Tech

Tech

BY Ron Ceridono Photography courtesy of Roadster Shop

Photography courtesy of Roadster Shop

oadster Shop, located in Mundelein, Illinois, has a long and storied history. Originally located in Elgin, Illinois, and founded by Bill O’Rourke in 1982, the shop’s focus was on traditional hot rods as the name implied. Unfortunately O’Rourke died in 2004. Jeremy Gerber, who worked at Roadster Shop, his brother Phil and father Neal bought the business. This was about the time that the automotive hobby was growing and Roadster Shop was set to grow with it.

Under the Gerbers’ guidance Roadster Shop began turning out an astonishing array of vehicles, including traditional hot rods, trucks, Tri-Five Chevys, muscle cars, and just about anything with wheels. But while the vehicles varied the one thing they all had in common was fanatical attention to detail.

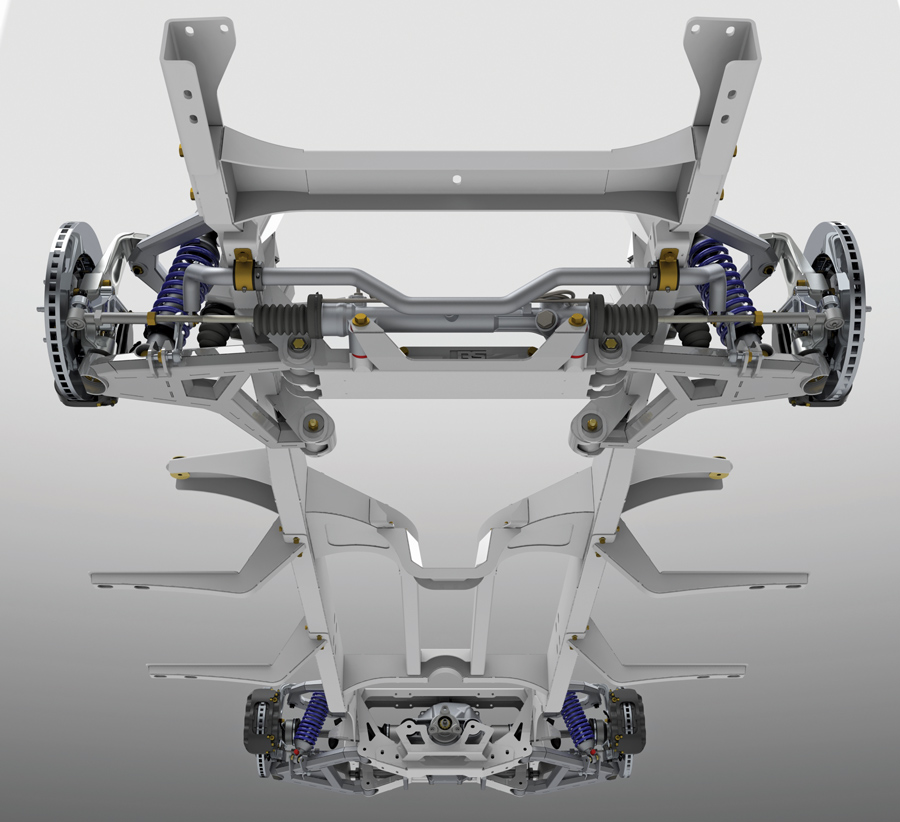

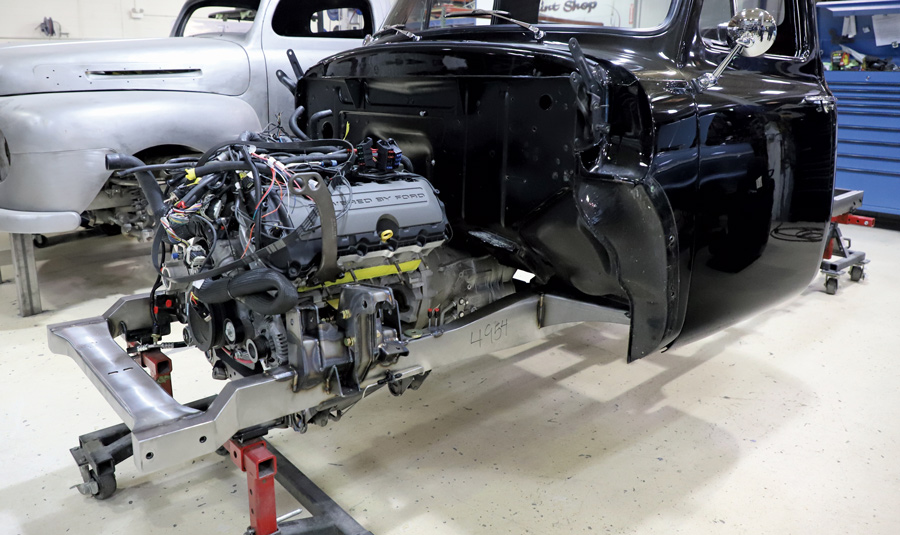

The Roadster Shop team is known for their ability to incorporate innovative design features that are so well integrated it takes a keen eye to pick them out. A case in point is the ’55 Ford F-100 shown here. Based on a Ride Line chassis with independent front and rear suspension, the wheelbase has been stretched to 116.75 inches (stock is 110 inches). Up front the tires will be 245/50R18 (27.6 inches overall diameter) on 18×7.5 wheels with 5-inch backspacing. In the rear 255/55R18 tires (29 inches overall diameter) will be mounted on 18×8 wheels with 5-inch backspacing.

