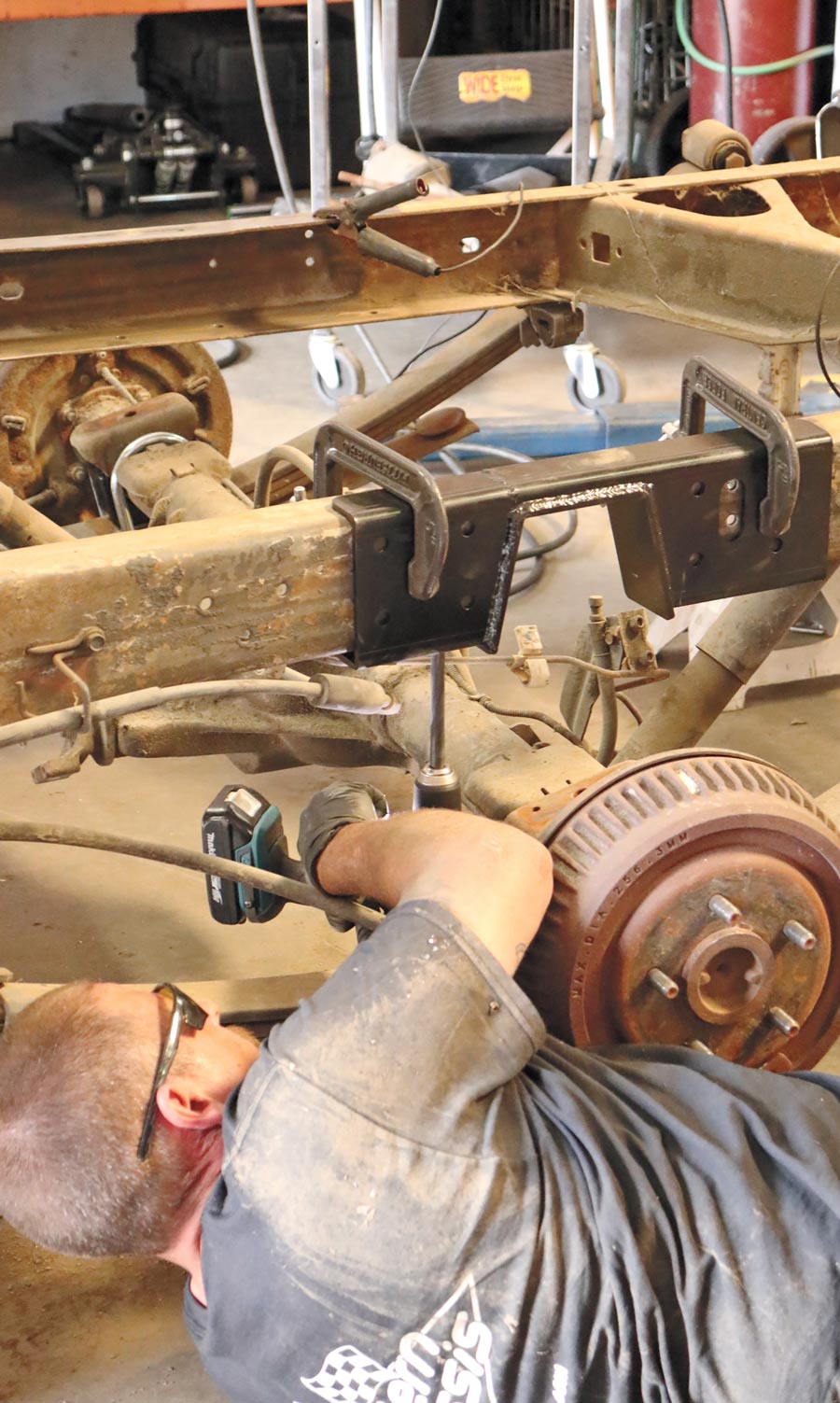

We’ve all seen our fair share of second-gen OBS Silverado Crew Cabs, so let’s just cut to the chase, shall we? (We’ll show the entire project once she’s laid down properly with fresh new underpinnings!) Here’s our volunteer patient’s rearend in its crusty-stock form—ready and willing for Western Chassis’ (WC) all-new Super C-Notch and 6-inch flip kit for 1988-1998 GM C1500s. (The 2-inch drop spindles and 2-inch drop coils are next on the to-do list.)

While new leaf springs are an option—and available directly from WC—we’re going to retain the Silverado’s stock pack and simply do the traditional flip with WC’s 6-inch perch/U-bolt kit. With the leaf spring safely removed (we’ll do one side at a time) yet the stock still attached, simply flip the spring from atop the rearend to below, the act of which in itself nets roughly a 5-inch drop.

