Tech

Tech

Overdrive?

Photography BY The Author

Photography BY The Authorrecall, many years ago, when Bluetooth first came out. At the time, it really had no relevance in my life. But just as computers themselves were maybe 10 years prior, little did I know that before long they both would practically rule my life!

Had you told me back then that one day that newfangled Bluetooth technology would have the ability to tune/control my transmission, I’d have laughed as hard as I did the day my graphic arts instructor told me that if I wasn’t computer-literate by Y2K I’d be hard-pressed to find a job!

Ironically, it was around that time (early ’90s) that GM introduced the 4L60E transmission. Essentially, the 4L60E is a grown-up 700-R4, with the adult aspects being the absence of a governor, standard valvebody, and those temperamental TV cables—all dictating the use of a computer in which to control the transmission itself. However, for the better part of the ’90s on through the ’00s, the 700-R4 ruled the classic truck market when it came to overdrive swaps. I’ve had my fair share of 700s, in the earlier years of my career (when companies were still trying to figure out the TV/carb linkage deal) to more recently (when practically everyone had the TV cable figured out), and can say that in the right vehicles they’re hard to beat. But, save for my late-model daily drivers, I’d yet to experience the computer-controlled joys of an electronic overdrive … till now.

Ironically, again, my very first OD trans was the smaller version of the 700, the lighter-weight 200-4R, which was supplied by my old friend Greg Ducato from Phoenix Transmission Products. So, on top of the fact that they’ve been in the game since 1983, it just seemed natural that I go to Phoenix for my very first foray into the electronic overdrive world. I wanted to replace the Turbo 400 in my 1969 C10, but since I’m sticking with the 454 big-block and not going the LS swap route, I had concerns about the compatibility. Those concerns were quickly dismissed, as I was informed that not only does Phoenix offer a “non-LS” 4L60E, they offer a standalone TCU. As Ducato put it, “Naturally, hot rodders were drawn to this trans as a means to finally get a reliable overdrive to go behind high-output big-blocks … unfortunately, it took the aftermarket a few years to come up with a simple, easy-to-install, stand-alone computer system that could be fitted to older, non-computer-controlled vehicles.”

