Underpinnings

Underpinnings

Kyle Tucker, president of Detroit Speed, has loved race cars since elementary school. That passion led to a degree in mechanical engineering and a job working at the GM proving grounds. Tucker worked initially as a test engineer gathering data acquisition on the Corvette program and later in suspension development. Then, in 2001, the corporate world was left behind and the doors of Detroit Speed were opened. As you might guess from the name, it all started in Detroit. What may not be so obvious is those doors that opened were on a two-car garage. However, it didn’t take long for the business to gain a reputation for offering the finest high-performance suspension components and as a result today Detroit Speed is housed in a 40,000-square-foot facility in Mooresville, North Carolina. It’s in this new facilty that Detroit Speed’s suspension systems are designed by highly qualified engineers and built by fabricators using state-of-the-art manufacturing technologies.

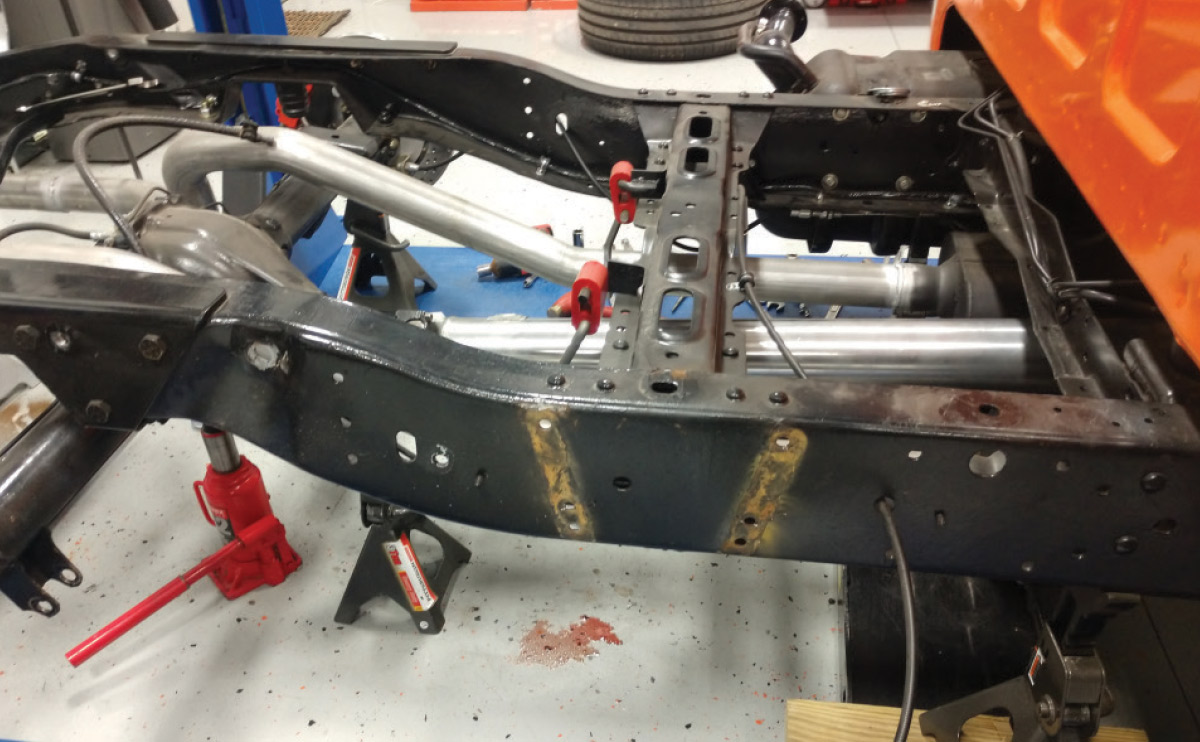

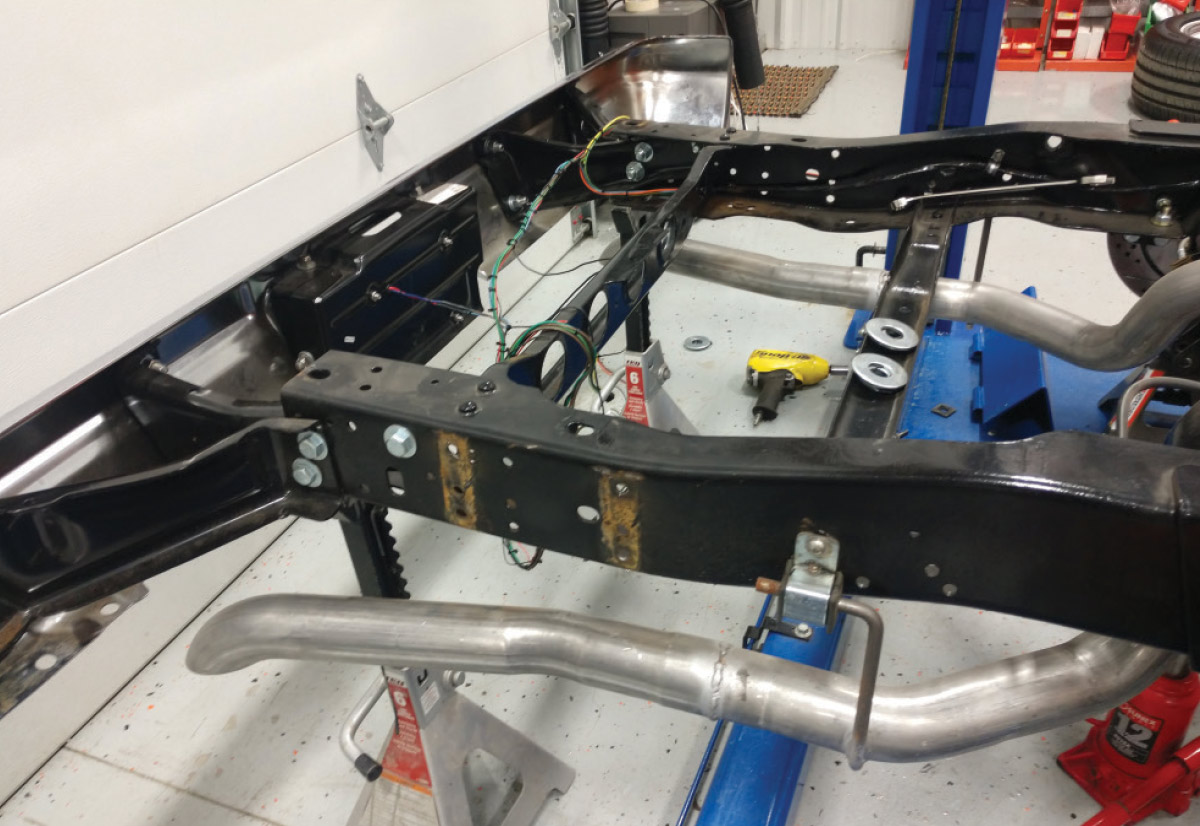

