Tech

Tech

BY Jason Chandler Photography BY Harrison’s Rod & Custom

Photography BY Harrison’s Rod & Custom

ne of the biggest concerns for truck owners, especially when you love the lowered look, is clearance. I remember back in the day grabbing the reciprocating saw and removing anything necessary to get as low as possible. As I have refined my taste and my concern for the longevity of my projects, I look for an elevated approach to modification. I’ve been looking for a way to do just that and bring you guys along in the process. Enter Bryan Harrison of Harrison’s Rod & Custom.

Harrison is known for hot rods with a true foundation in street rodding. His unique style continues throughout the Squarebody platform and is seen in each build they produce. With the builds Harrison’s Rod & Custom produces, driveability is of upmost importance. The Harrison style is true to hot rodding; you can always tell one of his builds apart from the rest. Staggered wheels and meaty sidewalls are a staple and you got to have clearance for that to work. With the popularity of the ’73-87 GM trucks, nowadays there are always a couple of Squarebodies in his shop. Harrison and I got to talking about this topic and he had the perfect scenario.

Harrison has always wanted to install the early ’73-80 Squarebody inner fenders in the ’81-87 platform and see what he could gain by doing so. The ’73-80 inner fenders have a larger housing and should be able to bolt in without too much fabrication. So, when his customer approached him, he knew we had to document it for Classic Truck Performance.

Daniel Chandler, owner of an ’89 Chevy Suburban (the Suburban carried the “Square” styling through 1991 before getting the OBS upgrade), sourced Harrison’s last summer for a static drop on his Squarebody Suburban. Sitting on a 5/7 drop, it needed just a little inner fender room but at the time he wasn’t quite ready for a full-on tub. Daniel wanted to stay with a GM look underhood. He recently reached out to Harrison after noticing some rubbing on the factory inner fenders and was ready to get them addressed. With the owner open to the idea of the conversion, Harrison reached out to Auto Metal Direct for the inner fenders and shows us just how easy it is to install with basic tools around the shop.

