Tech

Tech

Photography BY The Author

Photography BY The Authore’re the first to admit there’s nothing like the peace of mind and go-anywhere confidence that comes with electronic fuel injection.

We’ll also admit that, for all the convenience of it, the black plastic intake manifold of a factory crate engine and the requisite cone filter, clamped to a length of steel tubing serving as an air intake, don’t exactly complement the underhood aesthetics of a classic truck.

To split the difference, many enthusiasts have understandably been lured by the undeniably great look of a vintage-looking stack-style EFI system. That classic style doesn’t exactly come cheap. Some of the more inclusive systems can push to $6,000 and beyond, which can be difficult to justify when that simple black plastic intake comes already bolted to a crate LS3.

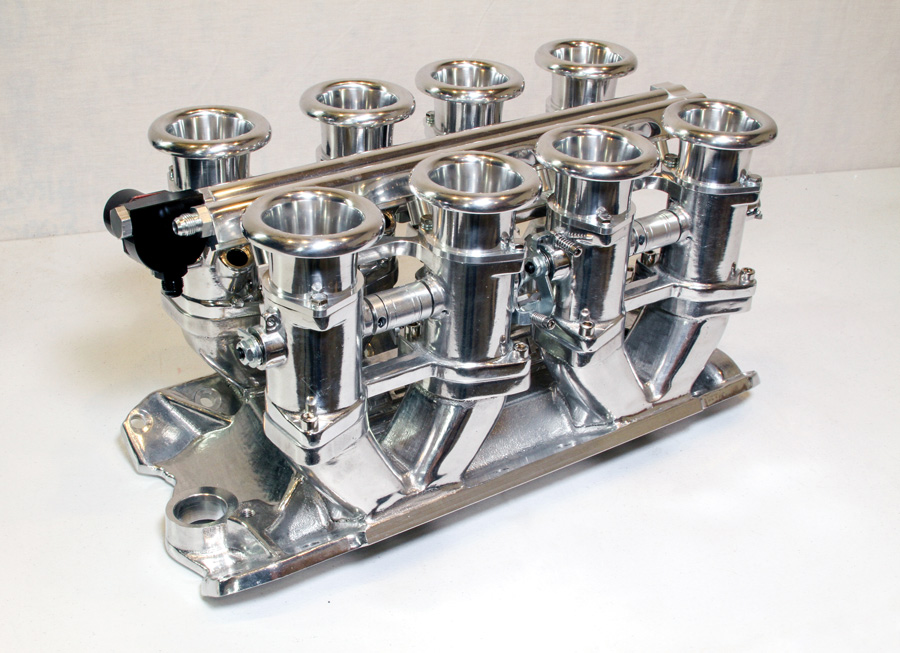

Then again, style counts. The stack-type EFI manifolds from Speedmaster appear to bridge the cost gap, priced at less than $2,300 at summitracing.com; and for another $1,300-$2,000 or so, the kit can also include an electronic control system.

Is there a catch? Yes. The parts that aren’t included with the kit—which is pretty much everything else required to get an EFI system up and running. The basic, sub-$2,300 manifold kit doesn’t include the injectors and necessary sensors, nor the ignition control system or a properly prepared distributor. Unless you opt for the version that includes the controller, there’s no ECM—and even with the control system, the injectors and other necessary components aren’t included.

For enthusiasts who aren’t deeply immersed in EFI theory and practice—and those who simply have an electronics phobia—it can be a daunting and challenging task to collect the necessary support parts, assemble them, and get it all wired up to run in a project vehicle.

That’s where Missouri-based Specialty Engine Builders comes in: They start with the bare Speedmaster manifold, for Chevy or Ford small- and big-block engines, and build it up with everything needed to install it, make a few quick harness connections, and fire up the engine. It is the solution to a problem the company’s founder, Jeff Donker, experienced with the trial-and-error of building stack-style EFI systems for customers’ engine projects.

“The Speedmaster manifold kit from Summit looks great and the quality seems top-notch, but it’s really just the foundation for building a complete EFI setup,” Donker says. “It comes with no assembly instructions or directions for the additional support components required to complete it, so anyone who’s not very familiar with EFI systems will be at a loss after they open the box. You don’t know what you don’t know, and that’s where we come in.”

