TECH

TECH

Images by THE AUTHOR & Marcel Venable

Images by THE AUTHOR & Marcel Venableith Jason Fonte’s 1959 Chevrolet Apache, the fire-scorched body of the truck was maintained with its historic character from the Paradise Fire in Northern California. But underneath, Fonte had the crew at Devious Customs in Riverside, California, completely transform the classic farm truck–style suspension into a modern show truck with a full Roadster Shop chassis that was kept in bare metal using a clear powdercoating to protect it. Naturally, a full air-ride suspension setup was called for and Fonte opted to upgrade it to the latest air management setup from AccuAir Suspension.

One of the standout features of the AccuAir e-Level+ system is its ability to provide an exceptional ride quality that is also consistent. Using their Height+ Leveling Sensors and intelligent algorithms, the Ride Monitor system will adjust the air suspension in real time, ensuring a smooth and comfortable ride, lessening bottoming out or scraping even if more weight is added to the truck or rough road conditions.

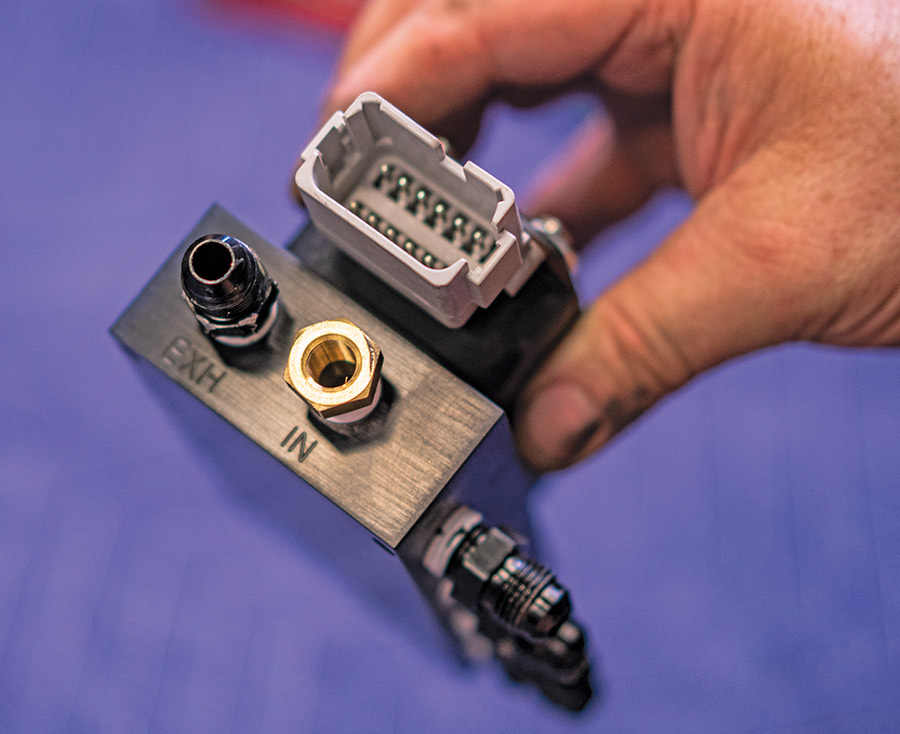

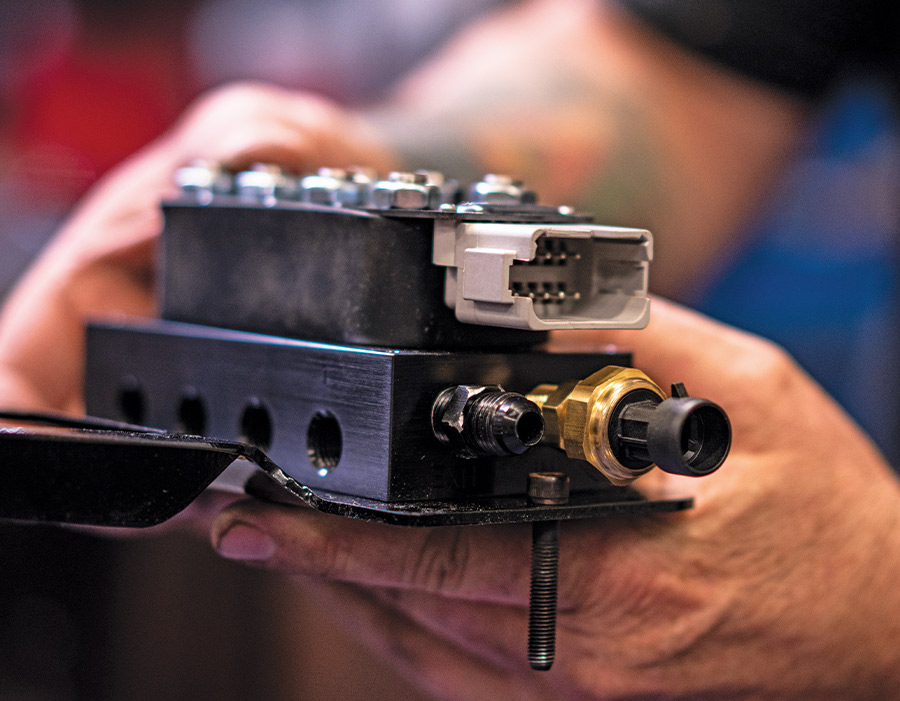

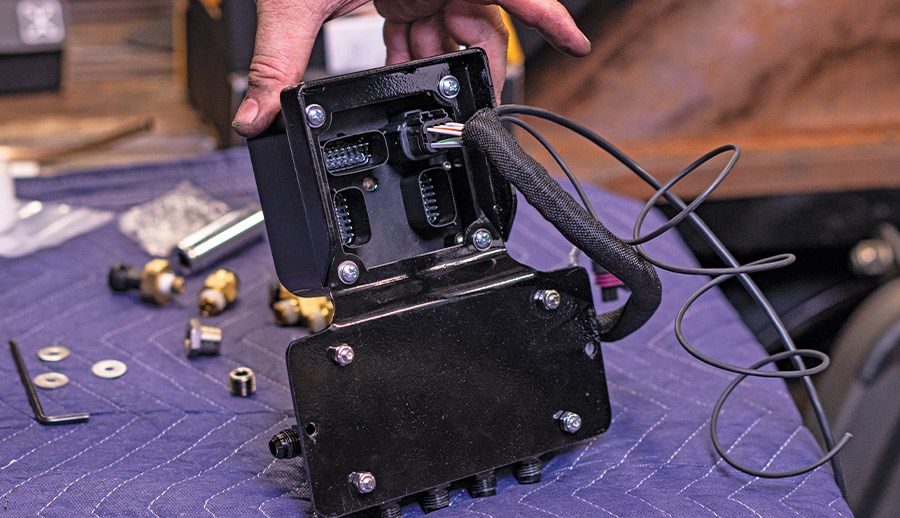

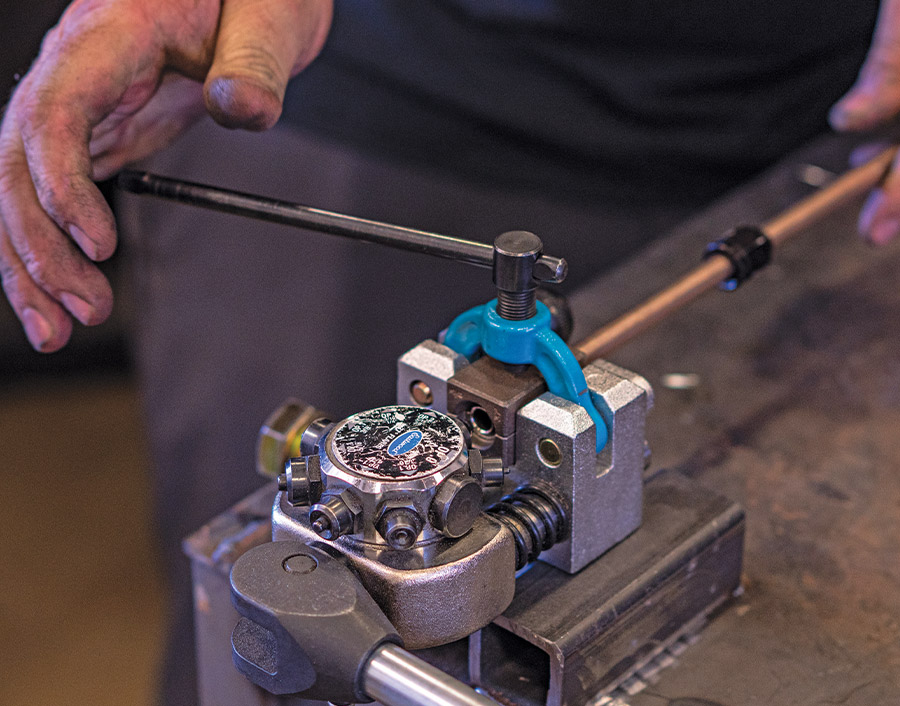

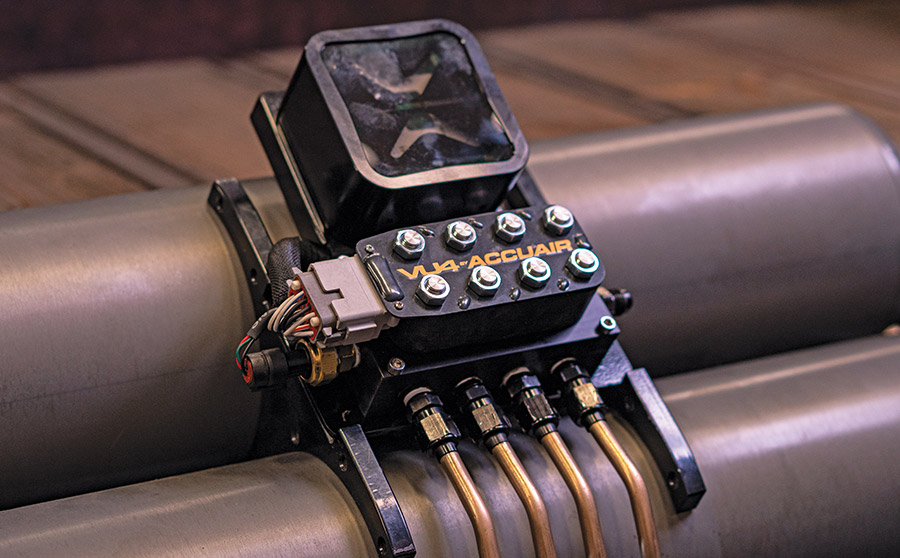

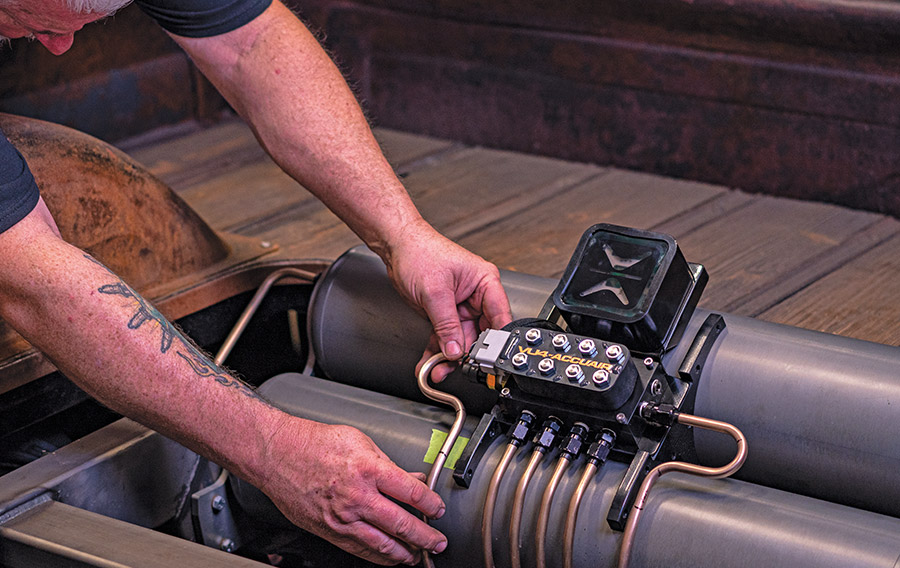

Of course, the AccuAir system was installed with a few custom touches by Devious Customs, including a custom mount for the ECU and air manifold. Hard line copper tubing was chosen to connect the valves to a manifold under the bed. The eye-catching copper lines matched the overall look of the truck and engine parts underhood.

Further protection to your vehicle’s electrical system was added to the controller with a colored LED indicating when your air compressor is running. This notification allows you to not only make sure your compressor isn’t having an issue but to know when you have enough air in your tanks to handle the pressure needed to cruise down the road.

SOURCES

SOURCES