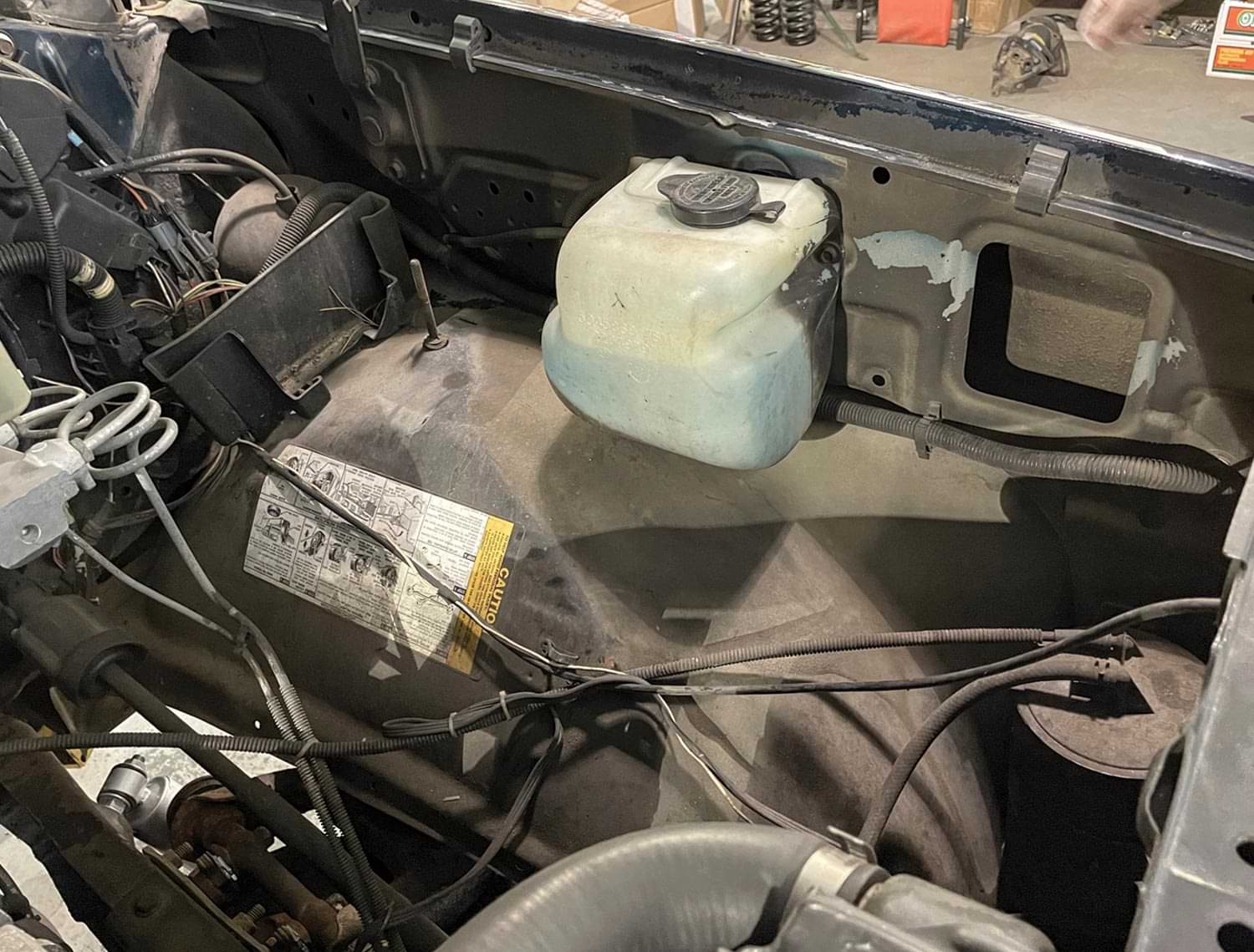

3. Bryan Harrison starts with the driver side inner fender. As you can tell, there isn’t a whole lot to remove here. The factory bottle jack is missing like most of these trucks, but we will need to address the vapor canister mount. More on that later.

