Tech

Tech

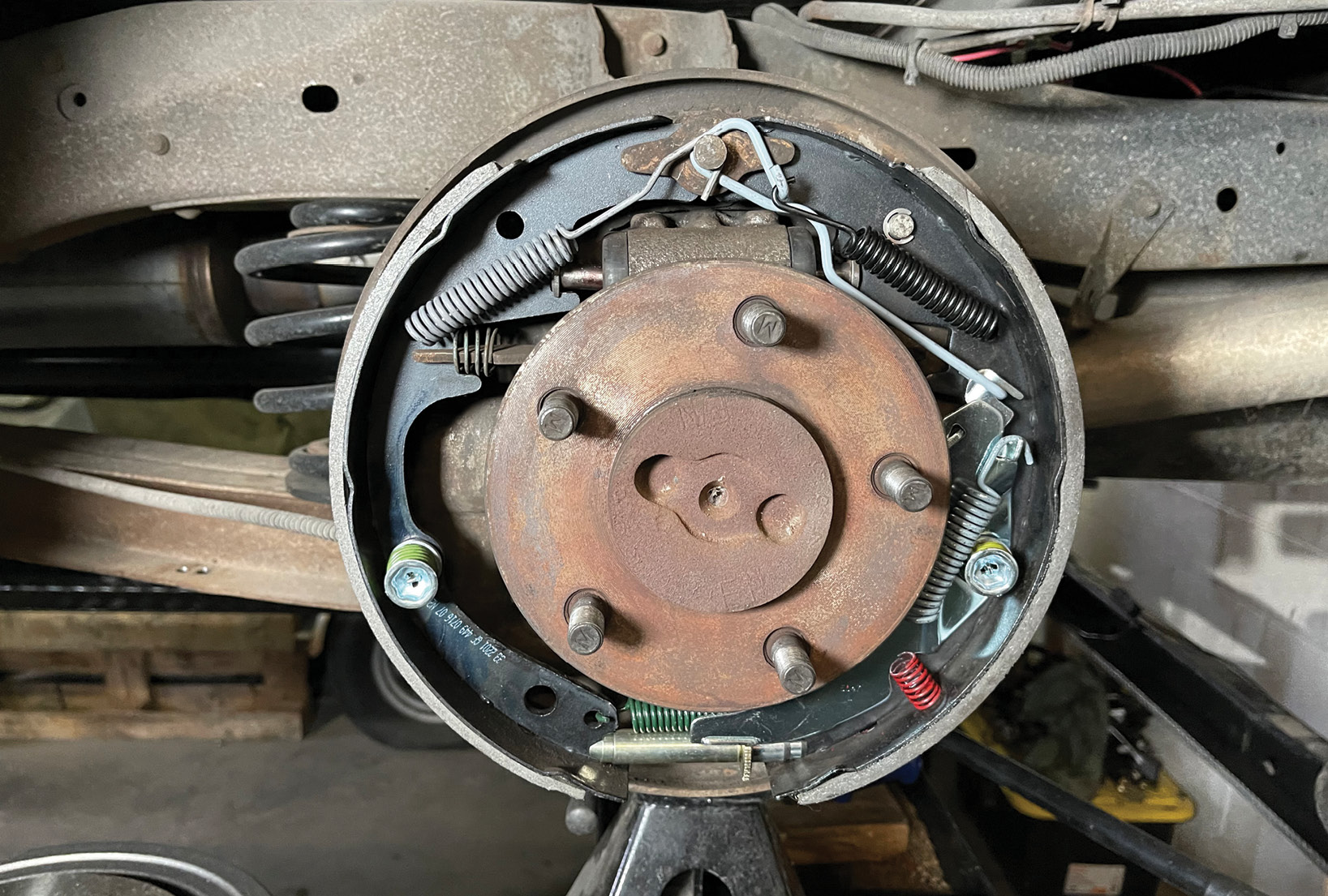

1. Not every truck needs four-wheel disc brakes, but every truck does need a well-maintained and functional brake system. With the help of Duralast replacement parts, we were able to update the stock rear drum system with new drums, shoes, and hardware to produce a factory-fresh braking action.

