Tech

Tech Photography BY The Author

Photography BY The Authorolling through the years of classic truck innovations, each decade can claim an endless score of achievements as their products went from the drawing boards to the assembly line. It’s easy to see that Chevrolet raised the bar from 1941-1946 with their Art Deco Series of trucks showcasing design elements never seen before. From the alluring horizontal- and vertical-styled grille to the flowing headlights that melted into the fenders and distinct crank-out V-shaped windshield, these era-defining looks made them truly memorable.

Imagine pulling back a set of barn doors revealing a cobweb-covered 1946 Chevy truck that somehow managed to survive through years of use before being parked and forgotten about. Wearing a well-earned patina, it’s decision time as you haul it out of suspended animation and make the commitment of bringing it back to life. Thankfully, the truck in our tech article managed to eventually escape from its hard-working past, making it a perfect subject to maintain its well-earned good looks while getting treated to a number of updates.

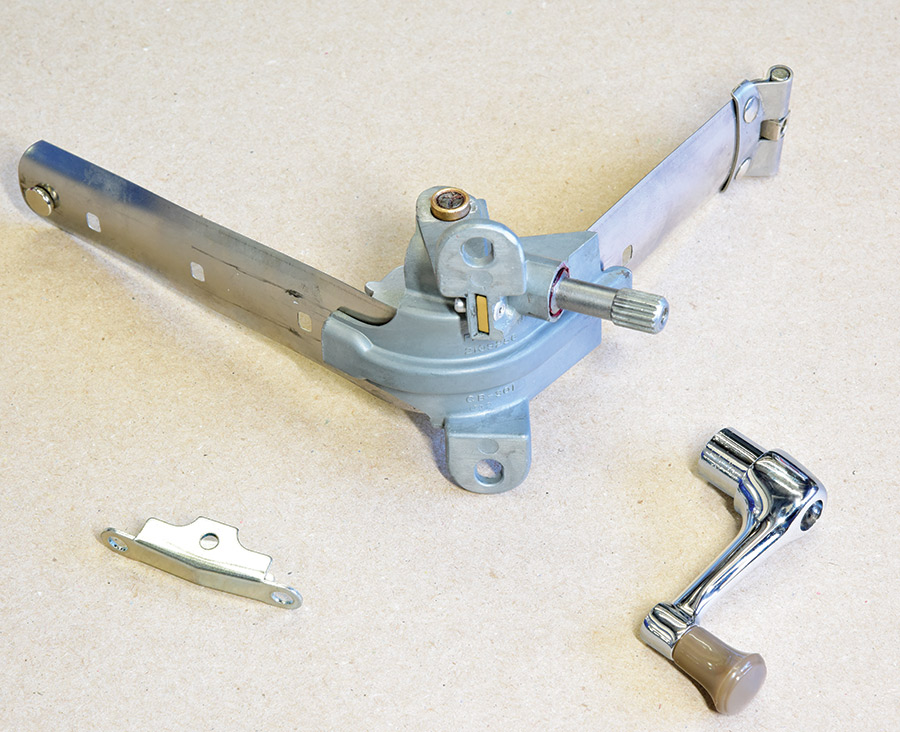

While assessing many of the areas needing to be addressed, it was easy to see a pronounced de-lamination of the two-piece windshield as well as evident scratching from the single wiper. A closer look revealed that the windshield-to-cab gasket was severely cracked along with the crank-out regulator being nearly seized and the wiper system definitely needing replacement. Wanting to talk with the experts on Art Deco Series trucks, we contacted Chevs of the 40’s in Vancouver, Washington, and spoke with their knowledgeable team regarding our needs. Being the world’s most complete supplier of 1937-1954 Chevrolet car and truck parts it was easy for them to lead us in the right direction.

