Tech

Tech

Images BY the Author

Images BY the Authorheetmetal panels are used extensively in classic truck projects, often for interior and underhood panels. While fabricating panels can be as simple as cutting and fitting, there are some simple tools that can add detail to create more visual impact, and each of these detailing steps add strength to the panel as well.

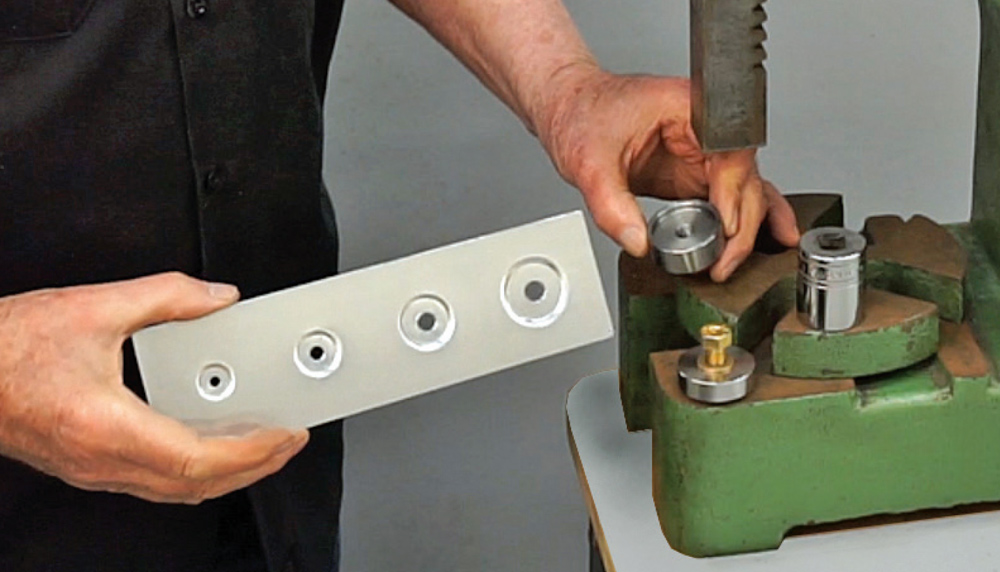

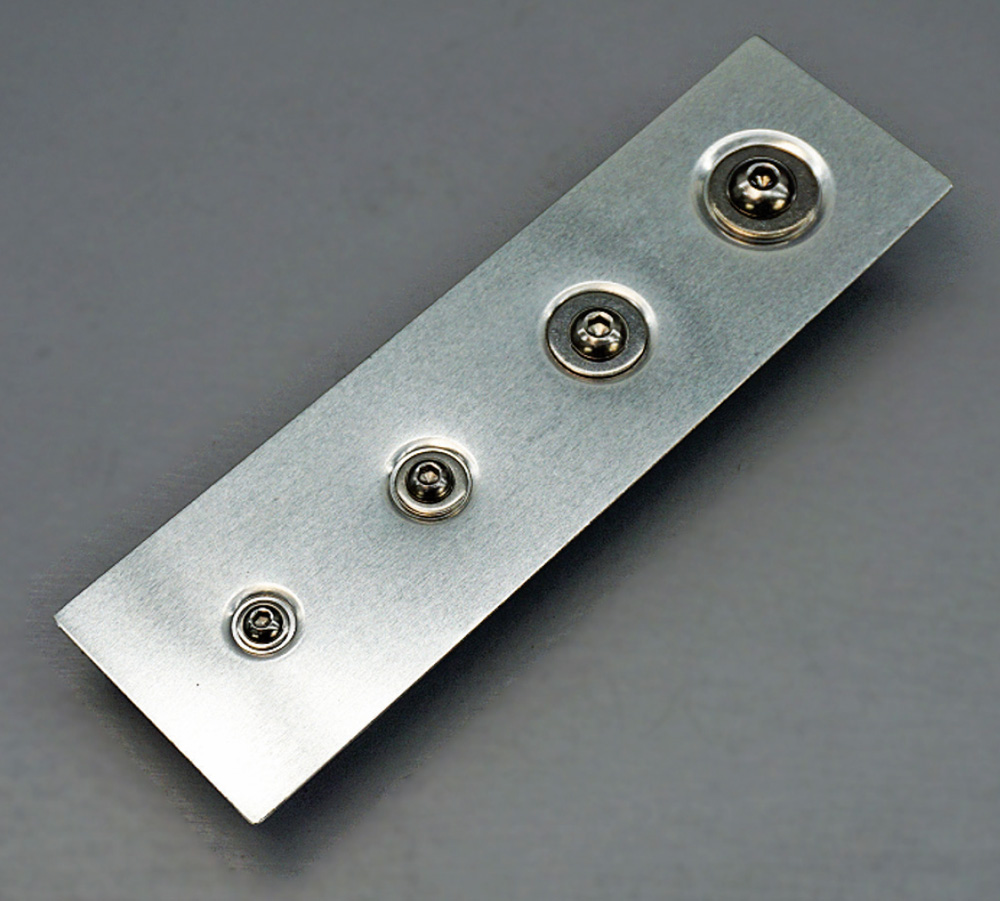

We will look at the Dimple Dies made by Hammerfab, which form a strong, good-looking detail around the heads of any fasteners. The most common styles are Flat Recess, Flush Recess, and the ever-popular Crater Maker. All of these dies are precision machined from heat-treated 4140 (chromoly) steel and are very durable. You have seen these used on many trucks featured in this magazine by both professional shops and homebuilders.

