Tech

Tech

BY Rob Fortier

BY Rob Fortier Photography BY The Author

Photography BY The Authorhen initially purchased, our 1969 C10 seemed, for all intents and purposes, as if all it needed to become roadworthy was tightening up a few nuts and bolts here and there. Well, that couldn’t have been further from the truth.

BY Rob Fortier

BY Rob Fortier Photography BY The Author

Photography BY The Authorhen initially purchased, our 1969 C10 seemed, for all intents and purposes, as if all it needed to become roadworthy was tightening up a few nuts and bolts here and there. Well, that couldn’t have been further from the truth.

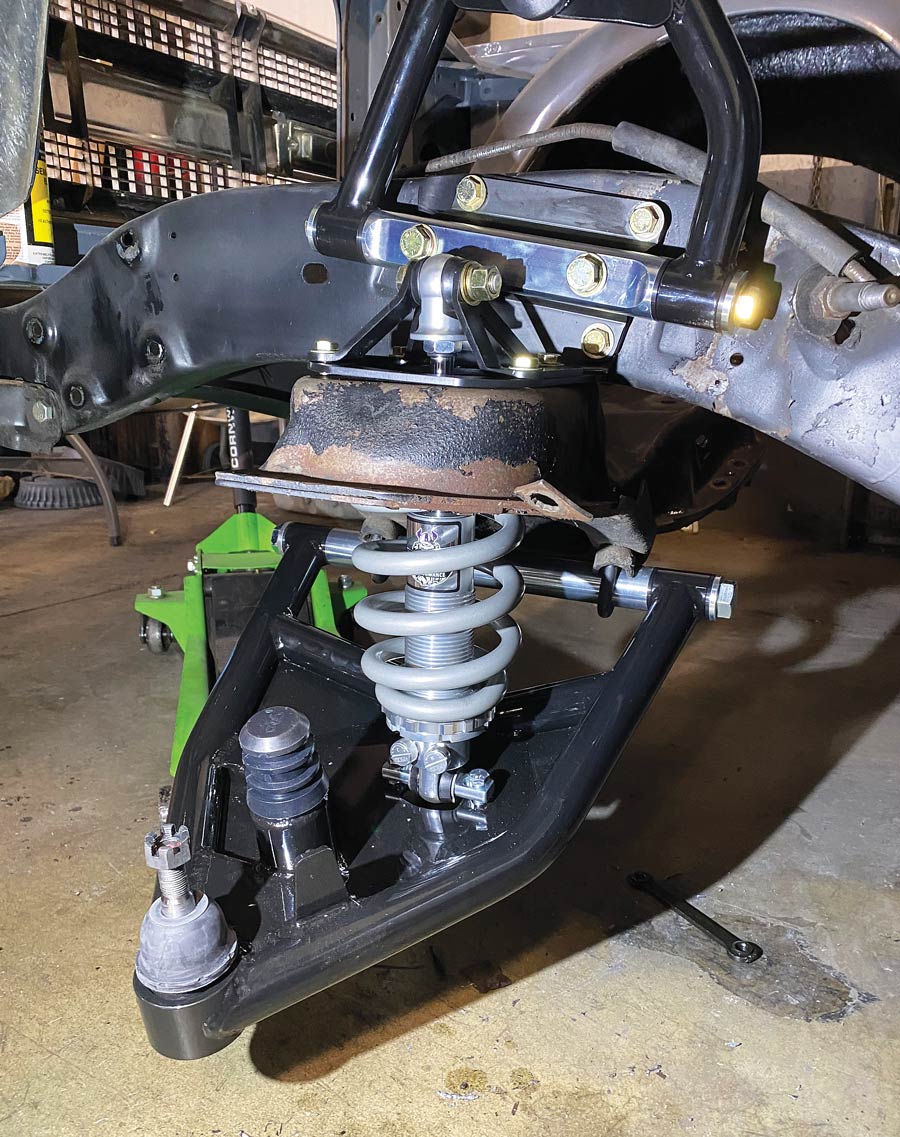

After tossing around a number of possible options to remedy the front suspension situation—including completely swapping out the front crossmember and utilizing a whole new suspension setup—what we initially assumed was an issue with said stock crossmember placement turned out to be the simplest problem to cure: the upper control arms were on backward! That realization led us right back to our first option of upgrading the front suspension using CPP’s Totally Tubular coilover conversion upper and lower control arms … with the correct upper arm placement, of course!

