Tech

Tech

Photography by THE AUTHOR

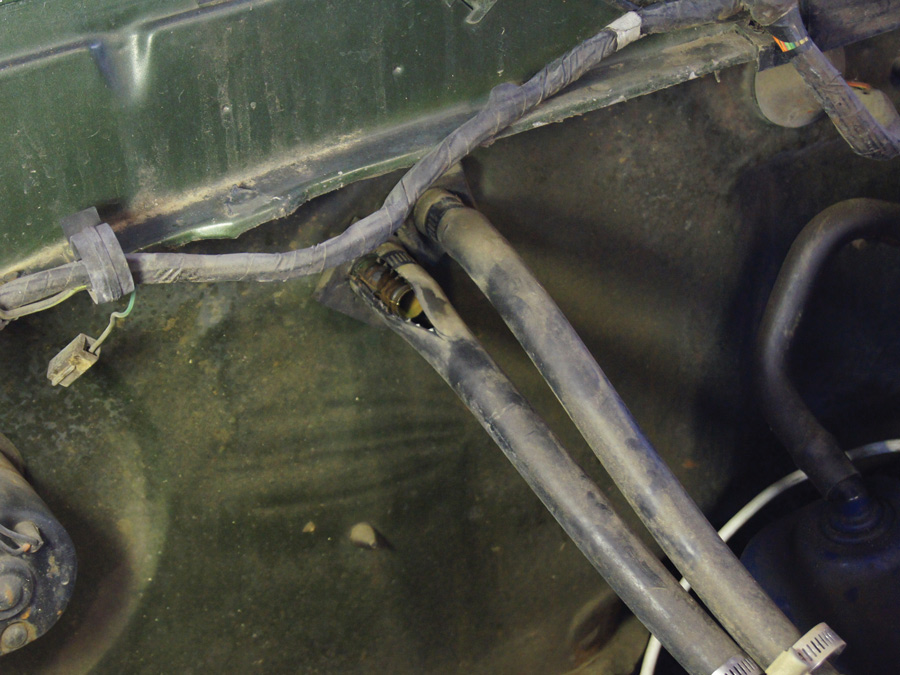

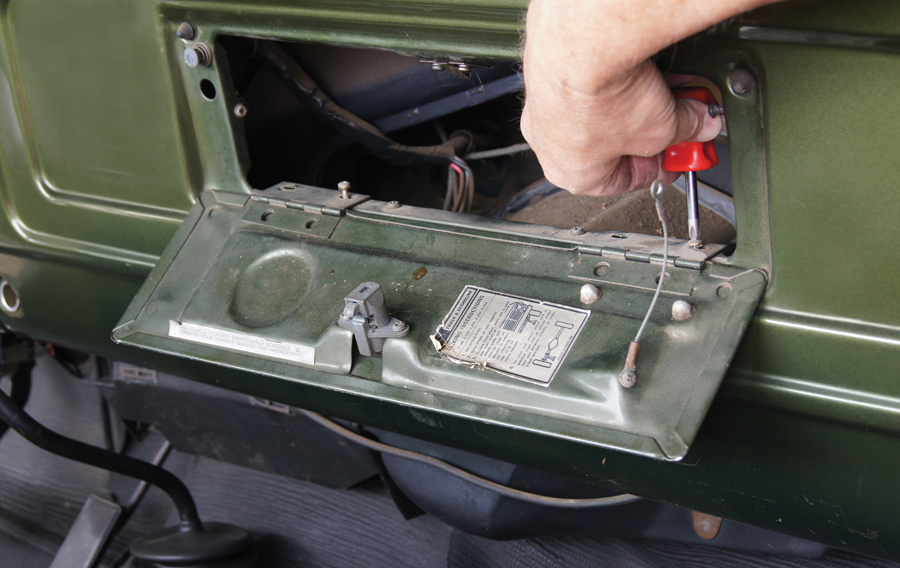

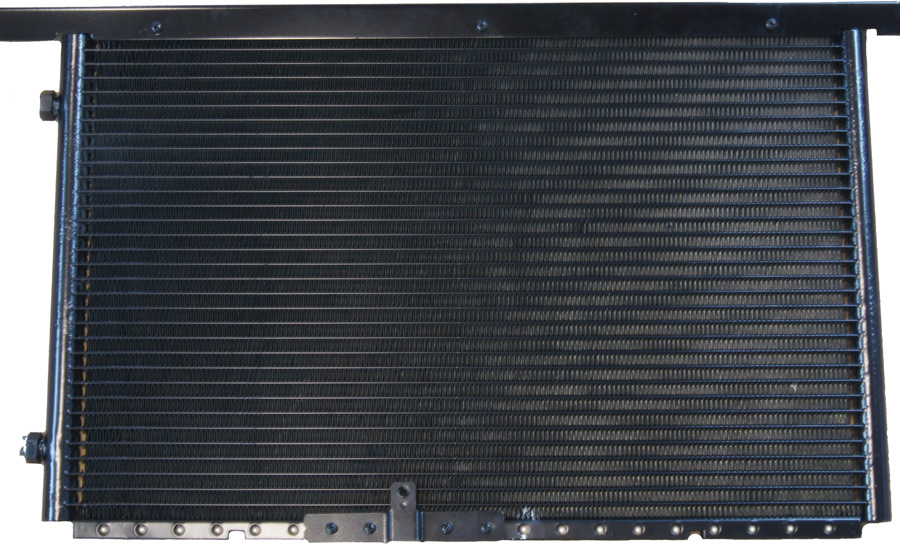

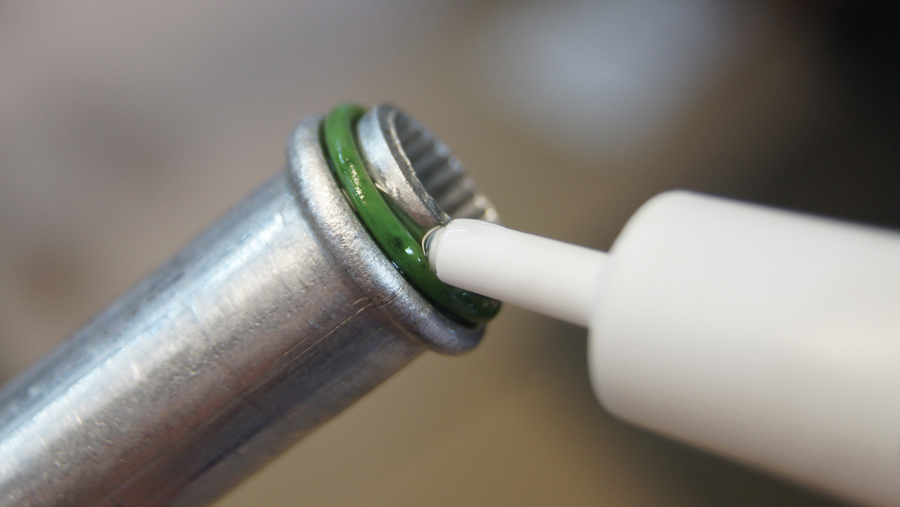

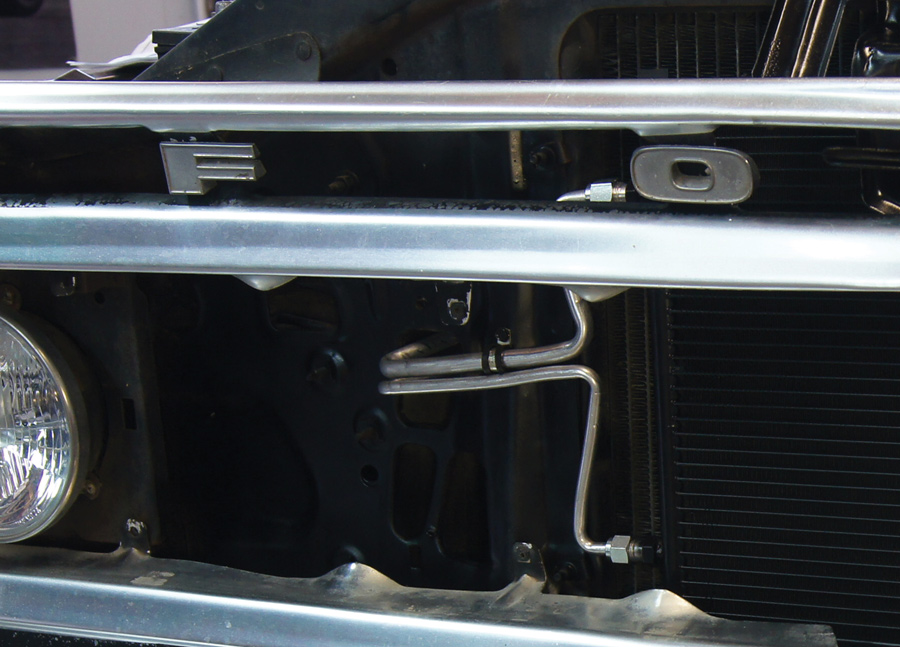