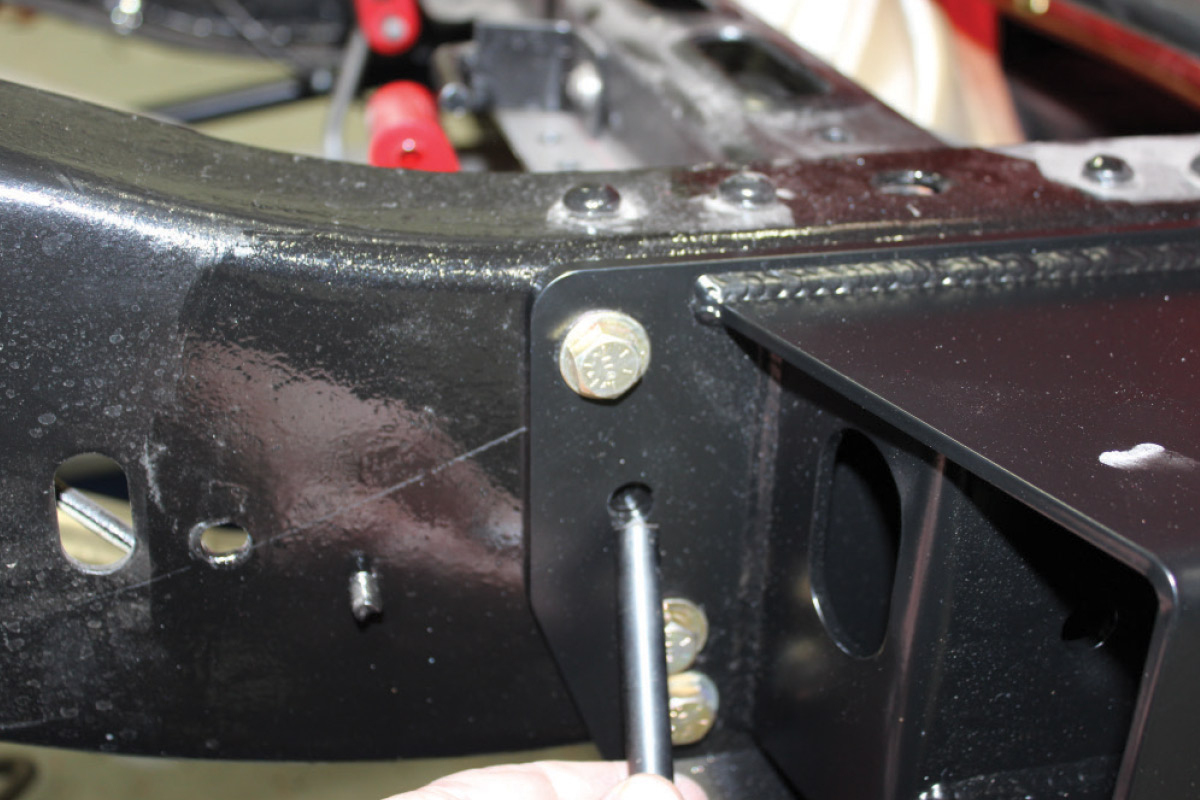

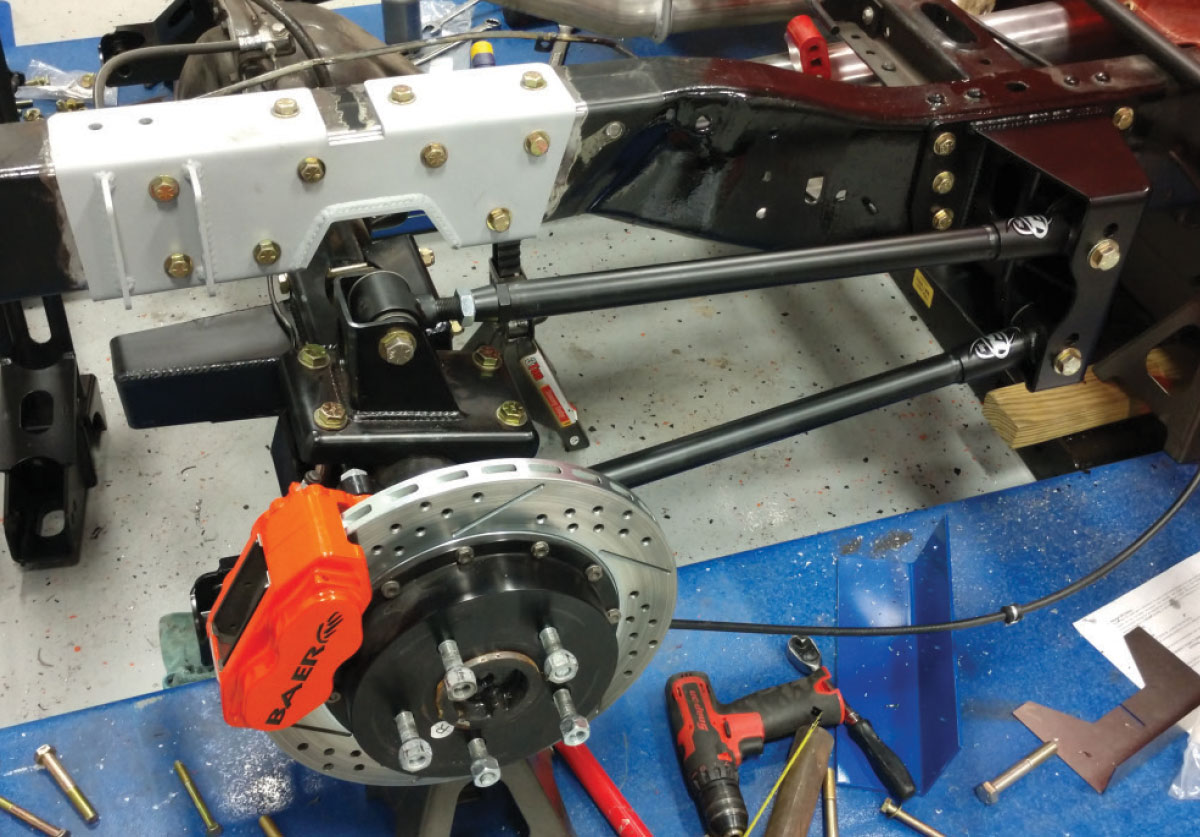

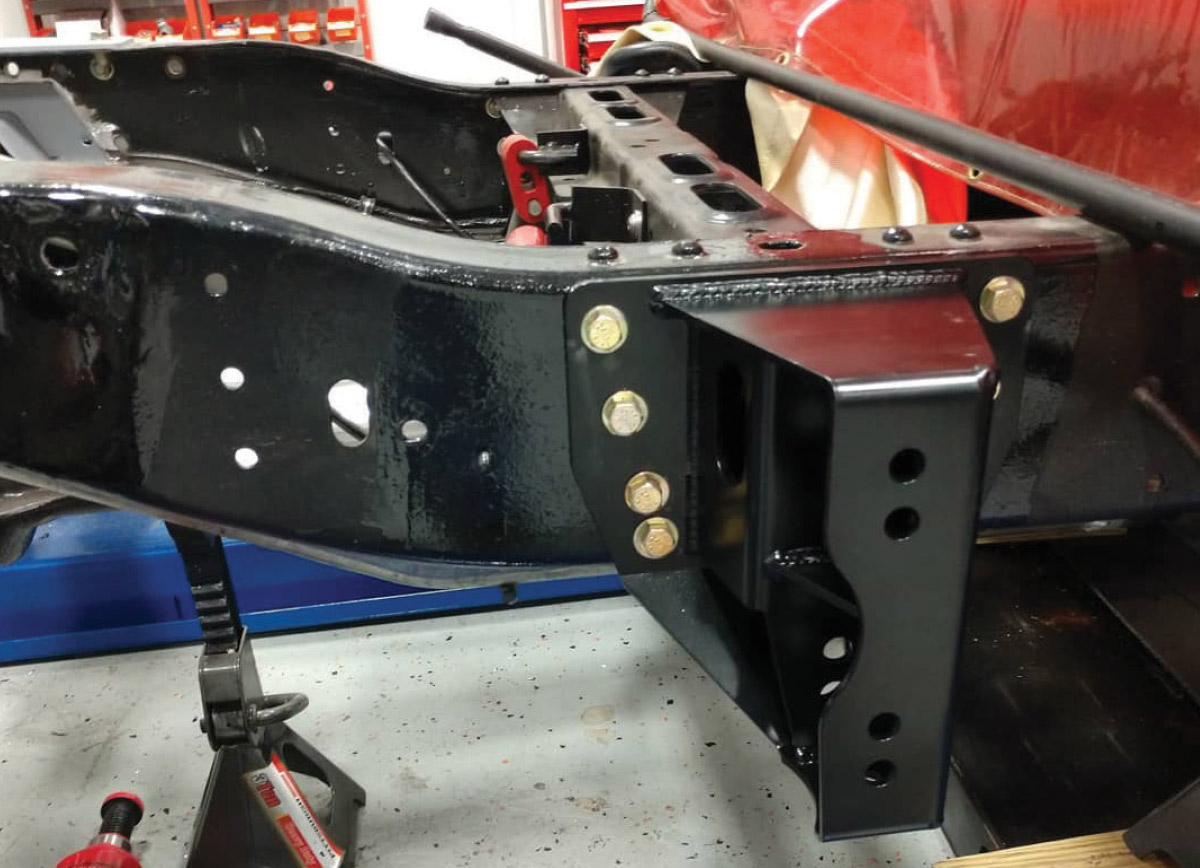

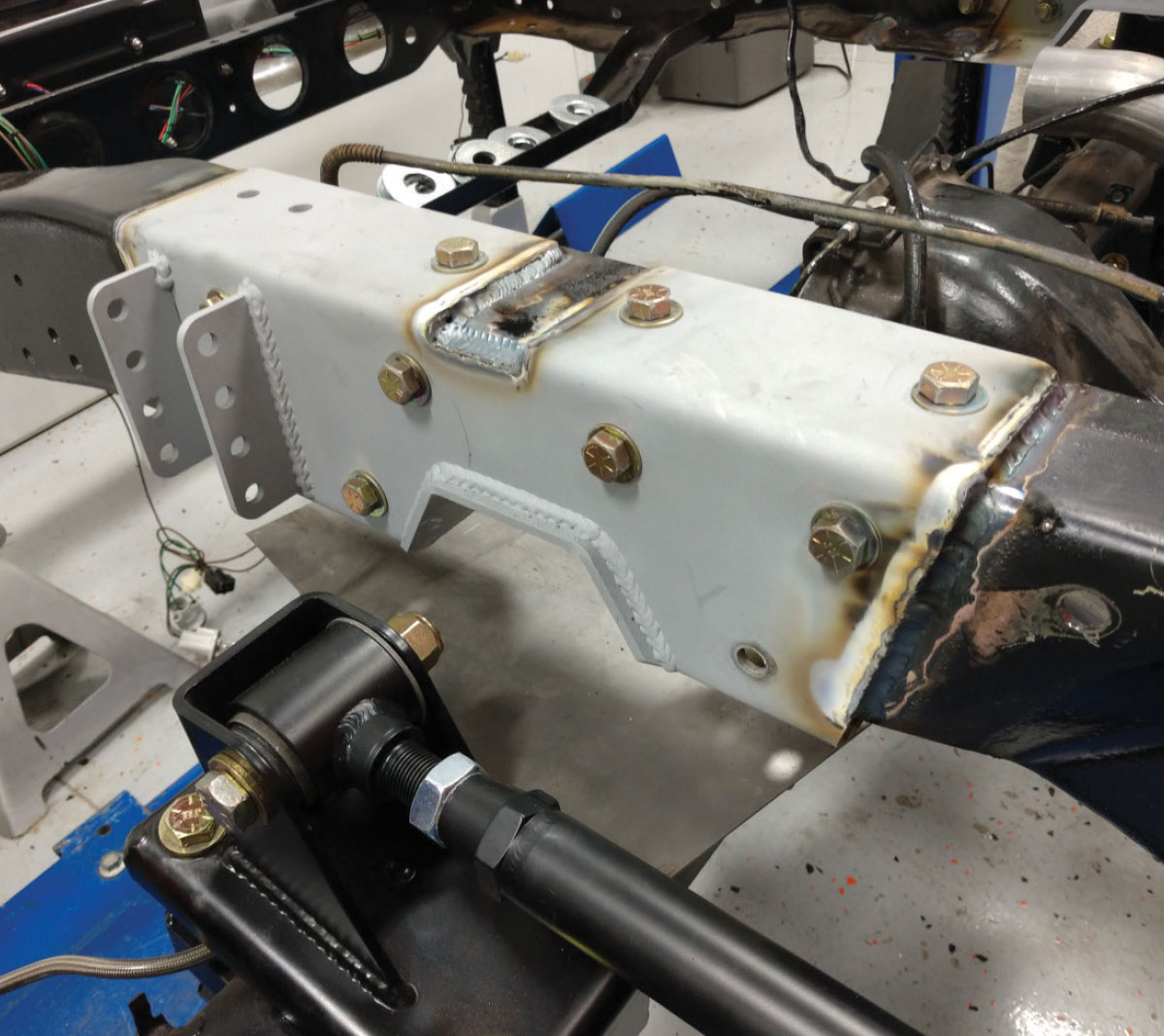

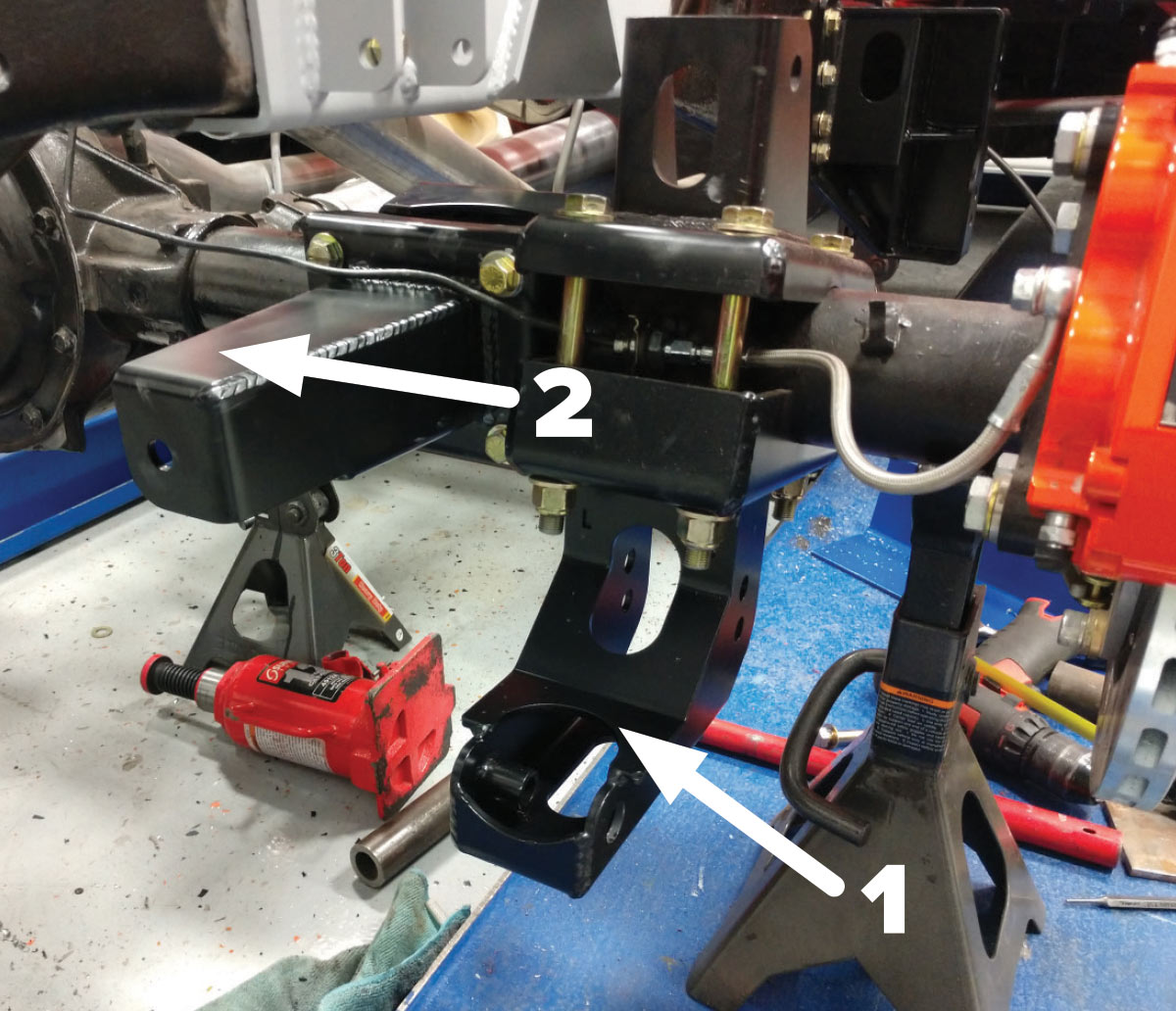

