The three generations of C10s can be credited, along with the Advance Design (1947 to 1955) for initiating the classic truck market as we know it today. Of the two, it can be said that the C10 really put the classic truck segment of the hot rod market on the map. Now we have the Square Body, OBS, along with other manufacturers, such as Ford, solidifying the classic truck market with popular models from within their marque.

Hot Rods by Dean has built many classic trucks, all makes, but the latest may prove to be a “bar setter” coming from their workbench in the form of a 1972 Chevy C10 featuring loads of body mods—the good ones—as well as the latest in chassis and powertrain performance.

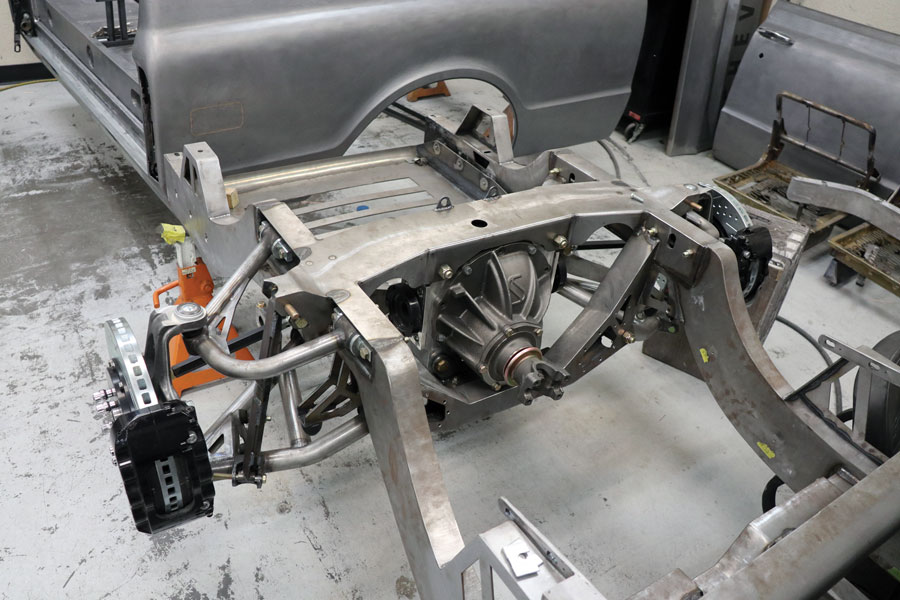

