Tech

TechInTheGarageMedia.com

Images by THE AUTHOR

Images by THE AUTHORwelding has long been considered the premier welding process. With constantly dropping equipment prices, we are seeing it used for more and more truck builds, both professional and amateur. The reason TIG welding is so popular is because it gives you unmatched control over every aspect of the welding process. This allows a knowledgeable welder to make a strong weld with an excellent appearance on any weldable metal. One thing that confuses beginning welders is that there are so many choices to make when buying equipment, and still more choices to get the machine dialed-in properly. In this article, we’ll focus on the torch, or handpiece, that you manipulate to get the welding arc exactly where you want it.

The heart of the torch is the tungsten electrode that the electric arc emanates from. This arc creates the heat needed to make a weld. With TIG welding, a shield of inert gas envelops the weld zone and the electrode, which keeps them from getting contaminated by the oxygen in the atmosphere. TIG torches have a cup that surrounds the electrode and guides the flow of shielding gas. There is a broad selection of cups available; we’re going to look closely at the different types and the unique properties they have.

There is an enormous range of work done by TIG welding—from workpieces smaller than a dime to titanium-hulled nuclear submarines. Torches are made in sizes to accommodate this broad range, but in the realm of classic truck builders most welding machines come with either an air-cooled #17 torch, which is good up to 150 amps, or a #20 water-cooled torch, which can handle 250 amps. For reference, 150 amps will allow you to continuously weld material slightly thicker than 1/8 inch in one pass, and 250 amps is good up to 1/4 inch. For short bursts, you can exceed these guidelines a little—but you can damage a torch by going over its rated capacity consistently.

