Tech

TechInTheGarageMedia.com

IMAGES BY THE AUTHOR

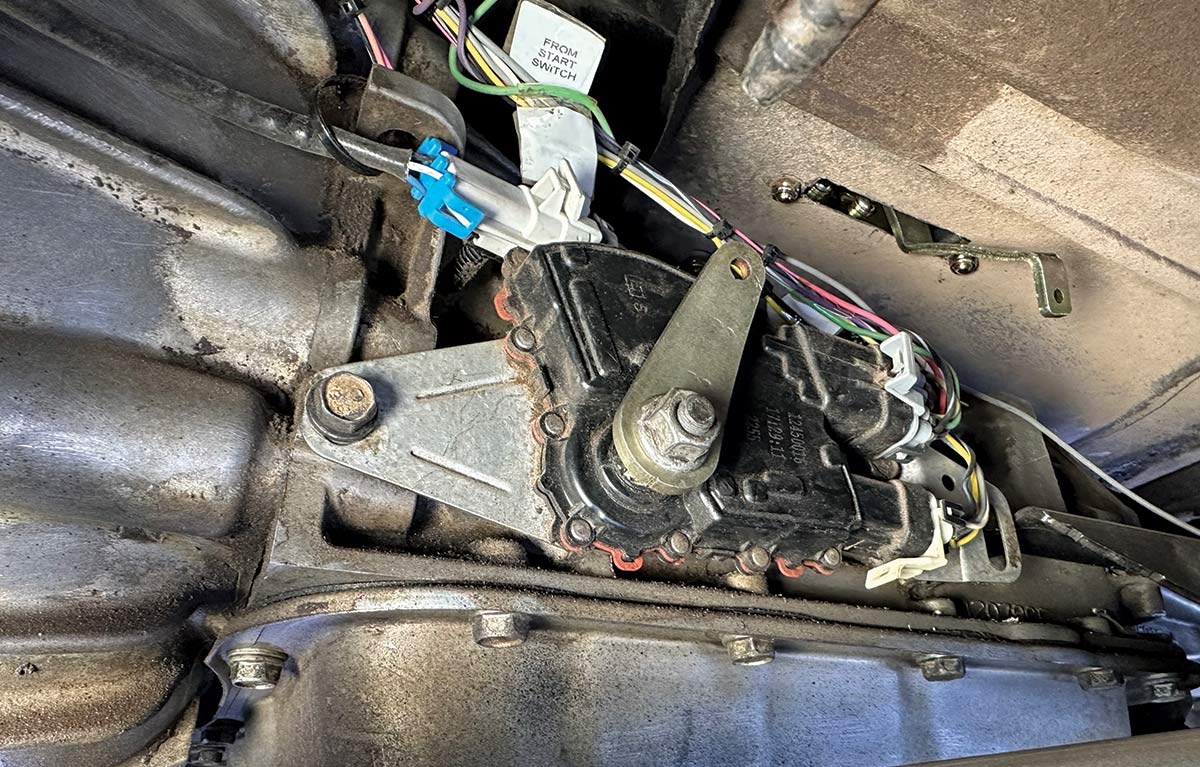

IMAGES BY THE AUTHORfter upgrading our 1971 Chevy Suburban with an electronic four-speed automatic transmission we’ve never been happy with the column shift linkage. The original three-speed detents were already a bit worn down, then things really got off-kilt when controlling the extra gear of the 4L60E. Couple that with a few creaks and rattles and it was finally time to address the issues at hand.

As fans of floor shifters, we started looking for a prospective shifter that had the taste of an original four-speed stick shift and would still fit well with a bench seat. The answer came up while surfing through Lokar.com where you can basically build a shifter through a click of options.