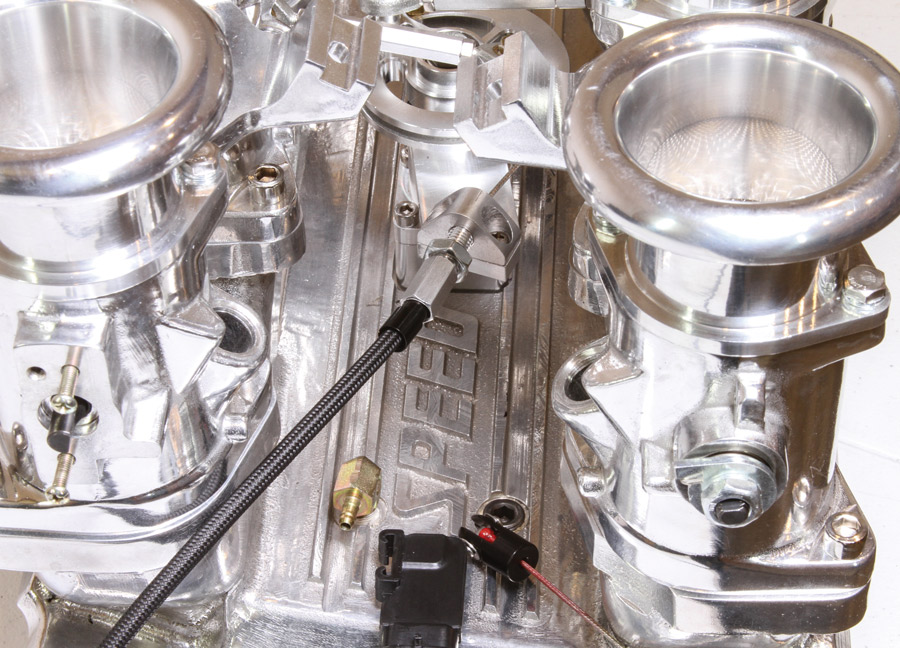

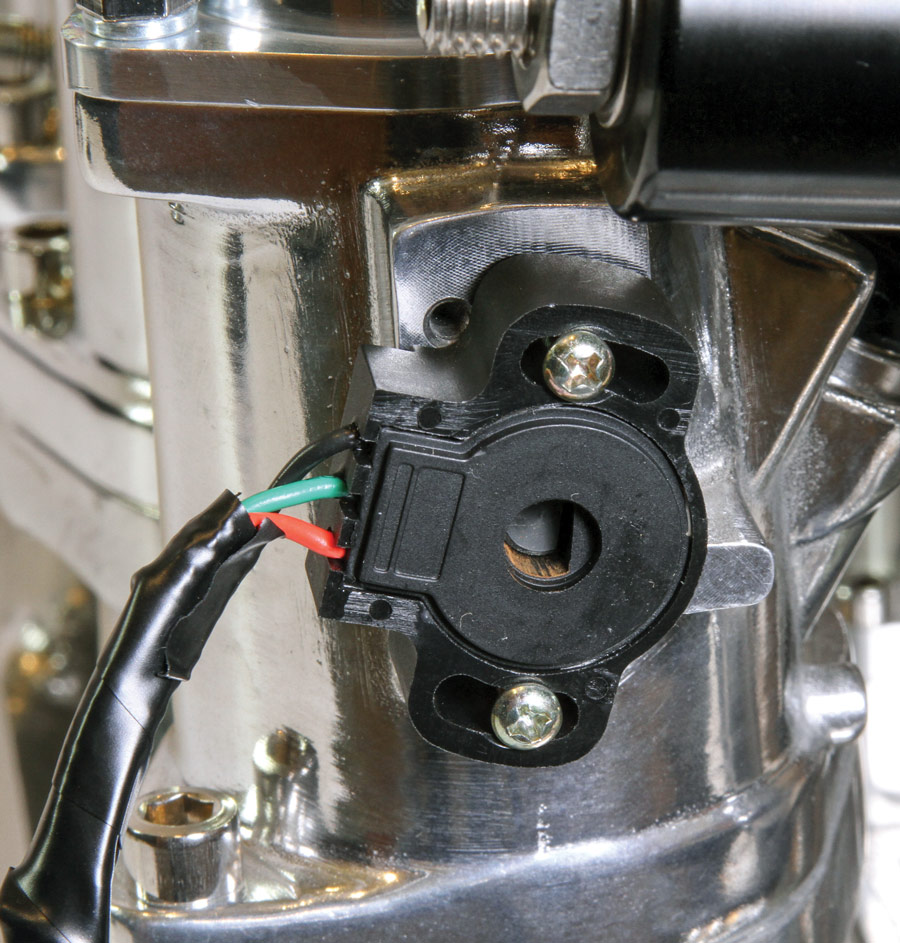

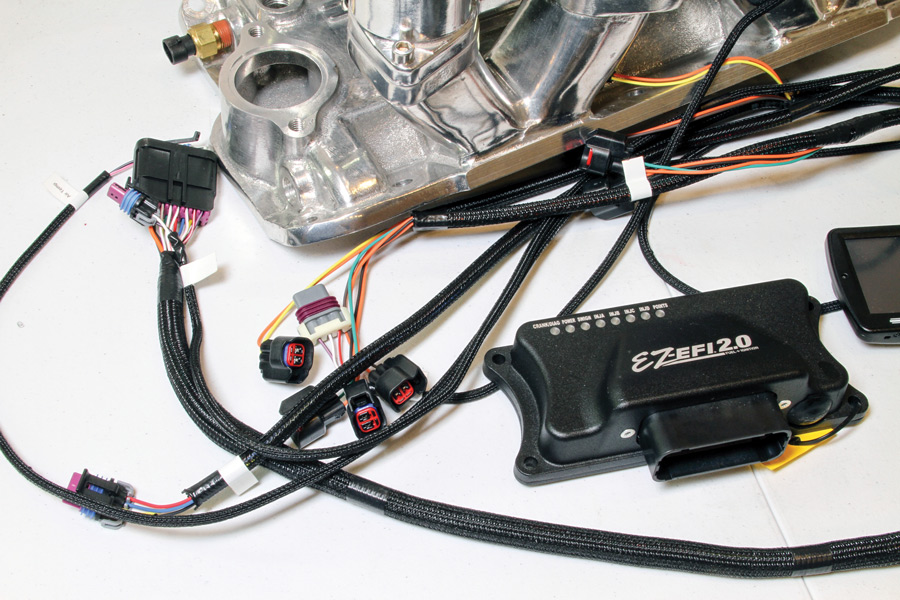

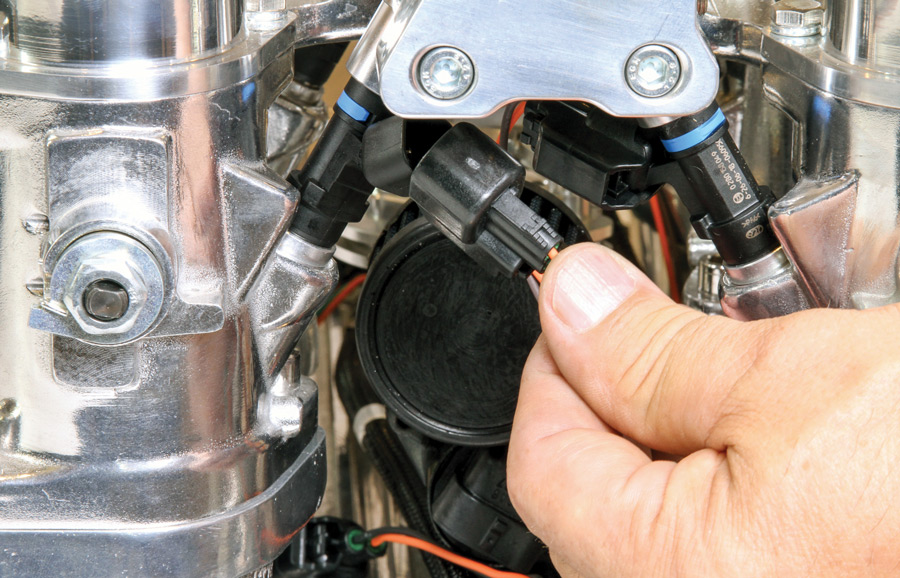

In a nutshell, Specialty Engine Builders’ kits include virtually every component required to start the engine after the assembled manifold is installed on the engine. That means the injectors are not only installed but wired to a supplied controller, along with the necessary MAP, throttle position, air temperature supplied controller, and other sensors.

