Tech

Tech

Images BY IVAN MARTINEZ

Images BY IVAN MARTINEZt’s 8:30 a.m. in Tempe, Arizona. The roll-up doors are open at Mobile Solutions’ fabrication training center, and the desert heat is already beginning to settle in. Inside, a fullsize C10 truck cab shell sits front and center, its bare metal dash a blank canvas. Around it, a group of fabricators from all over the country gather—some returning for their 10th class, others attending for the first time.

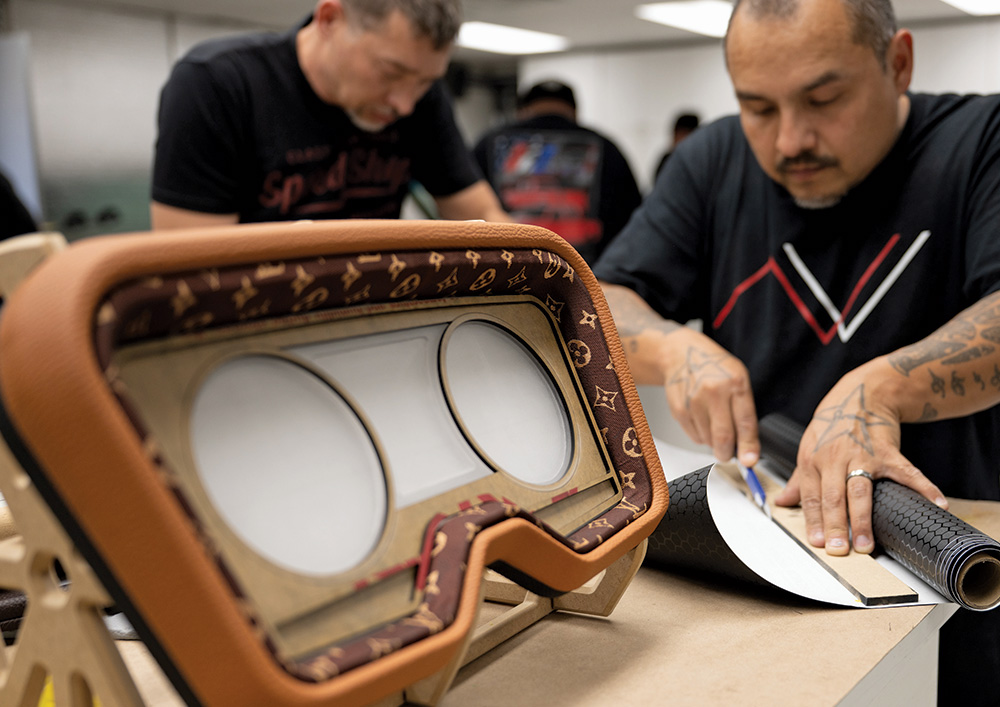

Over the next four days, they’ll work through the complete process of building a fully custom dashboard from the ground up—design, structure, electronics, upholstery. This is MasterTech 3D: Hot Rod Dash Build, a hands-on course designed not just to teach fabrication techniques but to walk attendees through the real-world process of turning raw materials into something refined, functional, and truly custom.

A live vehicle inspection began the process—studying the C10 cab’s geometry, identifying mounting points, and exploring how to blend modern visual language into a classic form. Using Peel 3D scanning tools, instructors demonstrated how to capture the cab’s interior dimensions, providing a digital foundation for conceptual sketching. Students sketched their ideas on paper and tablets, weighing layout options for gauge clusters, LED zones, and layered trim.

This wasn’t a class about shortcuts. Every decision had a reason. Brackets were adjusted for driver sightlines, bezels were designed with upholstery tolerances in mind, and the layering of panels was treated more like sculpture than assembly.

By afternoon, the nearly complete dash sections were test-fit into the C10 cab shell. Some required fine-tuning. Others dropped into place with little more than a light push and the audible click of brackets locking in. That moment—that dry fit coming together—was a turning point.

By late afternoon, the shop had taken on the quiet, focused energy of a studio. Students assembled their final pieces, cleaned edges, and prepped for presentation. One by one, they shared their work with the class—some polished, some still in progress, all shaped by intention.

By the time the shop floor was cleared, everyone left with more than a finished project. They left with a deeper understanding of their craft—and a renewed respect for the process behind it.