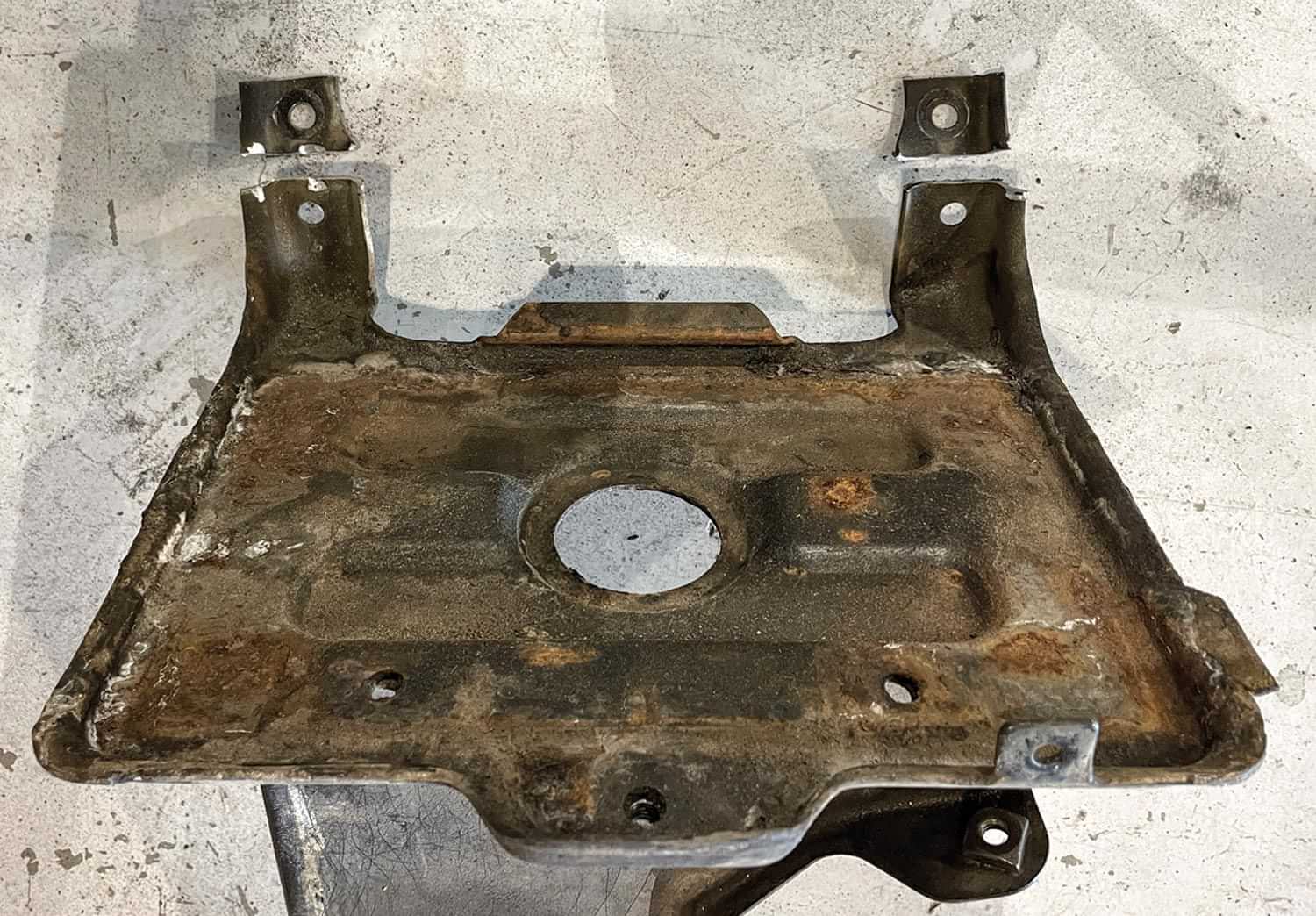

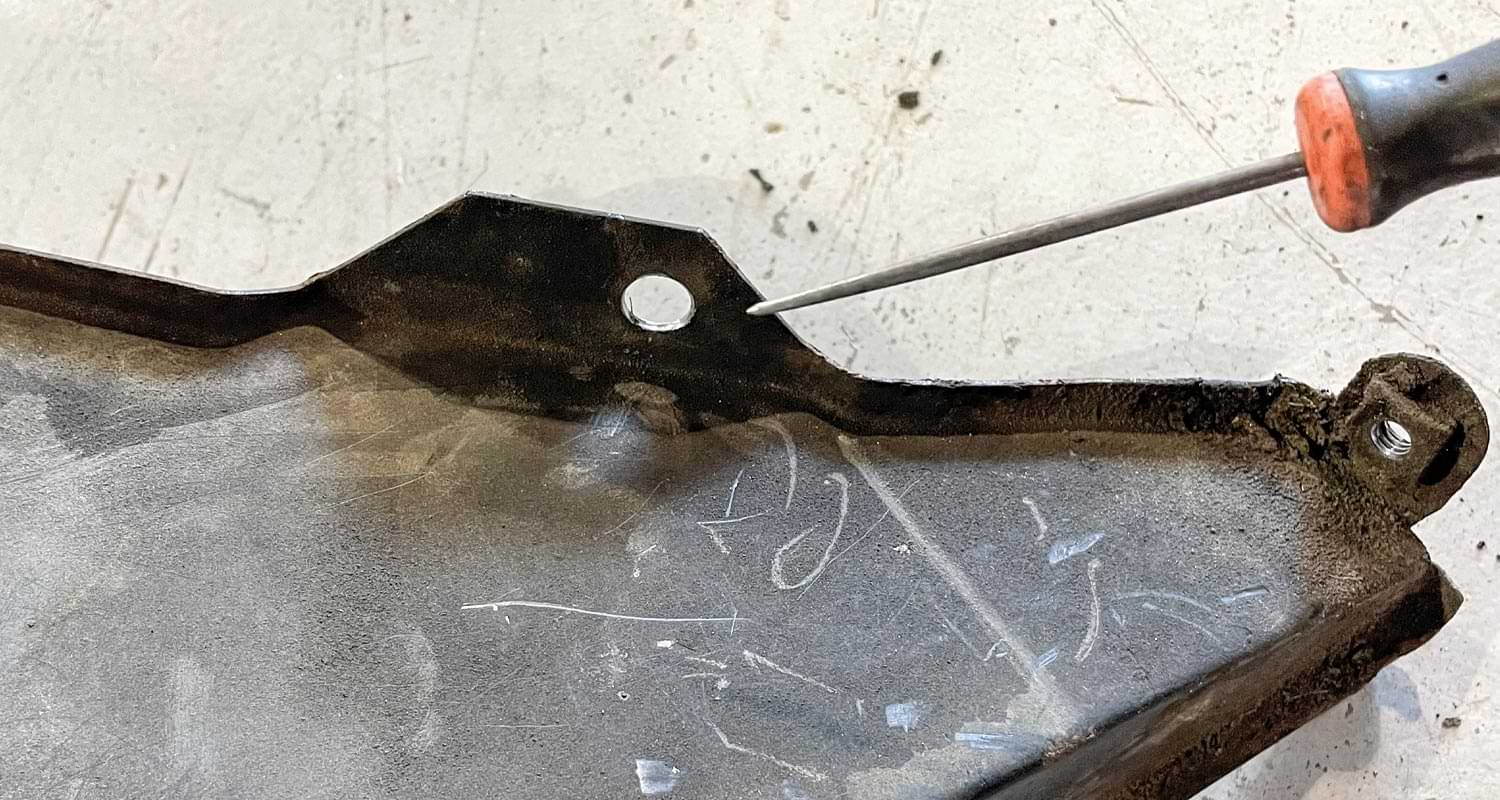

4. With the original inner out and next to the ’73-80 AMD version, you can see just how much clearance you’re going to gain over the factory ’81-87 inner fender.