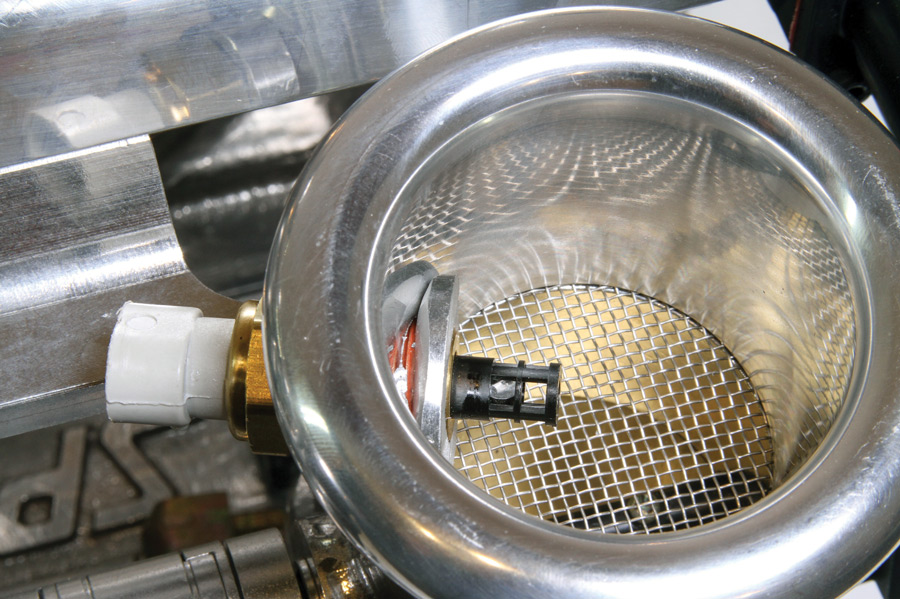

It’s all more complicated than it sounds, too, because injector plug-in styles differ and the seals for off-the-shelf injectors don’t necessarily fit the manifold perfectly. Even recommended sensors didn’t work well during Donker’s initial attempts.

“We spent countless hours trying different components until finding the perfect parts,” he says. “And, frankly, I wouldn’t wish that sort of trial-and-error process on anyone. It’s time-consuming and frustrating when something doesn’t work, because you don’t know where to turn next. We’ve done all the research and figured it all out, so the customer doesn’t have to.”

