Tech

Tech

PHOTOGRAPHY BY Adam Cecil

PHOTOGRAPHY BY Adam Cecilammerforming is one of the oldest metalworking processes around. It involves making a form from some durable material in the shape of the desired part, clamping a sheet of metal to it, and hammering the metal until it takes on the shape of the form.

Often these forms were made from wood, since it is fairly easy to work and the harder grades of wood provide enough durability to be used indefinitely. A properly constructed hammerform allows even a beginning metalworker to make a part that looks die stamped.

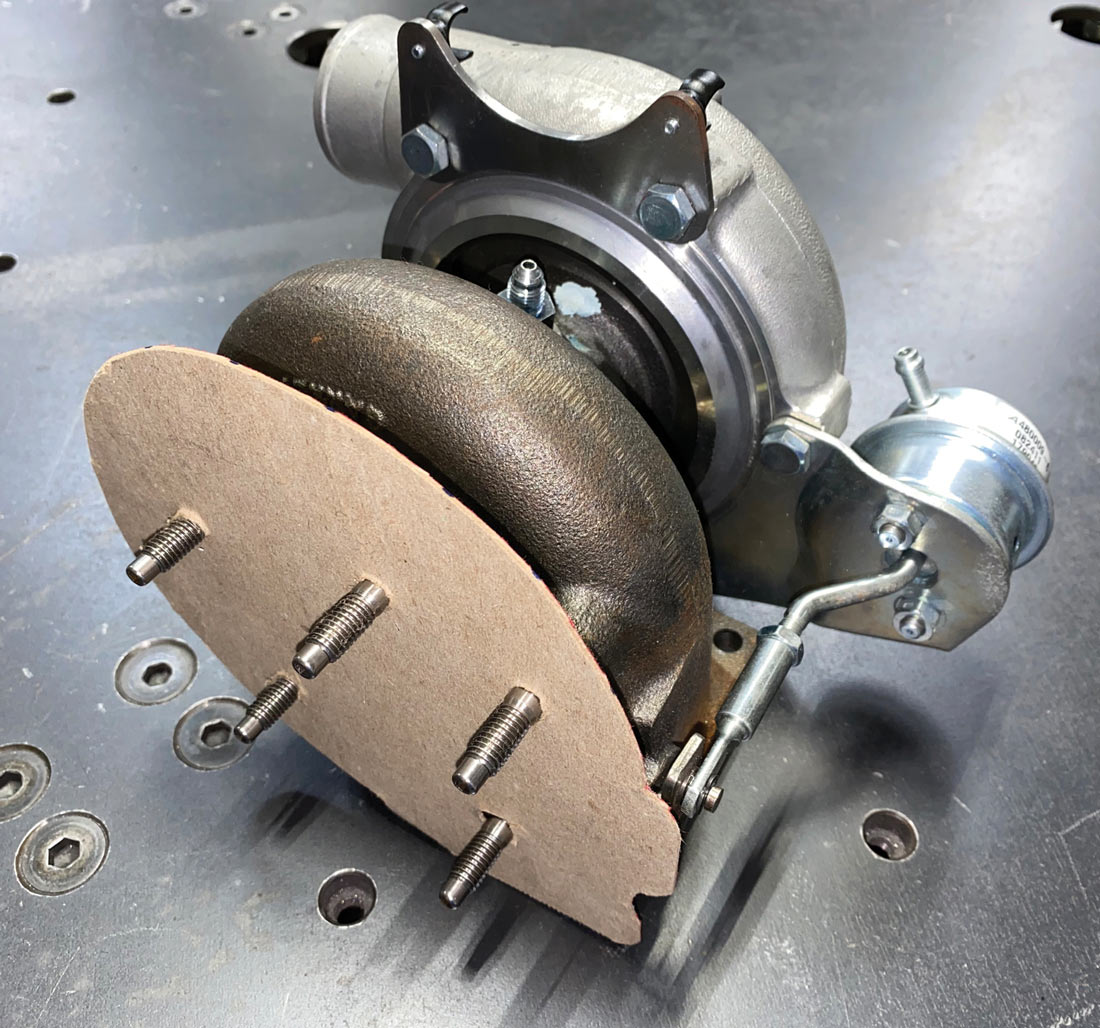

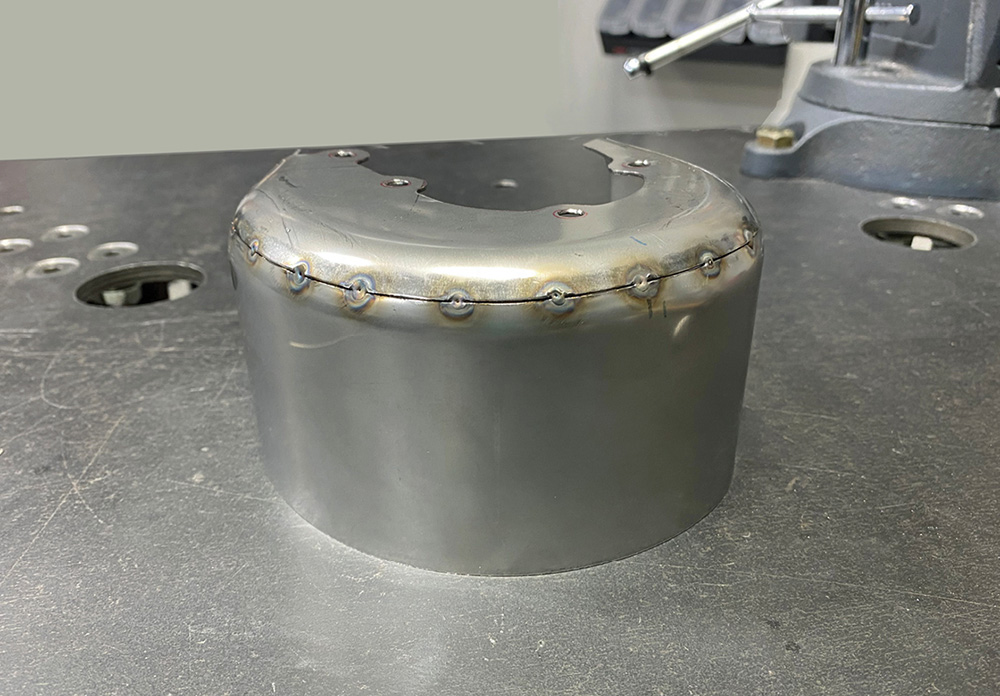

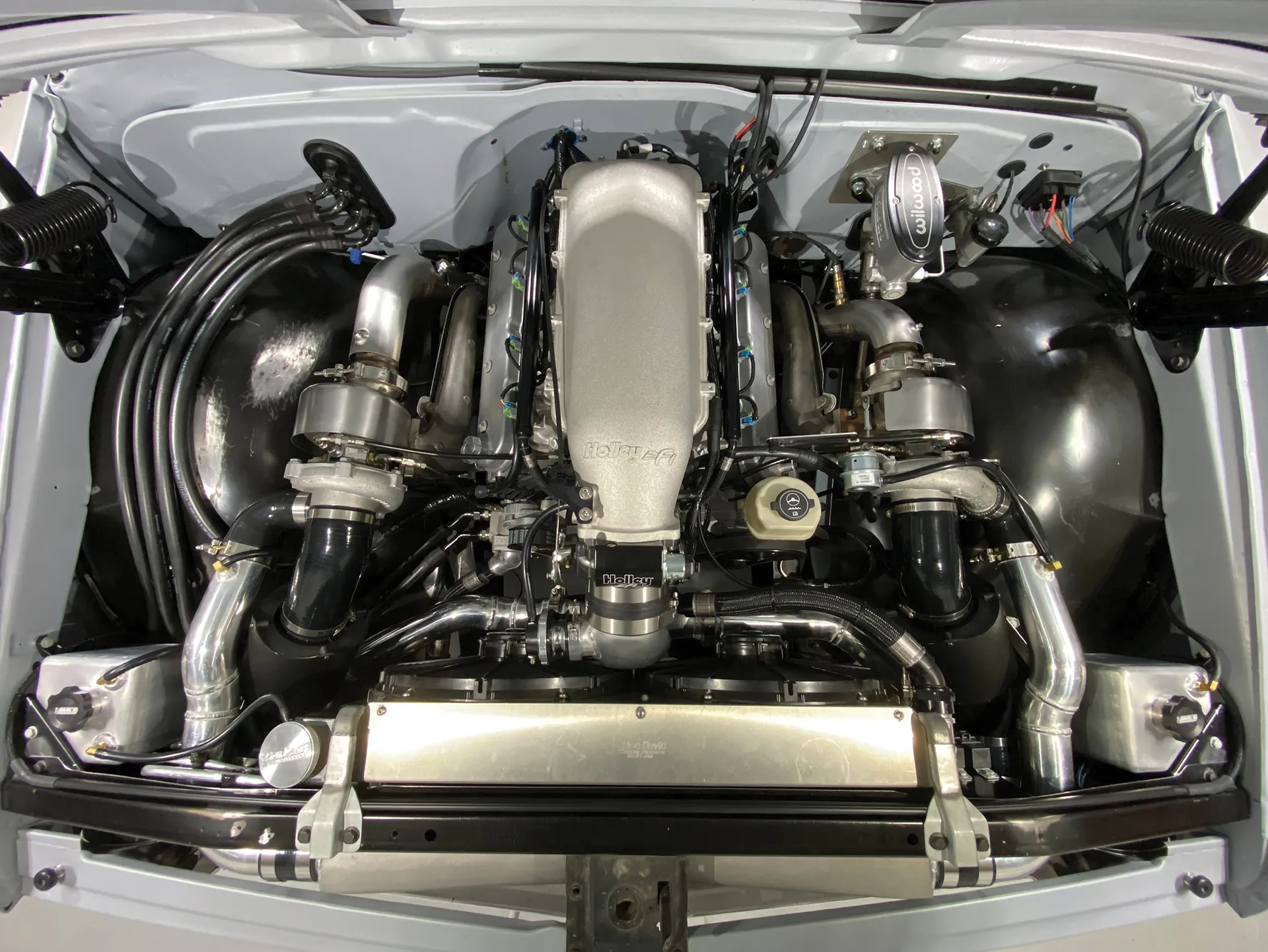

In this article, we will follow the work being done by Adam Cecil, a classic truck enthusiast who has had great results using this process. We’ll take a detailed look at the stainless turbocharger heat shields he made and a pair of tanks for the coolant overflow and the windshield washer fluid. All of these are for his ’68 Chevrolet truck with a twin-turbo LS engine.