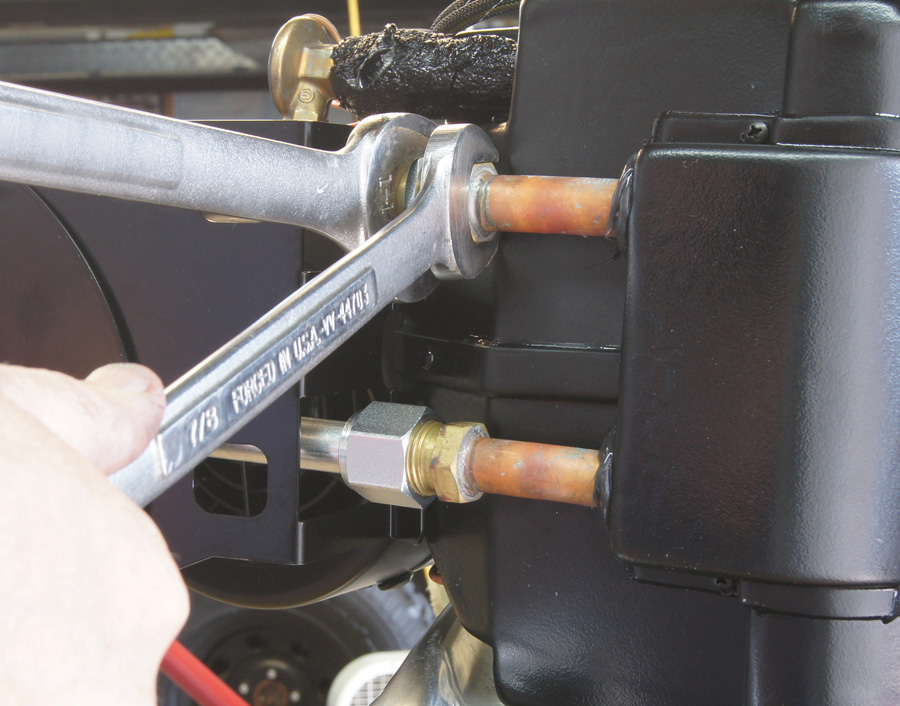

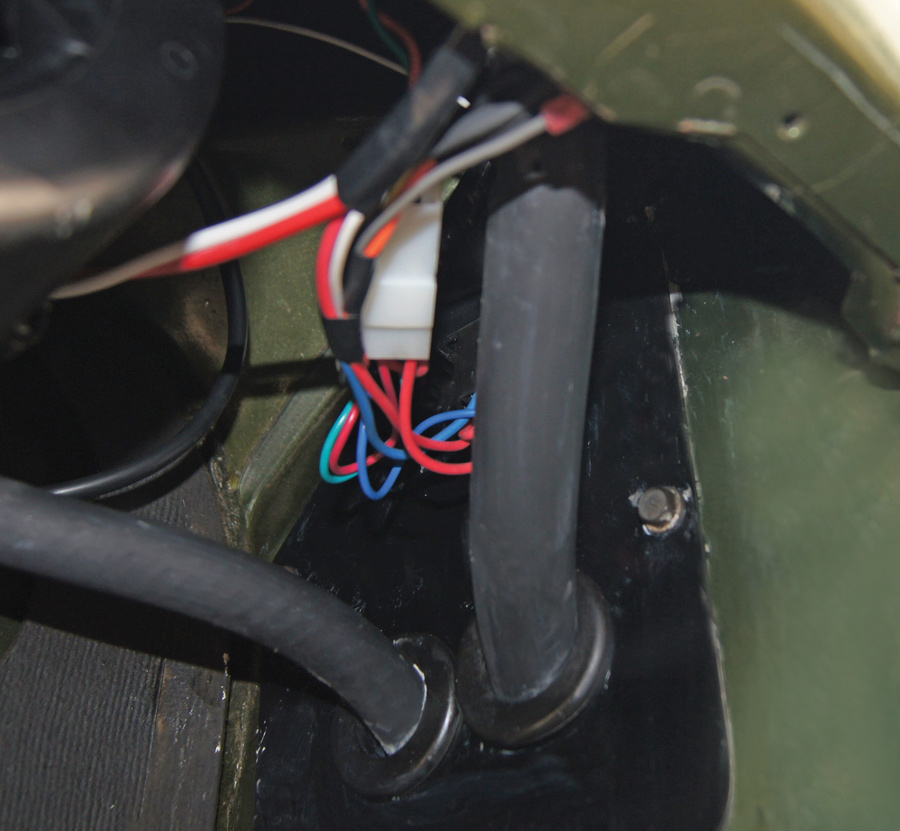

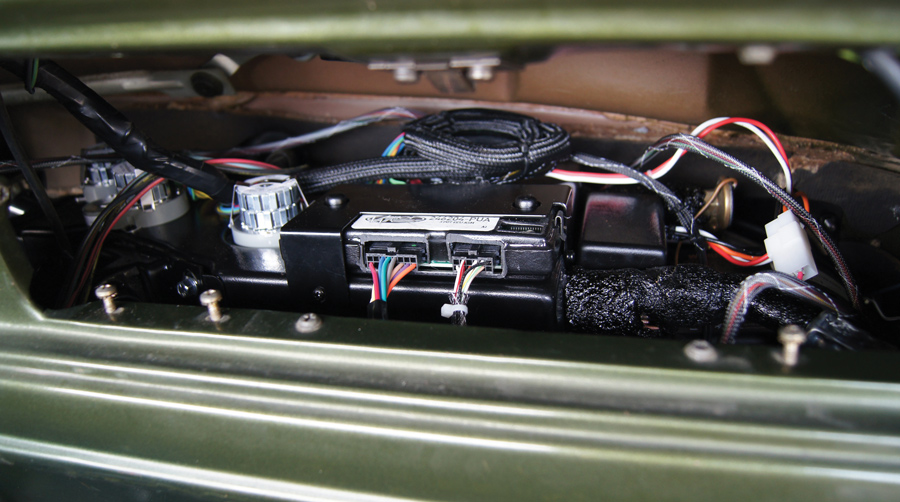

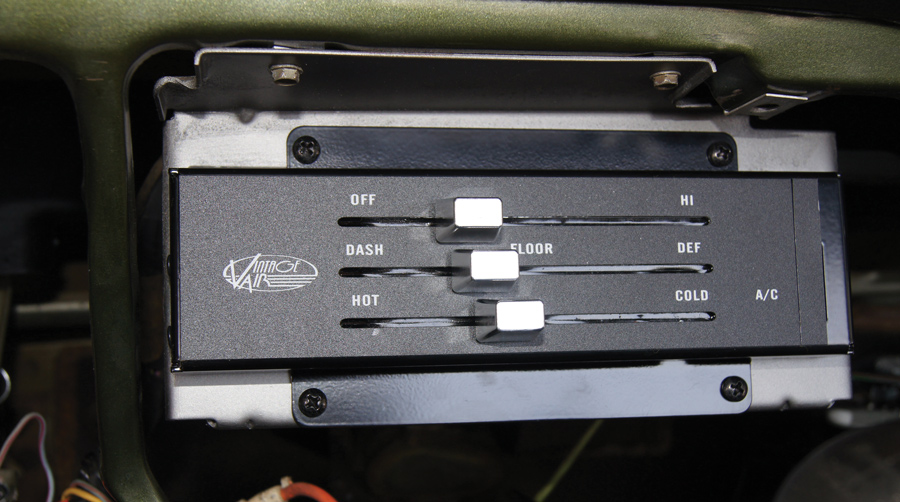

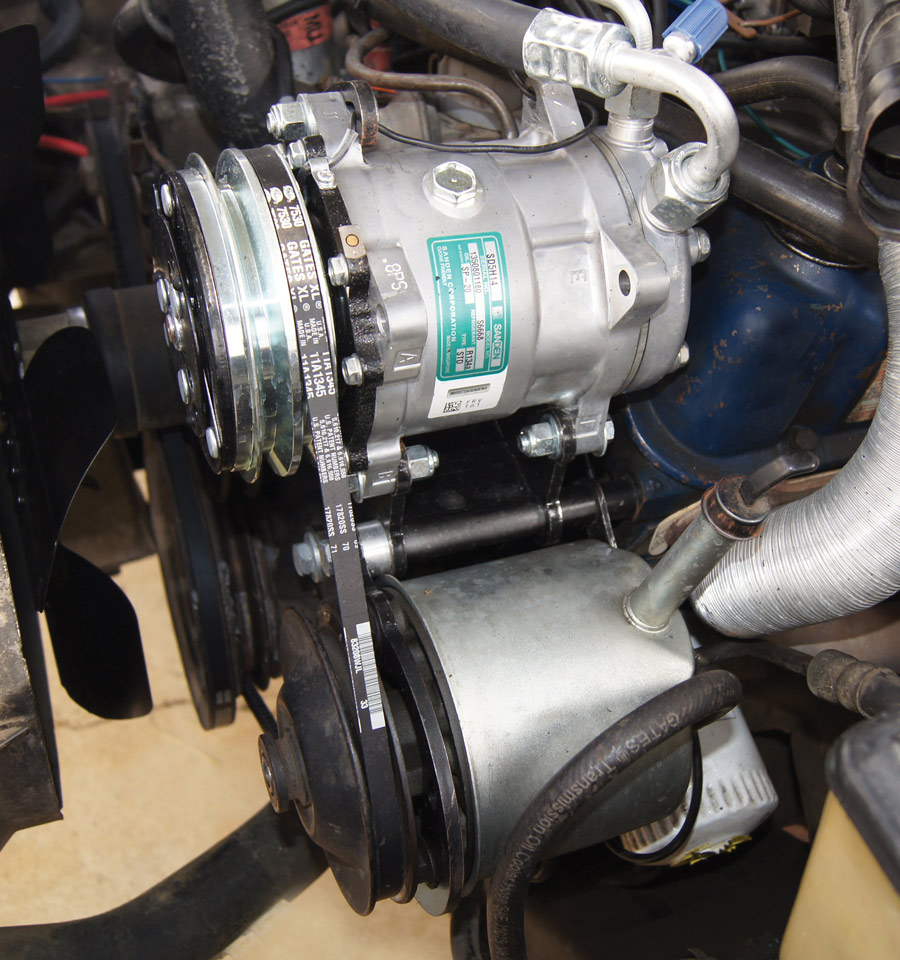

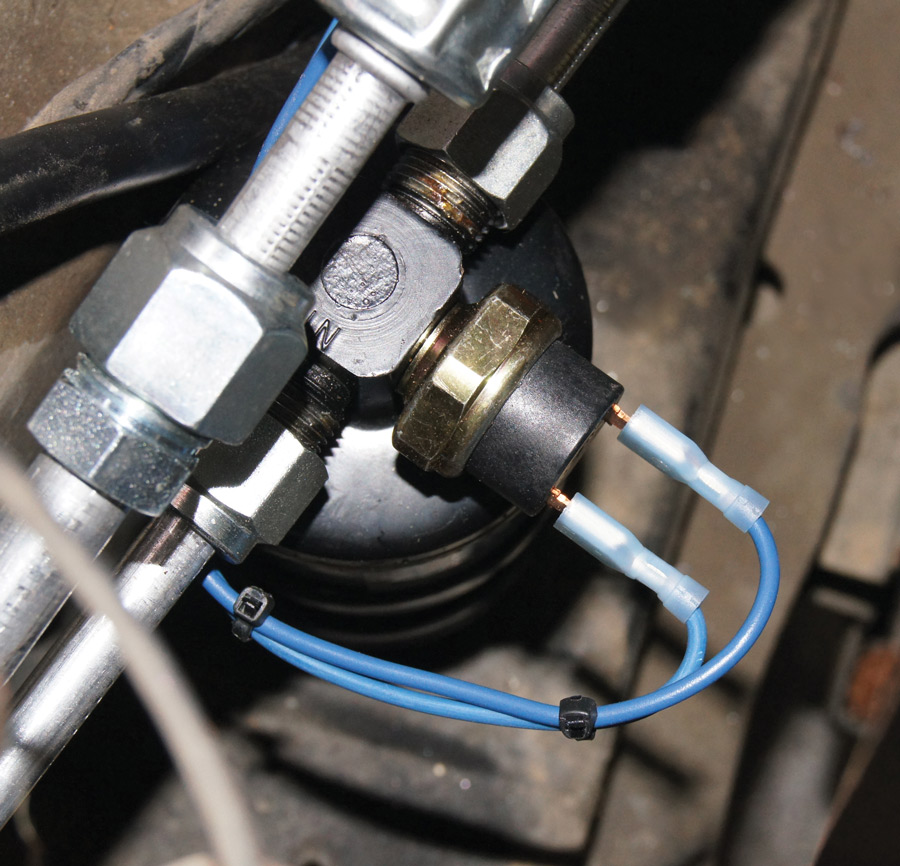

Photography by THE AUTHORrecently picked up a 1976 Ford F-100 Flareside project. It’s a somewhat unusual truck, built and sold in California. It has a 302 (where it seems most of these trucks have 360/390 FE motors or the big 460), a T-18 manual trans (affectionately called the Granny Low 4 Speed), power steering and power disc brakes but no A/C, and idiot lights in place of gauges. It was kind of a spur-of-the-moment deal, and I wasn’t sure what I was going to do with it, but I knew I “needed” it. I also knew, no matter which way I went with the project, it needed A/C and some real gauges. The dash bezel and pad were also in need of some help.

The entire transformation took us about three days in the shop, including stopping to take pictures as we went. None of the installation took any specialty tools (aside from a power steering pulley puller, which most parts stores will loan out) and the instructions for both the A/C and gauges were thorough and easy to follow. Now that we’re riding in style it’s time to decide what to do with the outside of the project.