Tech

Tech

Images by THE AUTHOR

Images by THE AUTHORveryone knows how one thing leads to another. When we’re thinking outside the box, we might as well color outside the lines, right?

Just a while or two back we dry fit assembled a Task Force Chevy reproduction Stepside bed, beginning with its squared-up wooden floor. We know; that’s not the way most builders go about that. It’s just how we did it that time, and it worked out mighty fine.

Recently, we’re wrapping up some mild custom touches for the same all-new Stepside bed assembly. If you caught this story’s part 1 (Jan. ’25 issue), you may recall taillights and tailpipes near the tail end, but there’s still a little more in store. We’ve still got some custom tailgate latches and catch cables to figure out.

Now, before we move forward, let’s take a spendy step back. This one’s on yours truly. It’s about the brand-new tailgate that we already have. Instead of one with the stock-configuration hook-and-chain latch setup, I should’ve ordered the same ’gate sans (that’s French for without) unnecessary hardware. To make the job at hand much easier, we’ll go on and purchase another ’gate.

As much as we still prefer the old-fashioned eye-to-eye parts procurement procedure, this time we’d rather not drive cross-country for it. At the same time, we’d still rather not have our customer pay today’s shipping costs. One way around that is to purchase the next tailgate from Speedway Motors. If you don’t already know, orders above $149 ship for free. Even though our needed item ships directly from the manufacturer, it also ships for free.

For quite some time I’ve had a recurring notion for custom tailgate latches, but it’s not an approach that we commonly see. When it came time to breeze the plan by the project truck’s owner, the pitch went out as a newfangled phone photo—and his instantaneous reply was, “Do it!” He then went on to say that he’s not the biggest fan of those rattling chains. These days, those are plain unpopular, period.

This won’t be what we’ll do, but who remembers seatbelt buckles affixed inside of bedsides to function as semi-discrete push-button tailgate latches? That was good old wrecking yard resourcefulness, and it was right in line with the times.

Today’s way would more likely involve kit form hidden latches. Granted, that’s the cleanest and easiest way to go, but it’s just not what I’ve had in mind. To flow with the flavor of this lower-than-high-tech build, ’gate latches won’t need to be invisibly hidden. They’ll only need to look as though they belong.

