Tech

Tech

And Other Myths Dispelled With a Coilover Kit From Aldan American

Photography BY THE AUTHOR

Photography BY THE AUTHORrucks are utility vehicles. Ask any old-timer chassis engineer from one of the original Detroit Big Three car companies and they will undoubtedly announce that back in the day trucks had one singular purpose: haulin’ stuff! That certainly was the original plan when General Motors’ C10 chassis arrived on the scene starting in 1960. Back then, only farmers really needed trucks, the rest of us were completely happy with big sedans and assorted muscle cars. But the truck market is massive today, with both regular folks who need to “haul stuff” and enthusiasts. We insist that today’s new trucks haul everything from fresh cut wheat to a team of 10-year-old soccer players with ease and comfort.

Obviously classic trucks have had a huge resurgence for a number of reasons, including their low cost; simple, modifiable drivetrains; and cool designs, just to hit the high points. Interestingly, the utilitarian aspect of these classic vehicles has taken a back seat to the fun-to-drive aspects they now deliver (pun intended). But those classic trucks still need a lot of help in the handling department. Enter Aldan American with their advanced coilover conversion system.

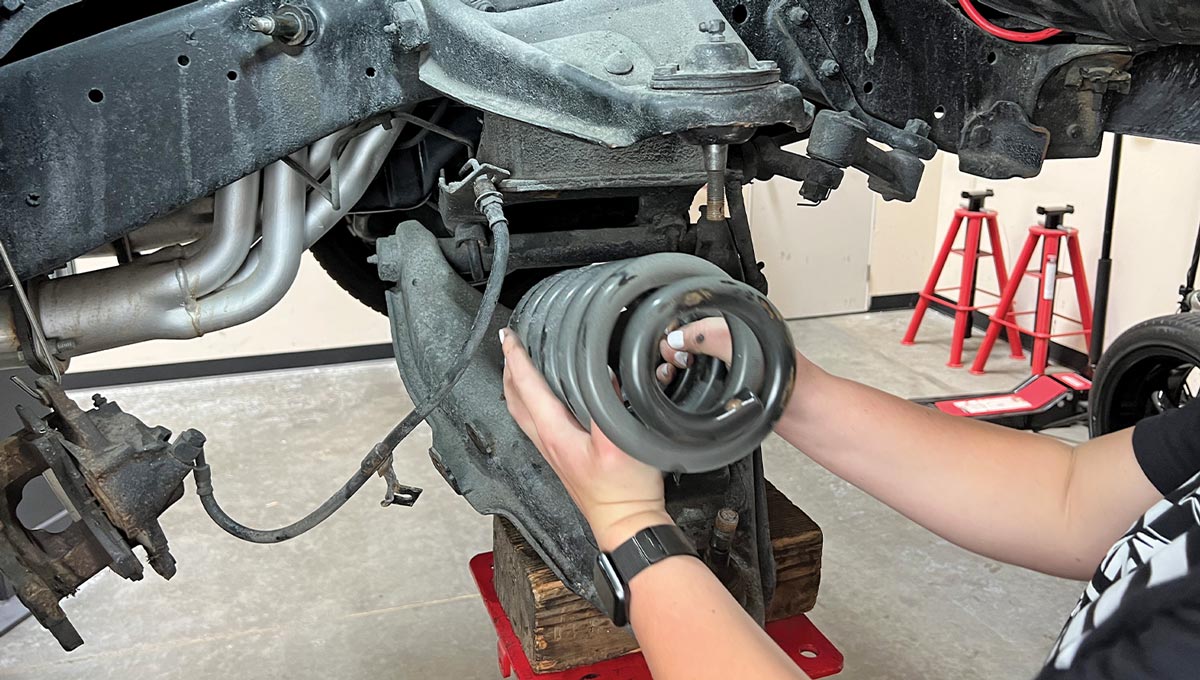

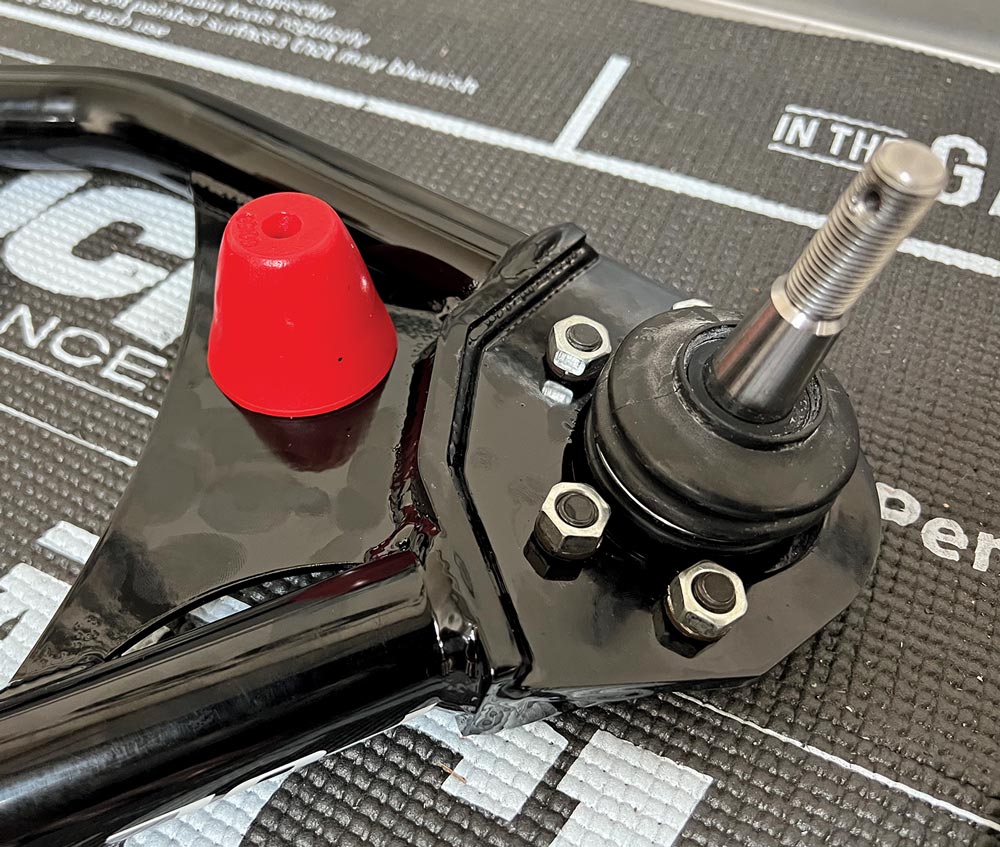

On ’63-87 GM C10 pickups, Aldan American does away with the independent tubular shock and coil spring and creates a coilover unit (coil spring and shock in one) that suspends the vehicle all on its own. The coilover from Aldan American can be tuned with differently rated coil springs (also offered by Aldan American) along with the ability to tune the shock valving by simply turning a knob(s) on the coilover to adjust either the compression (single-adjustable coilover) or compression and rebound (double-adjustable coilover).

Finally, with the Aldan American coilover system you can lower the ride height of the vehicle by as much as 2 inches by turning a billet collar that rides on the threaded shock body (using a special wrench available through Aldan American) that serves as the bottom mount for the coil spring. This adjustment allows you to reduce the calculated roll center of the suspension for greatly improved handling. With the exception of changing the coil spring, these adjustments can be completed without removing the coilover from the vehicle—that’s some pretty incredible versatility that those original GM C10 suspension designers back in the day could never have envisioned.