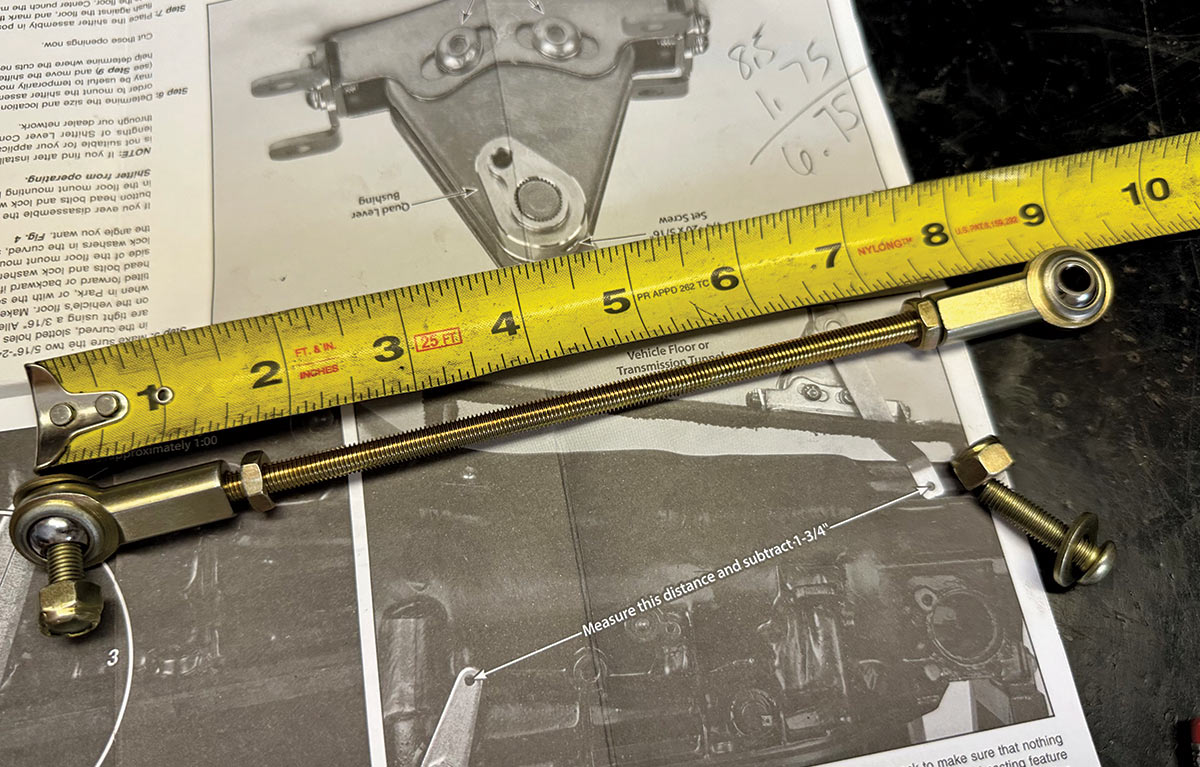

The simple procedure starts with selecting the mount of the shifter; a case mount, tail mount, or a floor mount model and if the shifter will have shift linkage, a cable, gated, or an electronic mode. Obviously, you need to know what trans you’re using but Lokar can help identify the trans pan if needed. Next will be selecting a shift lever, its length, and finish, followed by a shift knob. There are plenty of options, but it’s an easy process to get through.