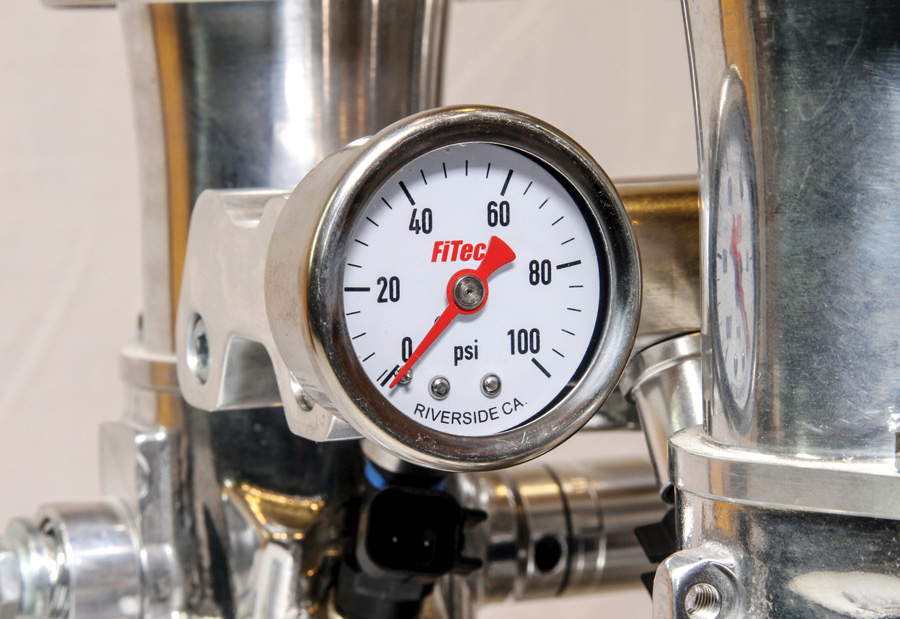

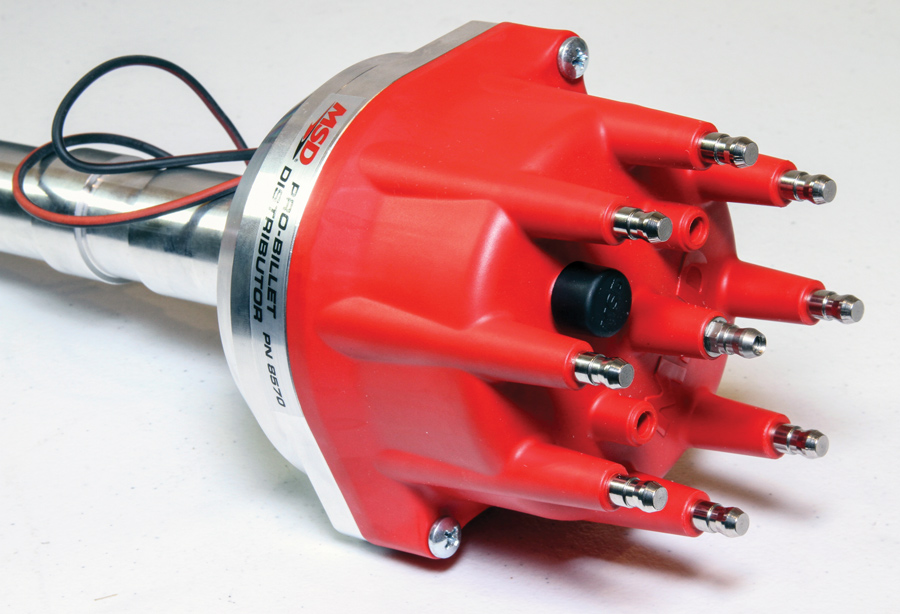

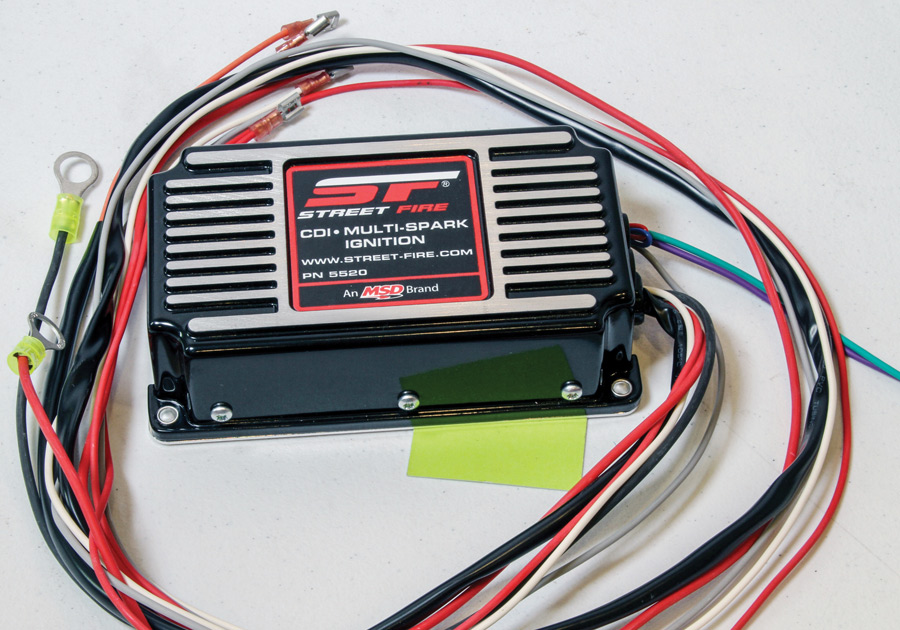

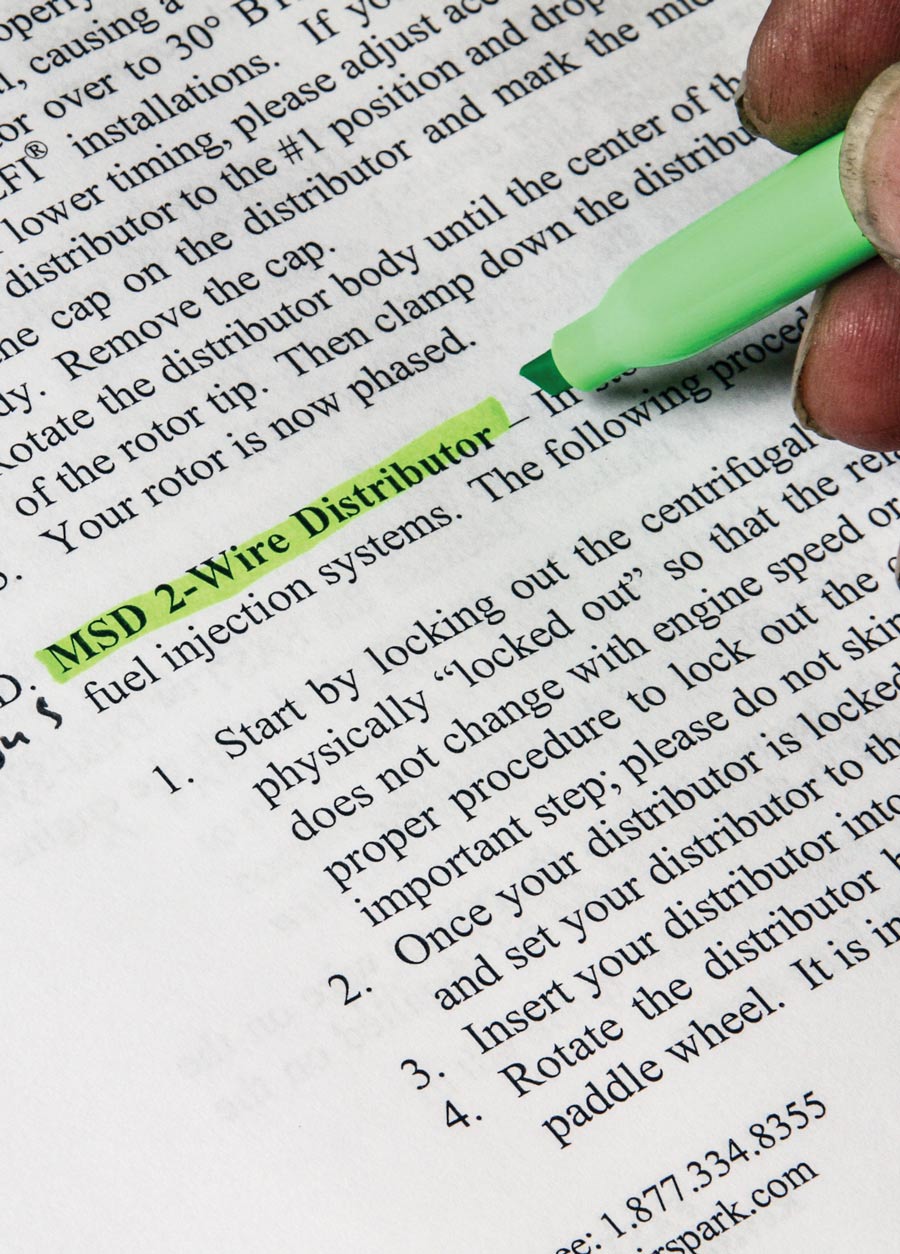

Additionally, Specialty Engine Builders’ kits include a prepped distributor, with the necessary lockout for mechanical or vacuum advance, because that duty falls to the engine control system—and it’s matched with a complementing MSD ignition control box. A high-pressure fuel pump is even included.

“It’s as close to plug-and-play as you will get with a fuel injection system like this,” Donker says. “We not only install all the components, we get them ready to run for the engine. You basically drop on the manifold, install the distributor and fuel pump, and plug it all into the controller. It should fire right up, without the need to chase parts, splice many wires, or guess at a wiring diagram.”

That’s exactly what happened during our visit to the company’s shop to document the assembly of a Chevy small-block system and watch another freshly built system be installed and started on a customer’s engine. It started on the first try and the included, self-learning control system had it running smoothly within seconds.

It was clear that from drilling one of the air horns to accept an air temperature sensor to modifying the distributor wasn’t a job casual enthusiasts, or those unfamiliar with EFI systems, would find easy to accomplish on their own.

And the cost? A Chevy small-block system starts at $5,495, which includes the cost of the Speedmaster manifold. Of course, because each kit varies with the specifics of a customer’s engine and installation details, the cost varies, but the bottom line is the price includes the control system, distributor, ignition box, and fuel pump, in addition to the injectors and sensors. It’s as complete as it gets—and the staff will get on the phone anytime to help customers walk through the installation and setup in their vehicle.

There’s no getting around the fact that stack-style EFI systems cost a few bucks, but the payoff in incomparable style makes the investment hard to beat when the hood is lifted. For those who want their system as close to ready-to-run as possible, the kits from Specialty Engine Builders appear tough to beat.

SOURCES

SOURCES