Tech

Tech

Photography BY THE AUTHOR

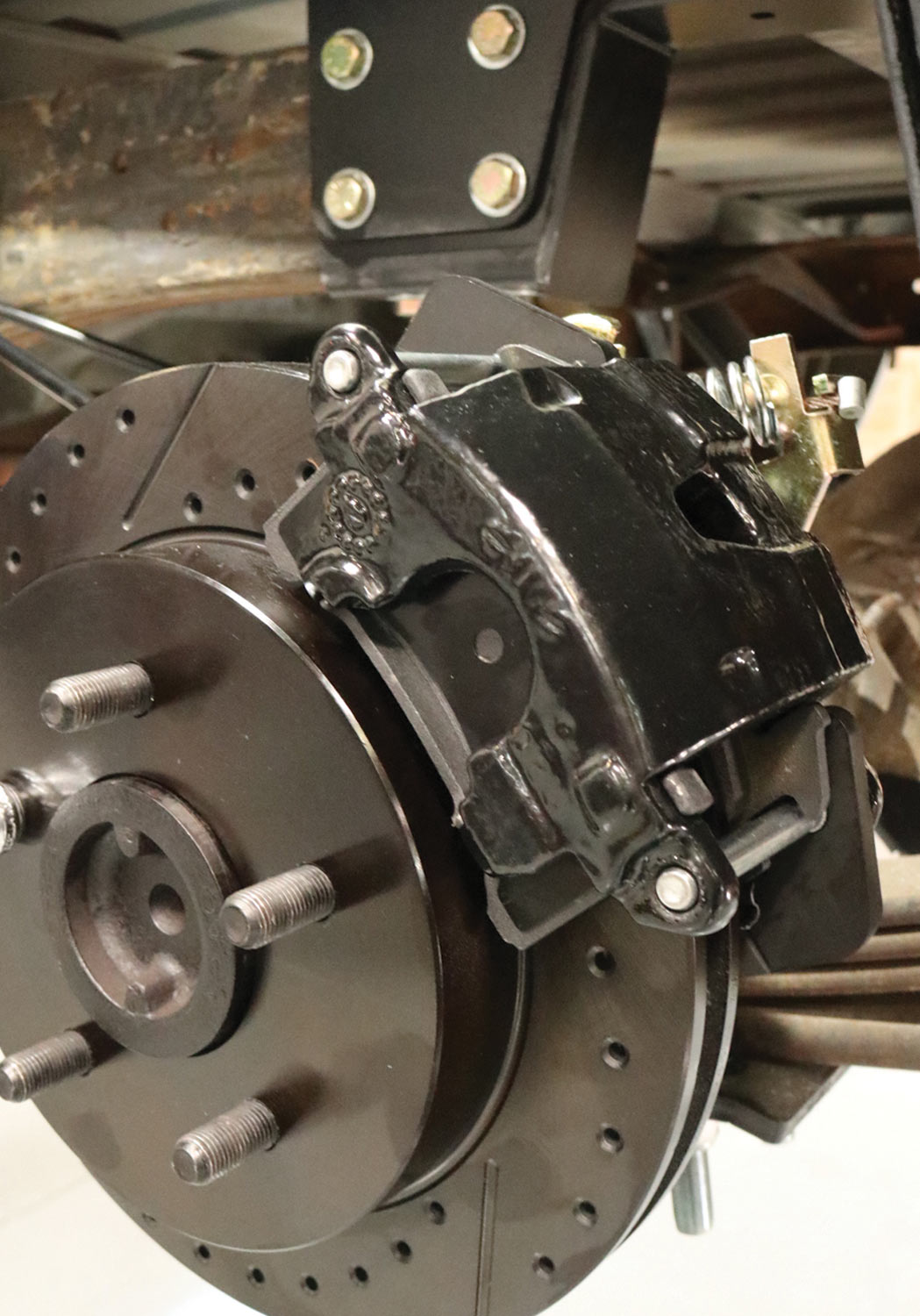

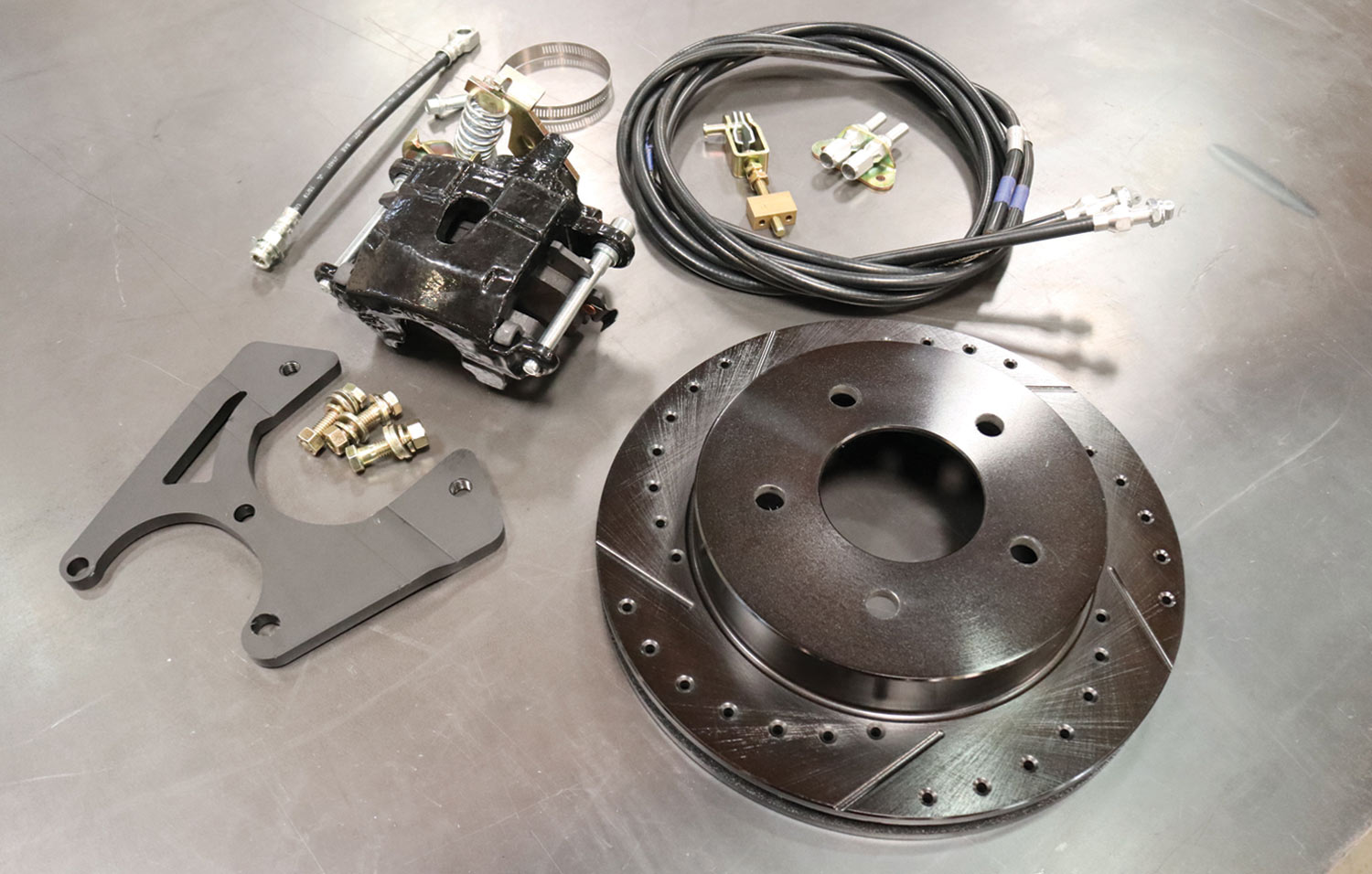

