Feature

Feature

IMAGES BY NotStock Photography

IMAGES BY NotStock Photographyohn Lamb fell in love with a neat 1961 Ford Unibody pickup truck at a local car show one summer. He was so attracted to the truck because his father had a red Ford Unibody pickup when he was a kid and has great memories of driving in that truck with his family. He requested to the owner that when he was ready to sell the truck he give him first right of refusal to purchase the pickup. John patiently waited a couple of years until he got the chance to purchase the truck.

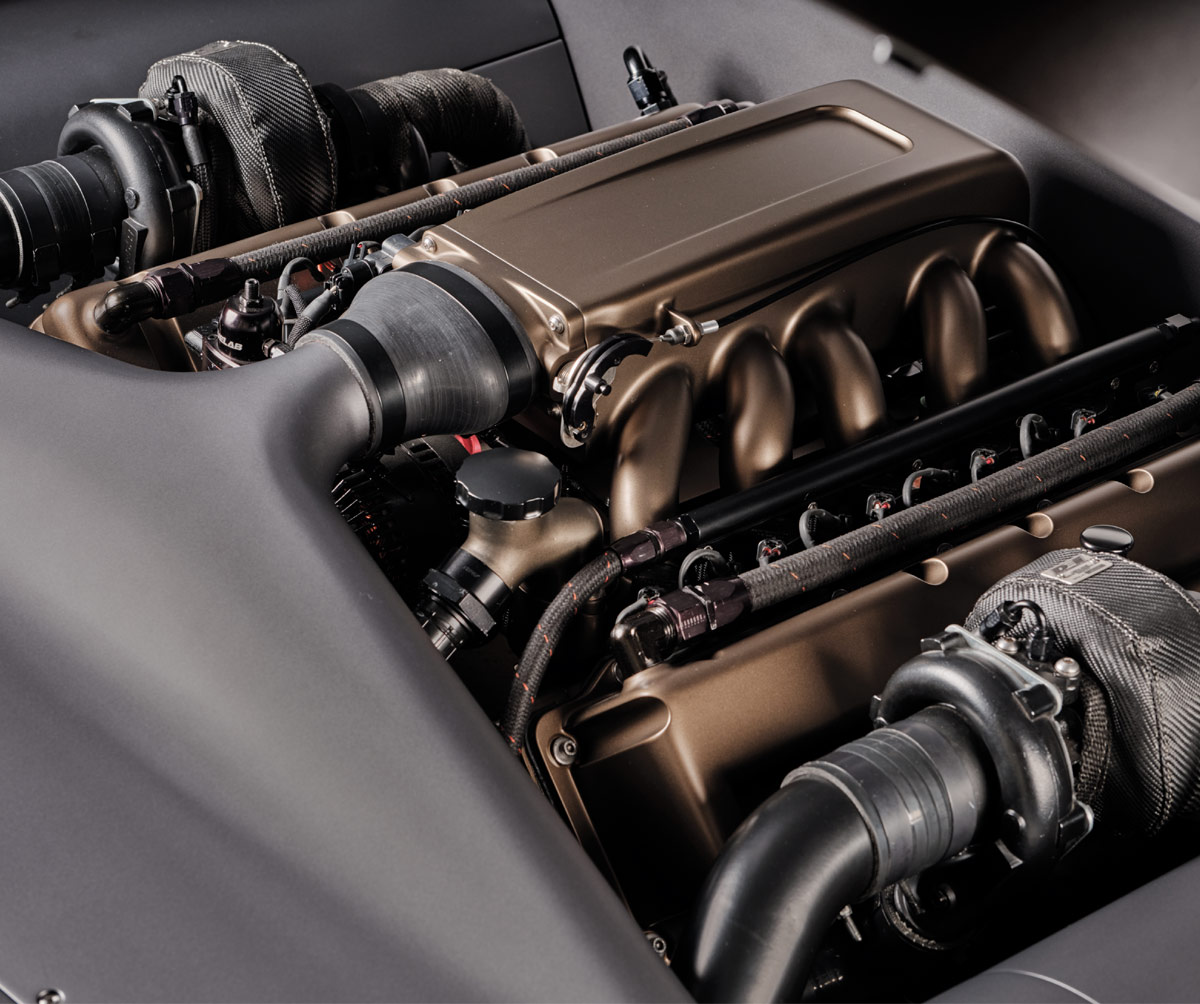

John had been interested in doing something different with the engine and was inspired from a local builder who had used Triton V-10s in his last couple projects and he thought it would be neat to use that same engine but build a twin-turbo version for his truck. John found a slightly used V-10 from a commercial work vehicle that was in a fire and purchased the engine from a salvage yard. John also purchased a Fatman Fabrications independent front suspension system and installed that kit, dropping the frontend of the truck down and improving the ride quality. His son, Jeff, helped by installing the new crossmember, which allowed room for the Triton V-10 powerplant. Jeff reworked the oil pan to get the lowest center of gravity for the engine in the chassis.

Next, John enlisted the help of Tin Man’s Garage’s Brian Limberg to fabricate a new firewall, floorboards, and trans tunnel to fit the new engine and transmission. John, Jeff, and Limberg hit it off immediately and the trio worked together closely as a team to build the truck. After the floor and firewall were completed the Tin Man’s Garage crew got to work finishing the rear suspension, setting up the truck’s stance, and figuring out the wheel and tire combination. A No-Limit four-link suspension was installed with a new fabricated 9-inch housing. A new sheetmetal bed floor was fabricated to go over the step notch in the floor. A custom tailgate was fabricated with a small wing that was inspired by OEM rear roof design from the back of the cab. The smooth one-piece tailgate was built with hidden hinges and the tailgate handle was moved to the inside. A new roll pan was fabricated with a frenched license plate. The license plate was formed to match the radius of the lower part of the tailgate. This kept the license plate from hanging down below the roll pan. The taillight housings were removed and straightened. A hammerform was made to better fit the original taillight housings. These newly formed sheetmetal pieces were blended into the original taillight housing sheetmetal/bed corners. A custom aluminum flush-mounted bed cover was fabricated to allow room for storage in the bed. The tonneau cover was eventually wrapped in black hearts cloth for a more elegant look.

The interior was treated to the typical smoothing and cleaning up of everything in the dash. A custom gauge cluster was machined and fabricated and then welded into the dash to fit recessed custom Classic Instruments gauges. The interior was painted a satin color-matched Maserati Rame, which was color-matched to the luxurious Italian leather and suede that was used throughout the interior by Schober’s Custom Hot Rod Interiors. A little splash of fun on the headliner and behind the reworked original bench seat was utilized with some gray toned plaid fabrics with maroon accents.

The wiring and all the electronics were engineered to mount behind the bench seat, mounting the two 6V batteries, Haltek engine management, American Autowire fuse panel, ground distribution blocks, and relays. Some easily removable panels were fabricated to gain quick and easy access to the components for troubleshooting if needed down the road.

The bodywork and paint by Adam Krause/The Refinery on this Unibody pickup is over the top. The body panels have been worked over thoroughly together as a whole to get the truck straight. The goal was to make the truck’s body appear as if it were cut out of one piece of granite stone and then polished. The deep metallic Mercedes Grau paint has been color sanded and buffed to perfection, making this truck look like a wet mirror.