Tech

Tech

Photography by THE AUTHOR

Photography by THE AUTHORhen new, many of what we consider today to be classic pickups were much more rudimentary when compared to their modern equivalent. Creature comforts, like climate control or a radio, were oftentimes only available as upgraded options on what would otherwise be a bare-bones workhorse. Power accessories were unheard of and anything that didn’t actually contribute to what might be the job at hand were omitted. Today, however, these trucks are receiving a new lease on life thanks to the revived interest in their use, not so much for work but for play as well. With that comes the upgrades that many of us have come to expect, having been spoiled by the creature comforts and build quality of modern vehicles. The addition of power accessories, climate control, et al, are standard fare on many classic truck builds today, as is an expectation of improved quality.

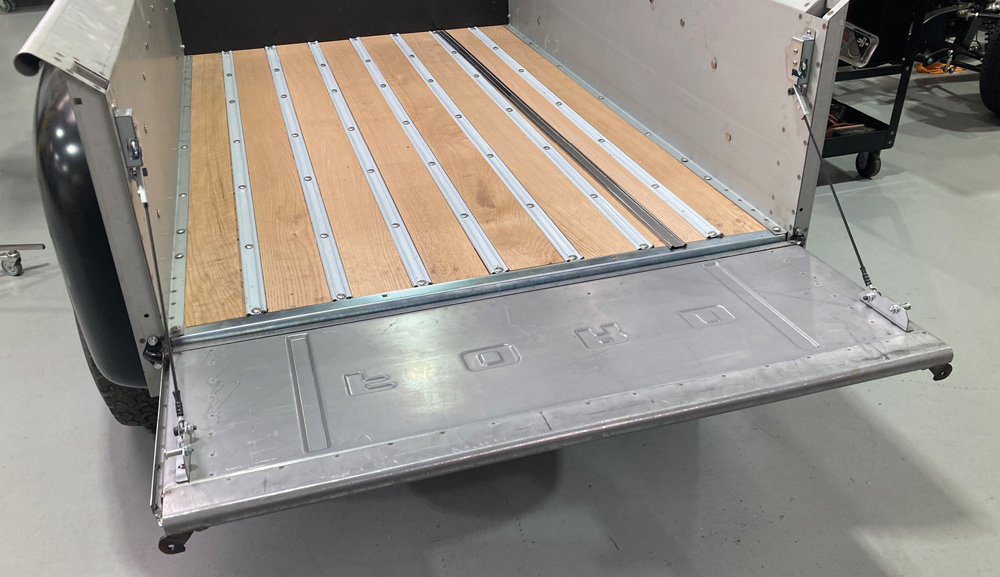

Fit and finish were unlikely talking points of our trucks originally, with terms like “strength,” “hauling capacity,” and “workload” being the more predominant adjectives. The doors and hood fit and that was about it, they opened and shut and that was the be-all end-all, for the most part. The hood and tailgate were likely the same. Things were adjusted to the point where they operated without conflict, with aesthetics and style oftentimes being overlooked or simply not of concern. Fast-forward to today and these trucks are being rebuilt to levels never dreamt of by their original designers, with fit and finish being a serious concern. This often requires reworking much of the original equipment to a point past its capability, requiring modification or complete replacement necessary. In some cases, there was no original equipment to achieve what we might set out to accomplish today.