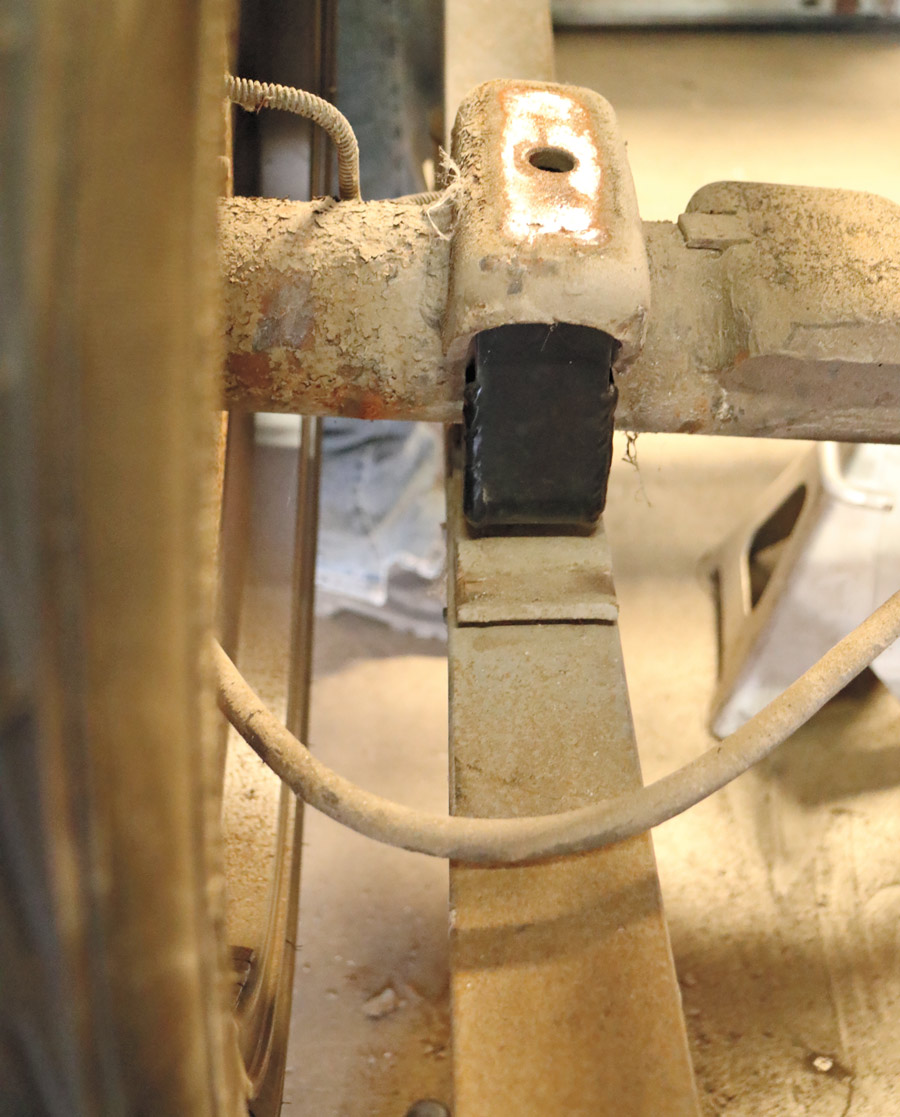

The fabricated flip perch saddle is designed to work “with” the stock spring perch, so no cutting/welding the rearend housing is required. Simply sandwich between the rearend and the spring …

… and further sandwich with the supplied U-bolts and lower spring plate, all the while keeping everything “snug” from the forward spring eye bolts back until everything is installed properly.

But here we are, three decades later, and guess what? The sport trucks of my day—the OBS, as the cool kids call them—are back … and I like it! Not so sure about the “old body style” nomenclature, however, but just like the Square Body before it became en vogue and then some, I’ve always had a soft spot for the “rounded squares,” as I prefer to call them. And when Western Chassis (WC), one of the original purveyors of then-NBS 1988-1998 GM C1500 Series drop kits (rumor has it WC produced the very first dropped spindle for this series truck!), called and said they’d just acquired a 1993 Silverado Crew Cab and were about to give it the old (school) 5/7 drop, no sooner was I there with camera in hand!

Once the extended rear spring hangers are hung, the complete 7 inches of the 5/7 drop are achieved in the rear with the WC flip kit. All that’s left now, besides installing the new shocks (last), is incorporating the Super C-Notch.

Using the WC Super C-Notch located off the factory reference holes on the framerail, we marked out the section of siderail that will need to be removed.

Whether you use a reciprocating saw, cutoff wheel, or, as we’re about to do, plasma cut the ’rail, you’ll want to make sure and support the top of the ’rail accordingly to prevent the back section of the frame from moving on you.

The right size (amperage-wise) plasma will slice right through the C1500 framerail like butter—and if you use a straightedge accordingly, with a good amount of linear precision!

With our C-notch window opened up, the new notch plate section can be installed (with a bit of rubber mallet persuasion) and located off the provided reference holes; the remaining installation holes can then be drilled directly through the notch plate (top and bottom).

After all the mounting holes have been drilled, the secondary notch plate will bolt directly onto the wheel-facing side (exterior) of the notch, as shown. Notice, too, that the top actually extends “above” the top of the notch/framerail: This portion will fit outside the inner wheelwell of the bed (which will only require the outermost part of the bedfloor crossbrace to be trimmed out).

Now that the notch is in and all buttoned up, the remainder of the rear suspension can be fully buttoned up as well—from the rear spring hangers to the U-bolts to the front leaf bushings.

Now that the notch is in and all buttoned up, the remainder of the rear suspension can be fully buttoned up as well—from the rear spring hangers to the U-bolts to the front leaf bushings.

What WC has to offer for the OBS crowd is what we’ve all become familiar with in the way of flip-kit drops, only more severe now! Some minor fabwork is required in order to ensure their Super C-Notch offers the most extreme rear clearance—without bottoming out, they claim—for their heavy-duty flip kit and extended spring shackles that, combined, will net a 7-inch drop. Additionally, seeing as that’s what got WC started in the first place, to keep the front from “speed boating,” they offer 2-inch drop factory-geometry ductile iron spindles and 3-inch drop coil springs (as well as coilover conversion kits and front/rear performance disc brake upgrades). Call or visit them online for these and other Chevy (and Ford!) truck chassis needs.