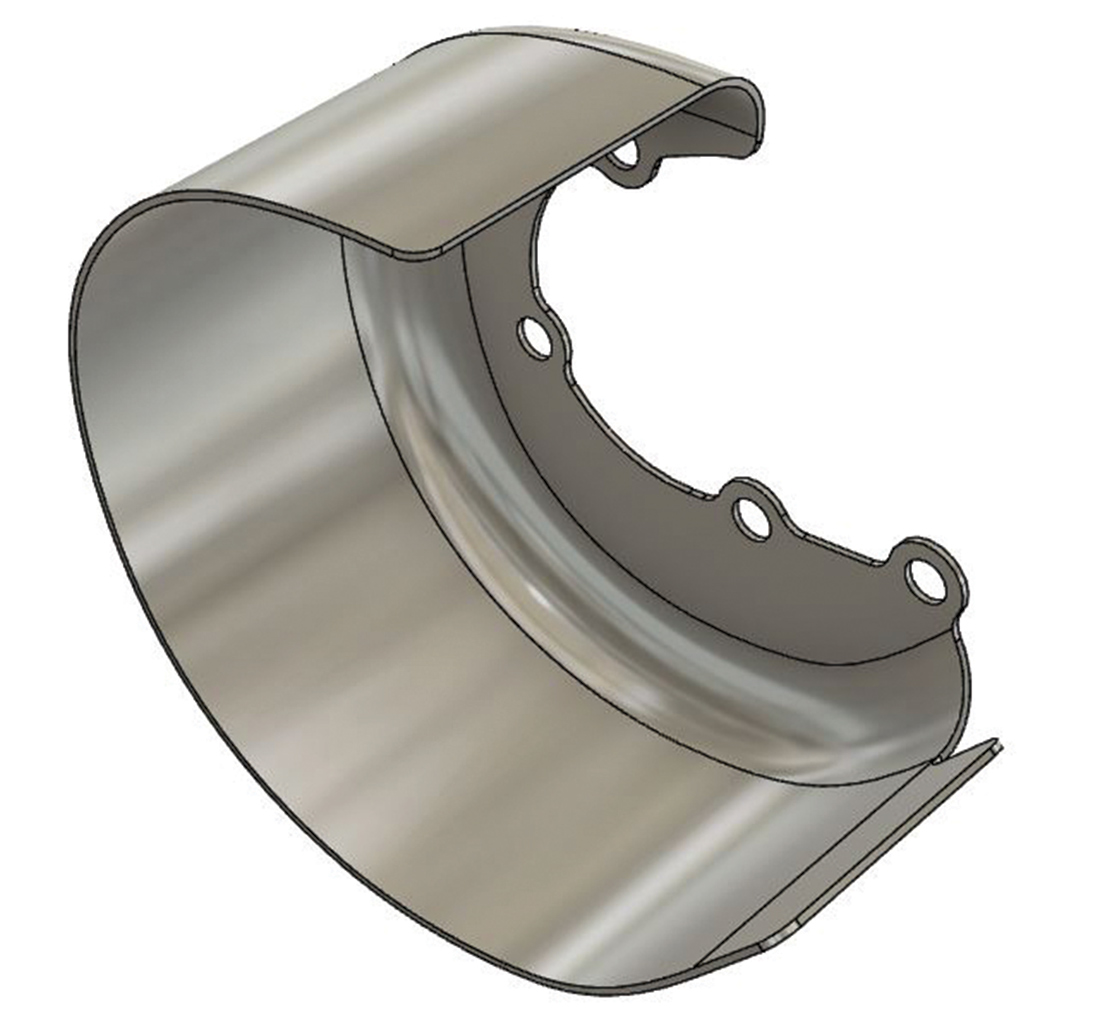

The first step is to create a computer model of the part to be made. These days there are many choices for CAD (computer-aided design) software, but Cecil uses Fusion 360 from Autodesk, which is available as a free download.