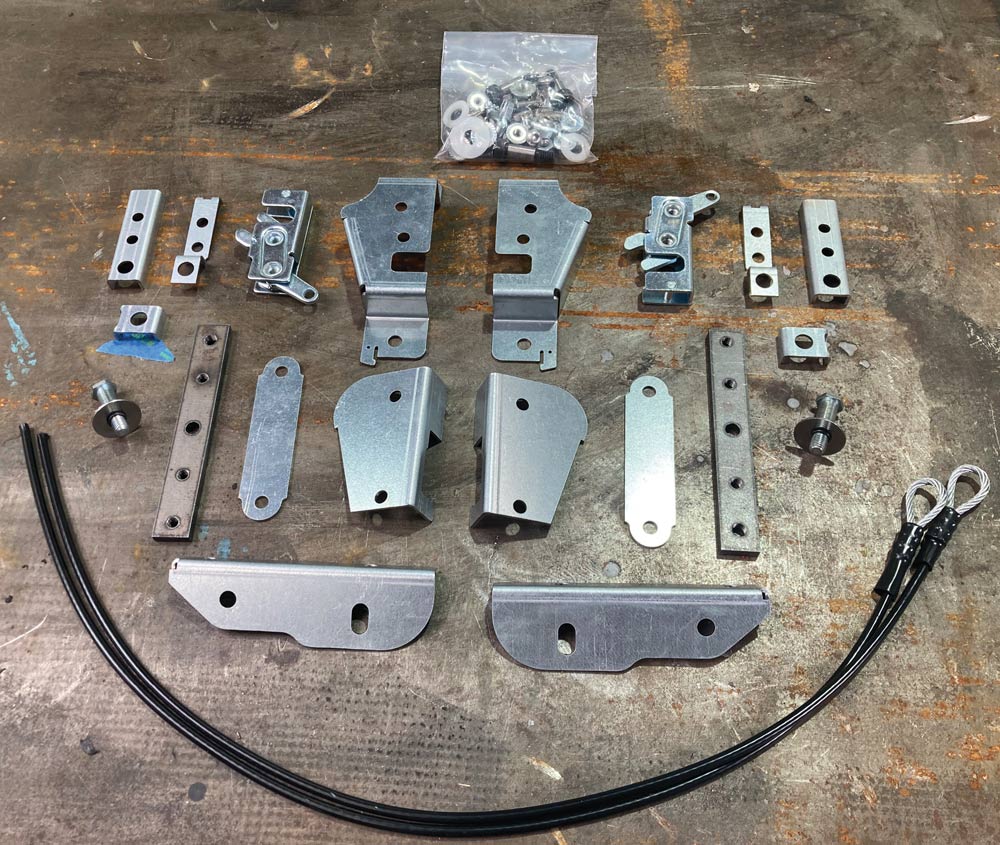

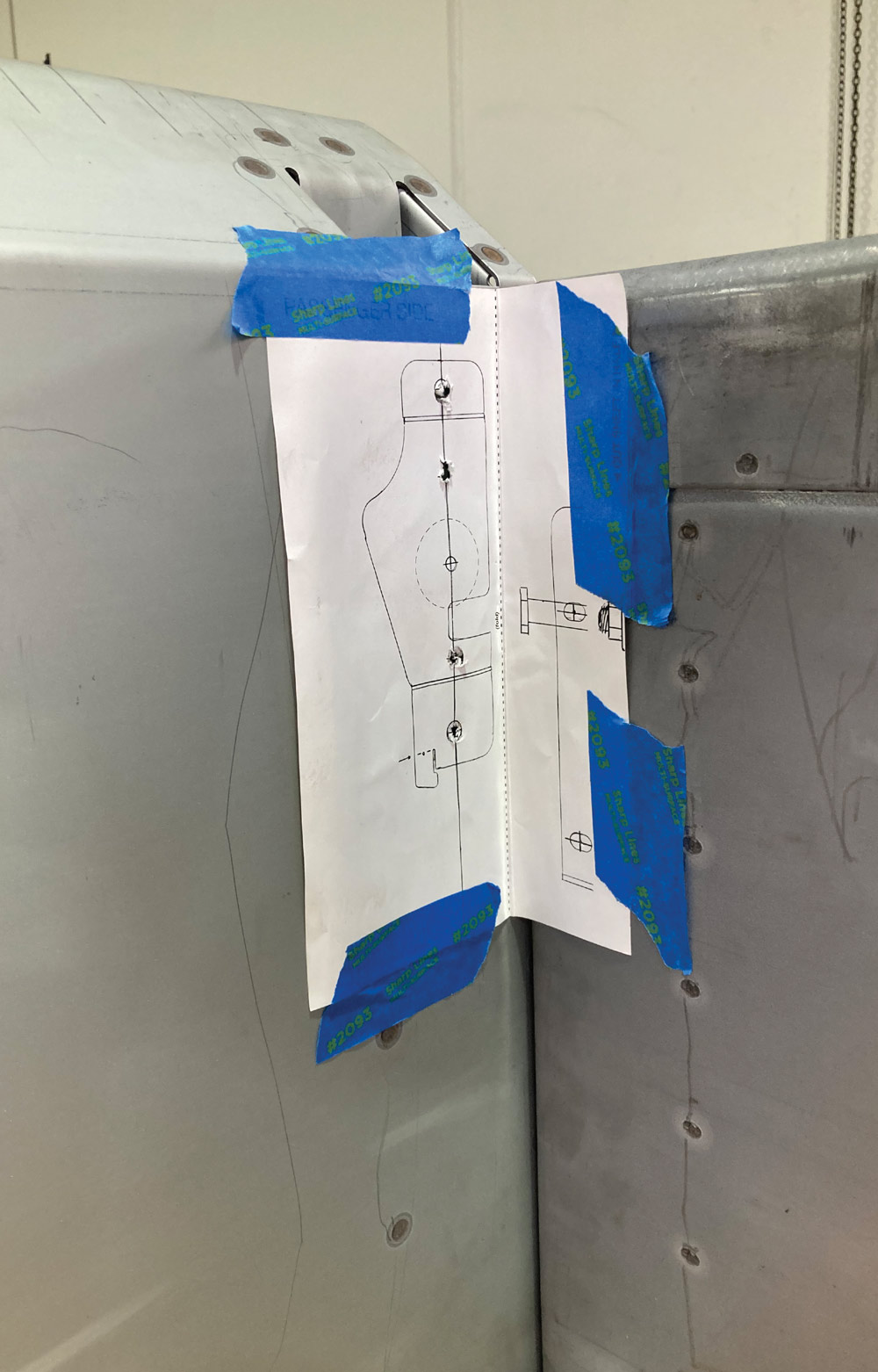

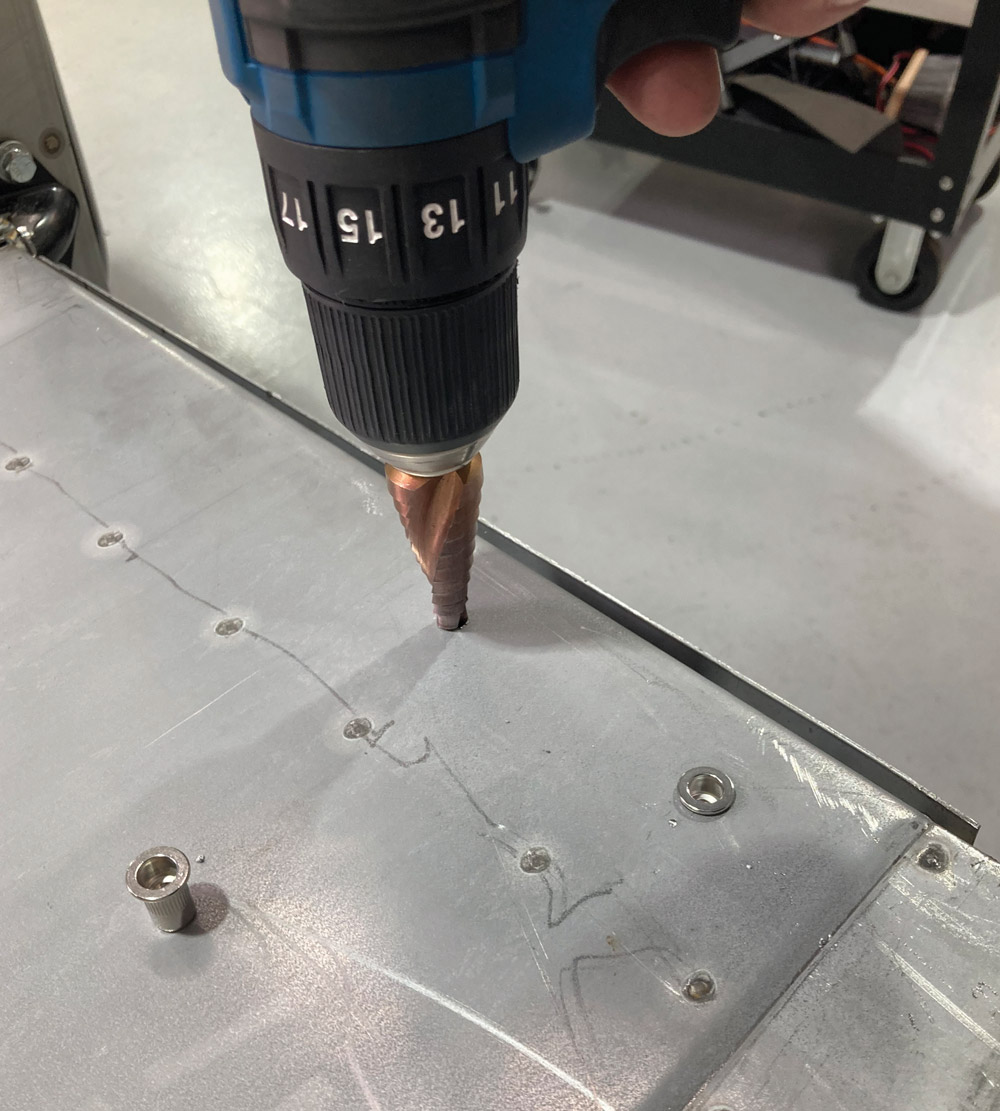

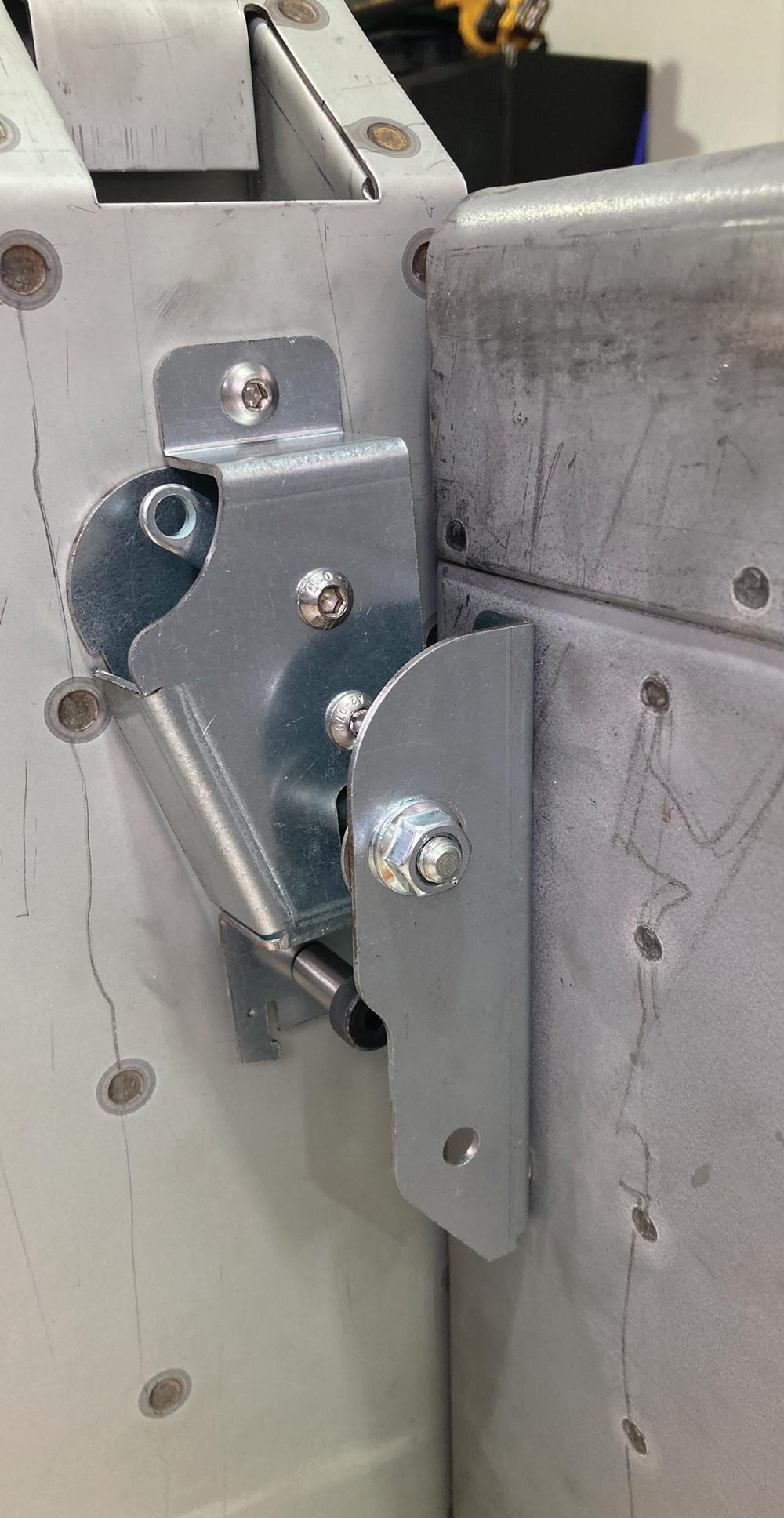

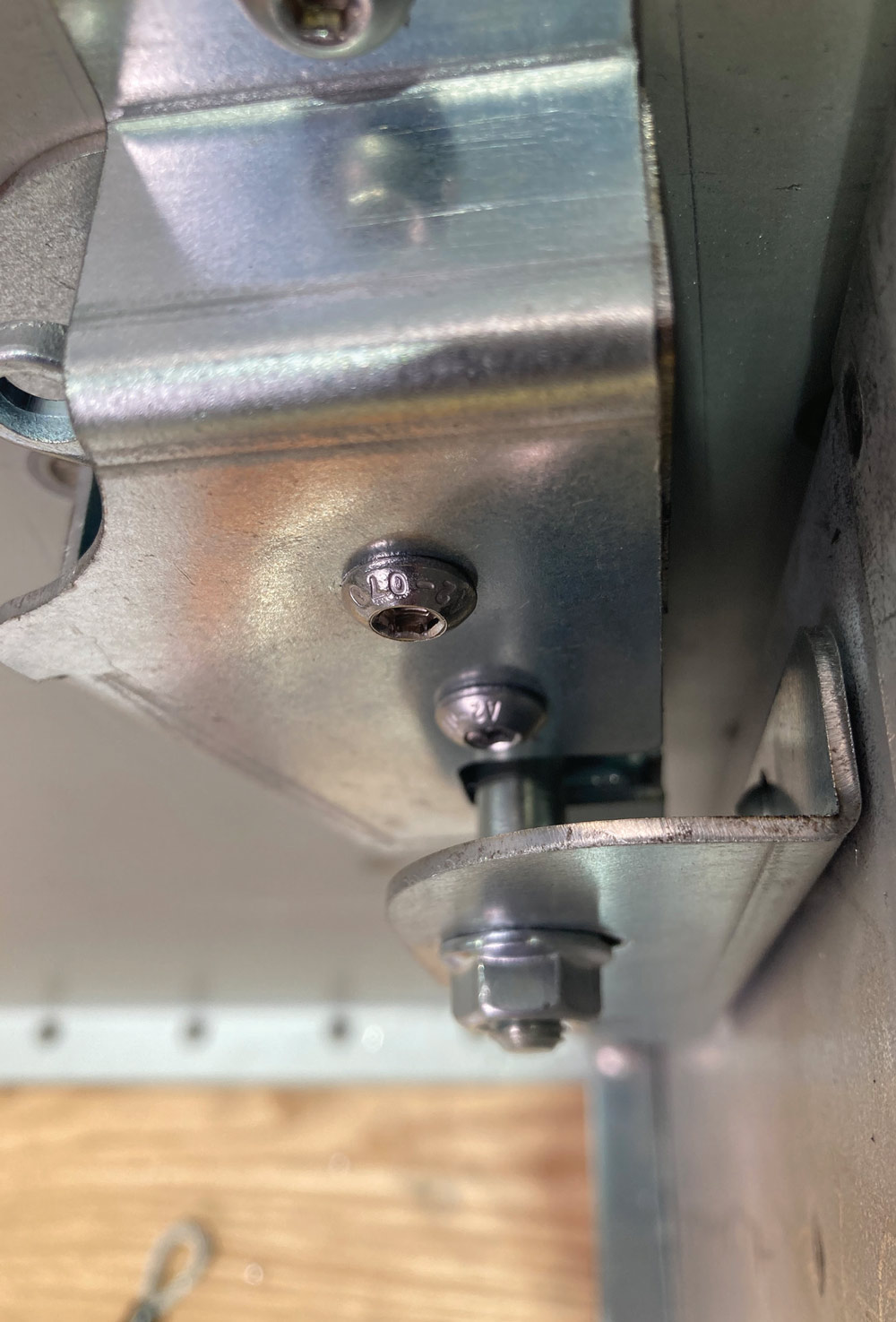

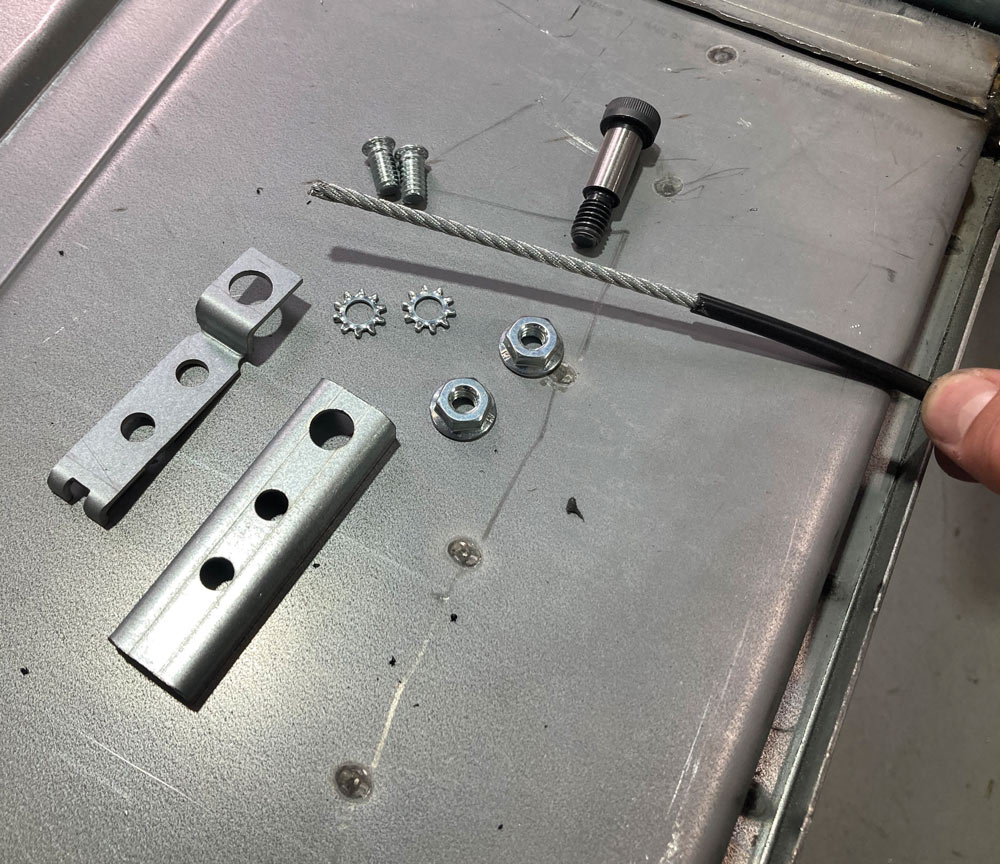

With the attention that these trucks now receive, it only makes sense to pay the same amount to the tailgate area, addressing the chain arrangement and improving an easily improved area. One of the best ways to do so that we’ve seen is by installing a Universal Tailgate Latch Kit from LMC Truck. This kit uses a modern rotary latch and pin to properly secure the tailgate when it’s closed, as well as vinyl-wrapped cables to support the ‘gate when it’s open. What’s better, the kit can be installed on nearly any latchless pickup truck, be it Fleetside or Stepside (that’s Styleside and Flareside to you Ford guys), F-100, Advance Design, Taskforce, F-1, C10, well, you get the picture. The kit can be installed by either bolted or welded methods as well, making installation easy for even the most mechanically challenged among us.

Following the assembly of our F-100 Flareside bed, we took a long look at the tailgate arrangement and agreed that those swingin’ chains weren’t going to be installed, with an LMC Latch Kit taking up their responsibilities instead. With a variety of hand tools we set out installing the kit on our newly assembled bed and in a couple hours’ time we had a tailgate that latched closed with ease and remained secure.

SOURCES

SOURCES