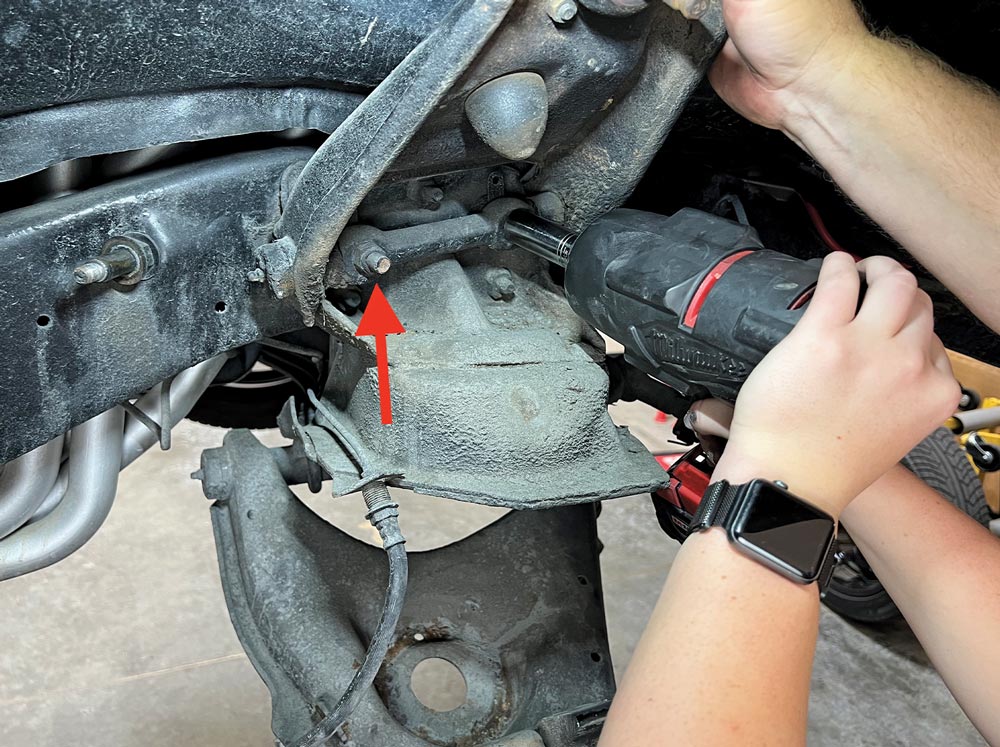

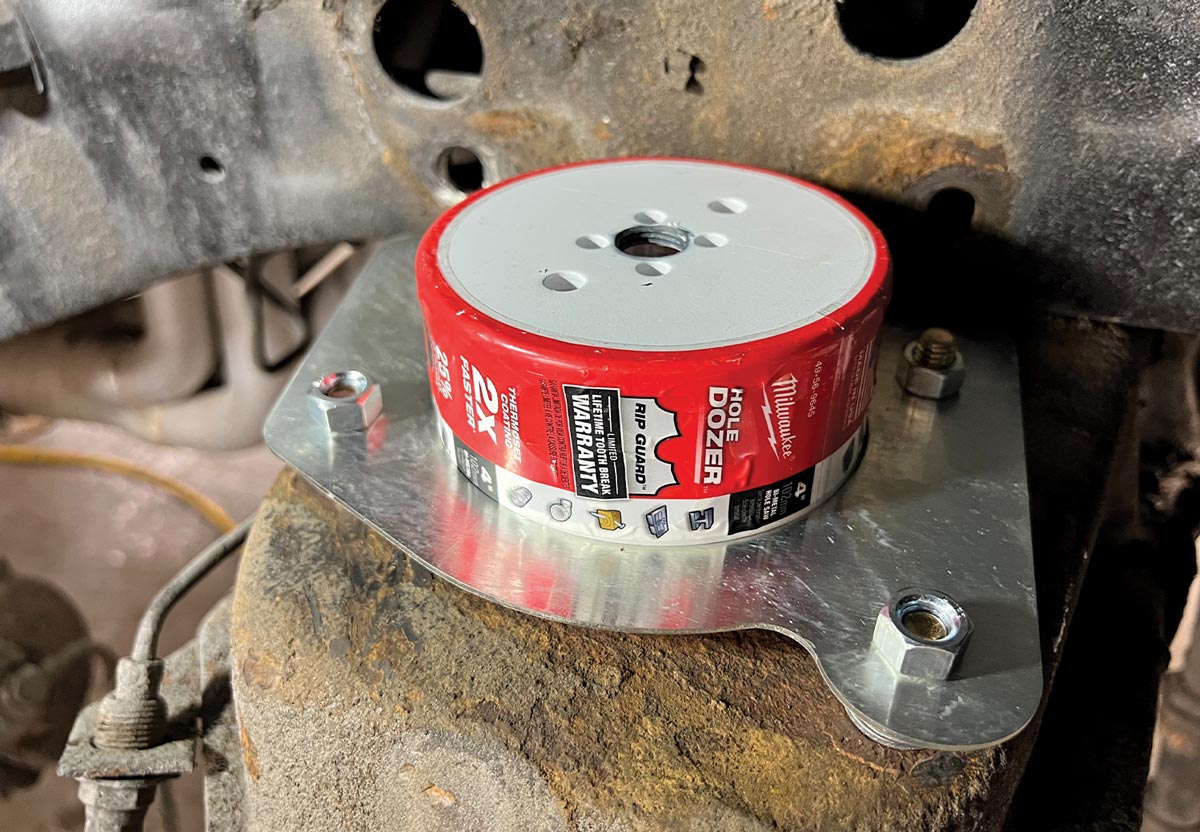

For this upgrade, Kayla’s white nail polished finger darkened significantly during the process. Having never worked on suspensions before, her abilities and the excellent design of the kits we used was on full display. The Aldan American front coilover upgrade can be performed with simple hand tools with one exception: the front suspension of our pickup had to be modified with a hole saw to create a hole in the front crossmember so the coilover can pass through.

Aldan American provides clear instructions throughout. The coilover kit includes a template to help position the saw as you cut through the crossmember. We used a right-angle air drill to spin the hole saw after mounting the ingenious guideplate designed by Aldan American’s Gary Nelson. In the end, the coilover fits up through this plate with no interference and all the handling and ride benefits promised by Aldan American. The kit will mount in the original component locations if you are using standard-mount shocks.

So take a ride in our C10 as we help this truck handle the curves like it originally handled a bale of hay. The conversion to modern handling components is simply amazing and easy to complete.

28. Kayla’s ’69 C10 is a sharp runner with lots of new chassis parts. These upgrades allow for amazing tunability not only for ride quality but also for stance as we can now lower the chassis as much as 2 inches in the front.

SOURCE

SOURCE