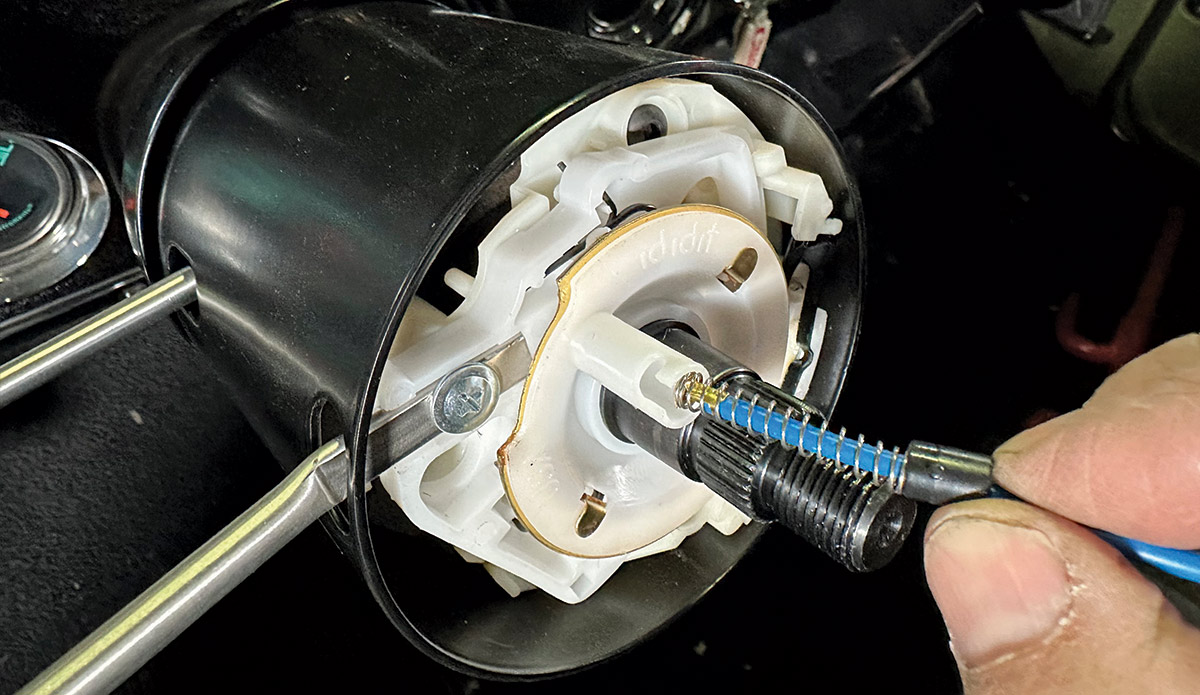

With a floor shifter coming soon, we opted to upgrade the original column to a smooth operating and comfortable tilt model from Ididit. They offer direct bolt-in columns for several classic trucks (and cars of course) that feature all new internals and wiring. For our three-door Sub, Ididit was able to recommend the right U-joints to use between the steering box and column shaft, plus the right size double-D shaft to get everything connected.

