Tech

Tech

1. Paul Wilson prepared for welding up holes in his ’52 Chevy pickup by adjusting his Miller Electric Manufacturing Company MIG welder on a scrap piece of sheetmetal.

BY RON CERIDONO Photography by THE AUTHOR & TIM FOSS

Photography by THE AUTHOR & TIM FOSS

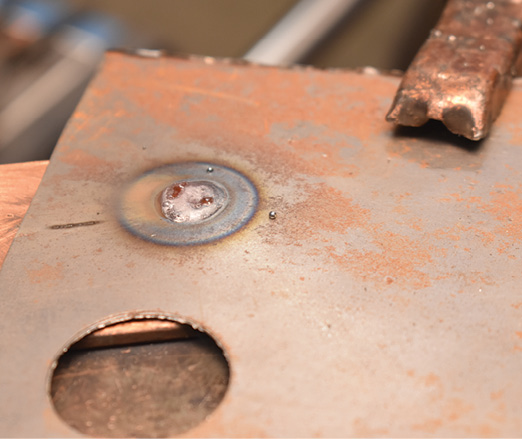

egardless of whether a classic truck is being modified or restored, chances are that during the bodywork phase of the project there will be holes in the sheetmetal that will have to be filled. As a general rule (keeping in mind there are extenuating circumstances), small holes less than a 1/4 inch in diameter can be filled by welding only; bigger than a 1/4 inch a copper backup plate should be used. Holes 3/8 inch and larger should have plugs welded in place.

Another consideration when filling holes is not to stack up a huge bead that requires a great deal of grinding. Keep in mind grinding can also create heat that may cause the area to distort. Another common mistake is grinding too much, making the area surrounding the weld thinner than it should be. The idea is to level the weld bead to match the surrounding metal and no more.

To demonstrate two different techniques we watched as Paul Wilson filled a hole in sheetmetal with a copper backup plate and his Miller MIG welder. Given the variations in welders and individual preference it’s impossible to recommend machine settings. The best advice we can offer is again to practice on scrap material that matches the thickness of the vehicle you’ll be working on.

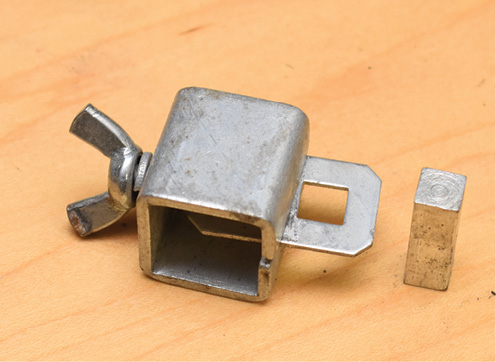

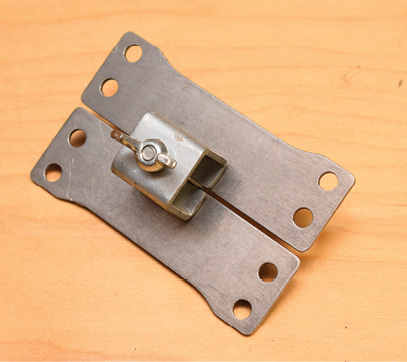

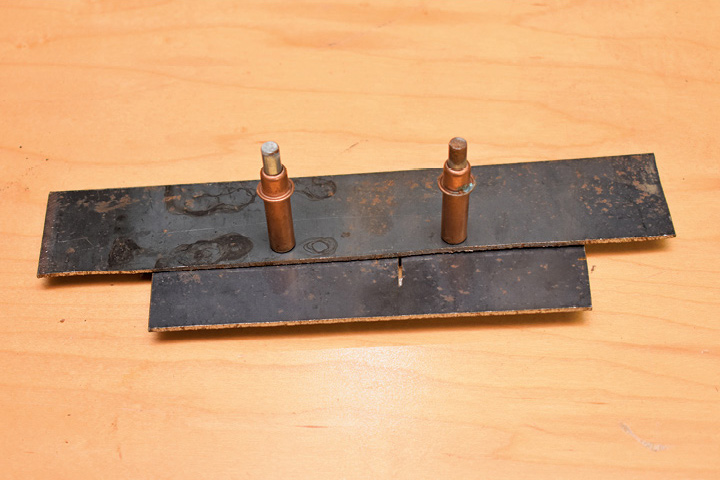

Filling small holes is usually done by making small tack-like welds around the edge of the hole, working your way to the center (it may help to slightly countersink the hole). Work slowly and try to keep the weld as flat as possible. If there is access to the backside of the hole being filled, copper backup plates, like those shown here, are particularly helpful.