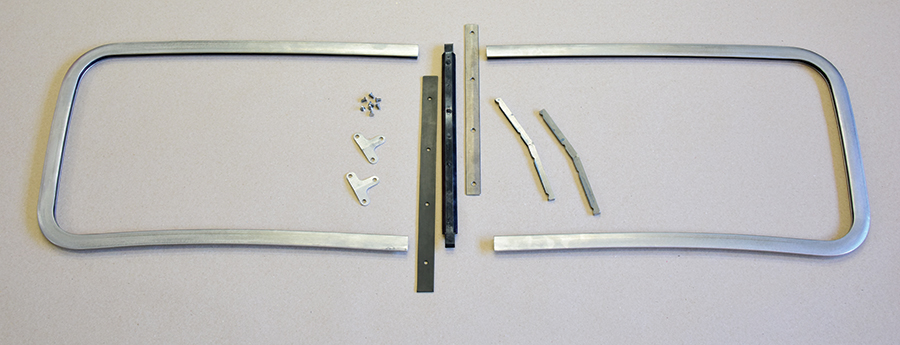

To handle the updates we met with Scott Roth, co-owner of Rothspeed in Milton, Vermont, who got started by carefully disassembling the entire windshield frame, crank-out regulator, and wiper system. It’s cool that Chevs of the 40’s offers the replacement windshield frame kit in either chrome or bare steel. For our purposes we selected the bare steel version that Roth worked his magic on by adding a newfound patina, matching the truck’s vintage surface. In taking on the job it was refreshing to know that Chevs stocks all of the parts needed, including windshield frames, glass, crank regulators and handle, gaskets, setting tape, and replacement wiper systems. In preparation for removal of the windshield frame it’s a great idea to give all the original hardware a healthy spray of penetrating oil to ease their removal. With safety always being a concern, be sure to wear protective glasses and gloves when taking on the job.

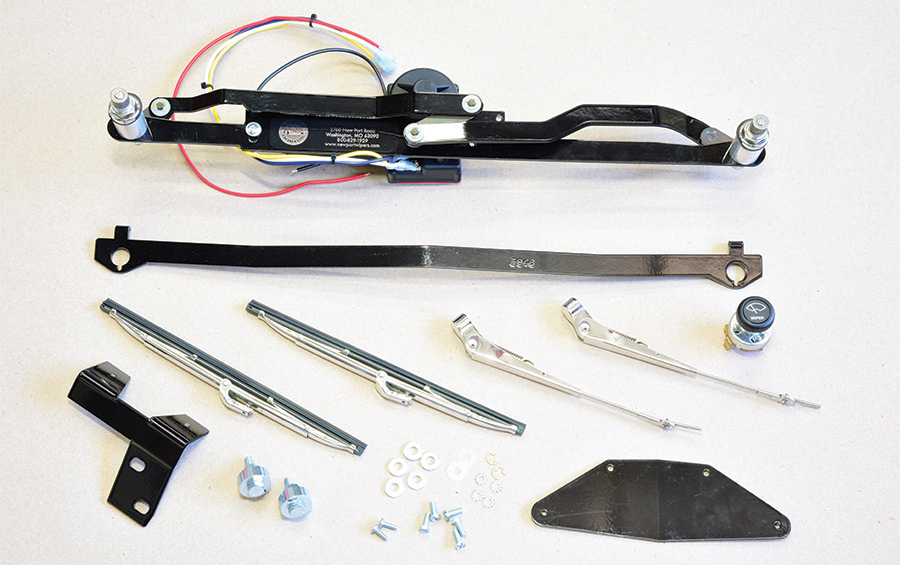

When it came time to addressing the original vacuum-operated windshield wiper system, Chevs offers a number of options, including a full rebuilding service for your original factory unit as well as numerous 6- and 12V offerings. For our purposes, we chose the Newport Engineering 12V system available for 1939-1946 Chevy trucks incorporating their exclusive “Clean Wipe” Wiper Drive. Newport Engineering features the latest technology and engineering in their kits to make upgrading from the obsolete vacuum single wiper system to a dual wiper system created to fit behind the factory interior header panel.

They include everything needed for a flawless installation in the kit, including a heavy-duty two-speed 12V motor, bronze oilite bushed transmissions, linkage, wiring harness, all mounting brackets, switch and polished stainless wiper arms, and blades. There’s even an easy-to-use drill jig to add the driver side mounting hole and drill the passenger side hole if your truck was originally equipped with a single wiper unit (as ours was) to make installation a snap. The completed upgrades look great and also restored full functionality of our crank-out windshield ventilation system as well as increased visibility with fresh glass and a new 12V electric two-speed dual windshield wiper system.

SOURCES

SOURCES