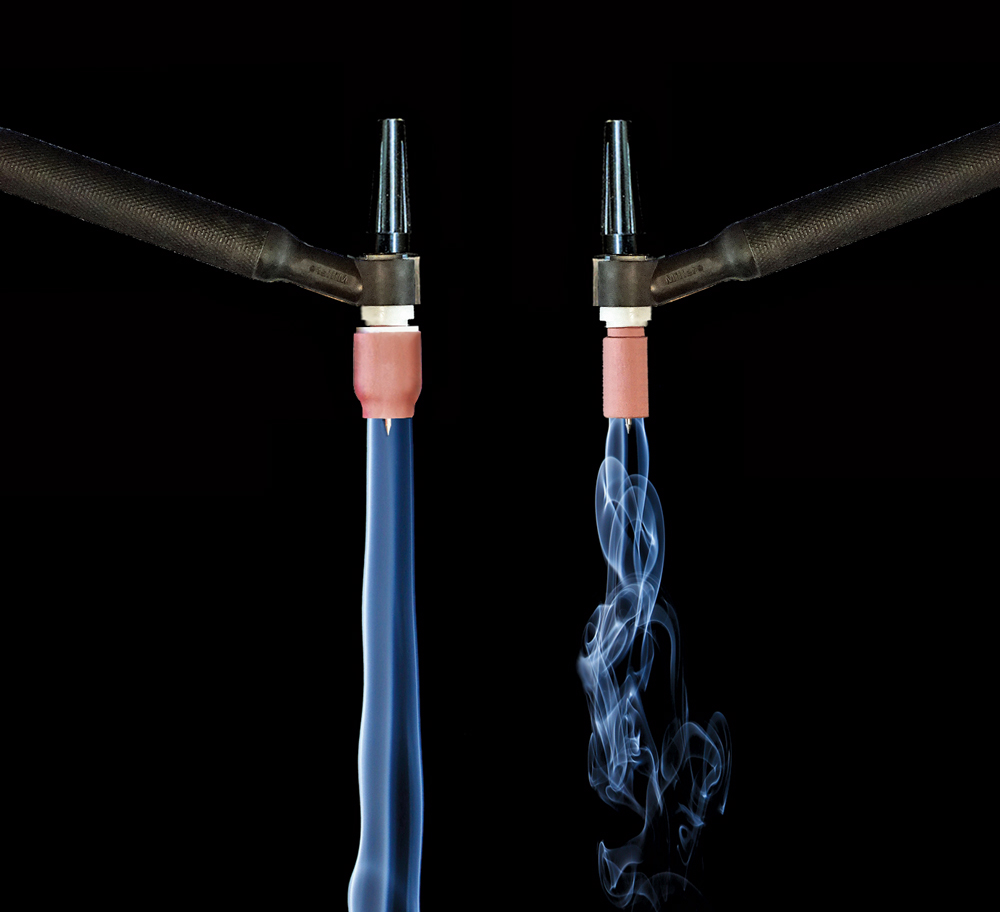

The tungsten electrode is removable, and the amount it protrudes from the cup is easy to adjust. It is held in place (and electrically connected to the power coming from the welder) with a copper collet. This collet fits inside either a standard collet body or a gas lens. The collet body is quite simple, basically a copper tube with a hole through the center for the tungsten, and a few holes on the side for the shielding gas to flow through. This works well enough for most welding applications, but the flow of gas that streams through the cup tends to be somewhat turbulent, and the erratic flow may not provide sufficient coverage in certain situations—like when the electrode needs to be extended from the cup farther than normal, or when welding highly reactive metals like titanium.

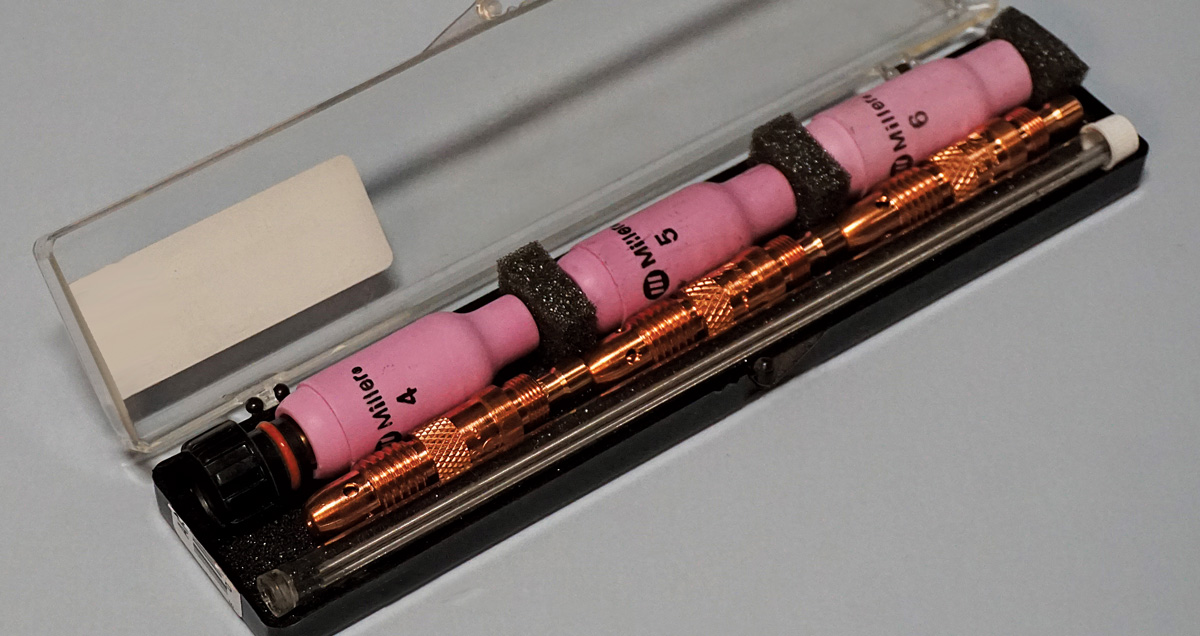

For these more demanding applications, a gas lens is used instead of the traditional collet body. The gas lens is a tubular device with a contact surface for the collet, but instead of having holes on the side there is a path for the gas to flow straight through the center, and there are layers of stainless screen that further smooth the gas flow. Because gas lenses are larger than a standard collet body there are special cups made to fit them.

