Feature

Feature

Images BY NotStock Photography

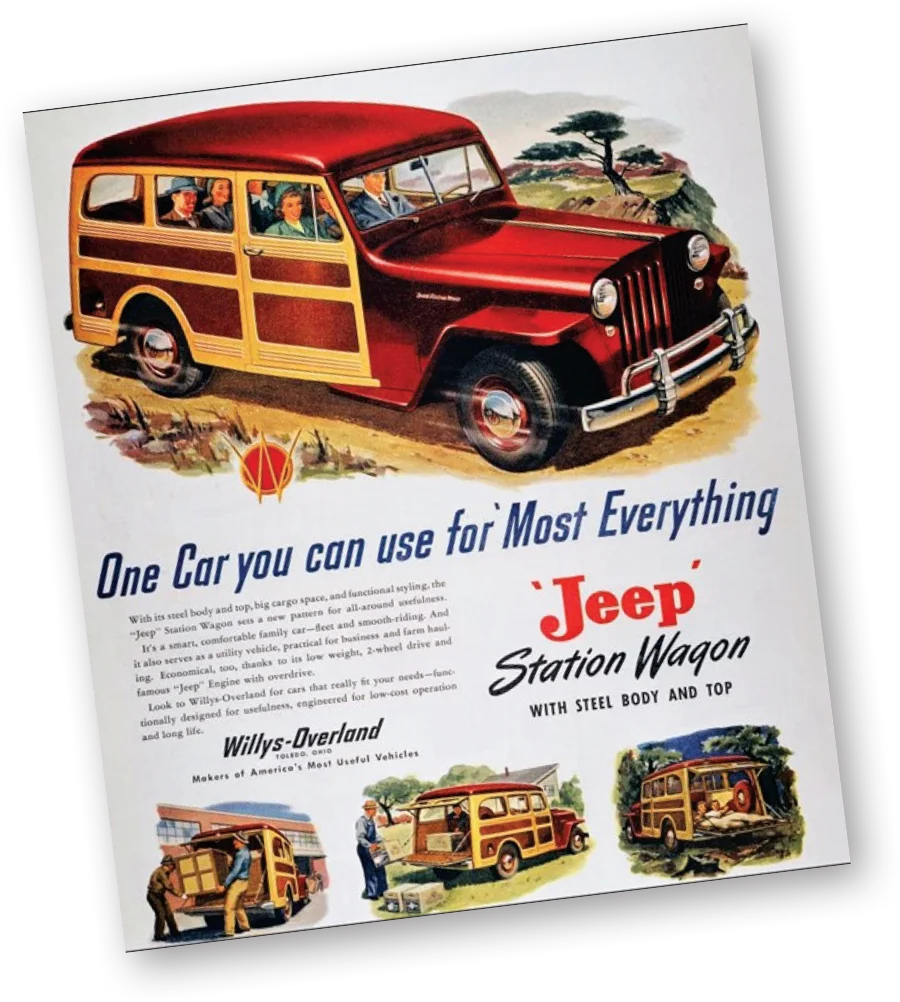

Images BY NotStock Photographye were on Facebook Marketplace searching for a shop Jeep to take wheeling. While scrolling through the ads, my wife came across the Willys-Overland Wagon rusting away in a field. She had never seen one before and started researching them. We found that a lot of people were cutting them apart and turning them into “wheelers” or doing very classic restorations. We talked about how it could be cool if we did something different and combined both of those worlds and paid homage to what they were initially meant to do.

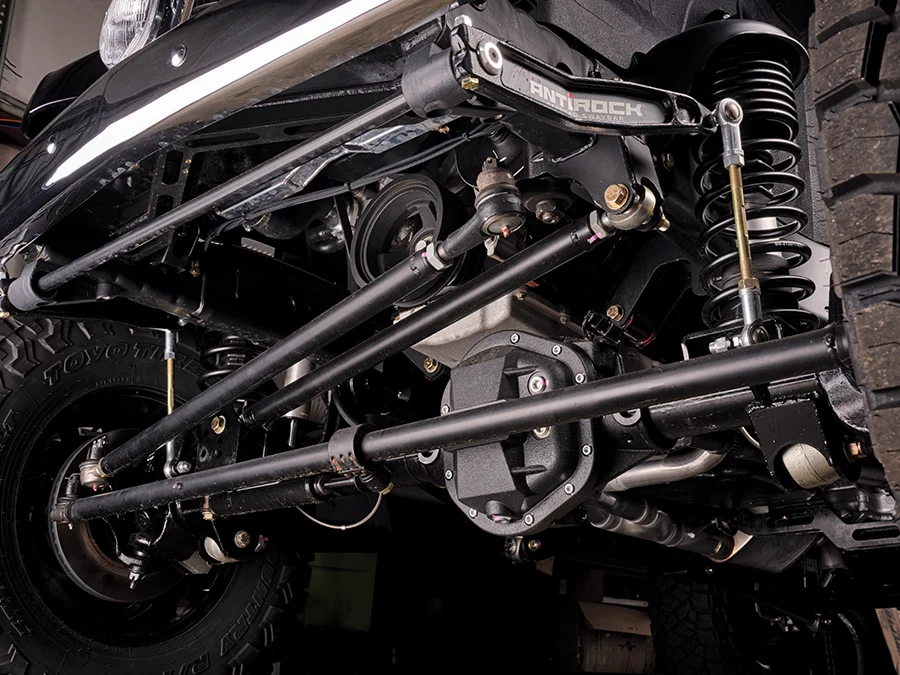

After reading various vintage advertisements we knew that we wanted the entire build to be centered around this duality of purpose: a smart family car with rugged capabilities but tweaks for modern times. Originally it was a 2WD vehicle, and on top of that someone had at some point changed the frame under the one we had to a C10 frame. We knew that it had to be 4WD and truly capable of off-roading. We made the suspension setup in-house and it sits on a three-link front and triangulated four-link rear. We used Metal Cloak springs and Fox shocks to achieve 3-1/2 inches of lift to clear 37-inch tires. We wanted to be able to clear a large tire while keeping the body as low as possible. The suspension was set up so that roughly 70 percent of the travel is downward. This allowed us to keep the center of gravity low. Considering it’s shaped like a big box, this definitely helped with driveability at highway speeds. It’s powered by a cammed LQ9 6.0L LS motor and a built 4L80E. To keep from breaking axles, it sits on an East Coast Gear Supply–built Dana 44 front and a Dana 60 rear with 4.88 gear and an E-locker front and Truetrac rear. It has the power and suspension to go anywhere you’d want to take it.

Overall, the main goal was to create something new and fun while paying homage to the vehicle. Something that a younger generation would love and something a purist would still appreciate. Thanks to the Hardline Customs crew, Jed Laborte and Dave Belzer; Tim Long at Dalton Automotive for the paint; Spencer at Top Stitch Interior for the upholstery; Andy Key and Jimmey Fowler at D and A Automotive for the engine work; Mark from Glass By Mark for all the flat glass; and Dan at Woodstock Muffler for the exhaust.