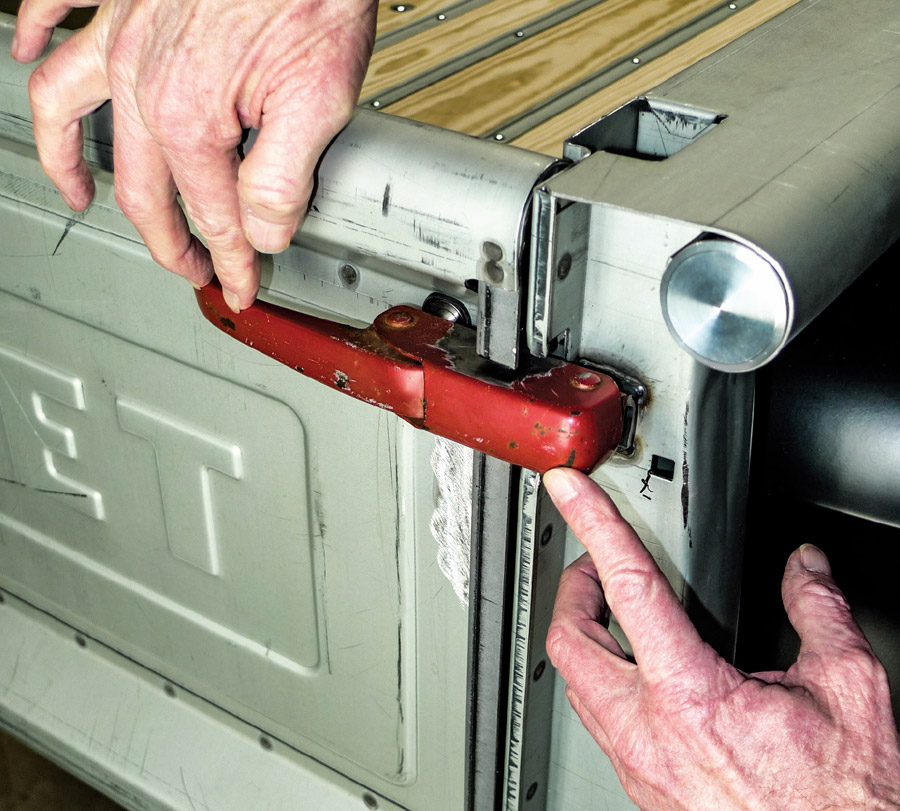

Like it or not, I’m particularly partial to tailgate latches from 1970s-era foreign-job pickups. Years ago, for a 1957 F-100, I used latches from an early Ford Courier. This time for our customer-friend’s 1955 second-series Chevy, let’s try latches from a 1973-79 (620-series) Datsun. They’re somewhat similar, they work the same way, and I happen to know where we’ll find a pair.

Since our new Stepside bed assembly has very tight ’jamb tolerances, there’s no place to cleverly conceal folding stop straps. Since the project truck’s owner restores and races vintage motocross machinery, we’ll need to come up with something strong enough—just in case he opts to use his toy truck to haul another toy to the track.

Last time, for cable-type catches, a pair of catch cables from a Dodge D-50 worked perfectly. Those are harder to find in wrecking yards today, but what we’ve found on an early S-10 Blazer would fit the bill—if only they weren’t so worn and frayed. As it works out, reproductions are affordably available, so this time that’s the way we’ll go.

Once again, for custom latches and catches, we do have easier options today. Even so, I think I’ll stick with my own notion. Like most of my own notions, this one was birthed in my favorite old wrecking yard. On that familiar note, let’s begin part 2 of our story there.

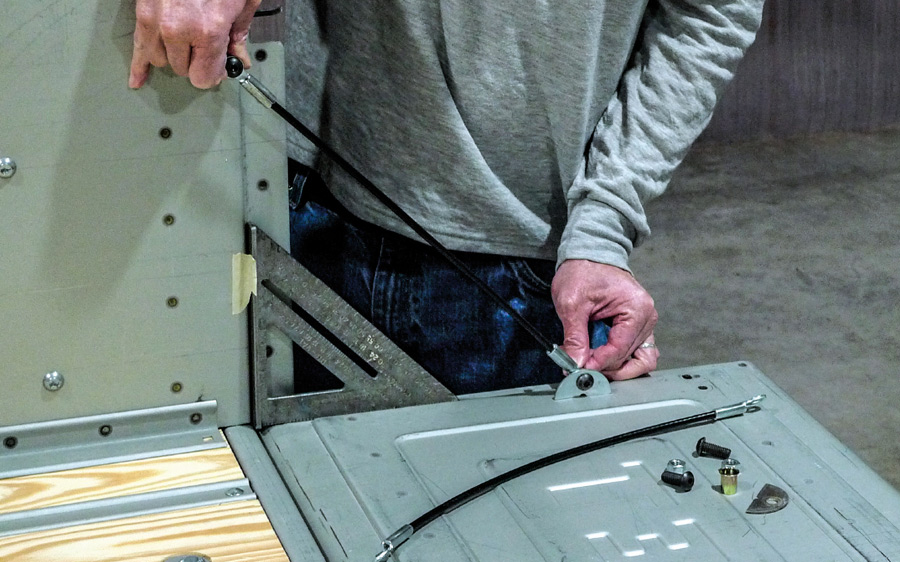

17. Settled back in, we’d like the open tailgate supported at a proper 90-degree angle. Last time with somewhat wonky repaired parts, stop cable tension was tough to get uniformly tuned.

SOURCES

SOURCES