Tech

Tech

IMAGES BY THE AUTHOR

IMAGES BY THE AUTHORhese days, when you talk about hybrids related to anything automotive, everybody assumes you’re talking about combining electric and gasoline motors. But if you go a little old school, “hybrid” has a totally different meaning. And that’s what we’re doing.

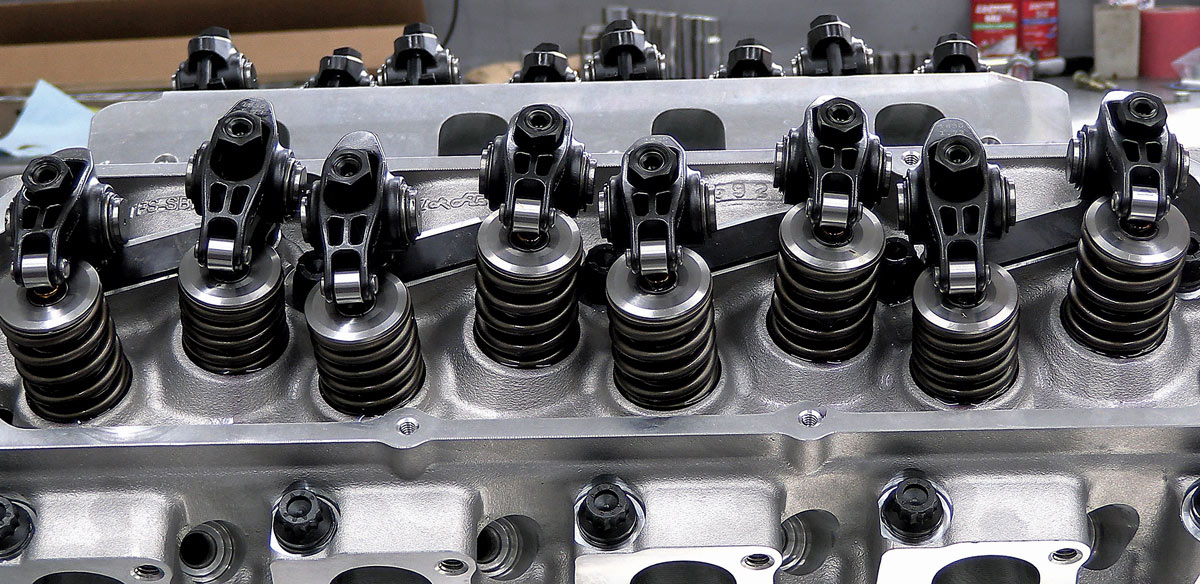

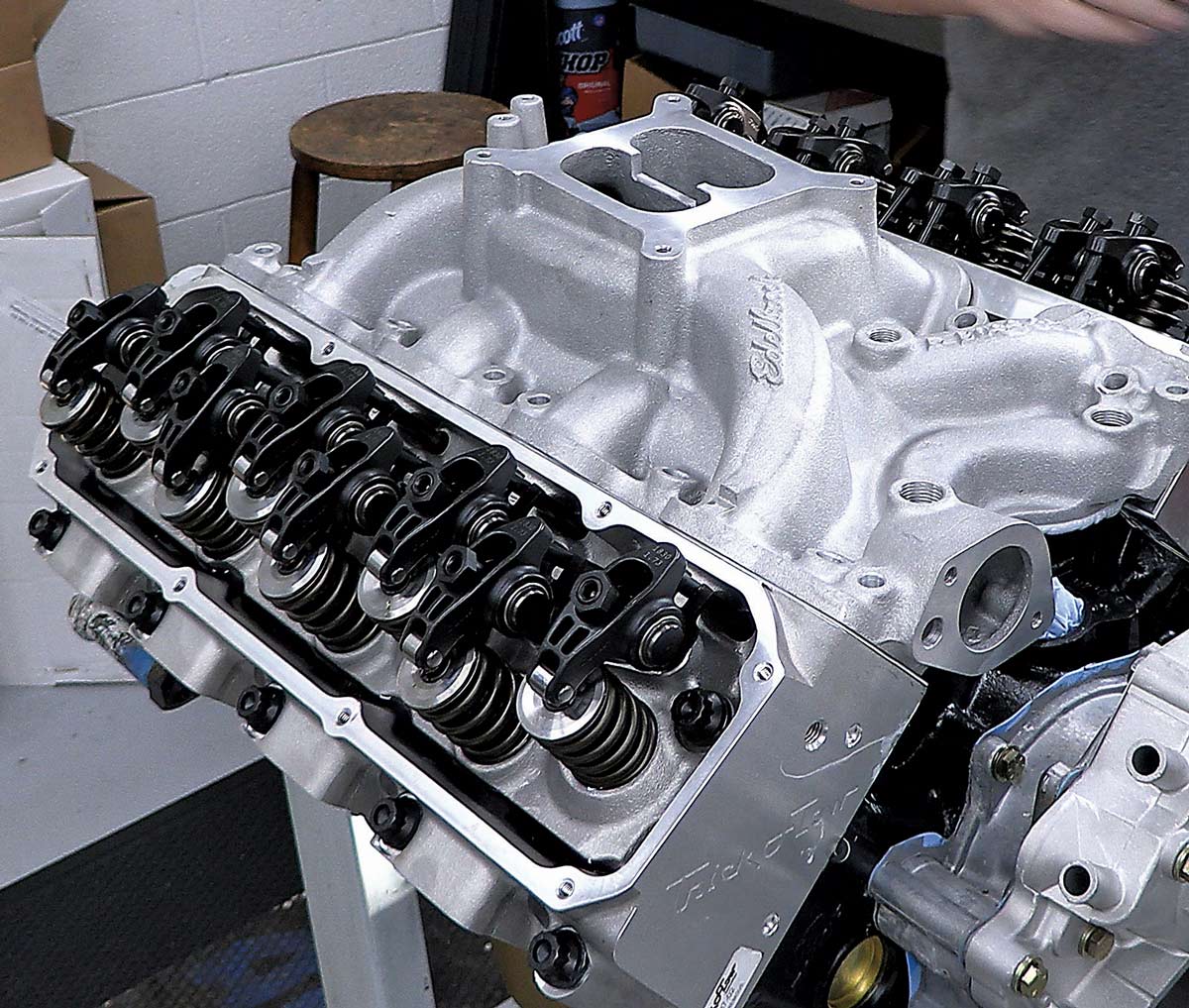

We’re building a Frankenstein hybrid, taking the best components from two engines that weren’t originally designed to work together and combining them into one big-inch beast. The combo is Ford Cleveland cylinder heads, intake, and some other pieces combined with a Ford Windsor bottom end (block, crank, pistons, camshaft). Appropriately, the name for this hybrid takes the name of the two engines (Cleveland and Windsor) and mushes them together to come up with “Clevor.”

The benefit of building a Clevor is to get the best of both worlds when it comes to the Windsor and Cleveland engine designs. By far the most famous iteration of the Cleveland/Windsor combo came from FoMoCo itself when they put Cleveland heads on a smaller 302 block to come up with the high-revving Boss 302, which made waves in Trans Am racing back in the day.