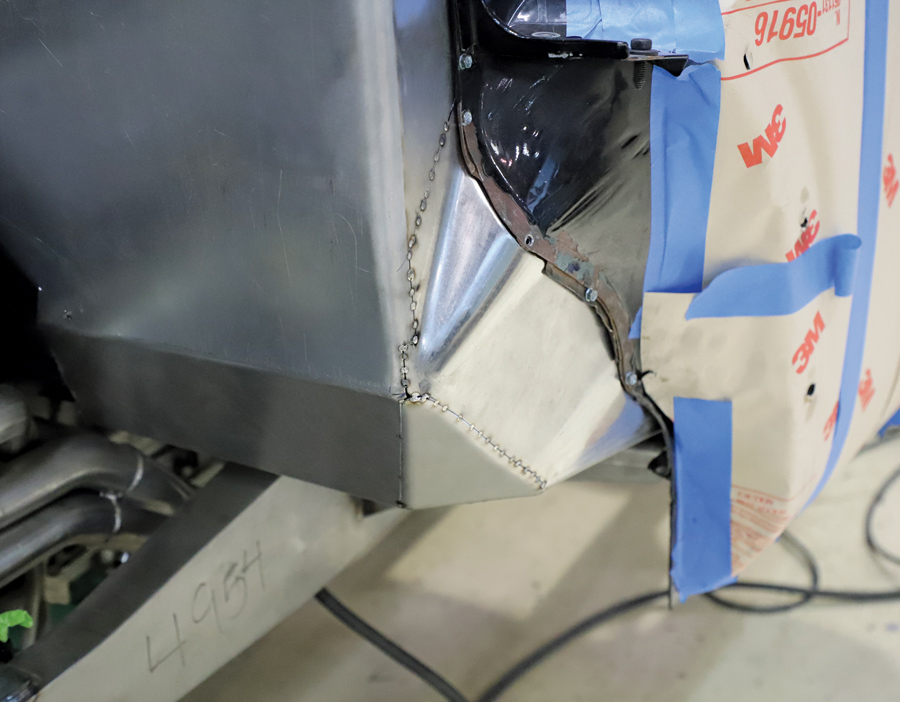

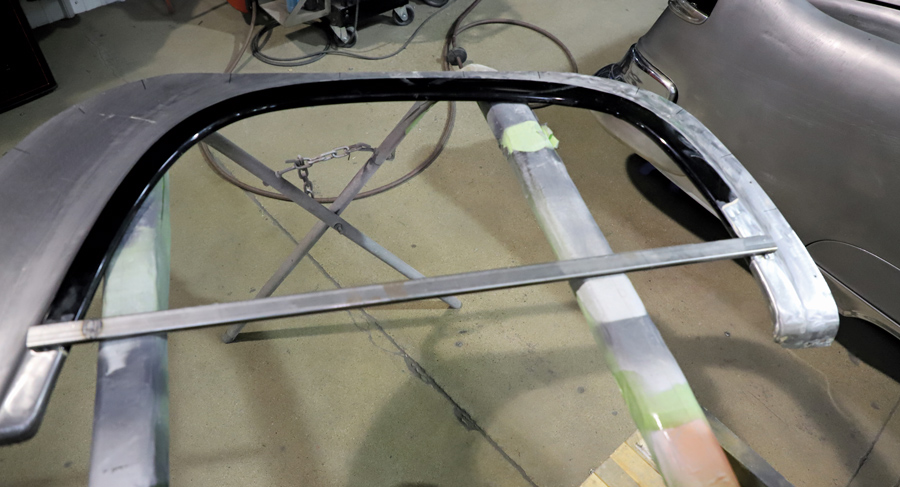

To accommodate the increased wheelbase, and to center the front wheels in the fenders, the wheel arches were cut loose and moved forward. The stock lips around the openings were retained and the area behind the wheelwells were filled in with 16-gauge sheetmetal. This subtle yet significant change gave the truck a more balanced profile—it’s one of those modifications that just looks right.

