Tech

Tech

Photography BY The author

Videography by Ryan Foss Productions

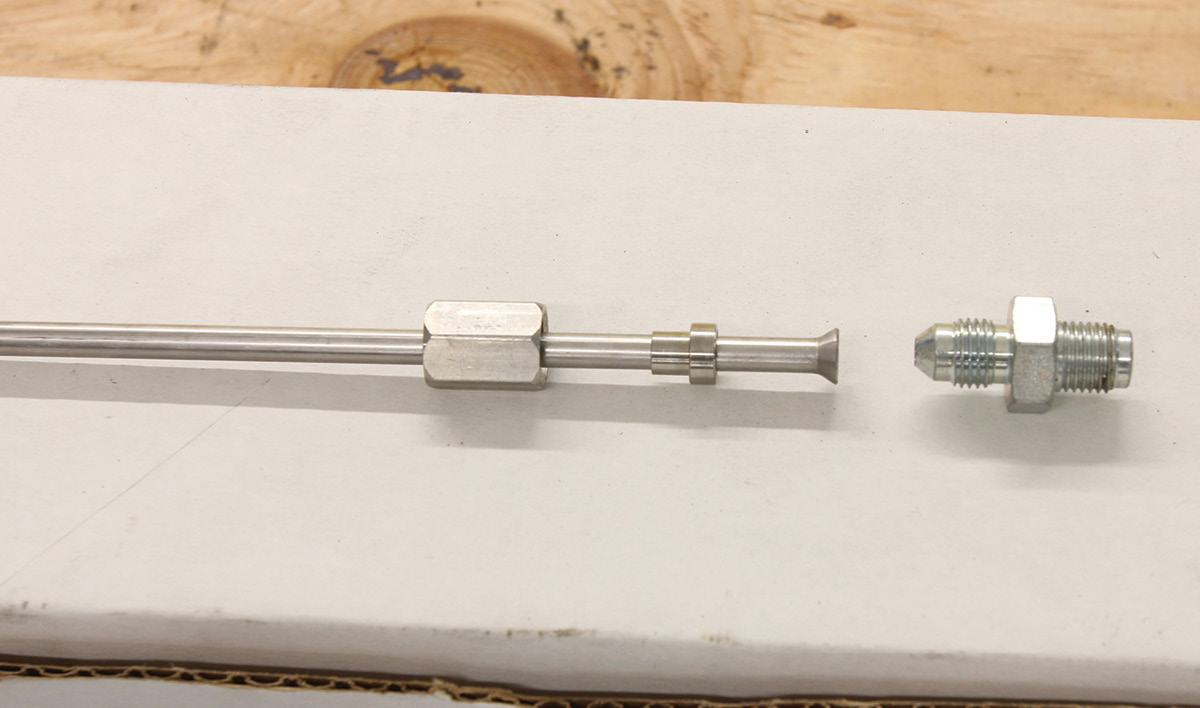

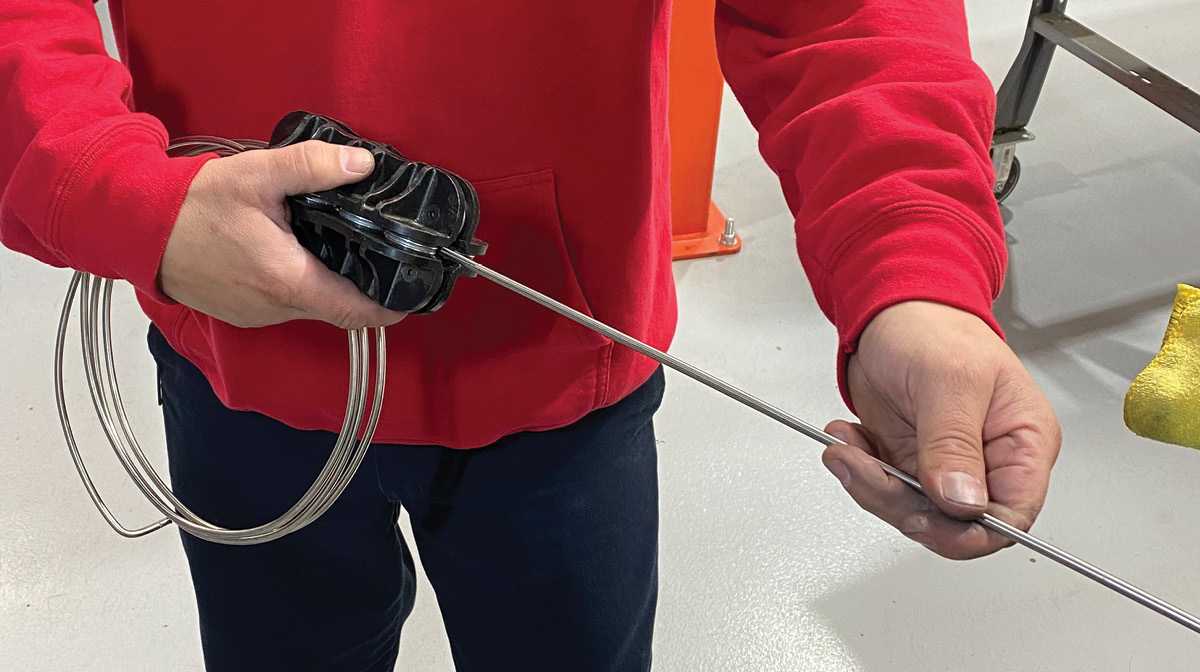

hen it comes to plumbing a disc brake system, you’ll find as many opinions as you will options when it comes to everything from line size to material, flaring techniques, and hardware. Here at the Clampdown Competition garage, we’ve had great experience using a simple kit from Speedway Motors, in addition to a handful of various fittings and hardware. So, when Editor Fortier invited me out to the ITGM Tech Center with the request to plumb his C10 project, I only had one request: contact Speedway and get one of their stainless steel brake line kits on its way.