BY TODD RYDEN Photography by THE AUTHOR

Photography by THE AUTHOR

rucks have been stopping proficiently with rear drum brakes for decades. Perhaps not the most effective form of braking available these days, but for many classics out just cruising the road, a pair of discs up front combined with a well-maintained set of drums in the rear will perform safely and just fine.

Don’t get us wrong, when it comes to quickly bringing our trucks to a slow or stop, you can’t go wrong with disc brakes on all four corners. The clamping action of calipers and rotors are far more effective and consistent, while having fewer moving parts. If we were working on a great-handling, big-powered truck, four-wheel discs would be our only choice.

We used Duralast because they have a wide variety of classic truck and muscle car parts with updated technology from the 50-year-old original equipment. We found new Duralast brake shoes along with 11-inch replacement drums. Our experience using Duralast has proven that their products will perform as good or better than the originals.

We were also pleased to find that Duralast offers a complete hardware kit (PN H7018) to replace all the return springs, retainers, and clips. They also had kits to update the self-adjusting mechanism, including the star-wheel assembly to replace our worn-down adjusters. Note that there are two kits: H2508 for the driver side and H2509 for the passenger. Wheel cylinders were also available but ours had been changed a few years ago.

The Duralast parts fit just like the factory components, making the replacement of the shoes a breeze and the new hardware was a nice update to the 52-year-old parts. The braking action was definitely improved and we now have confidence in our braking system as we roll into the road trip and cruise season.

2. With all of their springs, levers, and associated parts, drum brakes can be a little daunting at first look. The most important tip we can offer is to never take both sides apart at the same time! Note the rear shoe (on the passenger side) and how thin the brake lining is worn down. This baby needs some new shoes!