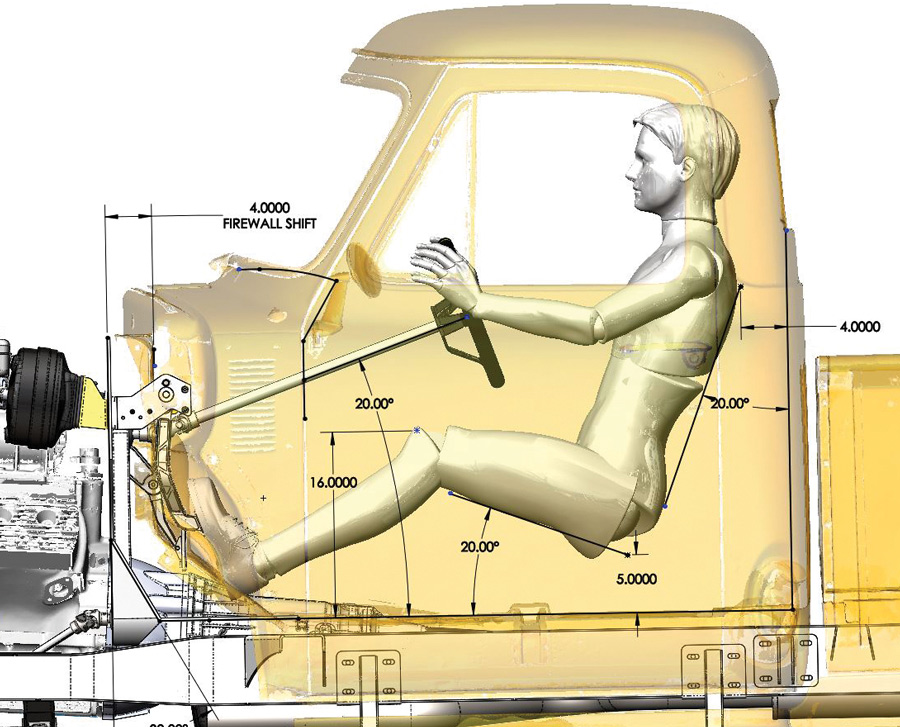

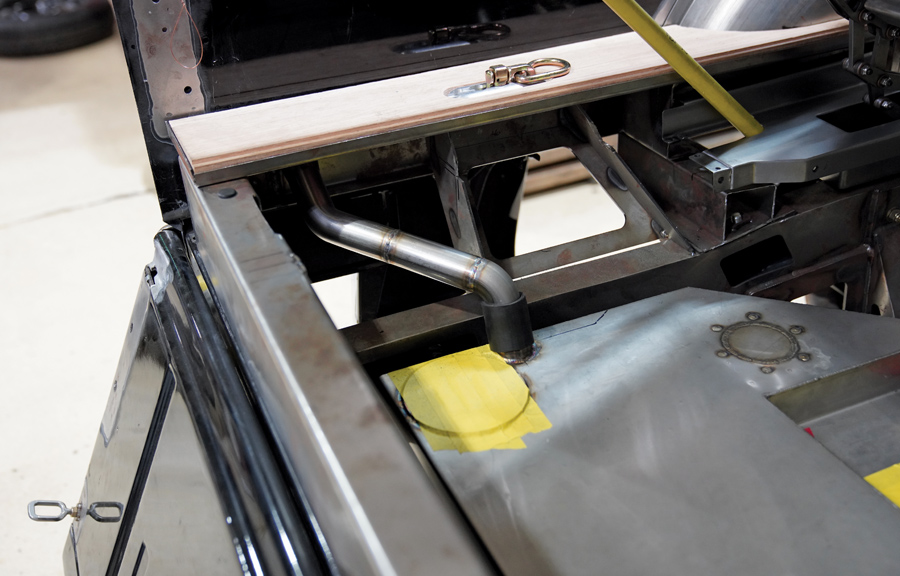

Another change to the cab was the repositioning of the firewall. But rather that moving it back as is often done, in this case it was moved forward. To provide additional passenger compartment legroom and accommodate underdash pedal assemblies, the engine and transmission were moved forward as far as was practical and the new firewall was moved forward 4 inches.

