TECH

TECH

Images by THE AUTHOR

Images by THE AUTHORhether you find yourself restoring a classic truck to its original spec or you’re building a full-custom show truck, one of the first things you’ll be forced to tackle is any underlying damage to the cab and sheetmetal. Be it dings and dents from a previous fender bender or full-on cancer caused by years of gathering debris in dead-end sections of sheetmetal, those imperfections need to be sorted before one can even start thinking about any body- and paintwork.

The fact that nearly every panel for most makes and models is available in the aftermarket makes for repairing these old trucks even easier. A quick peruse through websites like LMC Truck’s showcases said availability. So, it should come as no surprise that when it came time to start repairing the sheetmetal on our 1964 C10 project we picked up LMC Truck’s catalog and started a wish list of parts and panels. We started at the worst points, which are typically the lower sections of the cab where 70-plus years of crud tends to gather, creating a petri dish of moisture that ends up attacking the iron in the sheetmetal, resulting in rust, which ends up eating away the tin in the form of cancer. This is typically visible on the surface by small bubbles in paint, surface rust, or full-on sections of missing metal. Whatever the method of revelation, Confucius says, “It’s gonna be worse underneath!”

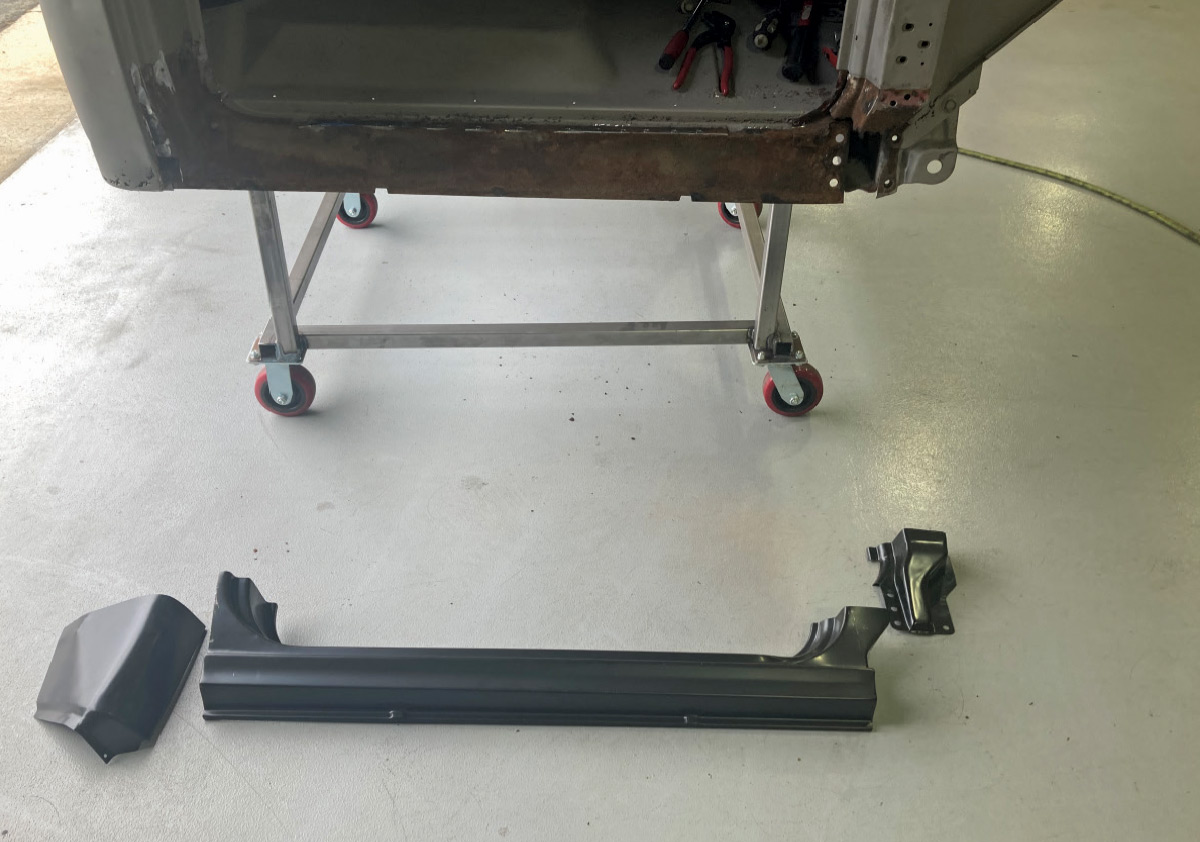

And that’s exactly what we discovered when we began peeling back the layers on our C10 cab. We could tell that the section at the bottom of the A-pillar was pretty bad, but only after removing the outer rocker panel and the lower A-pillar did we realize the amount of damage we were up against. No fear, however, as we had a great source in LMC Truck to help us repair our cab and get our project pushed along further down the road toward completion.

This month, we’re going to start by repairing the A-pillar section and the outer rockers. We’ll follow up in the coming months as we continue the repairs necessary on the C10.

SOURCES

SOURCES