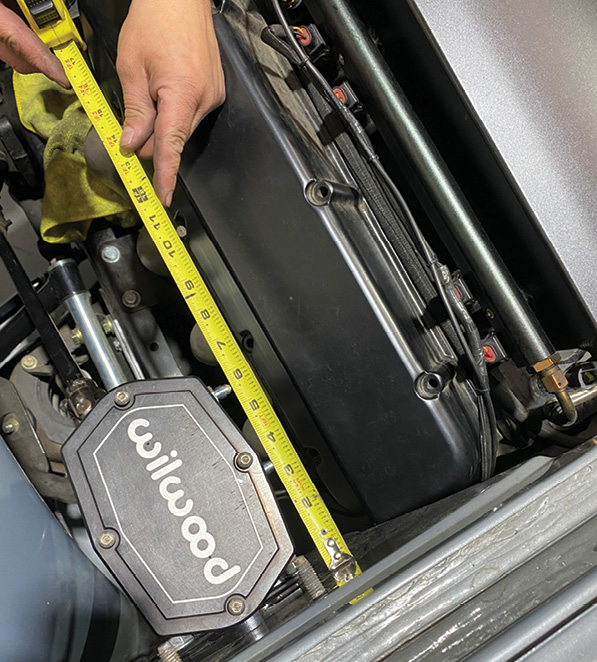

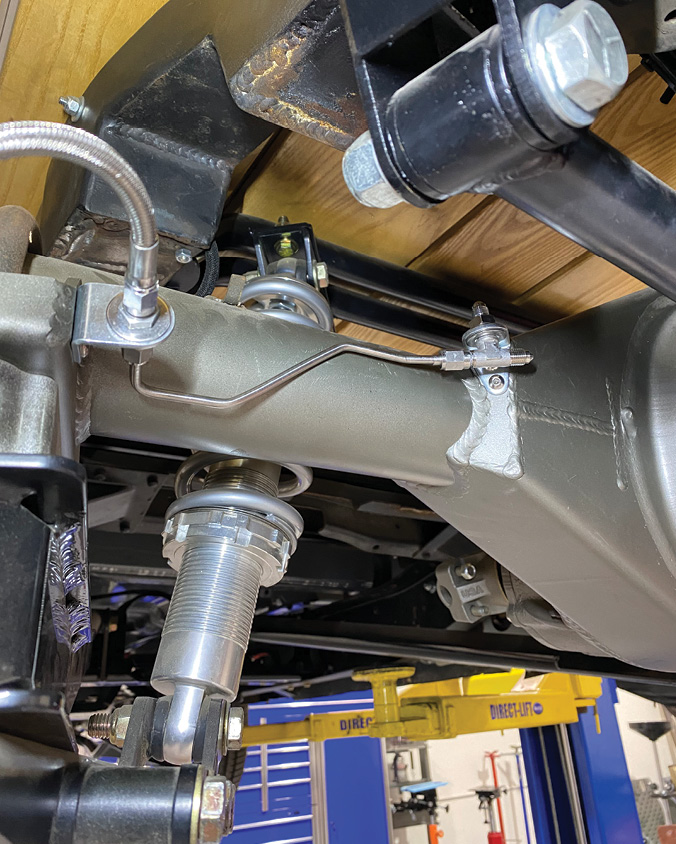

Rob’s truck was already a roller—that is it already had a full complement of Wilwood disc brake components bolted both front and aft. As we mentioned, it was lacking in plumbing but it was also lacking a brake pedal, linkage, and master cylinder. With the part numbers of both the front and rear calipers in hand, Rob contacted Mike Hamrick at Wilwood Disc Brakes, who recommended the correct size (7/8 inch) for Rob’s setup in a manual brake design. Inside the cab, a Lokar Performance Products Direct-Fit billet aluminum brake arm will handle the task of transmitting the pedal pressure to the master cylinder, adding a little style all the while.