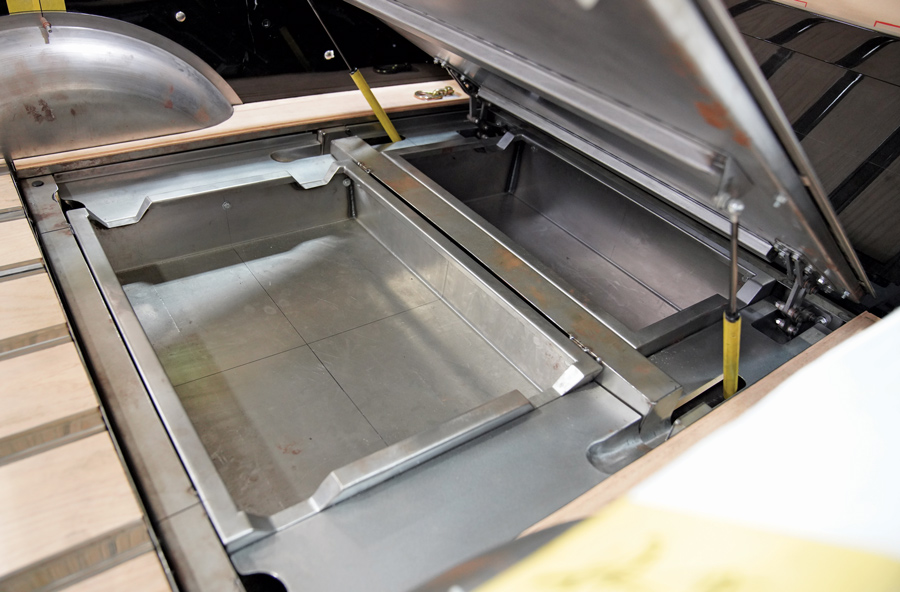

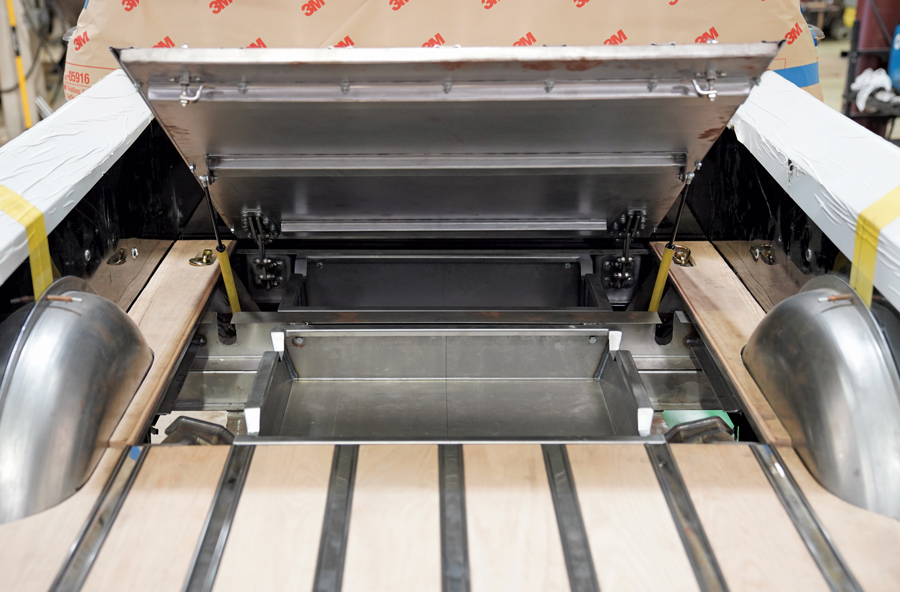

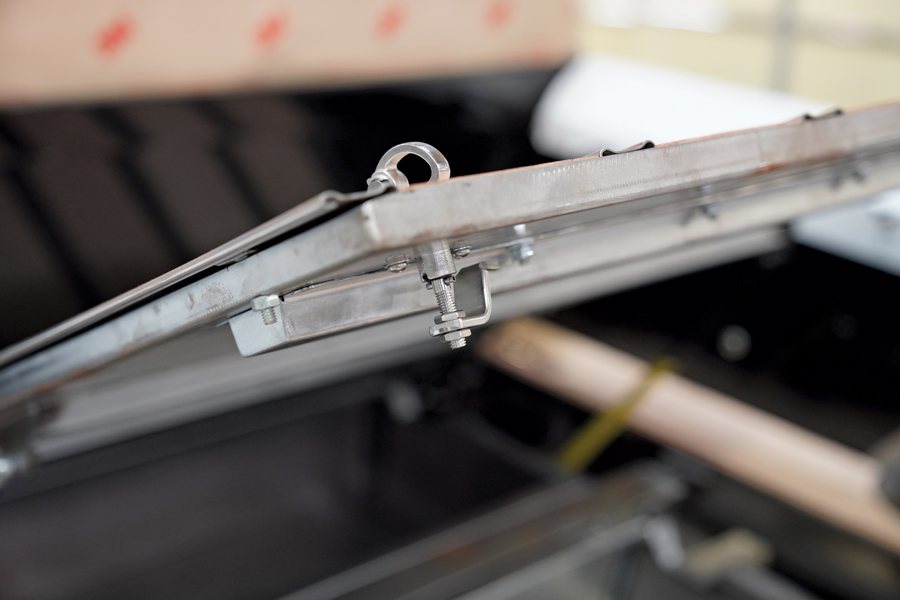

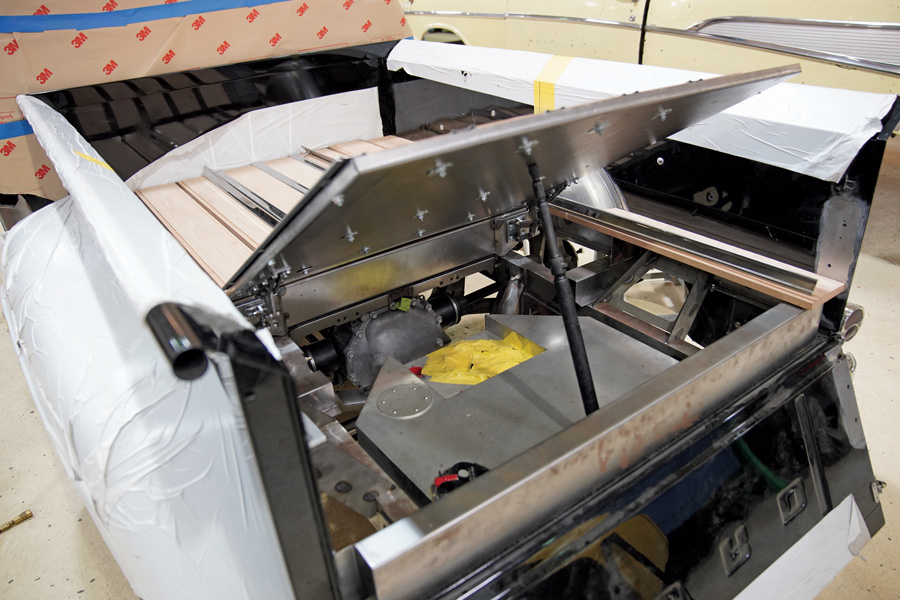

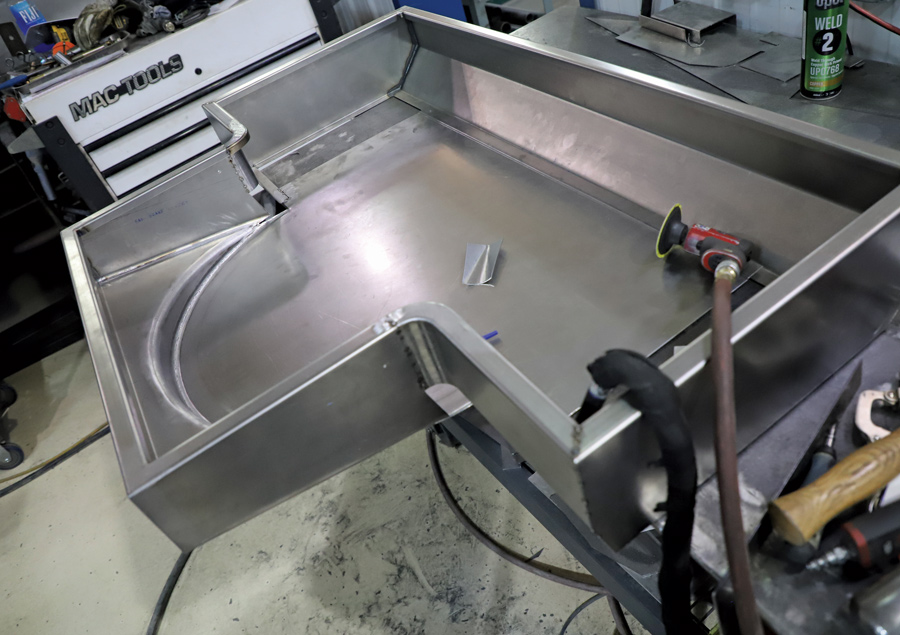

More thinking outside the box, or in this case under the pickup box, are compartments below the bed floor. Hinged sections provide access to the storage compartments and a spare tire carried in a space that is often unused.

Take a look at the following photos as food for thought. They just go to prove that some of the most subtle modifications are often the most effective.