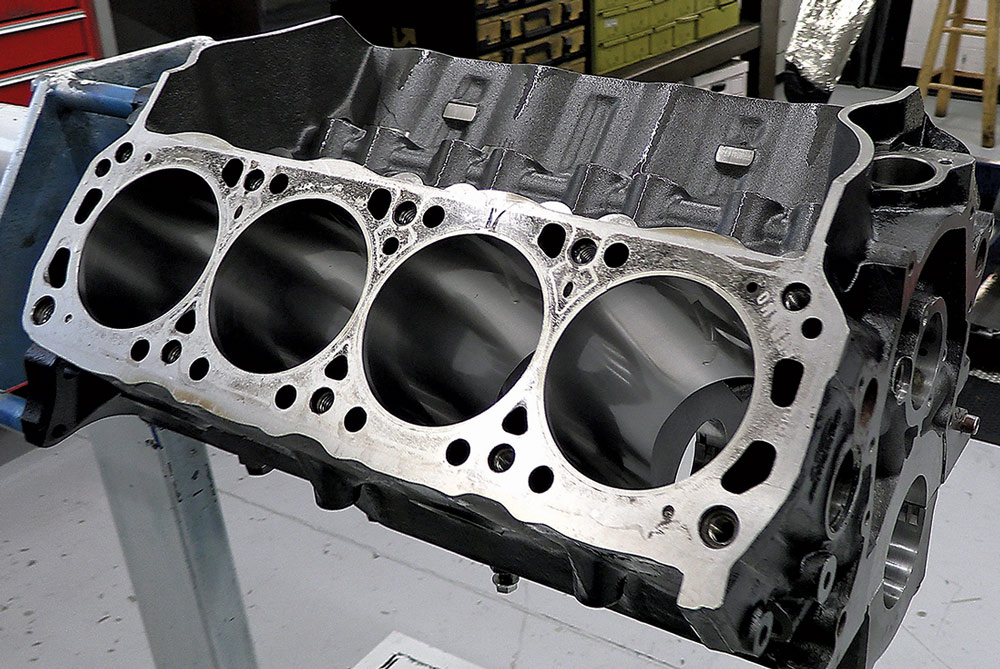

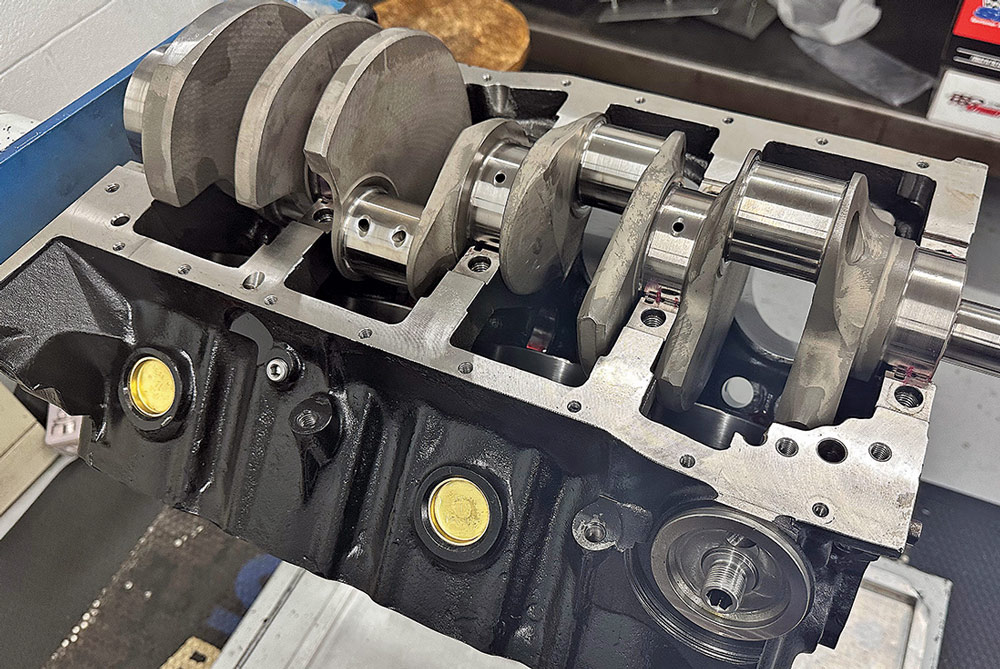

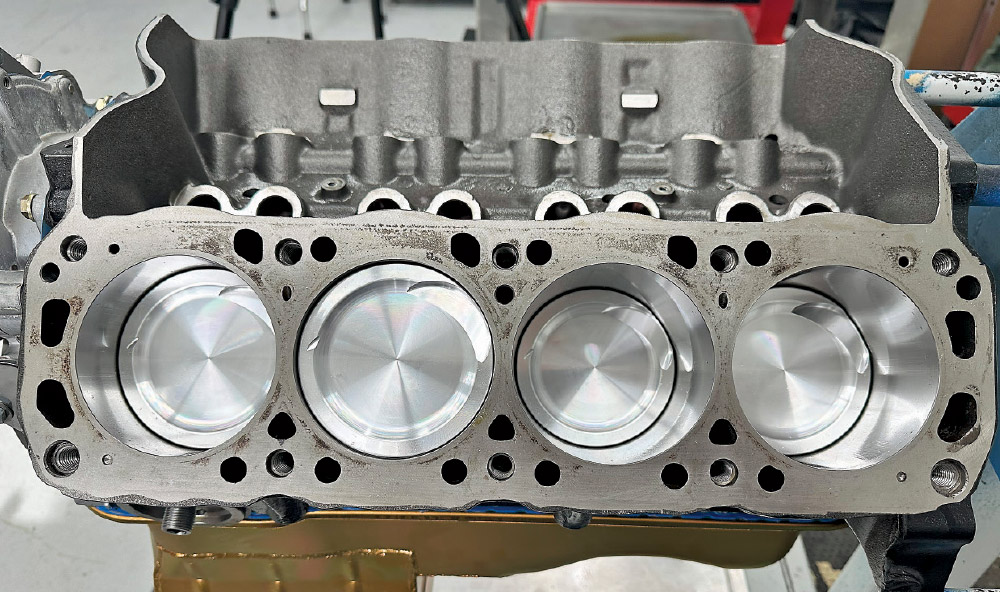

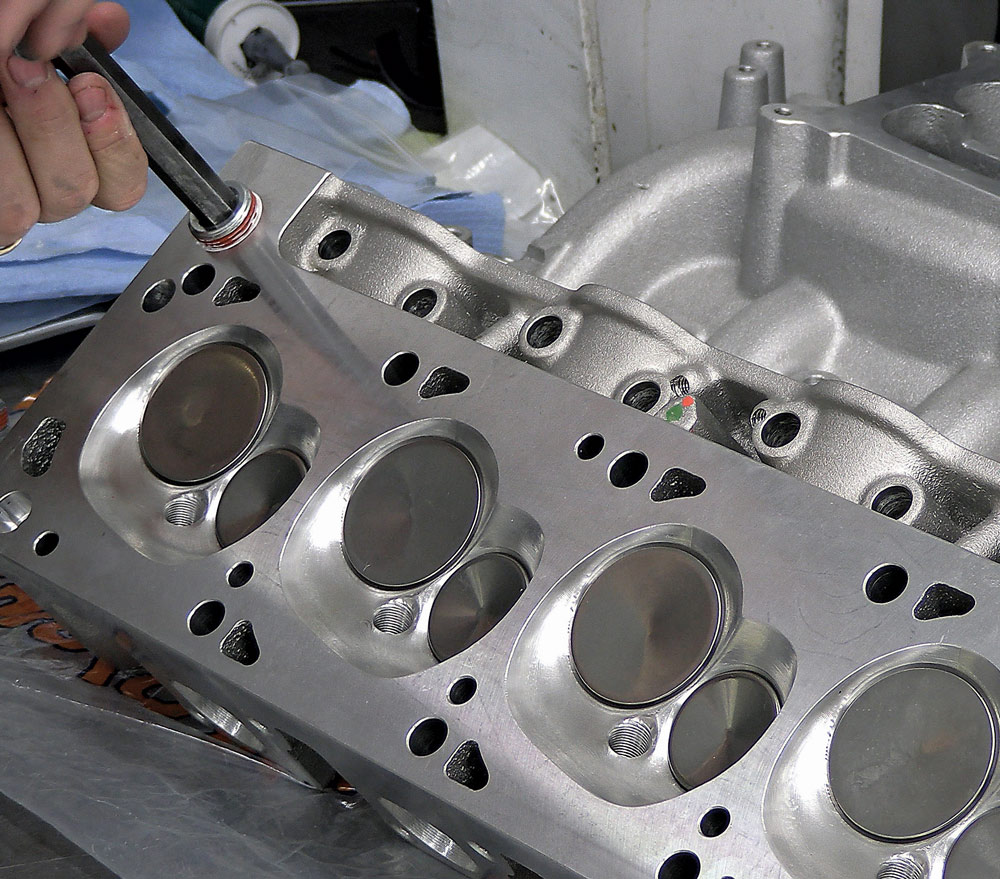

We, however, want big inches and even bigger torque, so we’ll be working with a bigger 351 Windsor block and then throwing in even more stroke. The Windsor block architecture has many advantages over its Cleveland cousin. Namely, it’s lighter thanks to an aluminum timing cover, has better oiling with a dedicated oil gallery, prioritizing oil to the main journals, and has tremendous aftermarket support. The Cleveland, meanwhile, has a cylinder head designed with a canted-valve arrangement. This means the intake and exhaust valves are angled just a bit in toward each other so when they open they open away from the cylinder wall for better breathing than a wedge-style valve arrangement like you will find in Windsor heads. But Ford didn’t produce the Cleveland for nearly as long or in the same numbers as the Windsor, so not only are good original components hard to find these days, the engine also doesn’t enjoy the same level of aftermarket support.

