Feature

FeatureInTheGarageMedia.com

Mike Di Maulo’s Flamed-Out ’45 Chevy COE is an Incendiary Build

Photography BY THE AUTHOR

Photography BY THE AUTHORhen Mike Di Maulo first laid eyes on a COE truck, he was drawn to it like a moth to a flame. “I had a fascination with trucks since I was a kid, and the ‘cab over engine’ design just drew me in. I was instantly hooked.” The Congers, New York, native decided early on that one day he was going to build a flat-nose for his very own; a truck that fired on all cylinders and created a hot mess wherever it roamed.

Flame On

However, Mike knew sooner or later he was going to find a good donor truck to build his own COE hot rod. That day came a few years ago when Mike spotted a good example for sale on the left coast. It wasn’t a complete truck, but it was a start. “I checked it out online and purchased the ’45 Chevy cab for my project from California. When it arrived to me here in New York, it was the first time I had ever seen one in person!”

From there Mike was on a mission to find all the parts he needed to bring his vision to fruition. “The bed was purchased from Pro’s Pick in Arthur, Ontario (Canada). That part was easy, however, I had a hard time finding rear fenders that would work with the truck. That took a lot of work. I ended up having world-class metal magician Colton Hardison from Hardison Metal Shaping make them for me from scratch. They fit perfect and really give this truck an amazing profile. That solved a lot of problems for me, to say the least.”

Next on the list was a chassis for the truck to tie it all together. “That’s when I found Roger Purdy from Pro Street Chassis in Chesterfield, New Jersey. He was a lifesaver.” Purdy forged ahead and built a custom cradle for the bed and cab. The suspension was built up using Art Morrison products with a Mustang II frontend complemented with a four-link out back. QA1 shocks help even out the ride on this COE.

A built, heavy-duty Ford 9-inch rear with 3.73 gears handles the power out back. The Strange axles spin a set of 15-inch Wheel Vintiques steel wheels shod in Hoosier Pro Street radials, 26×7.5×15 fronts and 31×18.5×15 rears. Wilwood disc brakes at the corners help this beast not become a burden, bringing it to a stop on command with the greatest of ease.

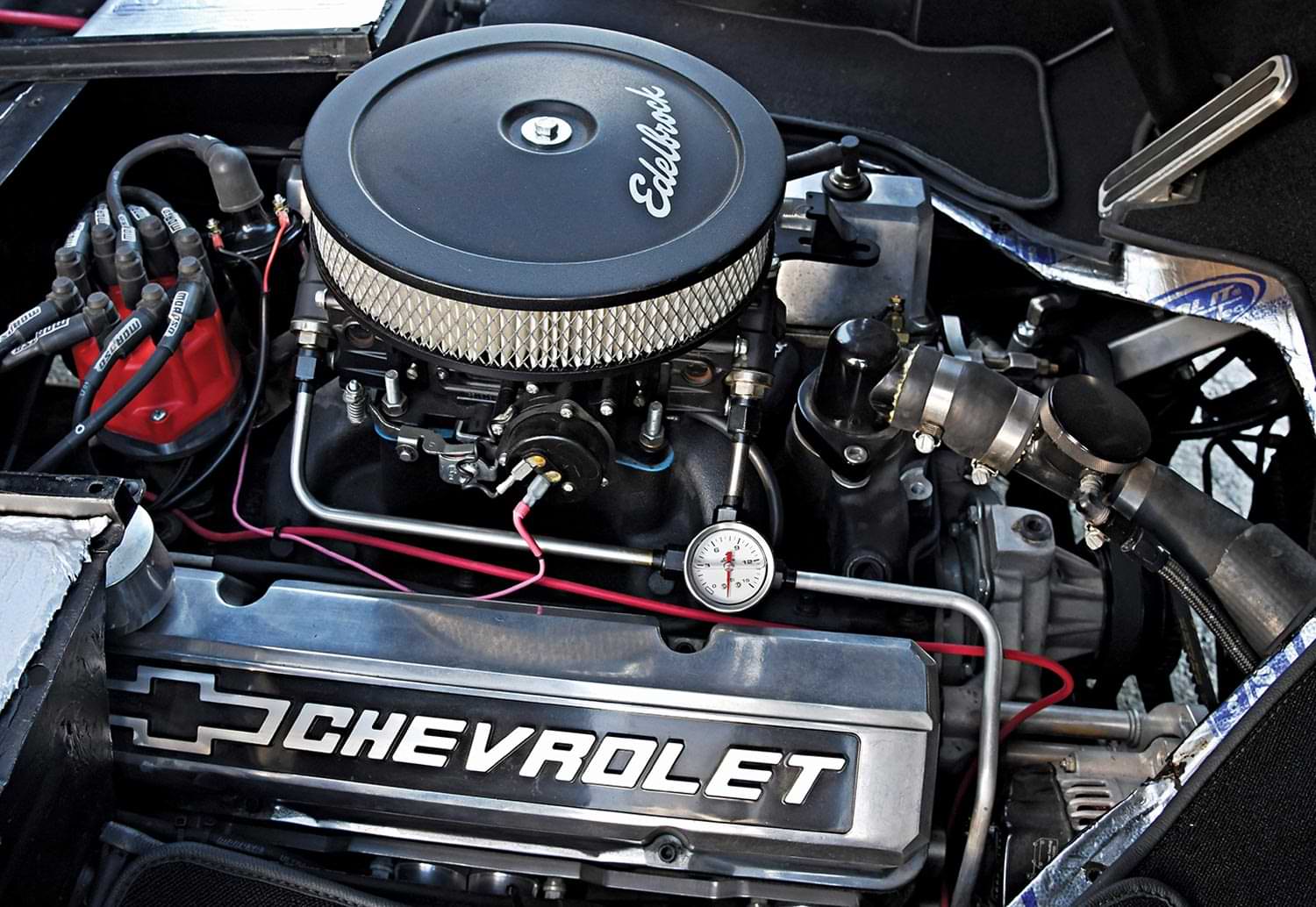

When it came to the powertrain, Mike knew not to skimp. “I knew the engine needed to fit without too much fabrication and built with enough power on tap to really set this truck off. Lastly, it had to be a Chevy powerplant. So, we decided on a small-block stroked out to 427 ci.” Like most of this truck, Purdy oversaw the build. It all starts with a Dart SHP block. A 3.875 crank rotates with JE pistons and H-beam rods. AFR heads top the cylinders. This beast is fed by a Quick Fuel 750-cfm carb mated to an Edelbrock intake. “The motor was tuned to 600 hp, which was plenty for my project.”

Paint was done by Sano’s Custom Paint in Dayton, New Jersey. Using the cab’s old paintjob as an inspiration, Sano’s designed its own custom paintjob for the COE. Purdy did all the necessary bodywork before Sano’s cleaned it all up and prepped it for paint. It was then sprayed in black lacquer and then the custom flamejob was added to complement the curves of the body. “With the blunt nose, the incendiary skin just sets off this truck. I think it all worked perfectly.”

Once finished, Mike could only ogle what he created. “This truck started life as a big, commercial drilling truck. I had a vision of what I wanted and followed a game plan to create the truck that I needed in my life. I have to say thank you and give credit to Roger Purdy for taking the project on and delivering exactly what I envisioned. [Purdy] fabricated the chassis, mounted the cab and bed, and more. Putting it plainly, [Purdy] built an amazing truck for me.”