Tech

Tech

Photography by THE AUTHOR

Photography by THE AUTHORremember, back in the day, Volare clips were all the rage for the early F-100s. Matter of fact, there were quite a few “specialists” within a 50-mile radius of where I lived. Today, however, with the advancement of the aftermarket IFS kits, not to mention the wide variety of available aftermarket chassis, it doesn’t make a whole lot of sense resorting to the older torsion bar clips.

That said, there is somewhat of a current trend in clip borrowing for the ’76-up F-100s: the ’03-11 Ford Crown Victoria bolt-in front suspension crossmember. Occasionally, you can spot these a mile away without having to peer under the truck, as the increase track width puts the front wheels at the fender’s edge if the right negative-offset wheel isn’t used. For the most part, however, the cast-aluminum cradle is an easy way to update that old split I-beam front suspension.

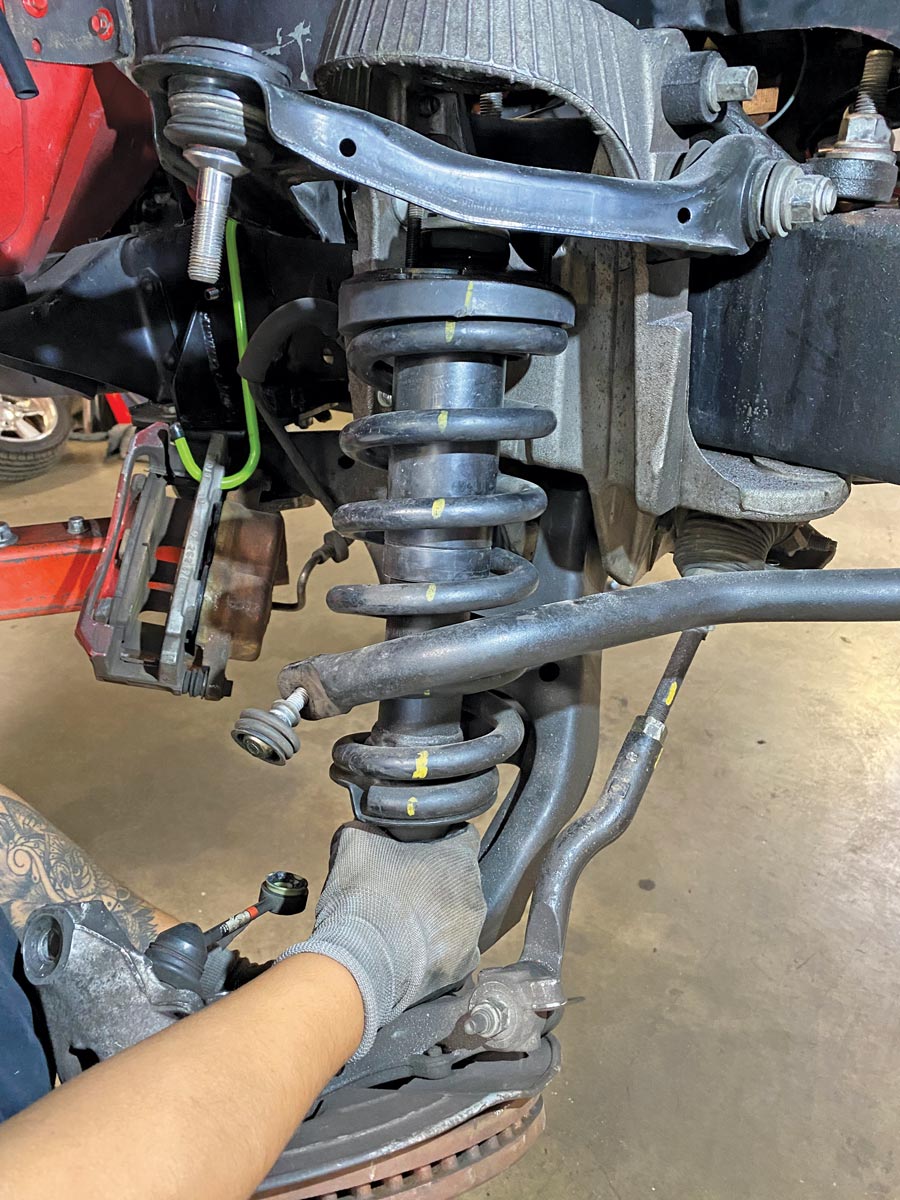

With the late-model clip you get a decent package deal: disc brakes, rack-and-pinion steering, the ability to install a modern engine/trans (including the Coyote) with ease. The only slight drawback other than the track width (which our friends at Fatman Fabrications offer an improved geometry control arm kit for!) is the standard coilover-shock configuration. But there is a cure for that as well—and it’s without a doubt one of the most affordable and easy-to-accomplish upgrades you can do to your Crown Vic–equipped F-100 … and get amazing performance results.