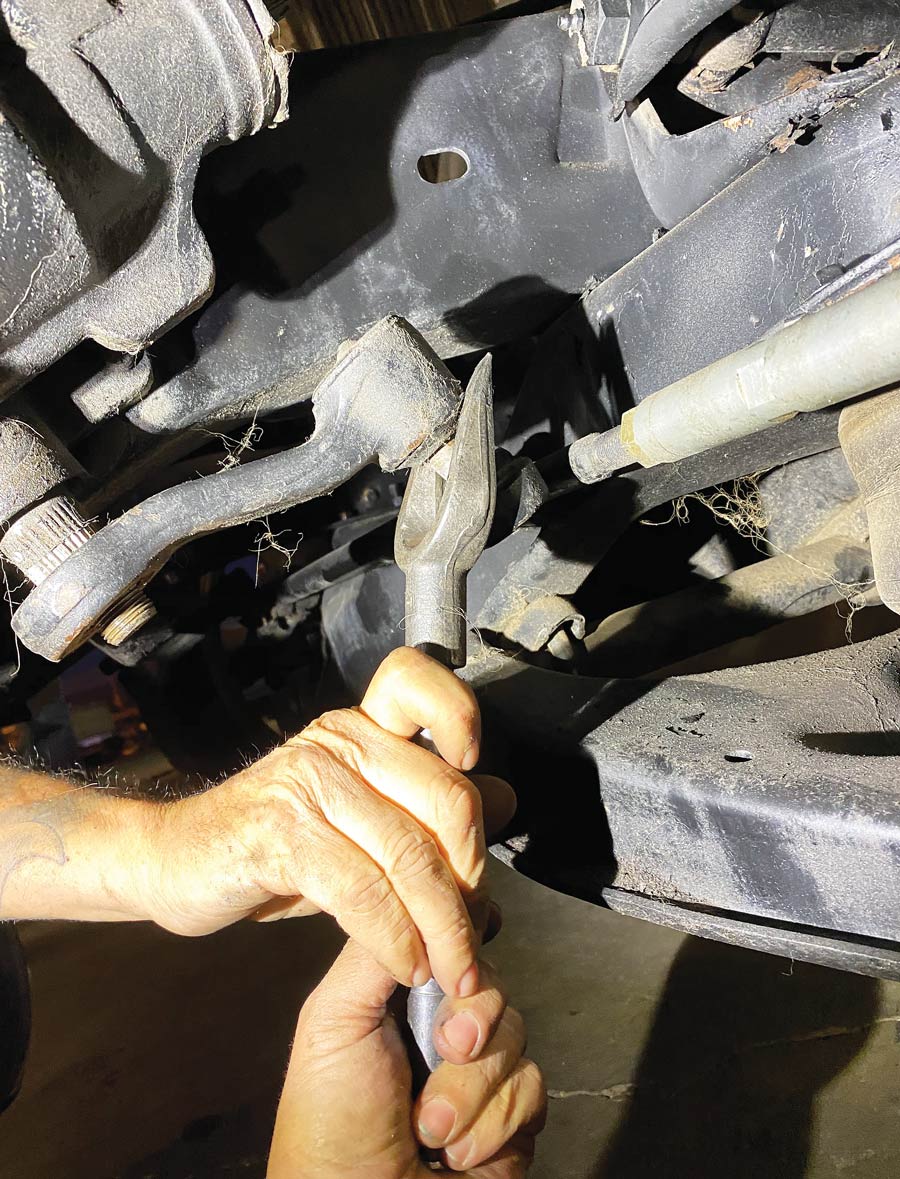

If you’re not familiar with CPP’s 1967-up C10 front coilover conversion kit, let’s take a minute to fill you in. First off, it’s the only of its kind on the market that retains the factory crossmember that provides the user with an “inboard” coilover—one with a full-travel shock absorber rather than an extremely compromised short-throw damper. To accomplish this, not only does the riveted factory upper control arm mount require removal, the upper coil hat portion of the underlying crossmember (beneath where the old control arm mount was riveted) must be relieved of 4-1/2 inches in diameter for the new coilover. Typically, this can be achieved with a bi-metal holesaw of that size, however the use of a decent-powered plasma cutter (as we will show) greatly eases and speeds up the process.

To address the worn-out factory steering components, we once again relied on CPP—this time for their 500 Series power steering box and complete steering linkage kit. Leading up into the cab, we’ll be using a Flaming River non-shift tilt column along with their repop Corvette-style flat three-spoke steering wheel. Since the suspension portion of this rehab treatment is rather lengthy and involved, we’re going to save that for next month so as not to skimp out on any important aspects! For now, let’s get this C10 back down on all fours appropriately!

SOURCES

SOURCES