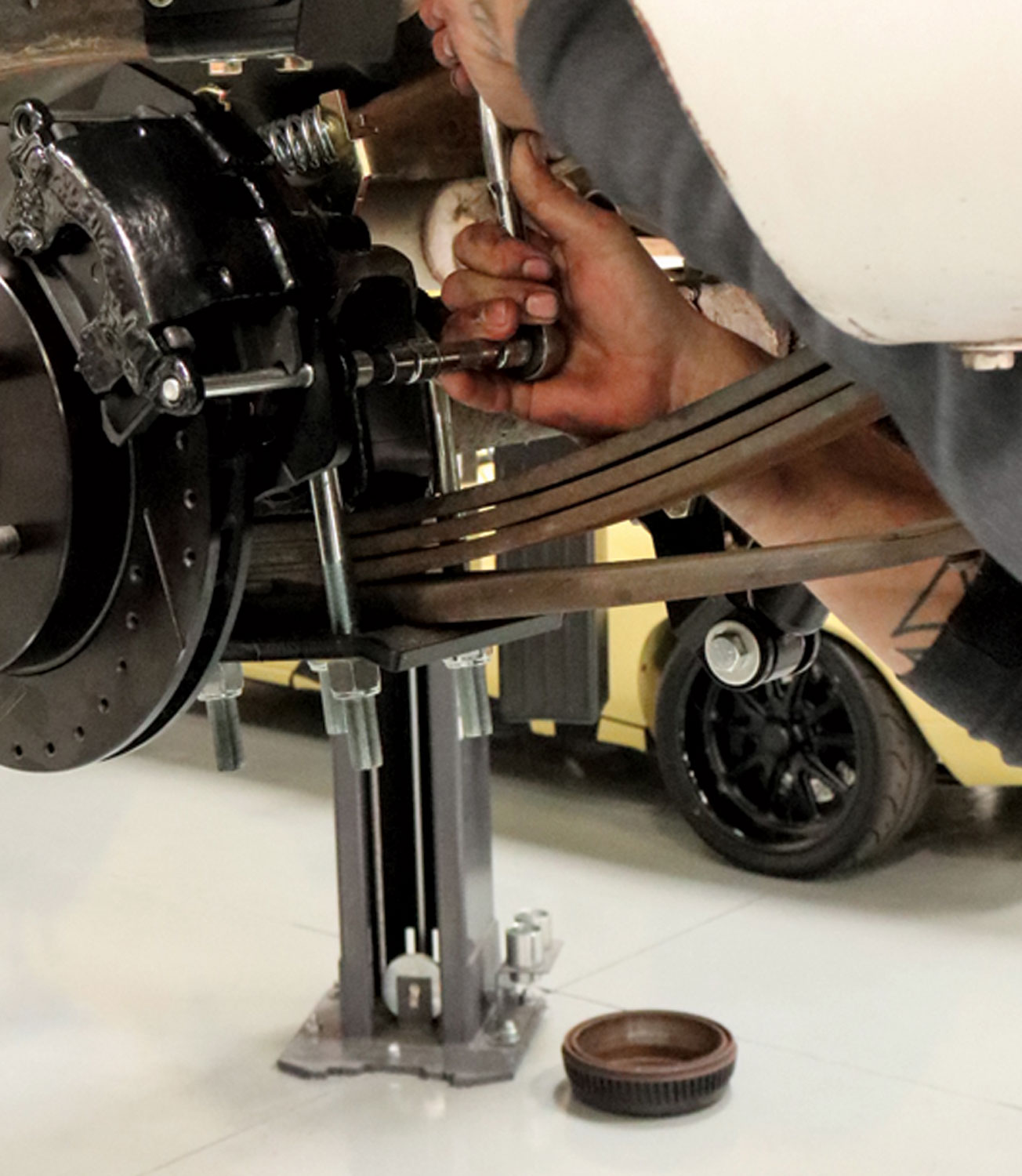