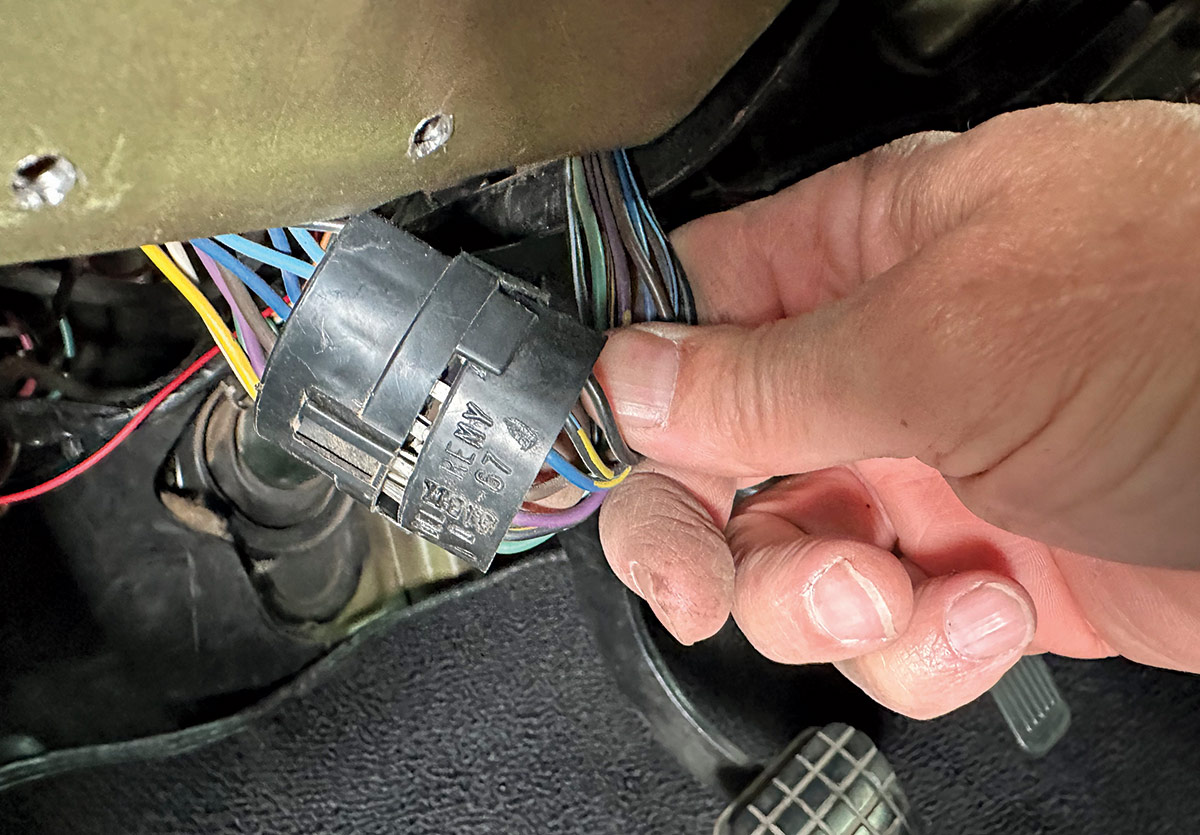

We had already planned on updating the steering wheel from the large-diameter factory wheel to a 15-inch muscle car wheel, which will now be a bolt-on affair with the new column. As for turn signal, horn, and flasher wiring, Ididit supplied a connector that plugged into the factory harness right to their column connector.