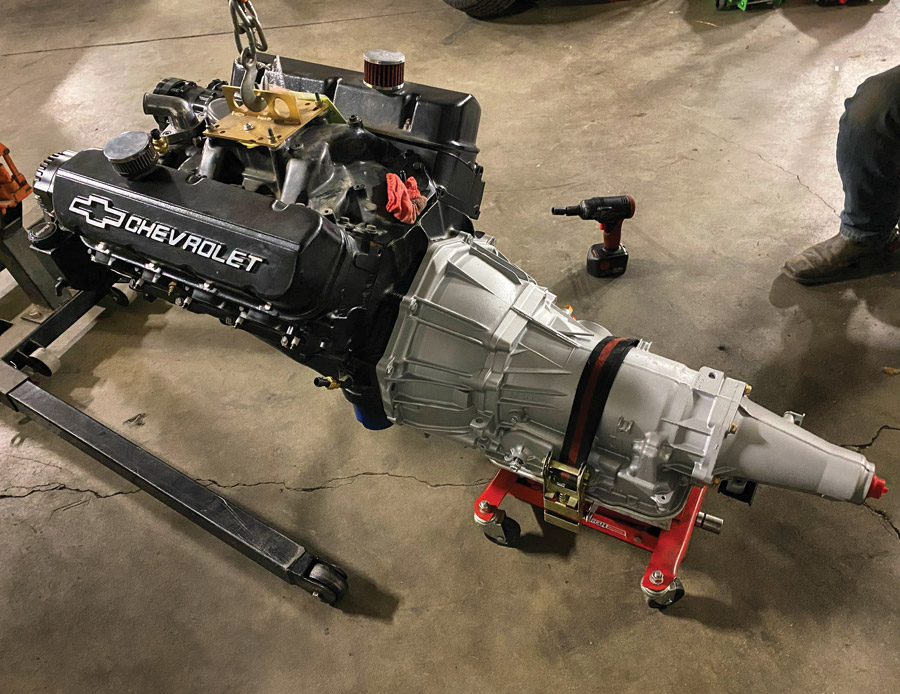

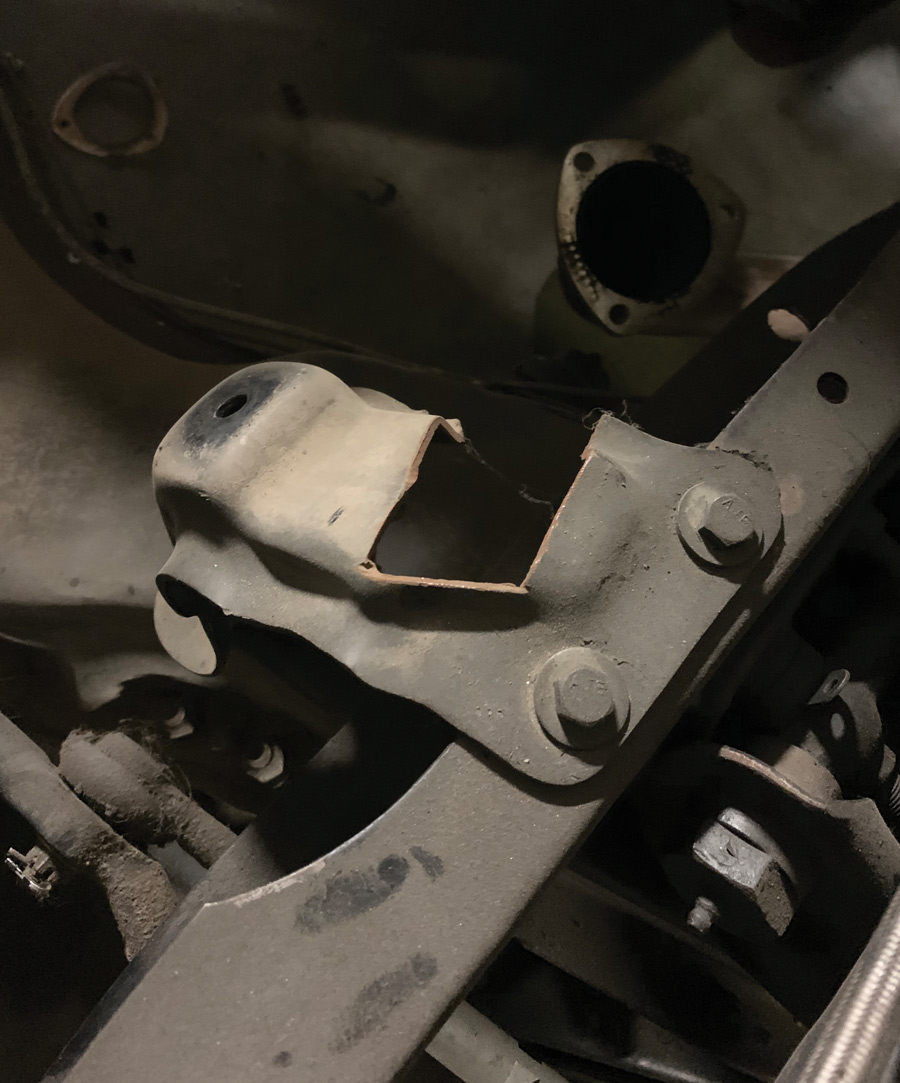

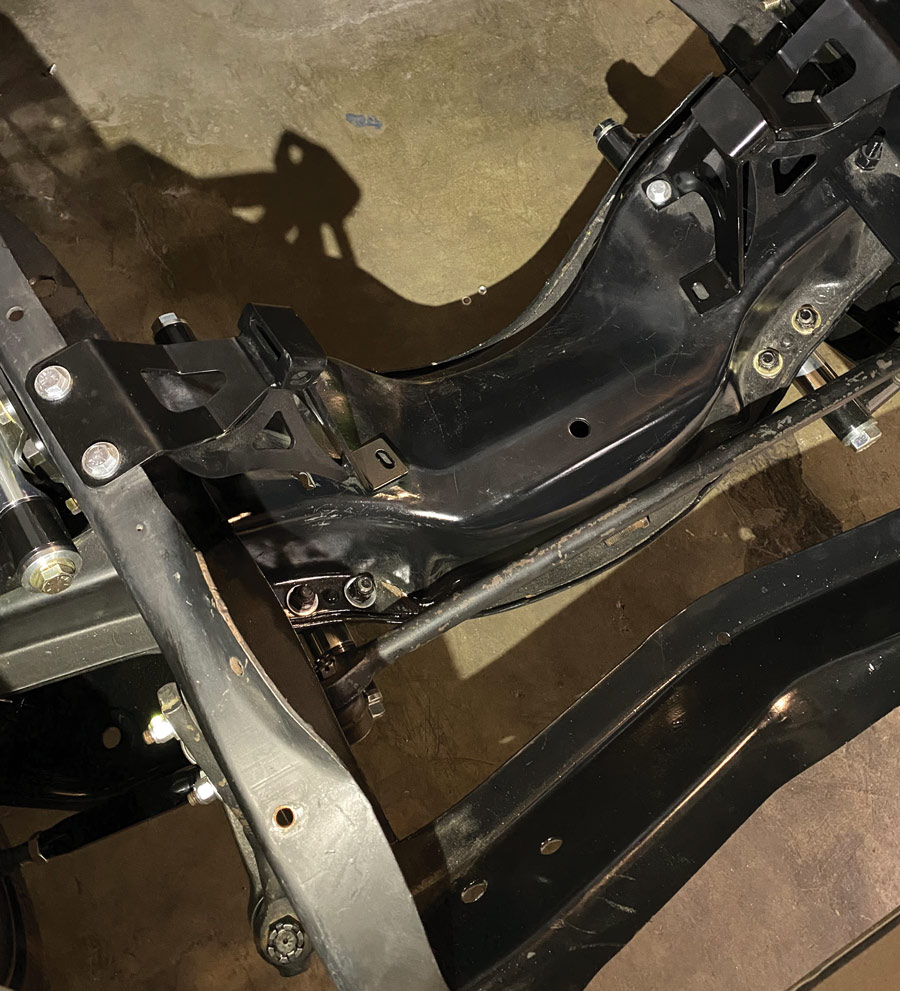

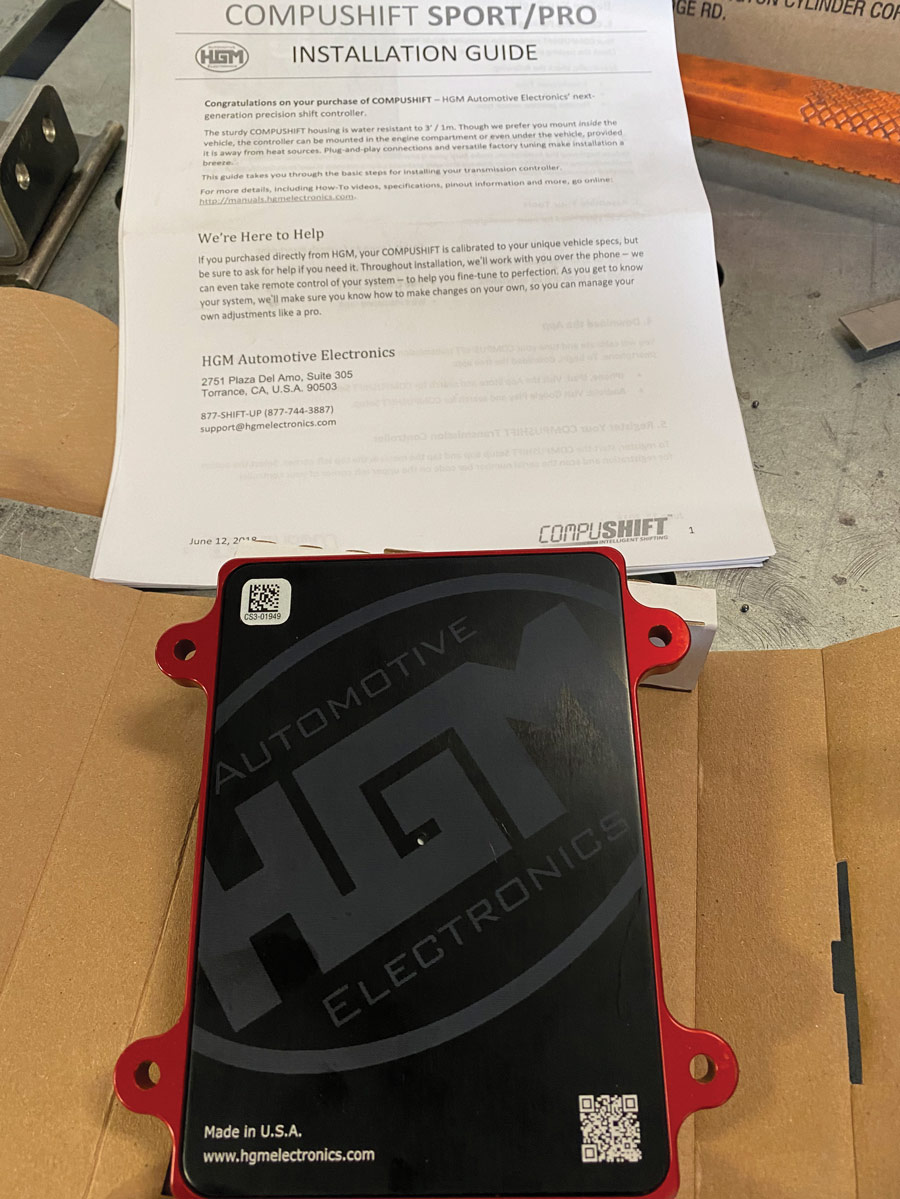

What Ducato ended up supplying was Phoenix’s PT4L60EST: their stage two “street/strip” 4L60E rated to handle 500 hp/525 lb-ft complete with a 298mm Torque Max 2,500-stall lockup converter, upgraded high-rpm clutches (up to 6,500 rpm), a G-Force 1967-1972 C10 trans crossmember, and CompuShift’s Sport/Pro precision shift controller (TCU) from HGM Automotive Electronics.