The dies come as a two-part set, with a male and female die. There is a center screw that aligns the dies, and with thin metal panels in the smaller sizes the screw can often form the needed detail. For larger size screws and thicker metal, a vise or press is recommended to push the dies together. The photos show how easy it is to use these dies and the professional-looking details they form.

There are some other dies available, for uses like flush-setting rivet nuts, Dzus buttons, and some other specialty applications. Using these simple tools can really step up the quality of your work.

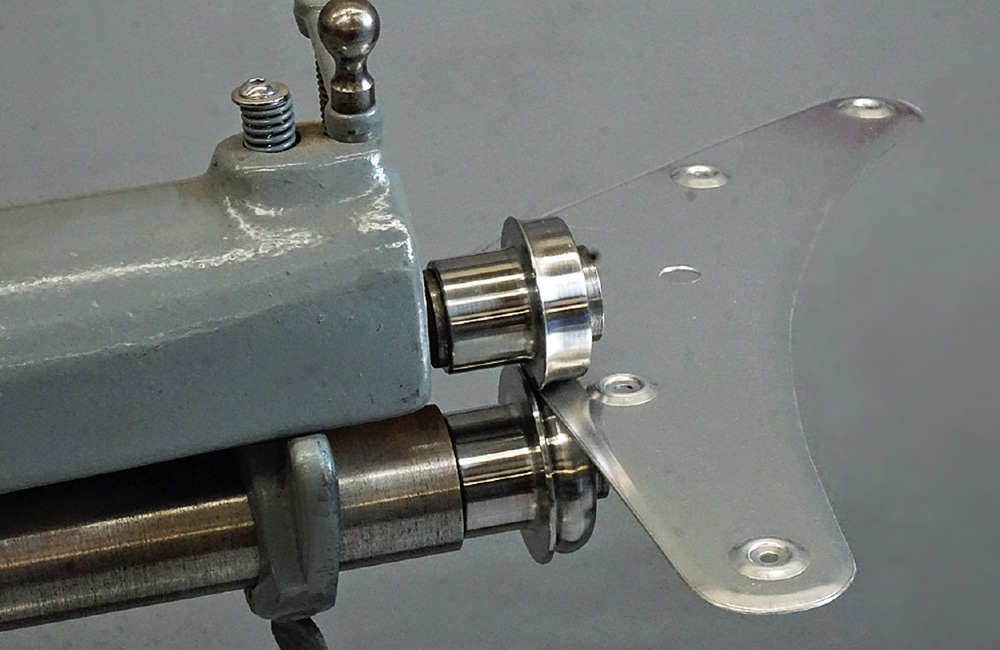

Round Over dies work on a bead rolling machine, and they put a curl on the edge of a sheetmetal panel. This is very simple operation, but it can offer a striking amount of style and strength. The dies have a guide built into the lower die, and as long as you keep the edge of the metal in contact with the guide, the curl will be perfectly formed. These dies are sold by Trick Tools and are available in four sizes. We are demonstrating the smallest size here, which is the 5/16-inch radius.

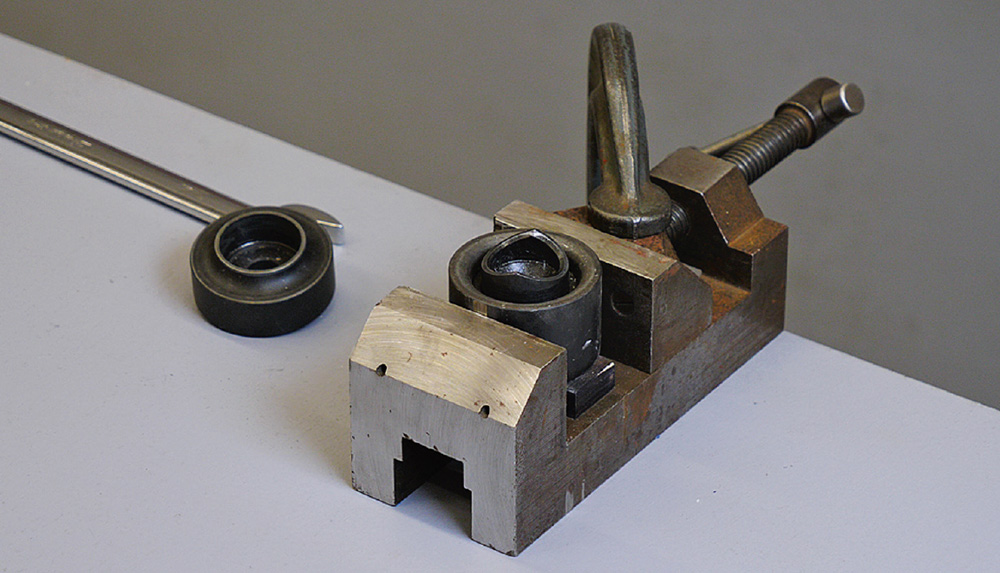

The Punch & Flare dies, made by Mittler Bros, make holes with radiused (or “belled”) edges. The round dies come in sizes from 1/2 to 3 inches; triangular and oval dies are available, too. Dies like these are used extensively in aircraft construction because they can both reduce weight and strengthen the panels they are placed in. Weight is not commonly an issue with truck builds but strengthening sheetmetal panels is often beneficial, and they have a unique look that most people like. These are often called “speed holes” by those in the trade.

The photos show many applications for these simple tools, and we’re sure you can envision many ways they can step up your metal-fabrication game!

SOURCES

SOURCES