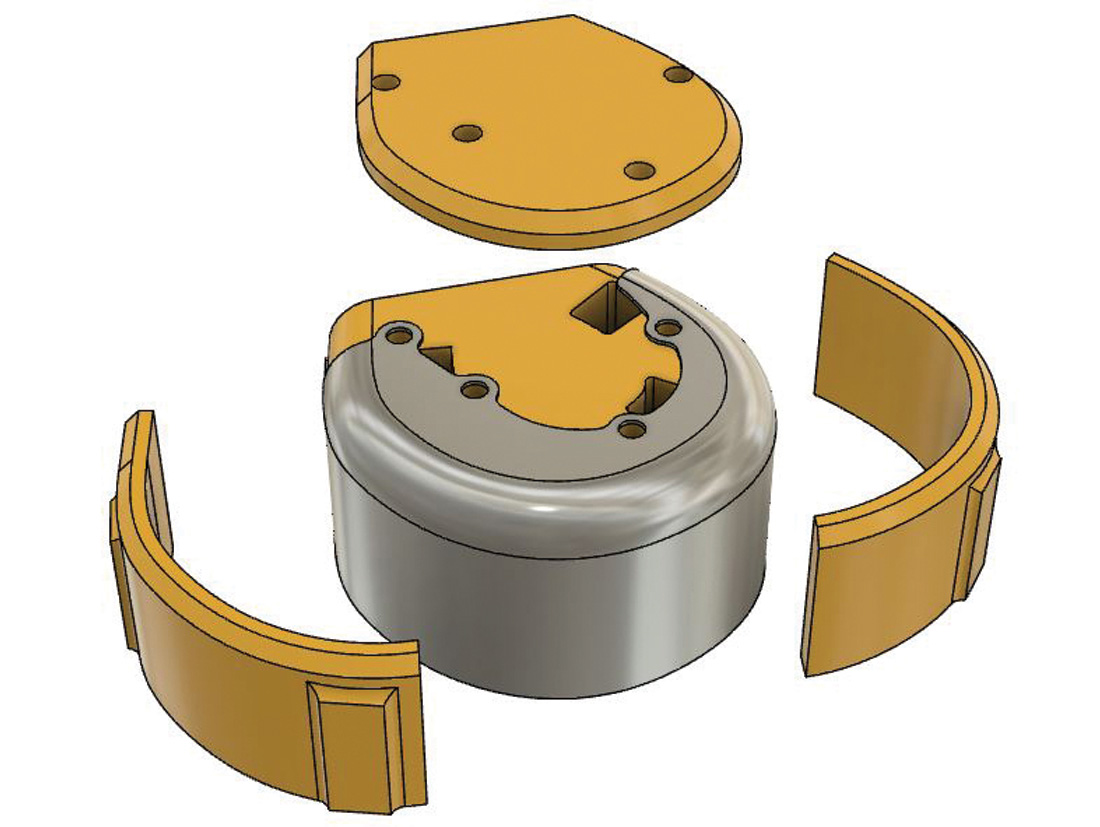

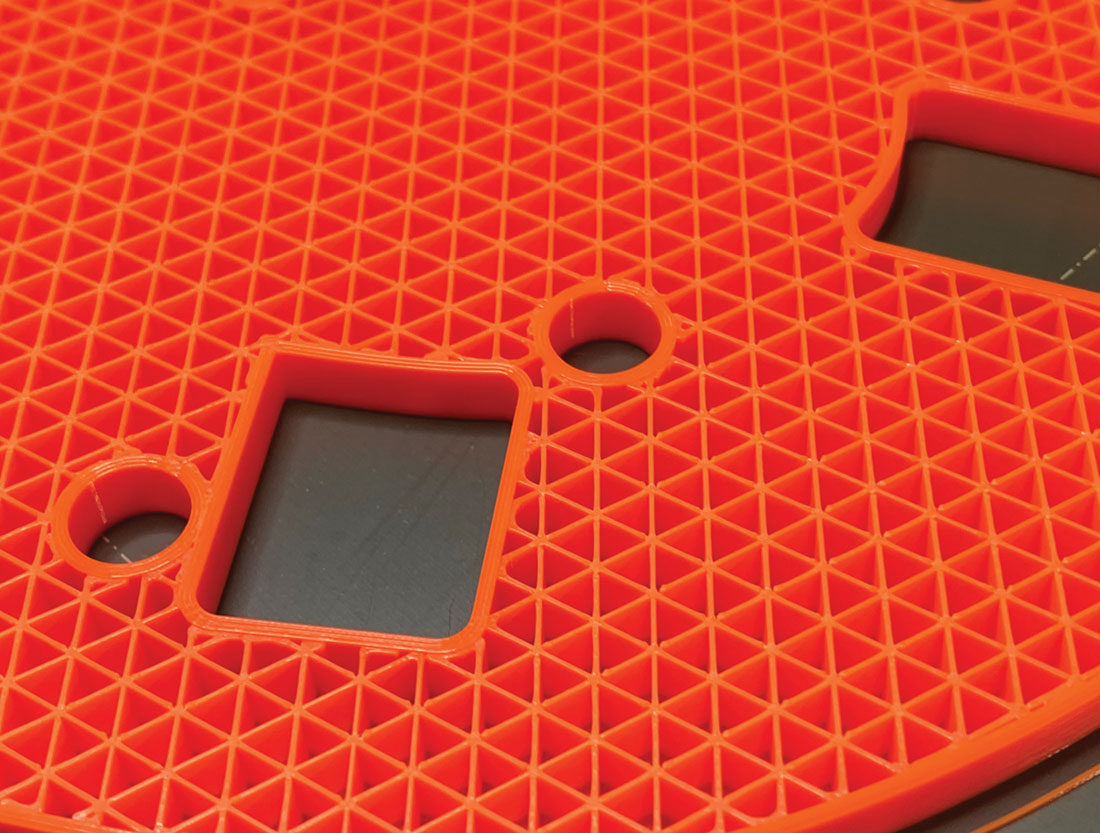

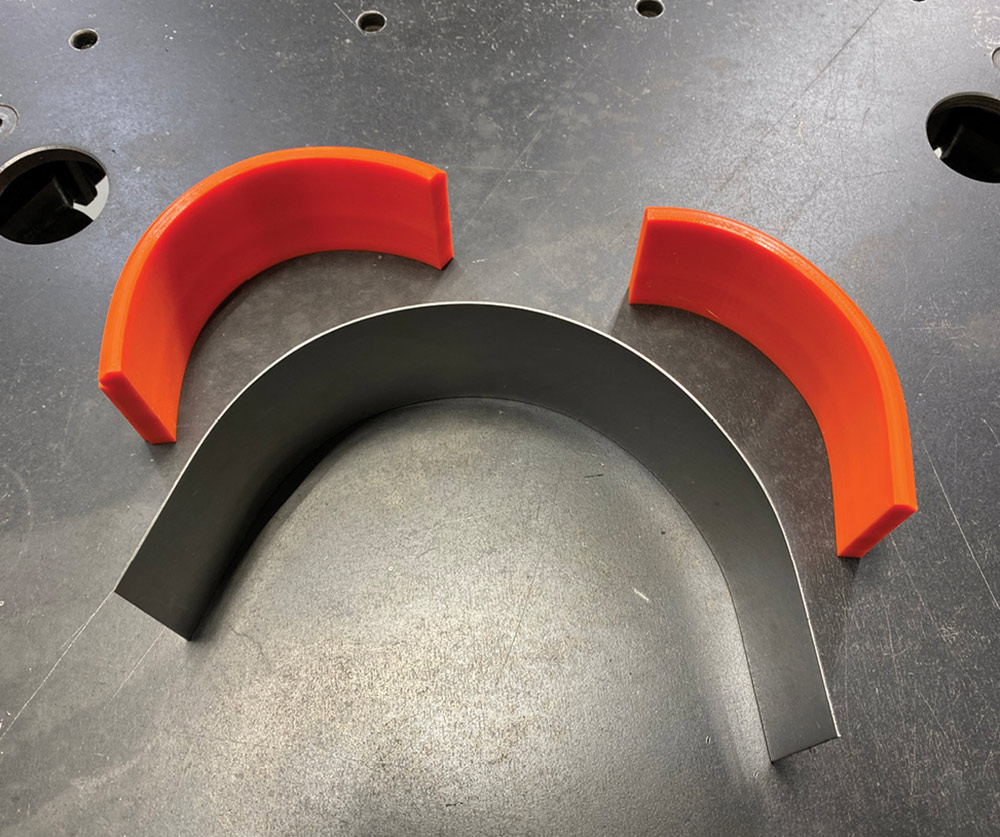

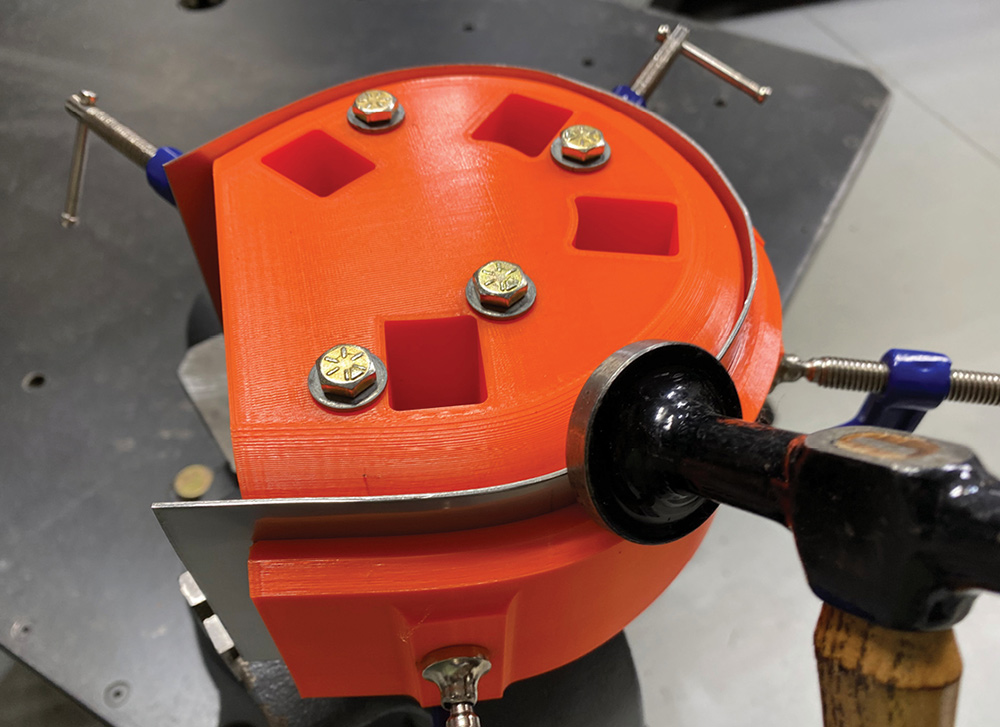

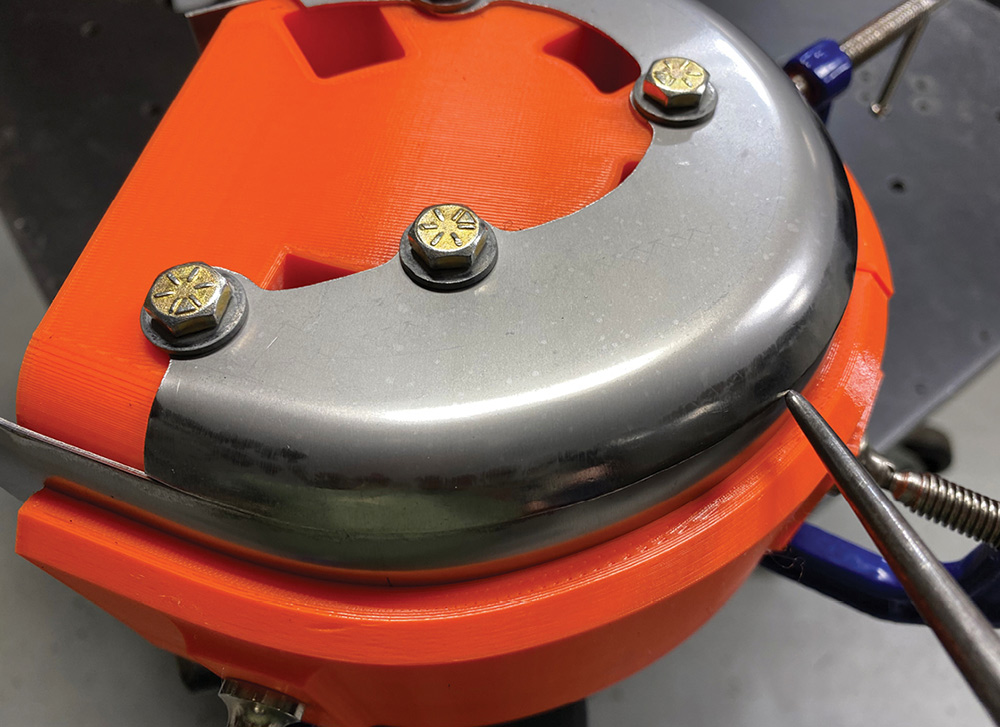