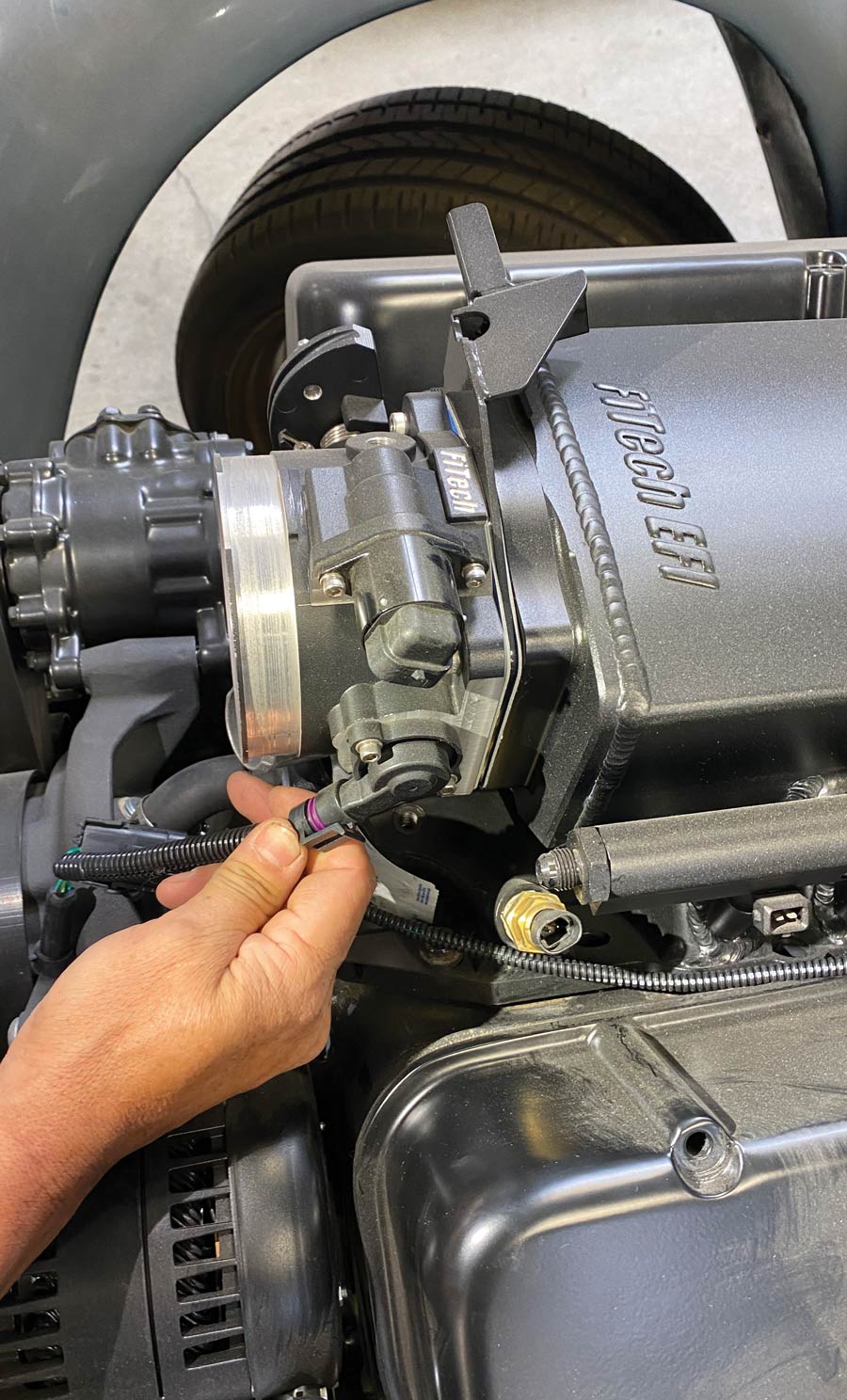

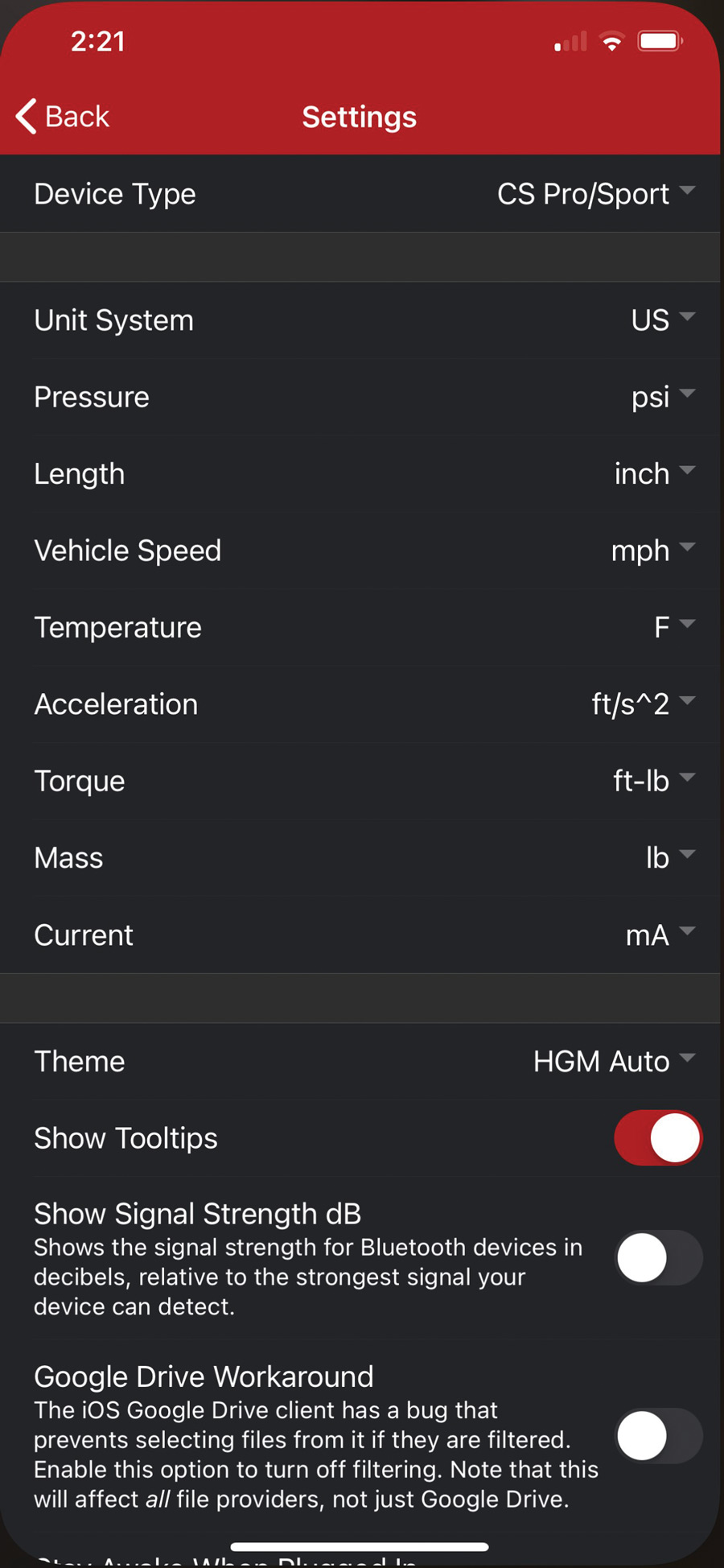

Both the transmission and its rear crossmember are true bolt-on/bolt-in—no cutting, grinding, drilling, adapting, or anything other than simply bolting said items in place on the back of the 454 and between the framerails of the C10! Now, when it came to the CompuShift TCU, I was still apprehensive at first—but as soon as we unboxed the shift control unit and realized what we were dealing with, well, let’s just say “plug-and-play” has never been easier! The best part is, the programming can all be done literally by the seat of your pants—while seated in your vehicle using your smartphone once you’ve downloaded the CS Setup App (the TCU, as stated, is Bluetooth enabled). The wiring harness took 30 minutes to install; the TCU just required an under-dash bracket to mount it off, which we fabbed up in the same amount of time. Combine that with the hour or so it took to mount the Phoenix 4L60E to the back of the big-block and drop it in the C10 and you’ve got the simplest “high-tech” overdrive trans install I’ve ever been witness to!

4. … we just had to provide the correct 168-tooth flywheel when mating the 4L60E to our 454 big-block.