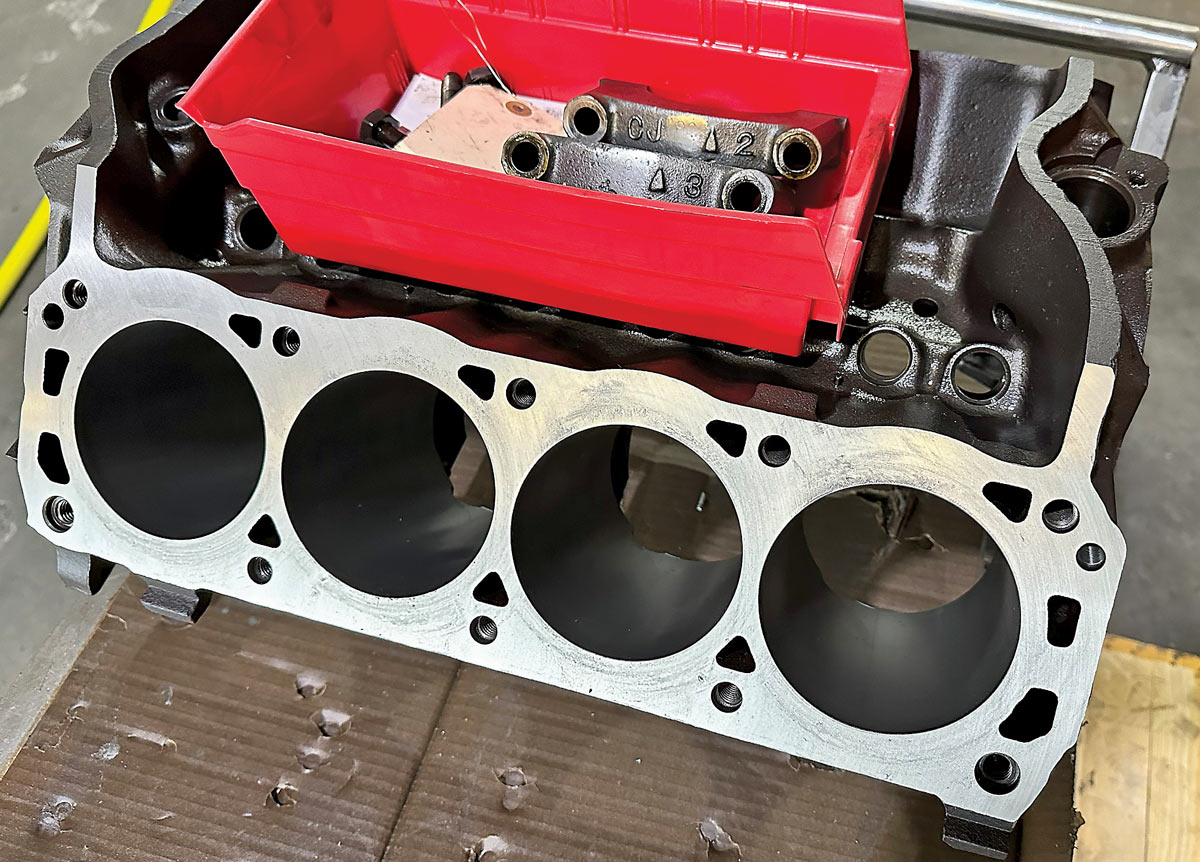

Fortunately, both the Cleveland and Windsor design share several key measurements that make putting Cleveland heads on a Windsor block possible. They share the same 4.380-inch bore spacing and head bolt pattern, so bolting a Cleveland head to a Windsor block isn’t an issue at all. What’s more, they even share the same valve arrangement and firing order, so you can even use a stock Windsor camshaft.