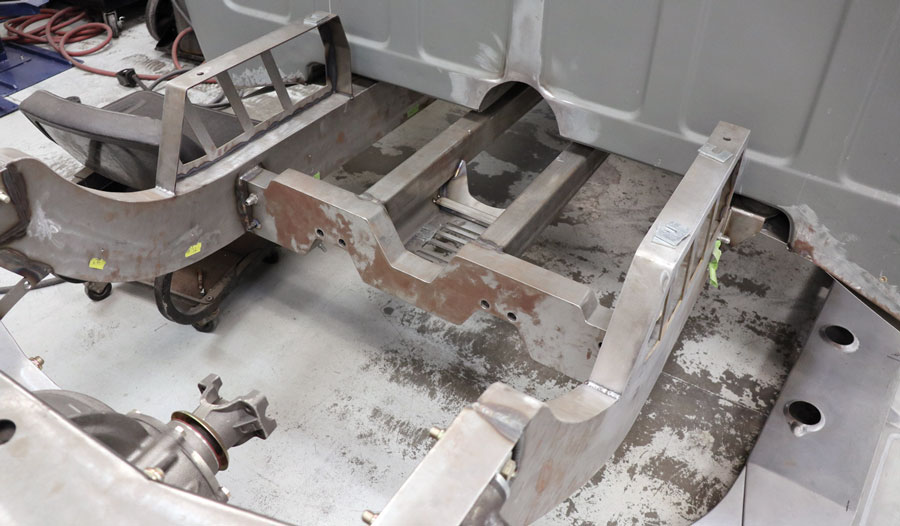

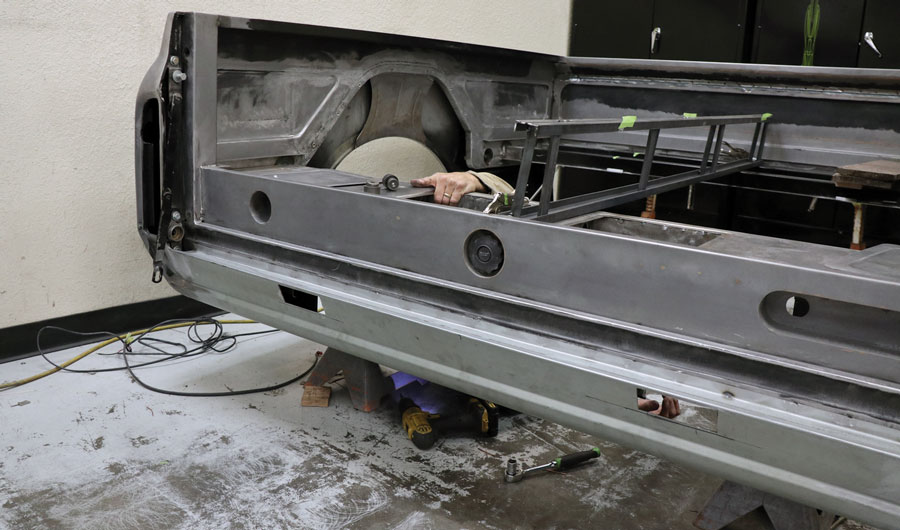

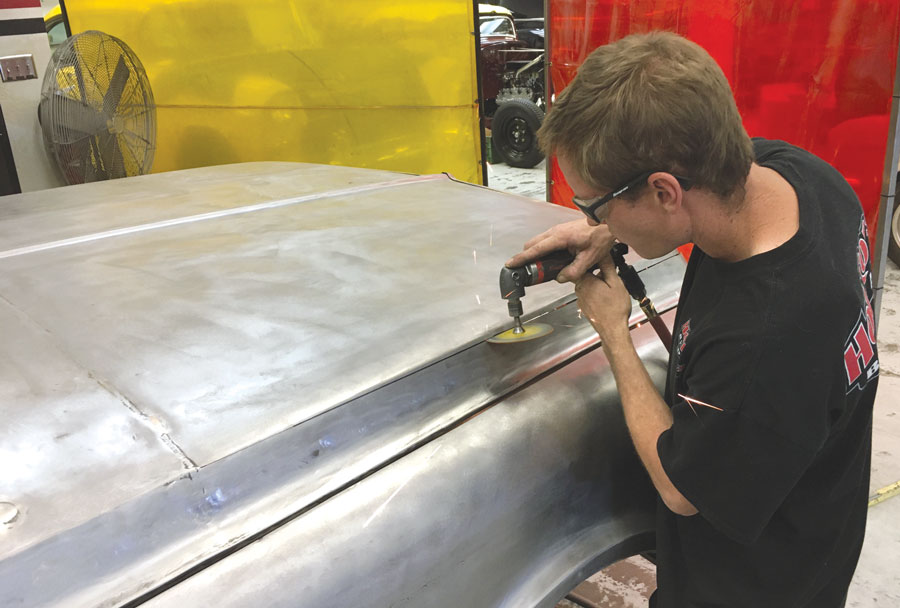

As you will see looking at the photos, this 1972 C10 is about halfway through the fabrication phase with a long way still to go. So now is the time for an up close and personal look to see what’s beneath. We asked Dean Livermore, chief wrench at HRBD, who would be tackling this latest build. Turns out, Ron McCorkle and Geoff Jones are charged with handling the fabrication and problem solving before body and paintwork process starts at HRBD.

The truck belongs to a customer who lives in Washington. He is no stranger to hot rods of all kinds and when he came to Livermore, he made it clear that this C10 was to be a “top end” build.