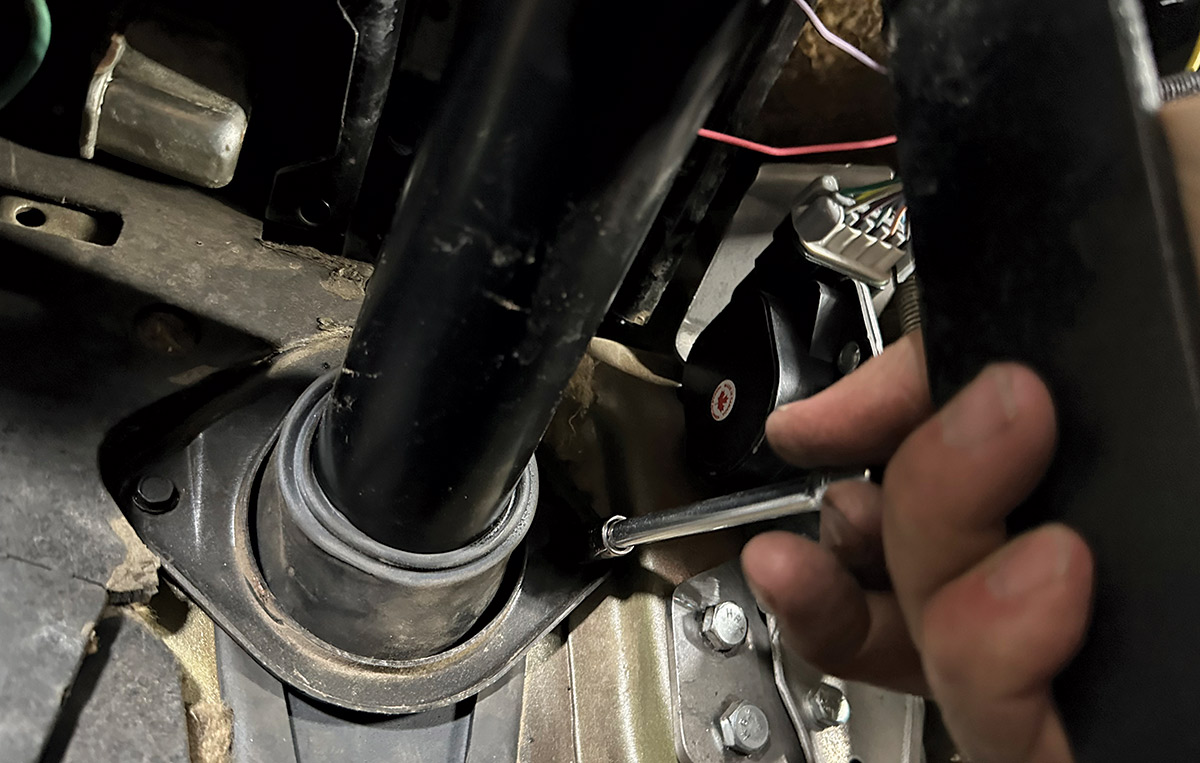

The Ididit column bolts right in under the dash and you’ll need to do some more careful measuring and pay attention while installing the new U-joints to the shafts for proper engagement. Ididit has done their homework to guide you through the installation process from start to finish so you can complete the job safely and correctly—as we achieved and detail on the following pages.