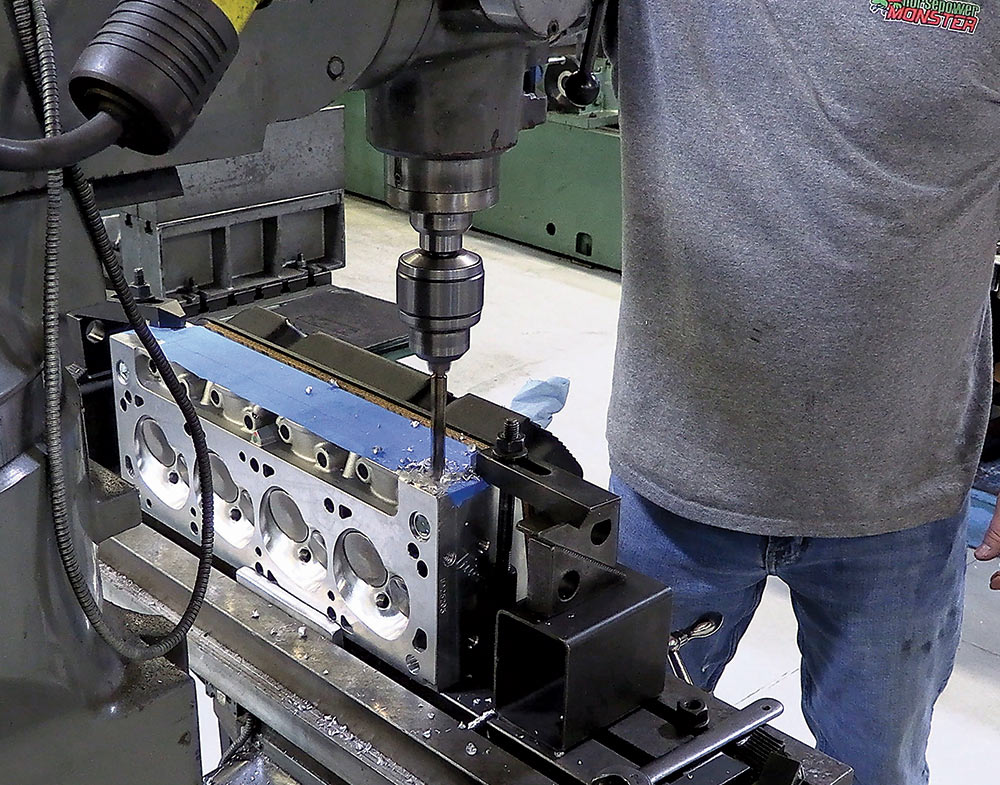

The main problem comes from the fact that they have very different cooling systems. The Cleveland exits hot coolant out of the block and the intake manifold is dry, but on the Windsor coolant flows through the block up into the cylinder heads and then through a coolant port in the base of the intake manifold before exiting. To make the Clevor cool properly, you usually must drill a few holes in both the block and the cylinder heads. But really, it’s not that difficult or intimidating. We’ll show you exactly what we did to make it work like a charm.

Since this is Classic Truck Performance, it would only be right for this engine to wind up in a righteously cool Ford pickup—and that’s exactly what is going to happen (eventually). We’re working with Chris Edge, an Army vet who is restoring his 1963 F-100 with his son. Edge drove the pickup while he was on active duty because it was the only thing he could afford. The previous owner had swapped out the original straight-six for a Cleveland and painted it bright yellow.