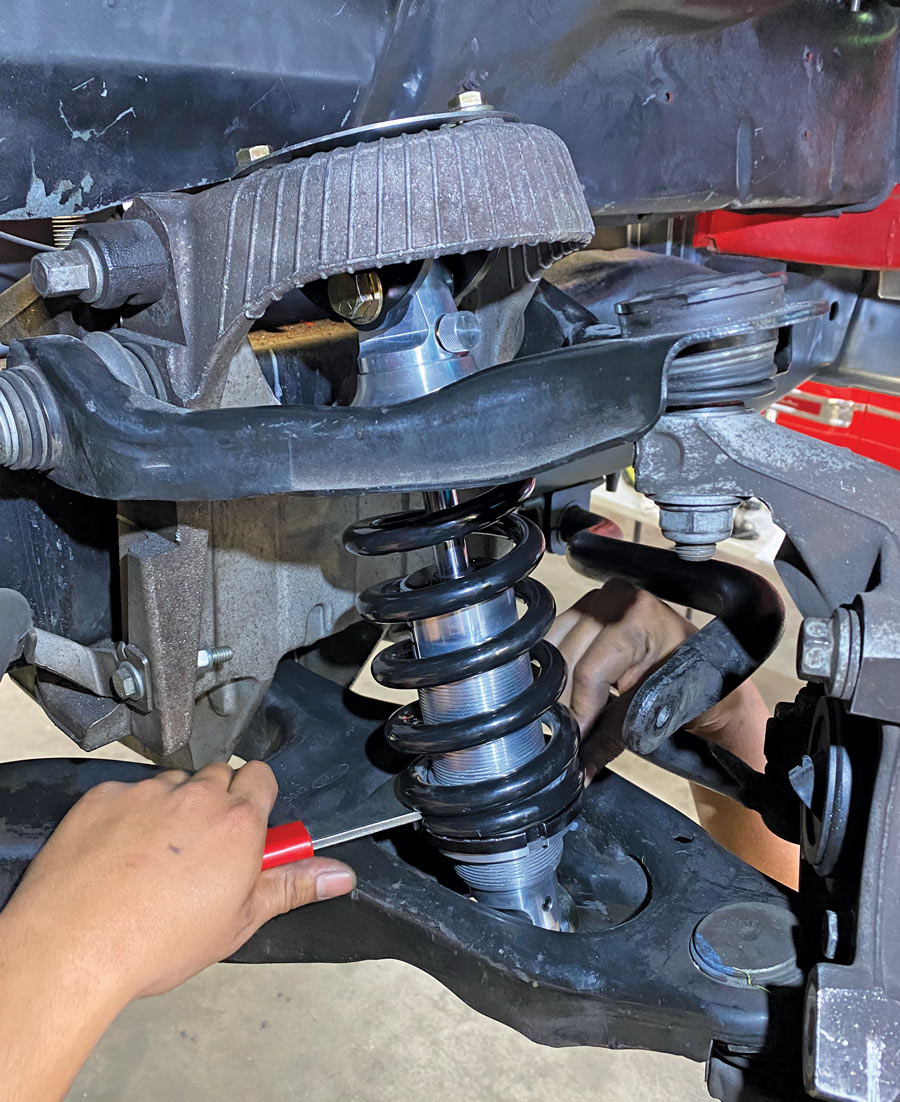

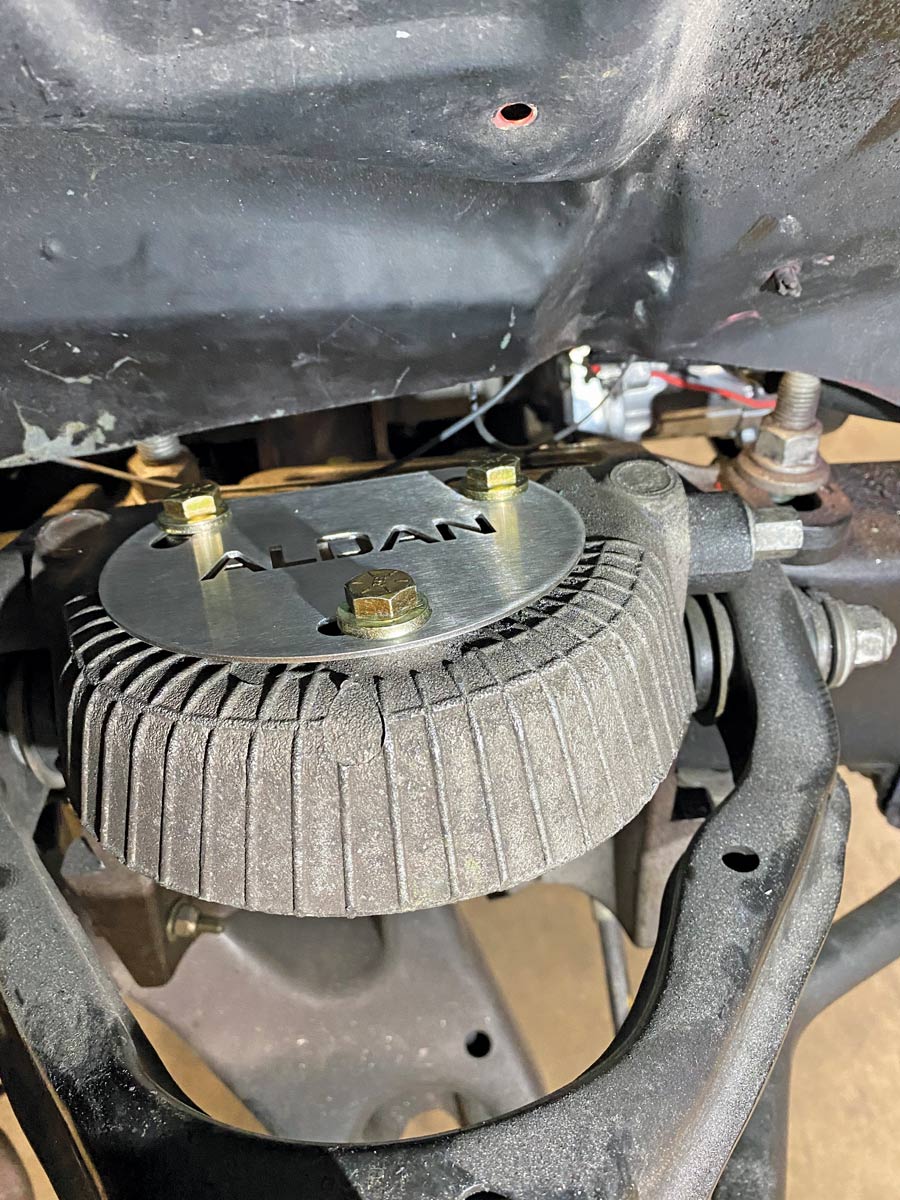

Aldan American now offers that simple solution with their bolt-in coilover kits for the ’03-11 IFS clips. They’re available in three spring rate options depending on your particular engine/trans (550/650/750 pounds) and offer up to a 2-inch lowered ride height (from stock with the OE coils) with a 12-position single-adjustable shock absorber. For well under a grand, you can add that high-performance ride and handling your Bumpside/Dentside deserves—and we’re going to show you just how easy they are to install.

approximately 1 1/2 inches above the first thread. Fine-tuning will be done once the coilover is installed and the frontend fully weighted.