Tech

Tech

InTheGarageMedia.com

Photography BY THE AUTHOR

Photography BY THE AUTHORo classic trucks have B-sides? Once they’re sitting down low enough, folks might not ever notice. Even so, those B-sides deserve some attention during a build—even if it’s only to ensure longevity.

This won’t be the first time this ol’ cab has gone underbelly-up. It’s been tilted cowl-to-concrete before back when we toiled to remove unwanted undercoating. This time we’ll be doing just the opposite as we’re aiming to replace the previously brushed-on goo with something more substantial—and far better looking to boot.

To abrasive-blasted steel we’ll apply a protective barrier of epoxy primer. Ordinarily we wouldn’t shoot more than two coats but on the advice of our go-to guru (an auto-paint chemist we occasionally confer with) we’ll make an exception. This time, over a two-day period, we’ll shoot three coats of epoxy primer, which we’ll attempt to illustrate when we get that far along.

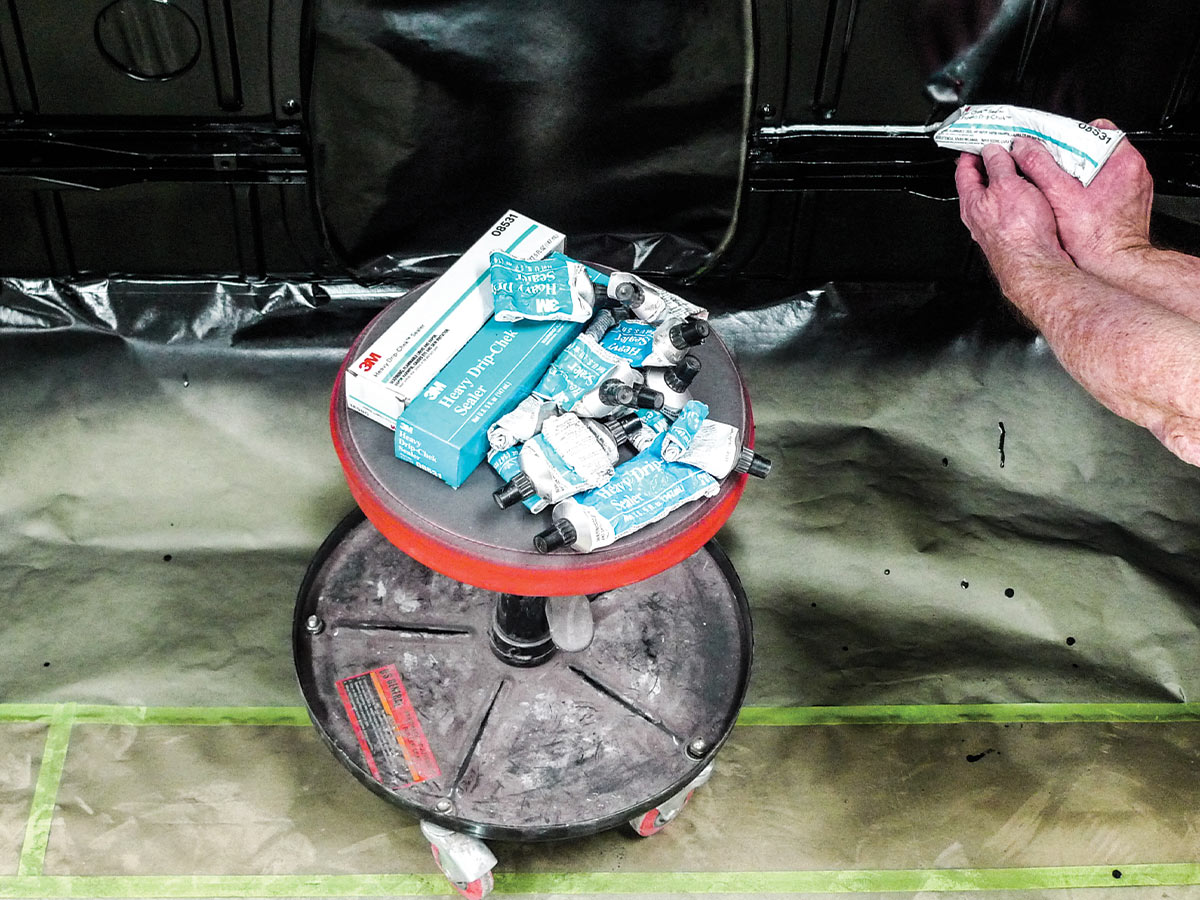

Our preferred epoxy primer can be recoated for up to a week. Once it’s cured enough to touch, we’ll seal any moisture-retentive seams. Then we’re planning to follow that up with a trustworthy rubberized undercoating. It’s nothing new. It’s a product that we’ve worked with since the middle of the ’90s that is still more-than-adequate today.