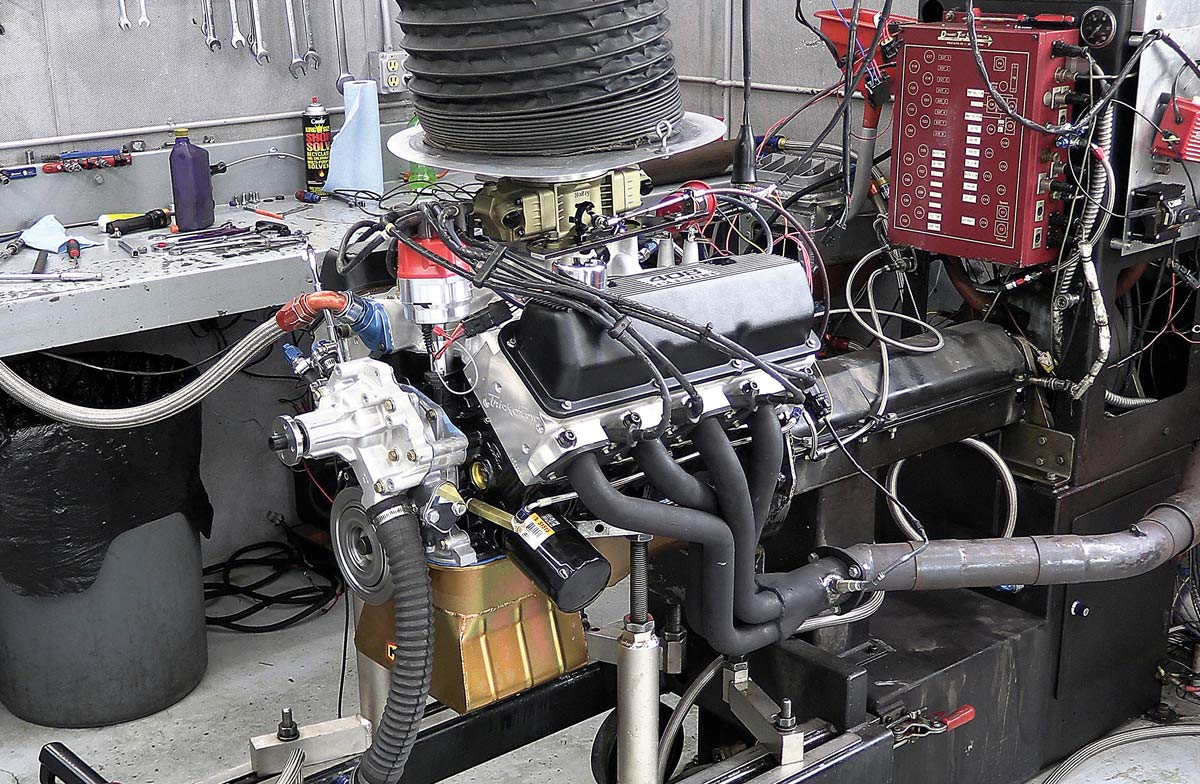

Edge painted the truck a much cooler shade of blue himself in his own shop and is slowly bringing it back into fighting shape. We offered to help out with the old Cleveland, but after teardown it was obvious the cylinders had already been bored to their limits. We already had a Ford Windsor block just sitting in the shop that had been used for an earlier build project but had never been run except for the dyno. So we grabbed it up and that became our excuse to go totally overboard and build a big-inch Clevor.