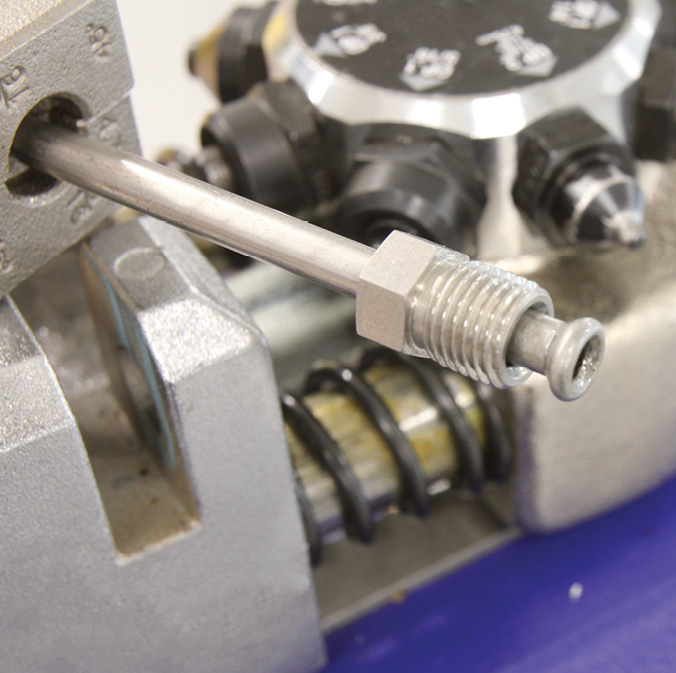

Once the system is plumbed, it still needs to be bled the old-fashioned way, but not until the master cylinder receives a bench bleeding. This ensures that no air is trapped inside the master’s valving that could cause problems down the road. After the master cylinder is bench bled, it’s reinstalled on the firewall and the lines reattached, then it’s time to get to cracking each caliper’s bleeder valve, starting with the furthest from the master cylinder. Slowly but surely the air was worked out of the system until we achieved a nice, solid pedal. From there, it’s time for a drive and a few brake system checks to correctly bed in the brake pads and adjust the rear proportioning valve.