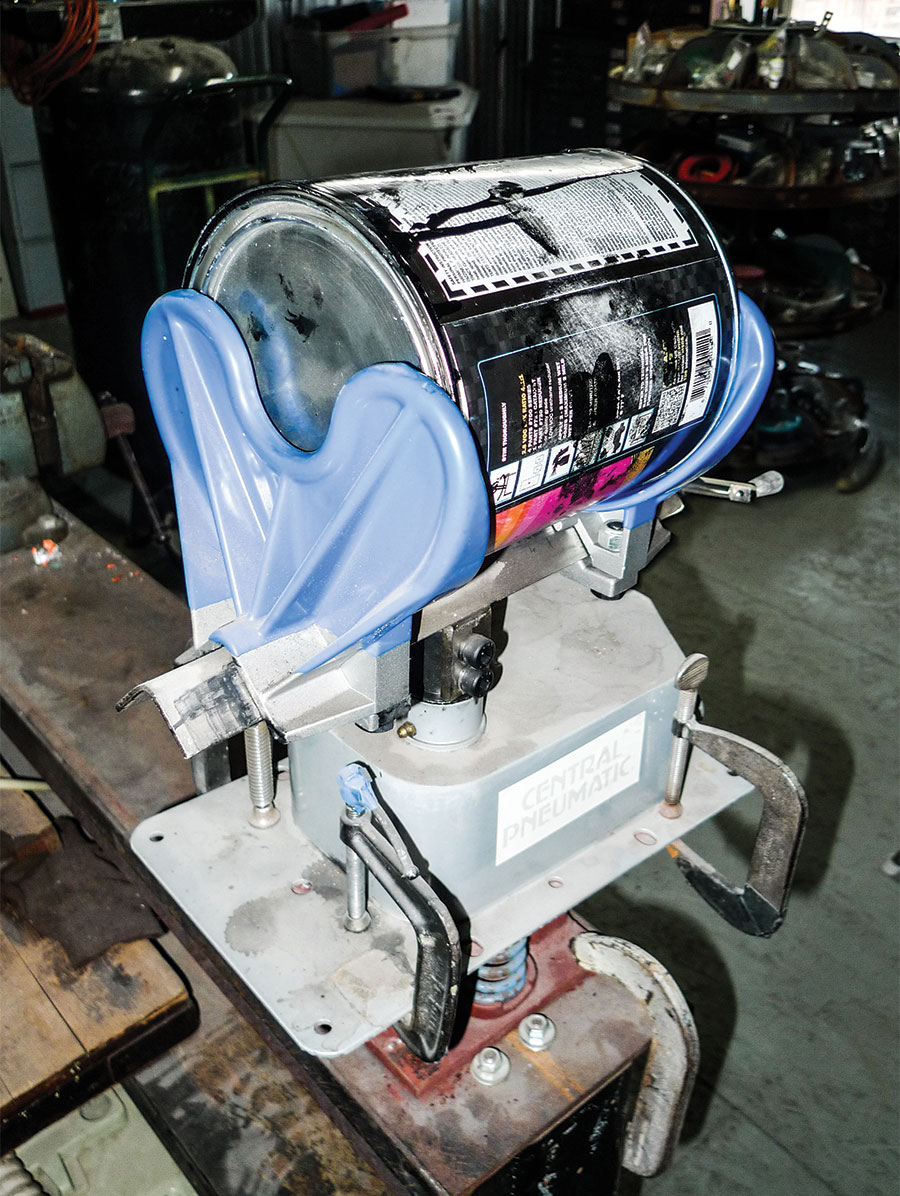

In this shop, our rubberized undercoating of choice is the no-cleanup version of 3M Body Schutz (PN 08964). It’s largely for corrosion protection but it’ll function as a sound-deadener as well. With this system and about a minute of play-around practice, we can dial in and control the texture for that special sort of medium-glump effect that resembles heavy orange peel once painted.

Why paint over 3M Body Schutz? Well, we don’t absolutely have to. As a matter of personal preference, I like to topcoat it with catalyzed urethane. With a slick finish, the undercoating’s outermost pores are sealed for strengthened stain-resistance and easier detailing down the road.

So, to get started, we’ll need padded jackstands, a box of nitrile gloves, and a few extra hands to safely tip this ol’ cab underbelly-up. Apart from a few recognizable items from Harbor Freight Tools, most of what we’ll use here is available from Summit Racing Equipment.

SOURCES

SOURCES