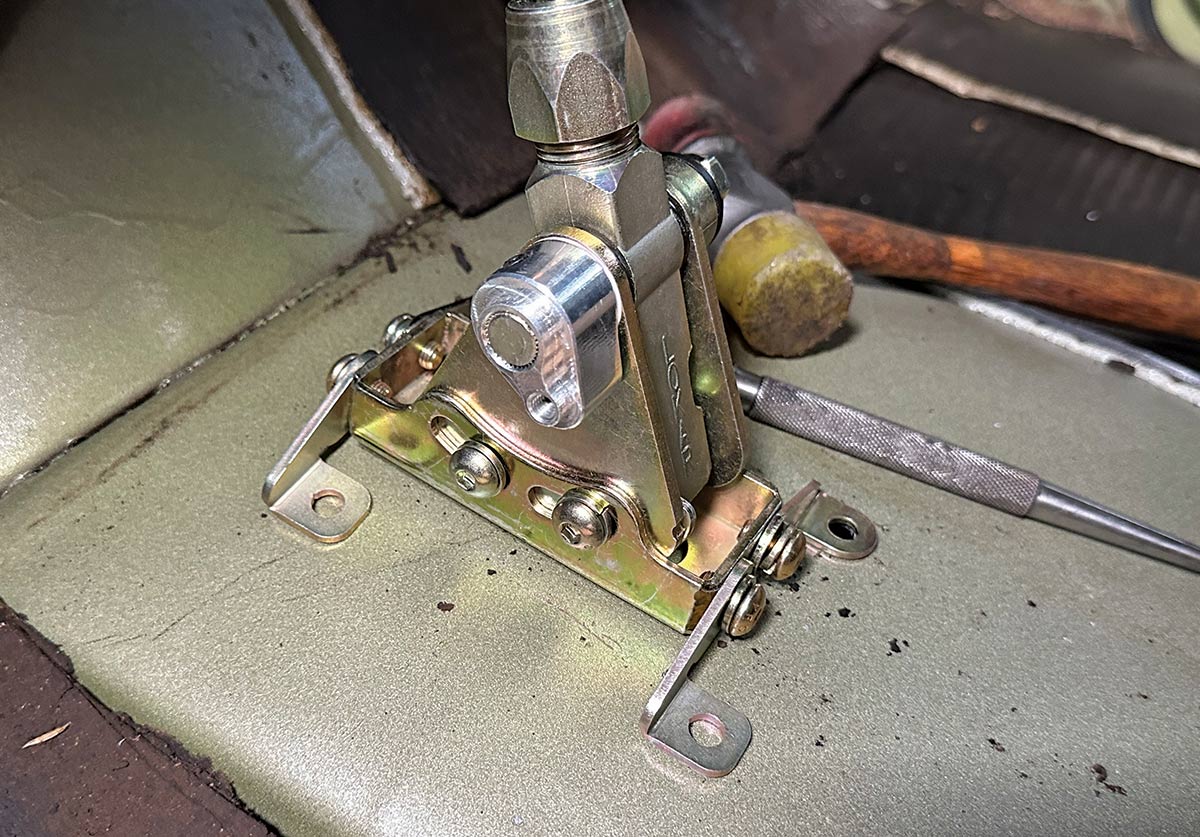

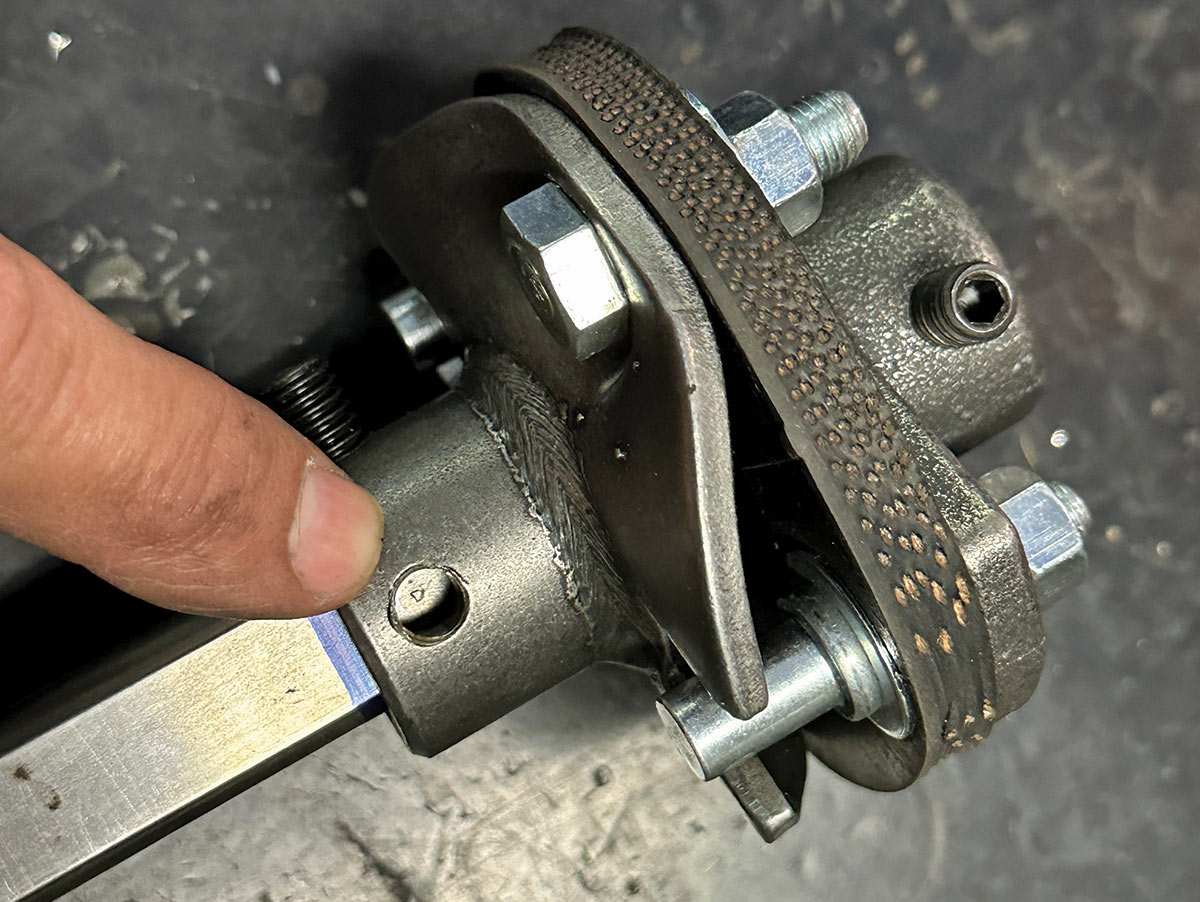

The Lokar shifter installation process requires removing the carpet to mount the shifter, a bit of measuring and assembly for the linkage, and a couple wires to route through the neutral safety switch; nothing that can’t be handled with hand tools and also following instructions closely.

In the end, it is so nice to finally have a firm gear selector position, perfect for pulling the shifter down into First for a quick 1-2 out of the driveway. The steering is quiet, concise, and we’re even surprised at how nice it is to have eight tilt positions to choose. There were two great upgrades that most enthusiasts can handle and that really makes a difference in the driving experience!

SOURCES

SOURCES