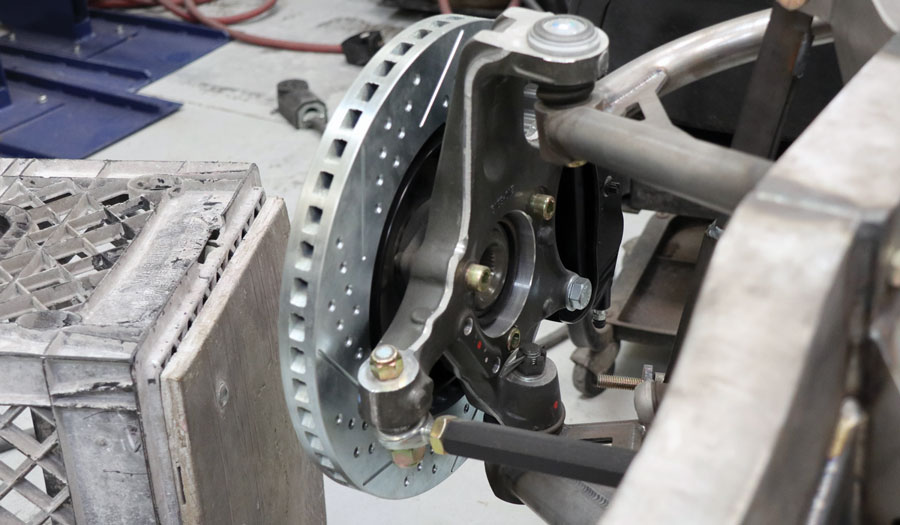

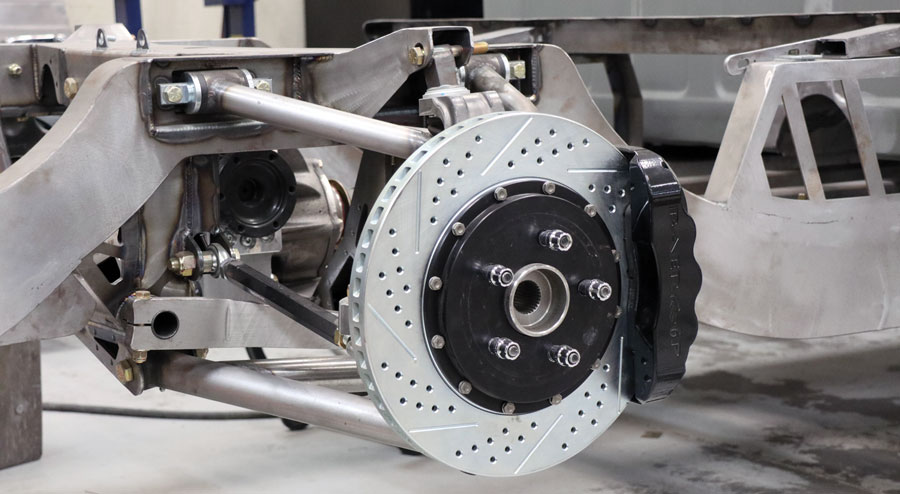

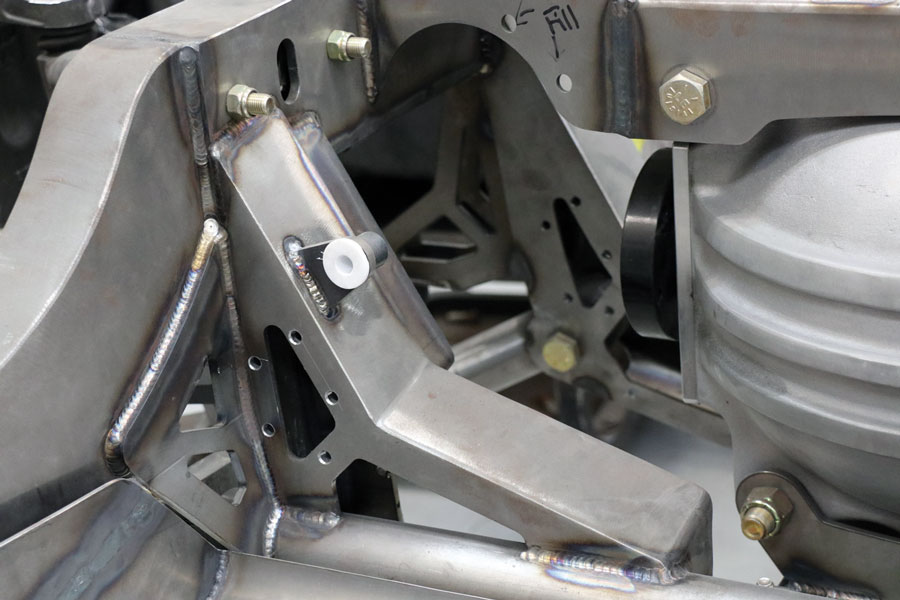

The 1972 C10 is based on a Roadster Shop Fast Track chassis plus a few optional concessions. The FT chassis (10-gauge boxed streel frame) with a front track width of 58-3/4 inches is designed around the Corvette’s C6 spindles, hubs, and ball joints allowing for the latest in braking and handling as well as street and track capabilities. Providing for the migration between street and track are the built-in caster and camber settings. The upper and lower control arms are RS proprietary and are designed and engineered from 4041 pre-hardened steel with adjustable upper and lower control arm mounts, heavy-duty splined sway bars, and billet aluminum steering arms. Included (but not shown in the photos) are Penske RS coilovers, while Baer six-piston calipers and rotors work with the C6 hubs at all four corners. Operating the brakes will be a CPP HydraStop hydraulic assist system manipulated by a Kugel Komponents swing pedal with Lokar brake and throttle pads. The chassis will roll around on a set of polished Schott Mod 5 d.concave Cover-Loc (18×10 and 20×12) wheels each wrapped in Michelin Pilot Super Sport rubber measuring 275/40R18 and 345/30R20—talk about getting enough rubber to the road! Additionally, the chassis provides for all the stock body and bumper mounts as well as the stock core support locations.