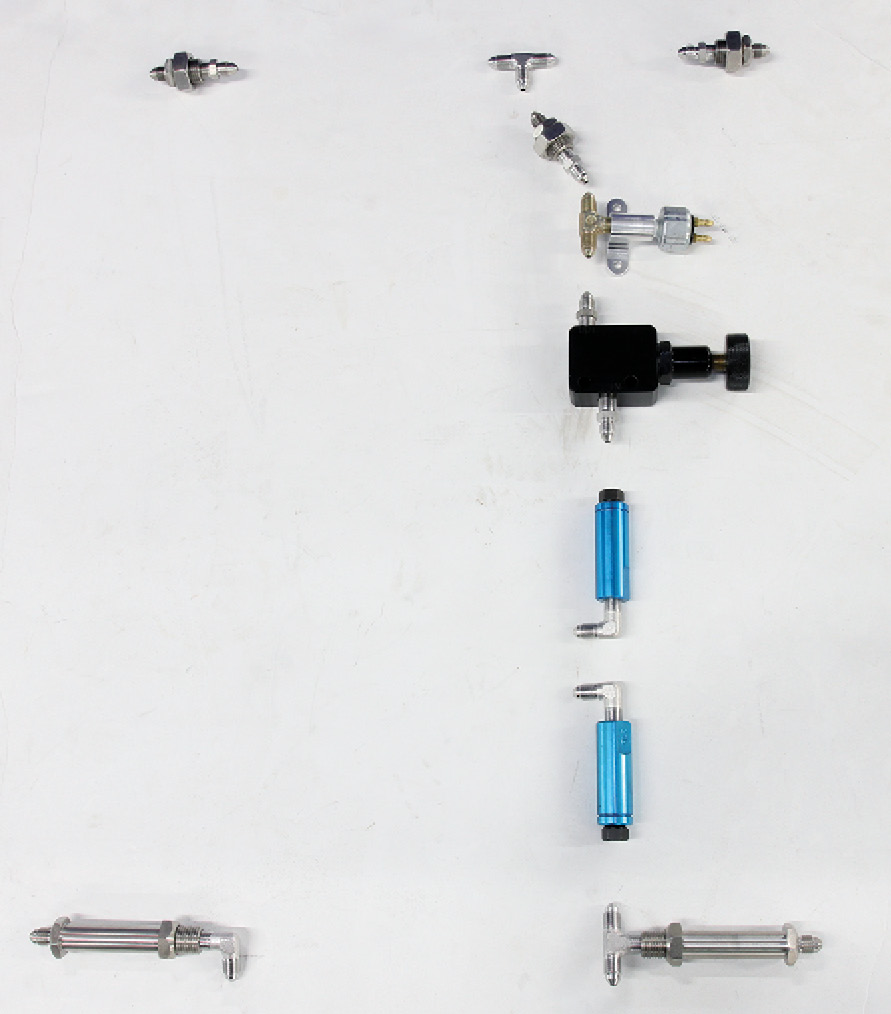

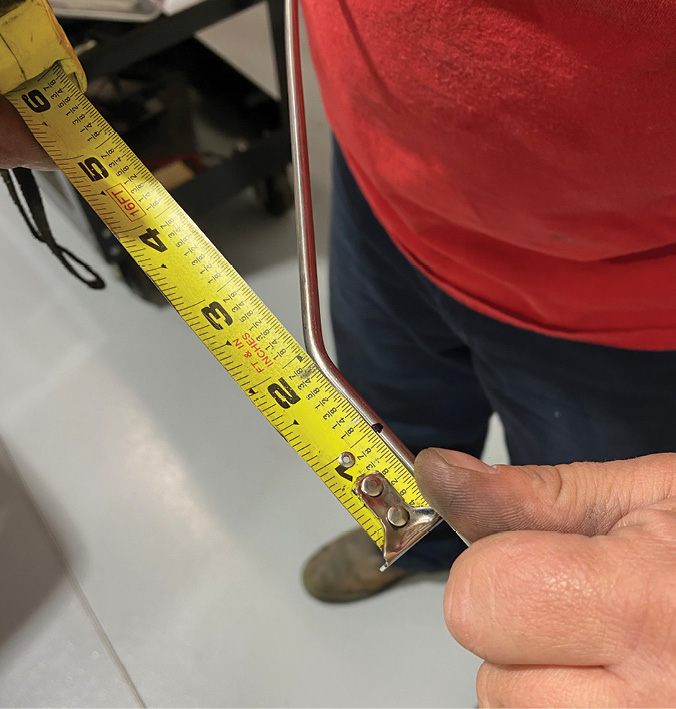

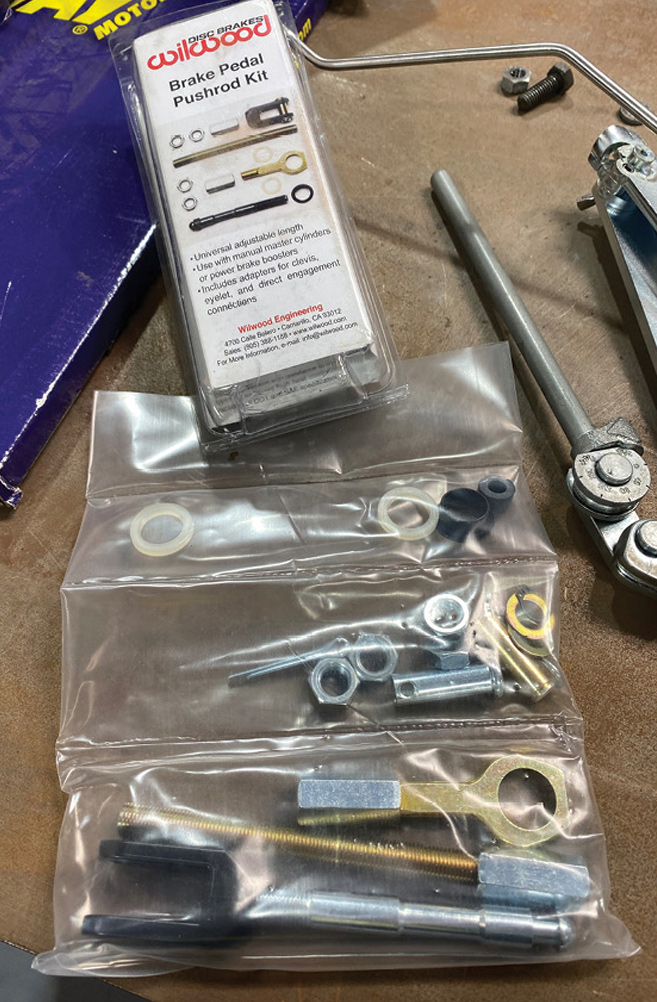

5. Like any job, careful planning usually yields the best results, and it’s no different when it comes to planning a brake line system. Here, I’ve laid out all the various tees, fittings, valves, and other components for a previous job to ensure we had everything on hand before a single line was bent or flared.

SOURCES

SOURCES