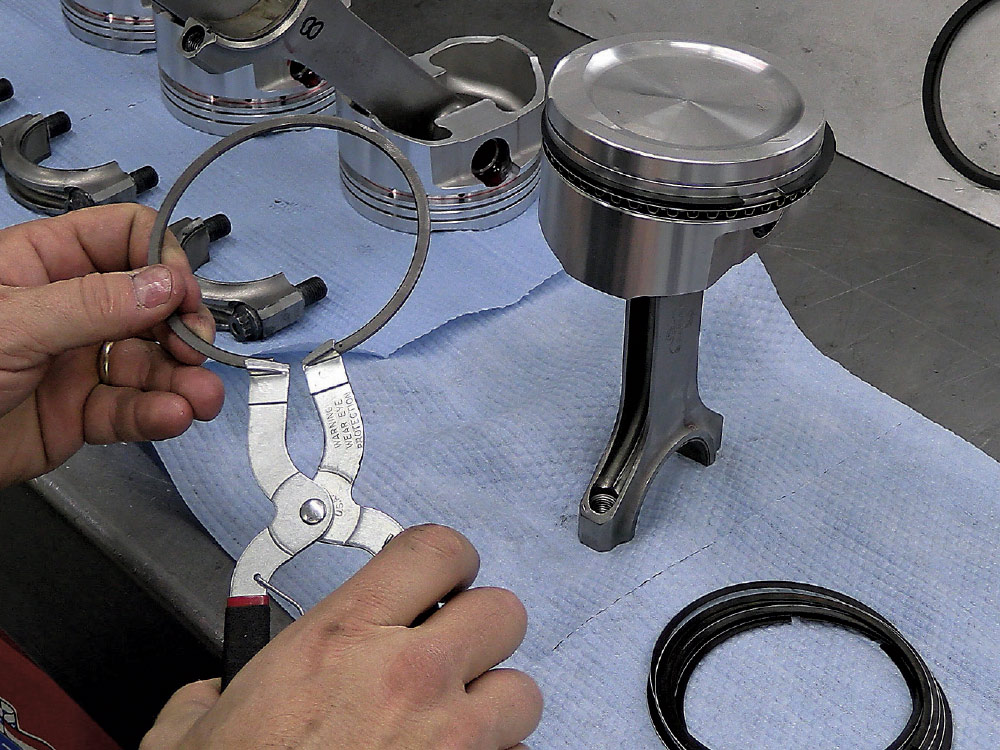

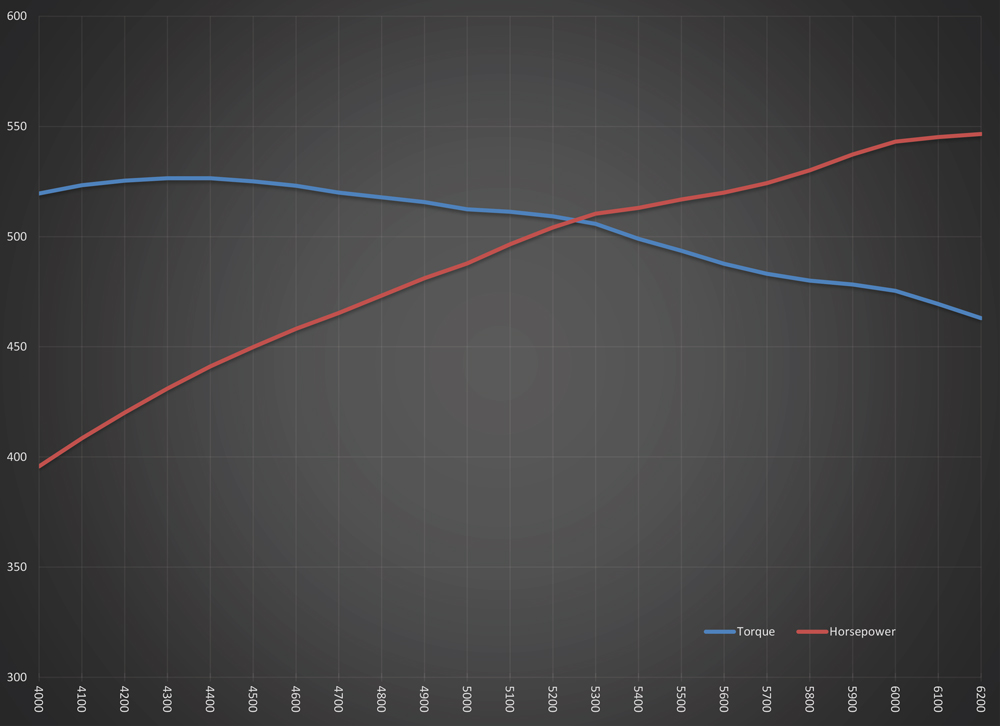

For you classic truck fans—especially when it comes to Fords—there are several reasons we’re bringing you this Clevor build. First, as we’ve already mentioned, the build combines the best of the Cleveland and Windsor engines. If you have a truck with either a 302 or 351 Windsor engine in it, this will bolt right up. Second, it’s unique and looks cool. Everyone is looking for something different, and a Clevor is definitely an engine combo that will help you stand out at the car shows. Or you can go with a smaller 302 block and build a 302 Boss replica. Our biggest goal with this build was to make tons of reliable torque on pump gas, so we went big and ended up with a 408ci stump puller.

Yes, there have been some incredibly fast classic trucks built—and we’ve covered many of them here in these pages—but most builds keep their classic truck heritage. American iron deserves tire-shredding torque and that’s exactly what we’re doing with this build!

SOURCES

SOURCES