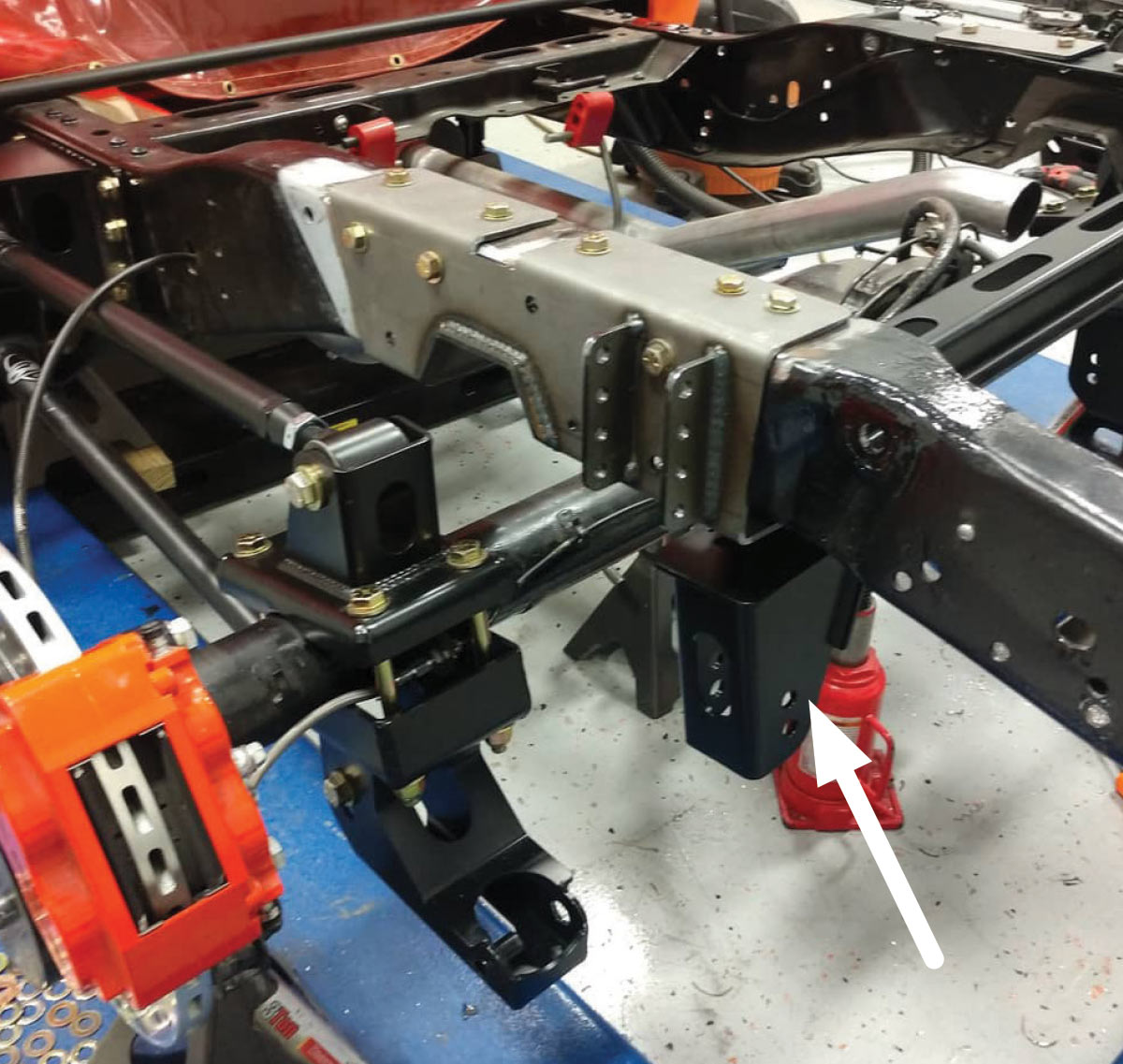

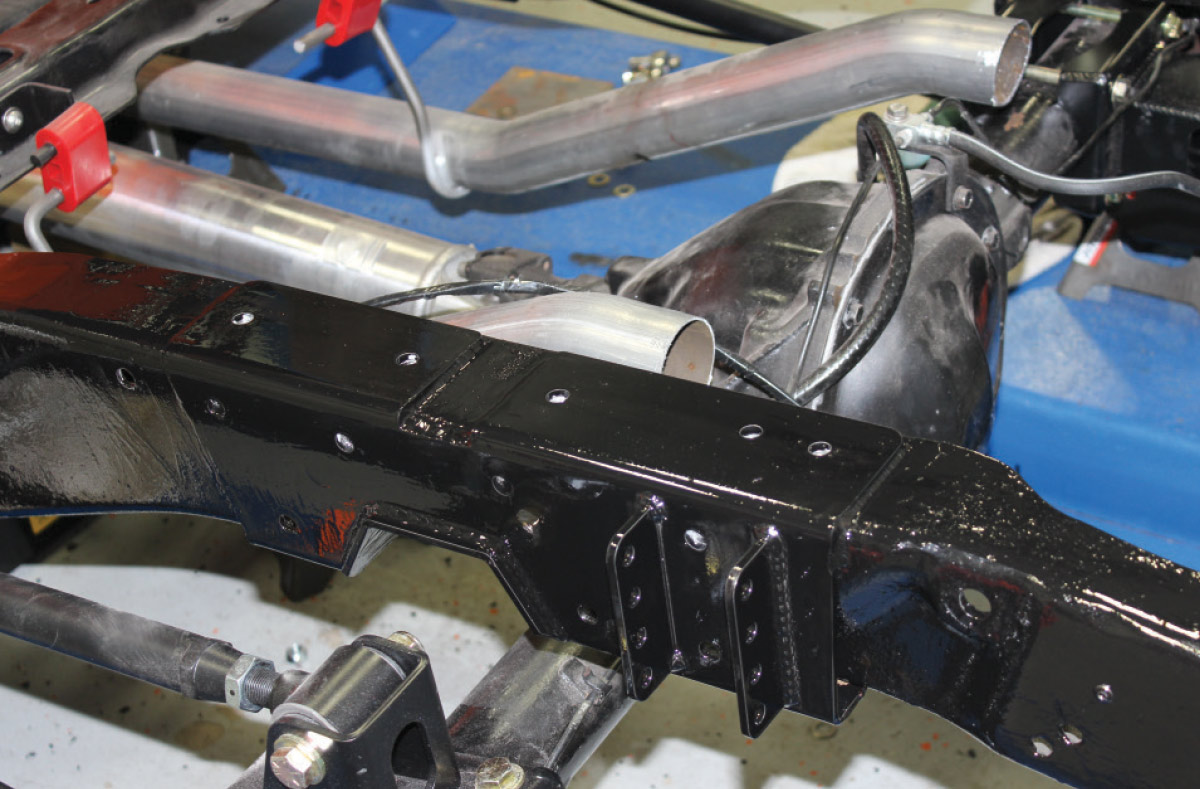

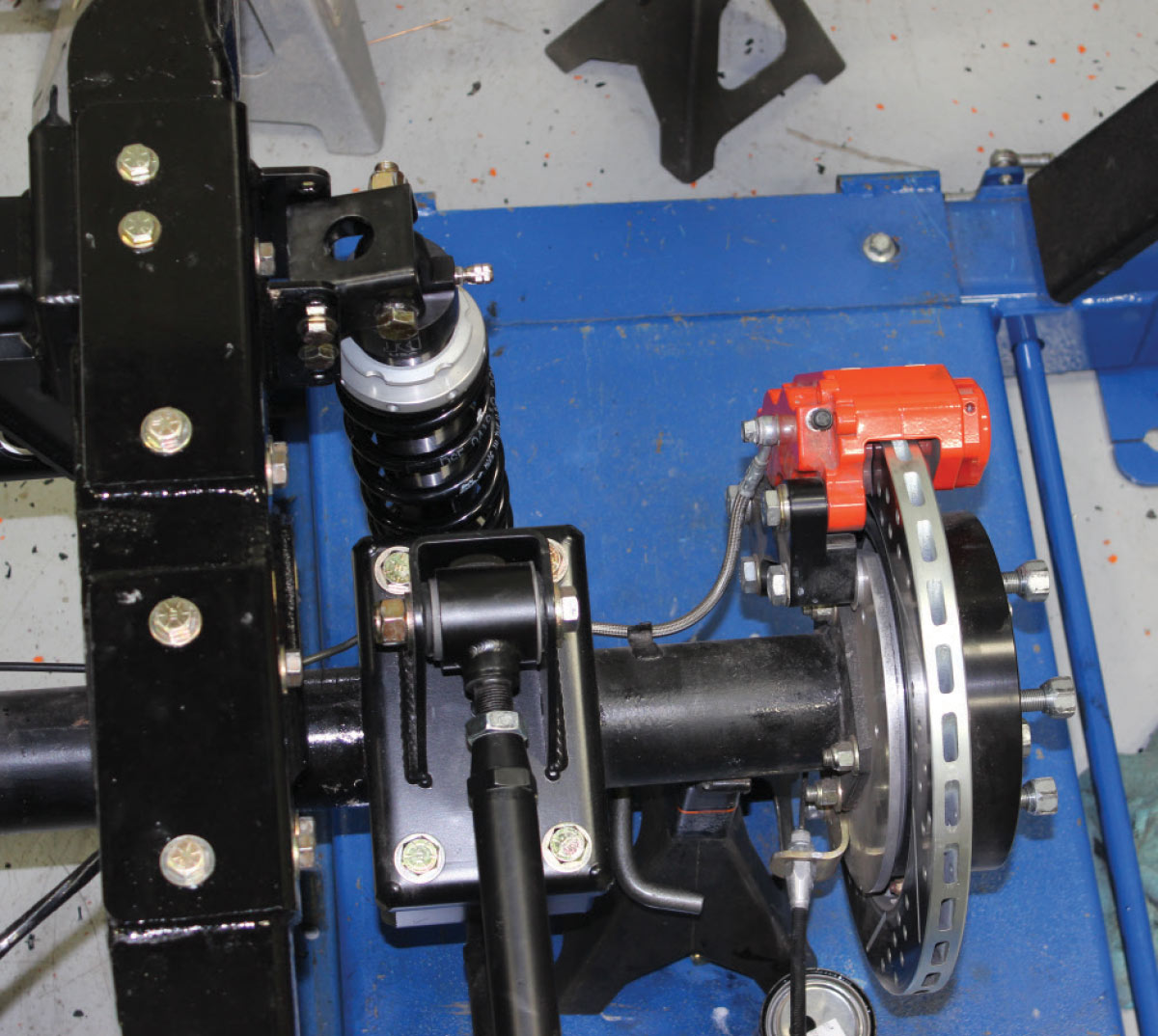

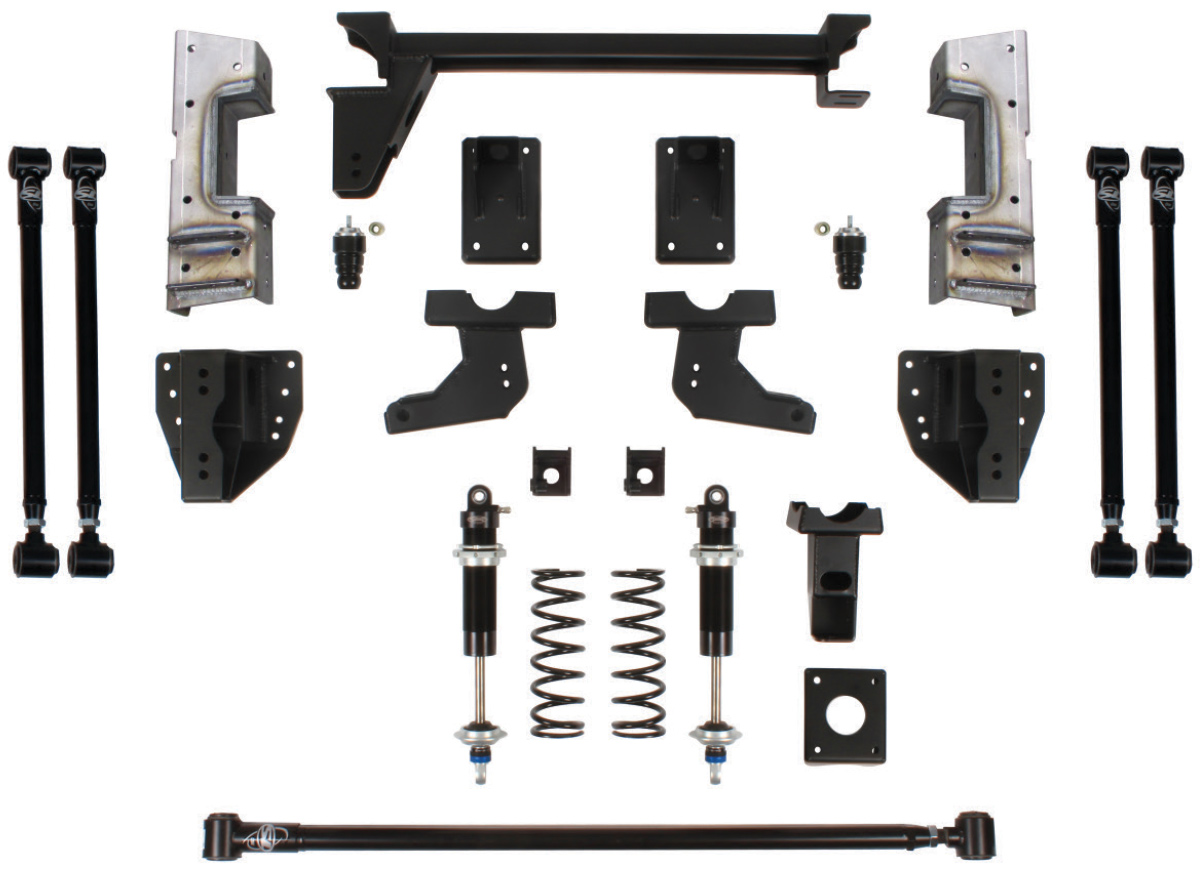

Detroit Speed’s QUADRALink system offers a long list of advantages, including a better ride and adjustable upper shock mounts to alter ride height and noticeably improved handling. Check out the following photos to see what it takes to provide your Square Body with the ultimate underpinnings.