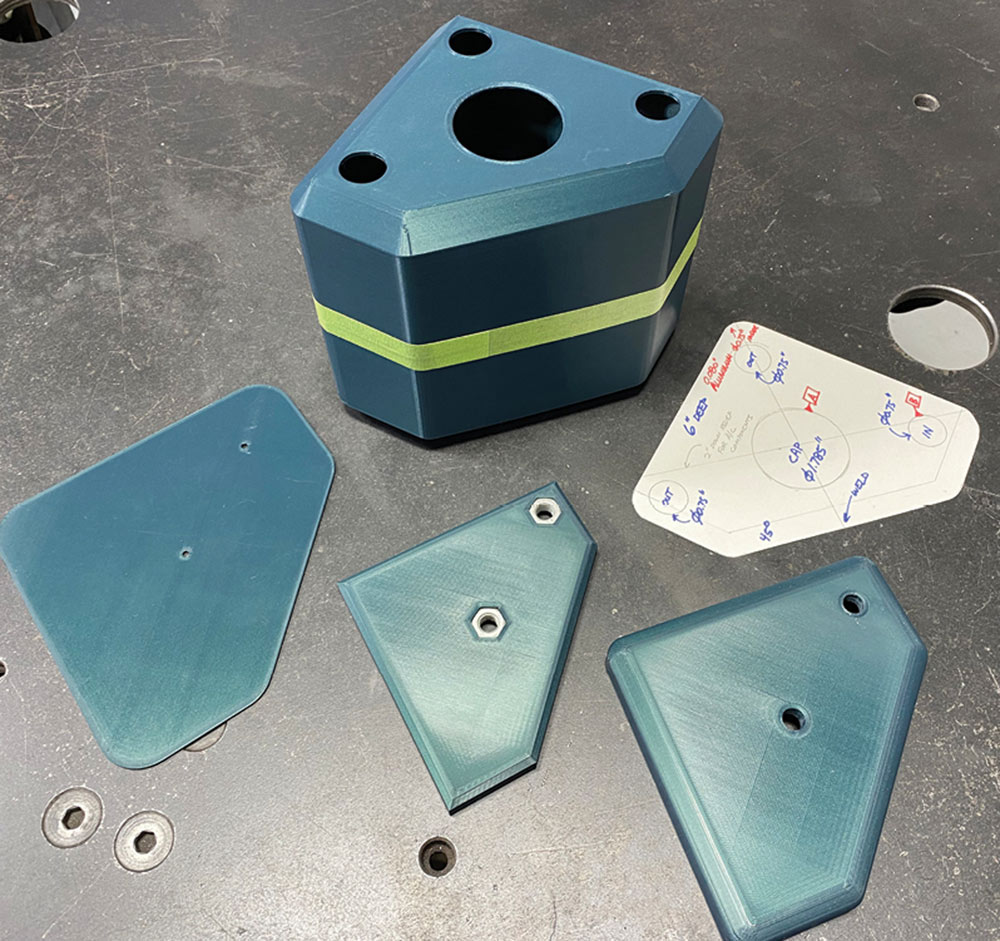

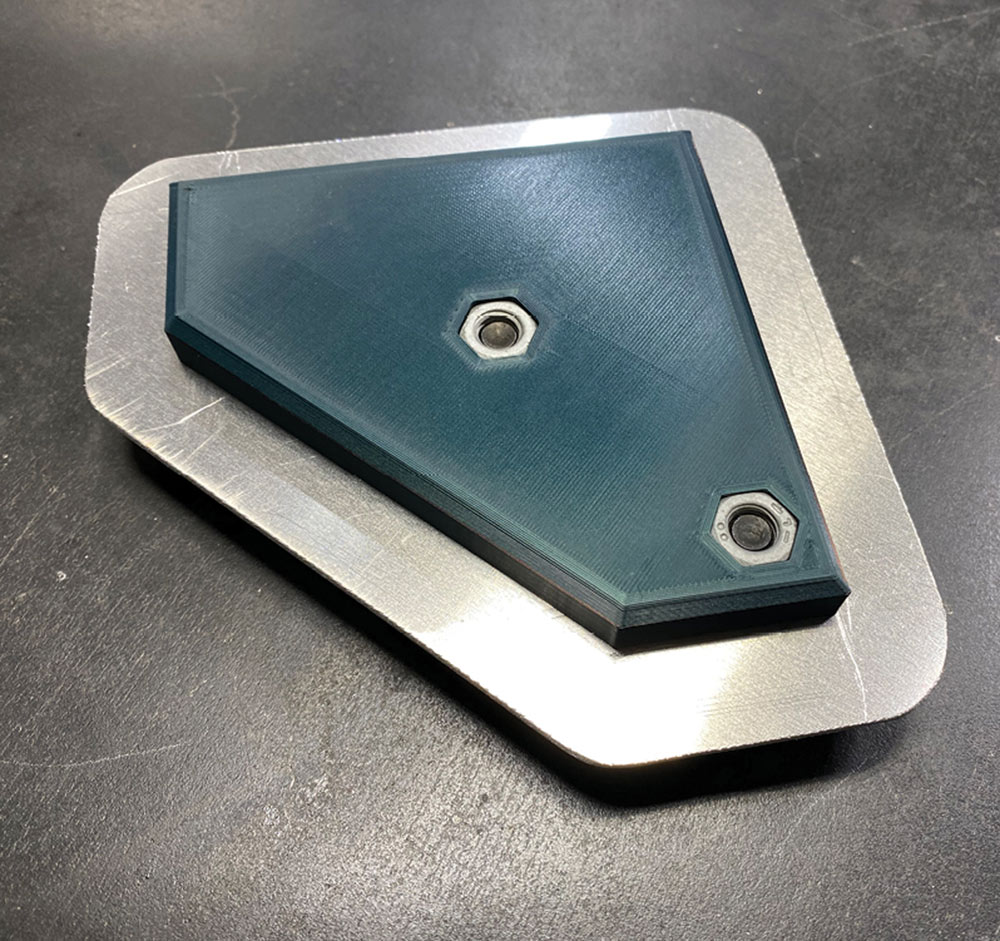

After the CAD model is created, the next step is to design the hammerform and clamping blocks, which will be a snug fit inside and outside the model. Alignment pins are generally used to keep the parts properly aligned and, when possible, these are made to coincide with features on the finished part so no extra holes will have to be filled. For the turbo cover, Cecil used the studs for the turbine outlet/wastegate cover for the alignment pins; for the fluid tanks, he used the centers for the cap and the plumbing fitting.