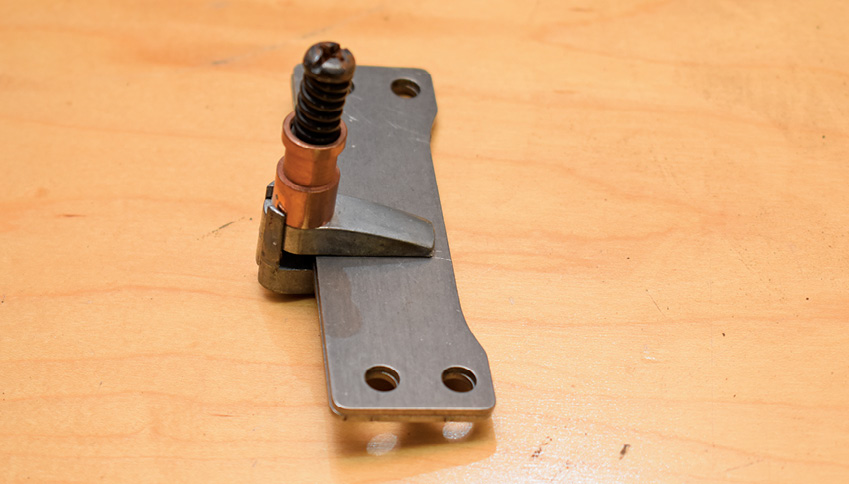

For larger holes, filler plates will be required. Tim Foss followed Kev Elliott, of Kev’s Rod & Custom, as he plugged the gas filler opening in a ’72 Ford pickup with a gas filler delete plate from LS Fabrication. Made from laser-cut, 16-gauge steel, the filler plate is contoured to match the contours of the cab.

After preparing the area to be welded, Elliott went about tack welding the filler plate in place with his TIG welder. A few deft taps with a body hammer had the filler plate fitting perfectly—after that the welding was completed and then ground smooth.

Remember when filling multiple holes move around to keep from concentrating too much heat in one area, try to keep the weld bead height to a minimum and use restraint when grinding. Filling holes in your hauler can be intimidating at first, but with patience and practice it is a skill that you can master.

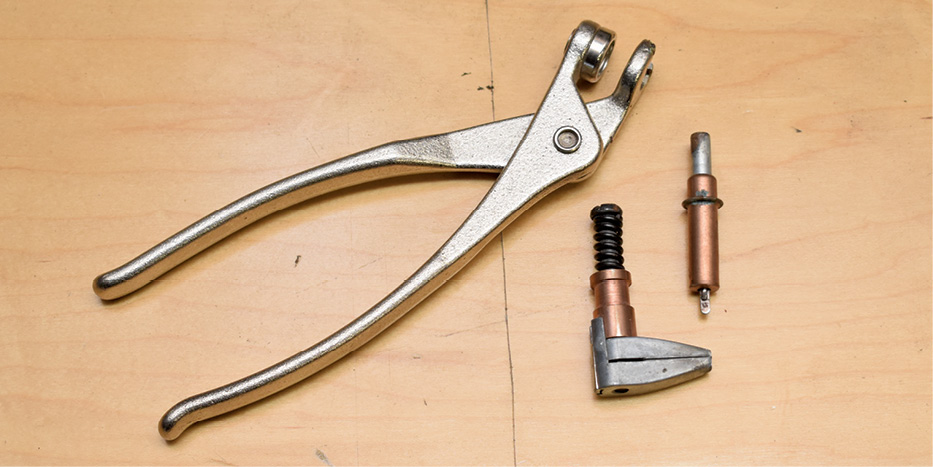

ere are three examples of sheetmetal tools you should have in your garage. We dug these out of our toolbox and grabbed some random scrap metal pieces to show how they are used.

2. The small 5/16-inch hole is typical of the holes in his pickup that will be plugged. The first step was to clean the surface with an abrasive disc.

3. An easy way to close holes is to use a copper backup plate held tightly against the backside of the metal. The plates without the handle have magnets to hold them in place.

4. Copper backup plates do two things: They act as a heat sink to help prevent warpage from welding and they make the hole easier to fill as the weld wire won’t stick to the copper.

5. The completed weld is virtually flat and will require little grinding to make it flush with the surrounding area.

6. To dress the weld a 60-grit “flapper” disc was used on a 4-inch electric grinder. The trick is to go slow and not apply excessive pressure, which can create heat and warp the metal—the very thing you’re trying to avoid.

7. After careful grinding, the location of the hole is practically undetectable.

SOURCES

SOURCES