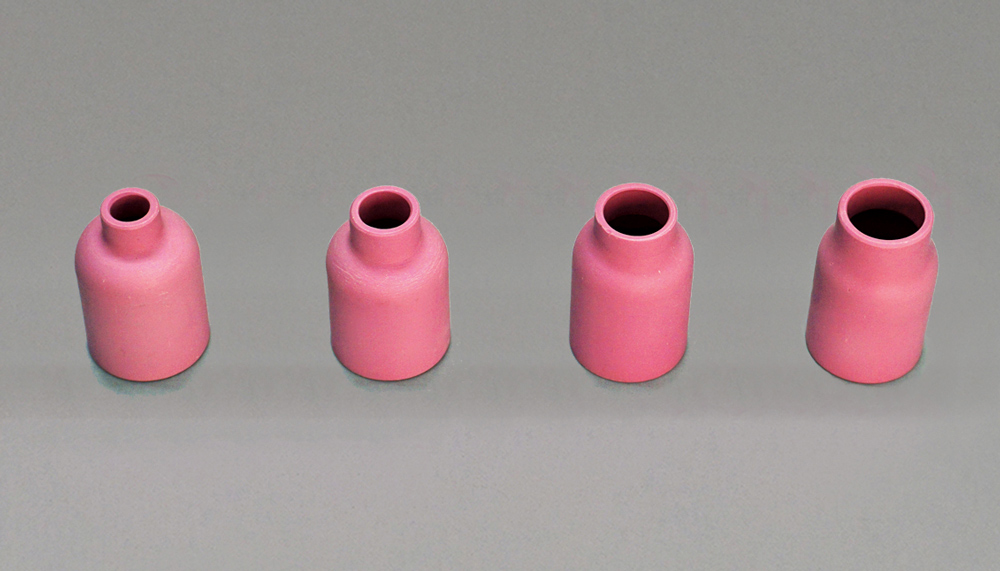

The cups are most commonly made of a ceramic material, which can withstand the extreme temperatures they must endure. Ceramic cups thread onto the body of the torch, so it’s important to select a cup that’s compatible with your torch. In general, the water-cooled torches are smaller for a given amperage rating.

There are clear cups too, made from quartz or borosilicate glass (Pyrex), and these are helpful in certain applications. They throw a lot more light into the welding areas, sometimes making it easier to see what’s happening, although there is some optical distortion if you look directly through the wall of the cup.

Cups are numbered by the inside diameter of their orifice, measured in 16ths of an inch. So, a number 6 cup would have an orifice 6/16, or 3/8 inch. A number 9 cup would have an opening 9/16 inch. In addition to the diameter of the opening, cups are available in many different lengths, from stubby to extra-long. It’s best to start with the regular length and add to your collection if special situations arise.

So, of course, everyone wants to know what size cup to select for their particular welding job. In the world of welding, the demands of most truck builders are relatively simple, so there is little need for exotic torches or cups. Any size between #5 and #8 will work for the vast majority of these welding projects. While a gas lens will work perfectly, there will be little benefit unless you need to stick the tungsten electrode out of the cup more than normal. The maximum recommended “stickout” for the electrode is equal to the opening in the cup, so that’s 5/16 inch for a #5 cup and 1/2 inch for a #8.

The larger the cup, the more gas you need to flow; argon gas is expensive, so for that reason alone, you might prefer using a smaller cup for most work. There is a very simple formula to use for gas flow: multiply the cup size number by 2 and that’s the amount of gas flow you need in cubic feet per hour (CFH). So, for a #5 cup, 10 CFH is sufficient. For a #8, you can bump it up to 16 CFH.

Aluminum is more reactive than steel, so a little more gas flow may be beneficial, but you should NOT use a lot more gas flow than this formula suggests. That can induce turbulence in the gas flow, which may cause air to be mixed with the inert shielding gas. As a rule of thumb, don’t use more gas flow than 2-1/2 times the cup size.

All of these considerations are geared toward properly shielding the weld pool and the tungsten electrode, and there are lots of varieties of electrodes, too—but that’s a story for another time.