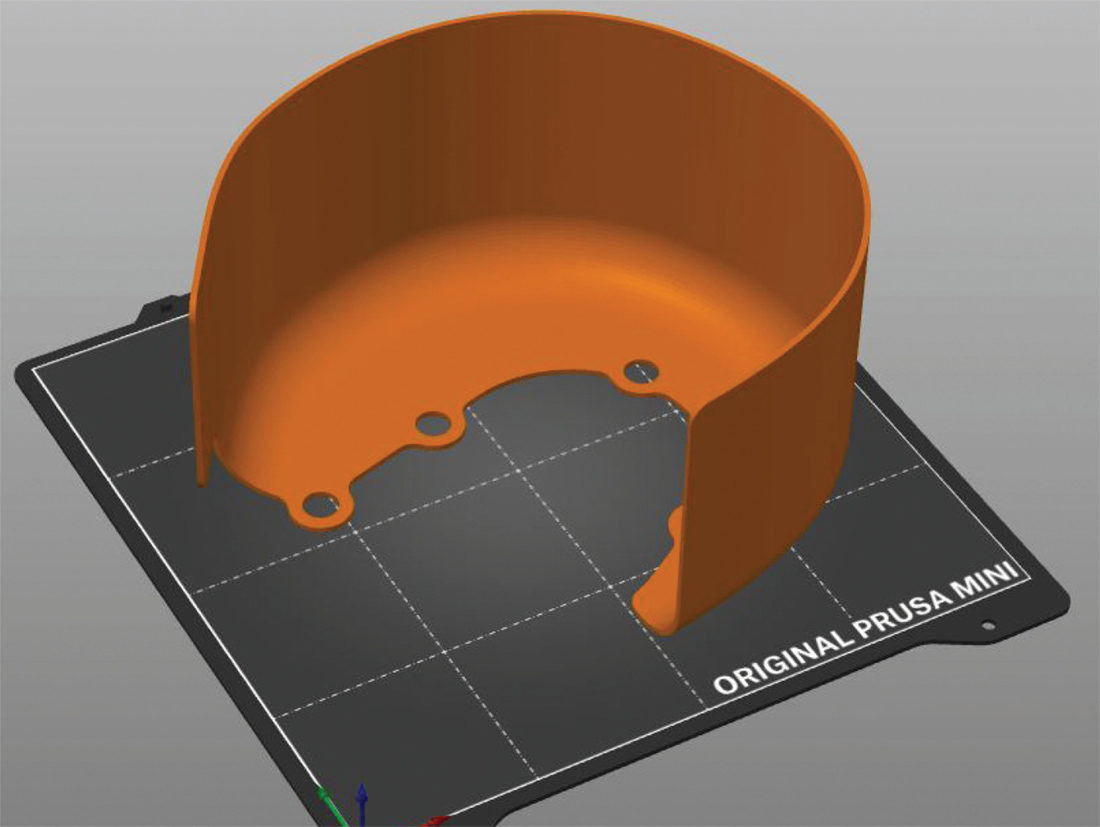

Once the parts have been designed in CAD, another software package is required to generate the G-code that the printer runs on. Cecil used another free software package for this called PrusaSlicer.

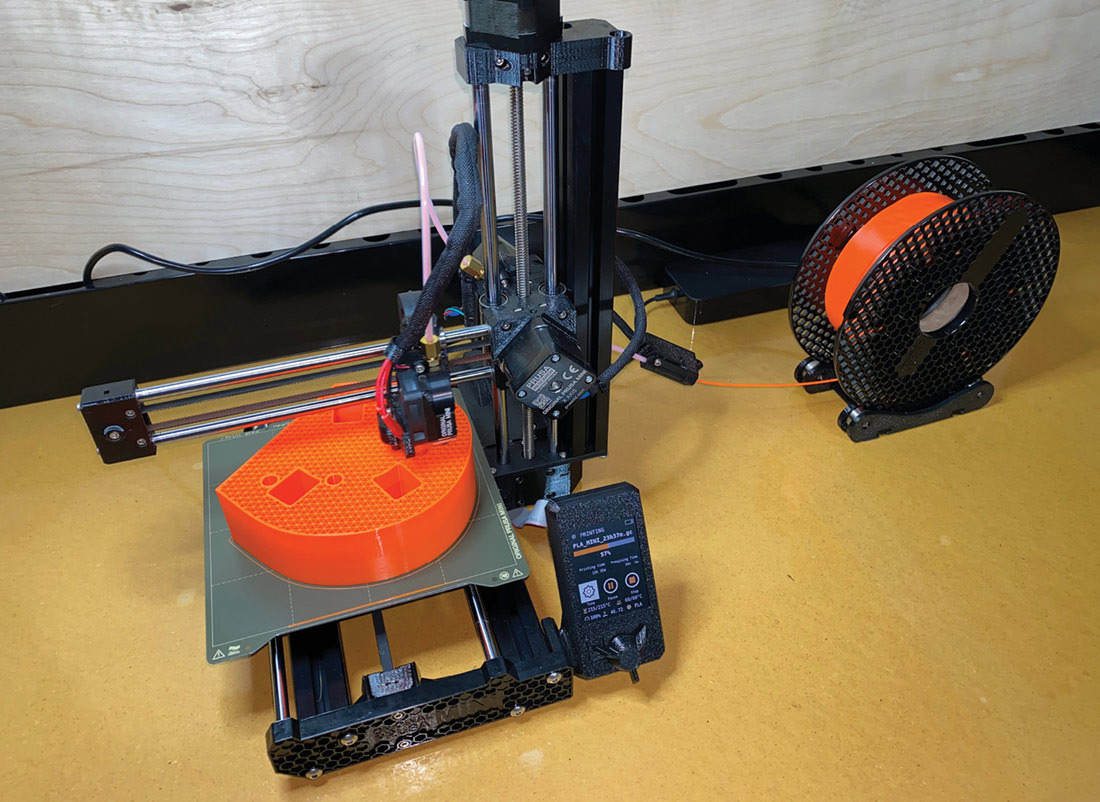

There are many printers on the market, at widely ranging price points. Cecil chose a Prusa Mini+ printer. Its build volume is a 7-inch cube. He reports they provide excellent customer support. This printer is just over $400 in kit form, but several other companies make simplified versions that start around $200. You get more features at the higher price points but the entry-level machines are VERY affordable these days.

There are many different filaments used for 3-D printing. Cecil chose PLA, one of the most common, and a 2.2-pound spool costing $30 was sufficient to print the hammerform and clamping blocks for the turbo heat shield.

It took about 24 hours to print the parts needed for the heat shield, but the printer can run unattended, day and night.

Once the forms were printed, it’s a simple job to cut the metal blanks, clamp them in place, and hammer the edges. Then the parts can be fitted together and welded. Once the welds are smoothed you are left with a clean, accurate construction that rivals the look of a die-stamped part!

Look through the accompanying photos to see the details of this process. It could open up a whole new world of possibilities for many classic truck builders!