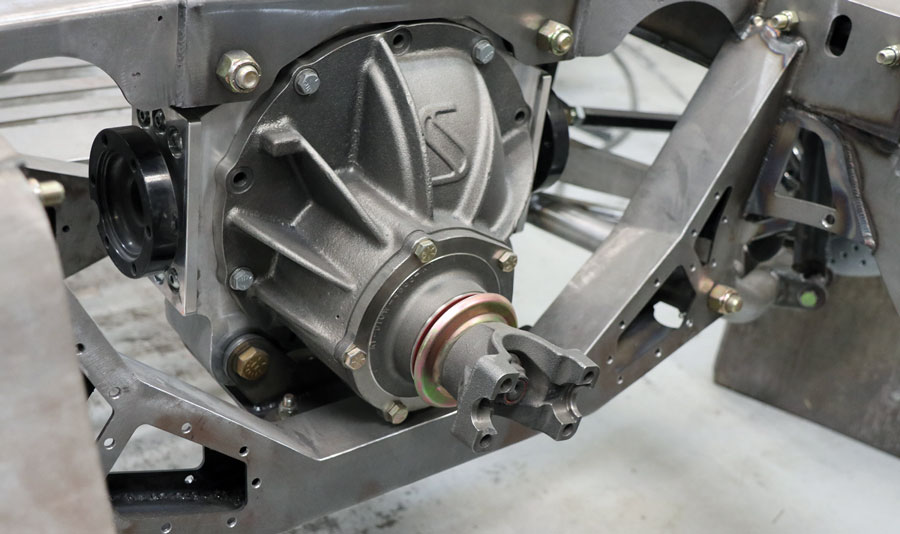

The RS fabricated center crossmember and mid-brace is designed to eliminate flex and twist under hard acceleration, cornering, and braking, while providing for a 3-inch exhaust. More goodies include the adjustable trans mount providing for all of today’s popular transmissions (auto and stick). Working our way rearward the supplied rearend is a Strange Engineering Ford 9-inch with 31-spline axles. However, look closely at the HRBD C10 build and you will see the optional Roadster Shop IRS attached to it. The FT chassis will also allow for 10-inch wide wheels and 295 series tires up front, while fitting a 12-inch wide wheel and 345 series tire in the rear. Another HRBD ordered option are LT motor mounts; stock would be small- or big-block Chevy. Optional mounts are for LS/LT motors, while there are a few modifications to the frame. This was done to mostly handle the custom fabricated bed rails, uprights, and custom gas tank holders.

(800) 362-9709

hotrodsbydean.com/

(847) 949-7637

roadstershop.com

Livermore spec’d the chassis to run a LT4 6.2L (376ci) V-8 that runs a supercharger (1.7L Eaton R1740 TVS) directly from the Chevrolet Performance catalog (PN 19332621). It’s the most powerful engine offered in a Corvette (including current C8). With nine pounds of boost it will come in at 650 horsepower and 650 lb-ft of torque.

The LT4 is fit with Rotocast A356T6 aluminum cylinder heads that are stronger and handle heat better than conventional castings, with lightweight titanium intake valves, stronger forged aluminum pistons, and a forged steel crank, and connecting rods. This potent V-8 will back up to a Hughes 4L75E trans modified to handle the added torque supply along with a 4,800-rpm stall converter. Handling the gear section will be a Lokar Electronic Sport Mode shifter, while supplying the fuel will be an Aeromotive system.

The body has received a number of modifications with the most notable being the top chop coming in at 2-1/2 inches. The doors, while chopped at the top, have metal added to the bottom, effectively “absorbing” the rocker panel section. What was once part of the body is now incorporated into the doors. Next, the hood/cowl section is now one-piece, pancaked, and looks a bit like the 1969 hood, with a 2-inch taper (metal cutout of the hood at the sides where it “breaks over”) from the front of the hood to the cowl where nothing is removed. The leading edge of the hood was laid back 3 inches. From here the wheel well profiles were narrowed—3 inches in front and 2 inches in back and brought down over the wheel/tire fit.

The bed is custom-made as is the dash. The bed will feature custom wood and have a tri-fold opening custom wood floor, custom battery (Optima) holders, and grip the 26-gallon stainless steel Rock Valley gas tank. The dash is another custom fabricated piece–it has a stock feel but is one off and will house the Classic Instruments AutoCross gauges, Vintage Air heating/ventilation and air conditioning, an ididit steering column, entertainment system, and the glove box.

As for the color, well here’s one area that inevitably changes during the course of a build. But for now, Livermore tells us that the owner and he have agreed on black with two accent colors: red and silver/pewter. There you have it. We will be back to see how things progress and, of course, we will have the final feature on this bar-setting C10 hauler.