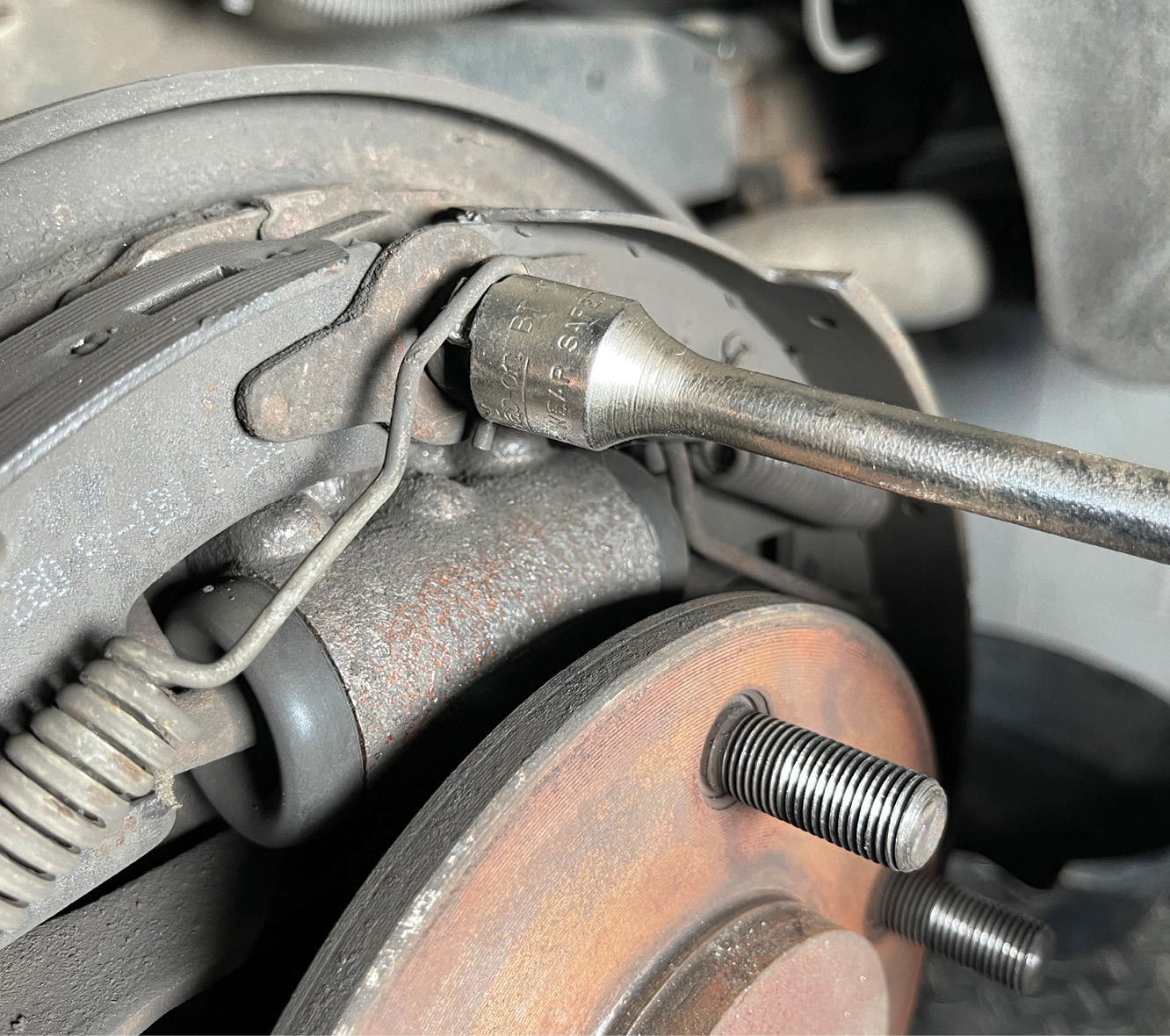

3. Drum brakes are self-adjusting, thanks to this little star wheel screw adjusting mechanism and lever. In short, when you back up and apply the brakes, the star wheel unscrews to push the shoes out and closer to the drum. In this case, the adjuster has done its job and has “unscrewed” as the linings have worn over time. Note the worn-down teeth; time for a replacement.

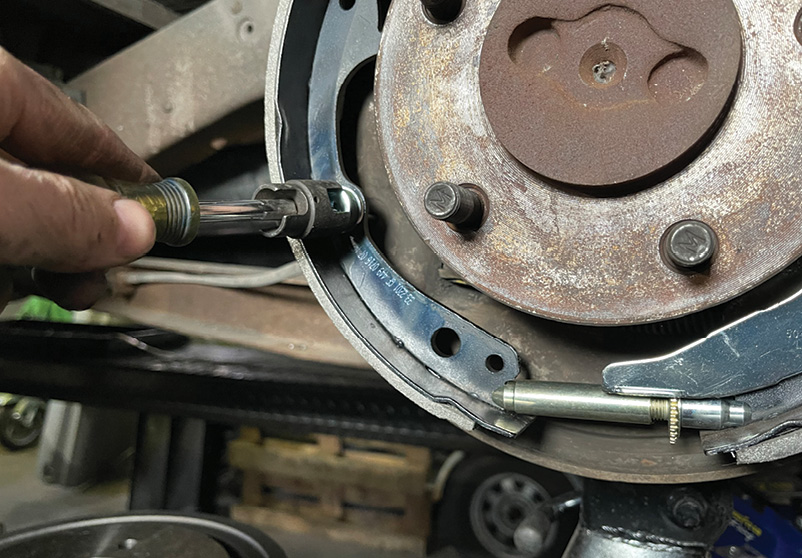

4. These two tools will make life a lot easier when replacing the shoes. The nutdriver has a special socket designed to remove the shoe hold-down retainers while the other tool will easily remove and help install the different springs.

5. Start with a good bath with a quality brake cleaner. This will get rid of all the lining dust that will instantly turn your hands black. The cool thing about brake cleaner is that it dries within minutes and leaves no film.

SOURCE

SOURCE