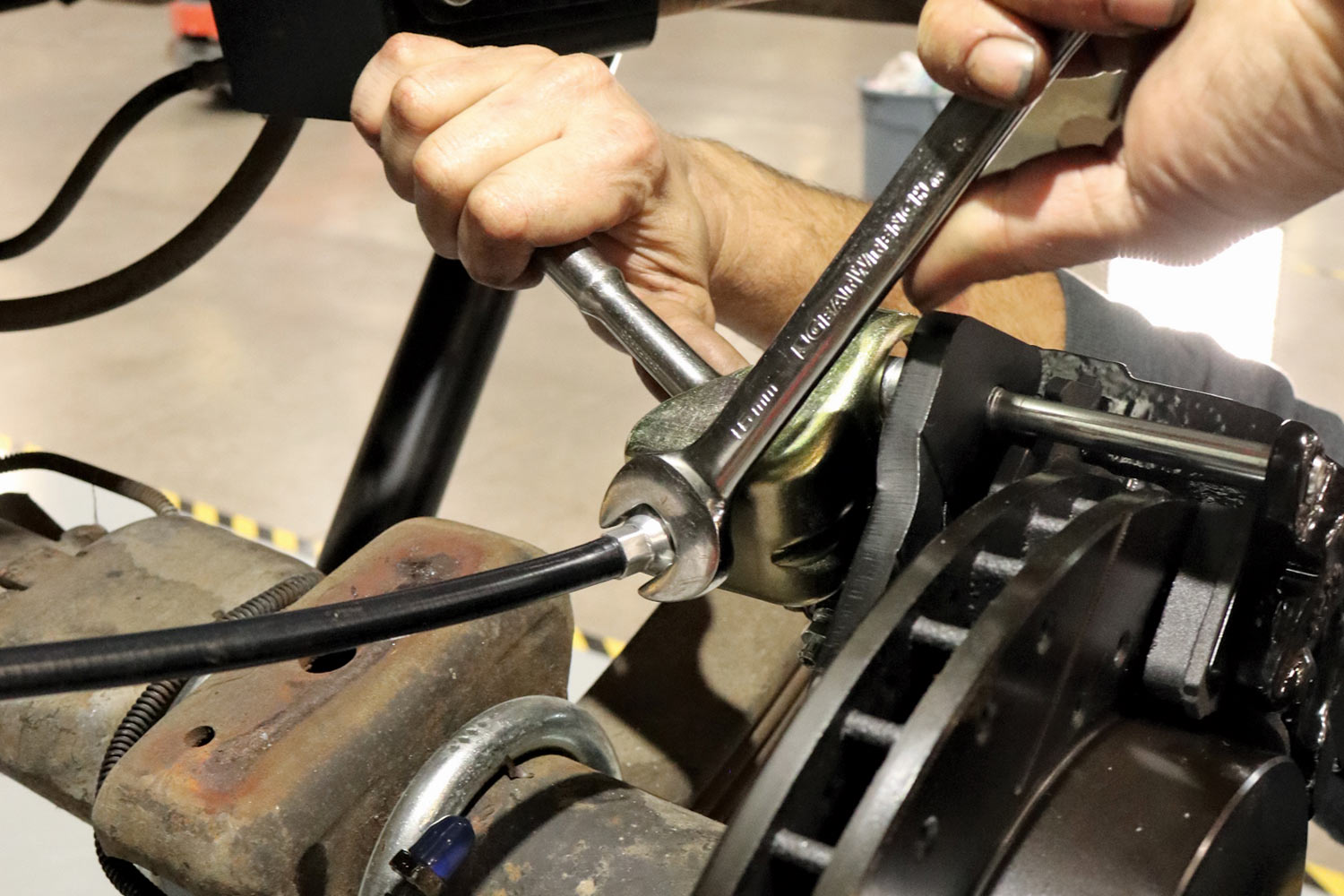

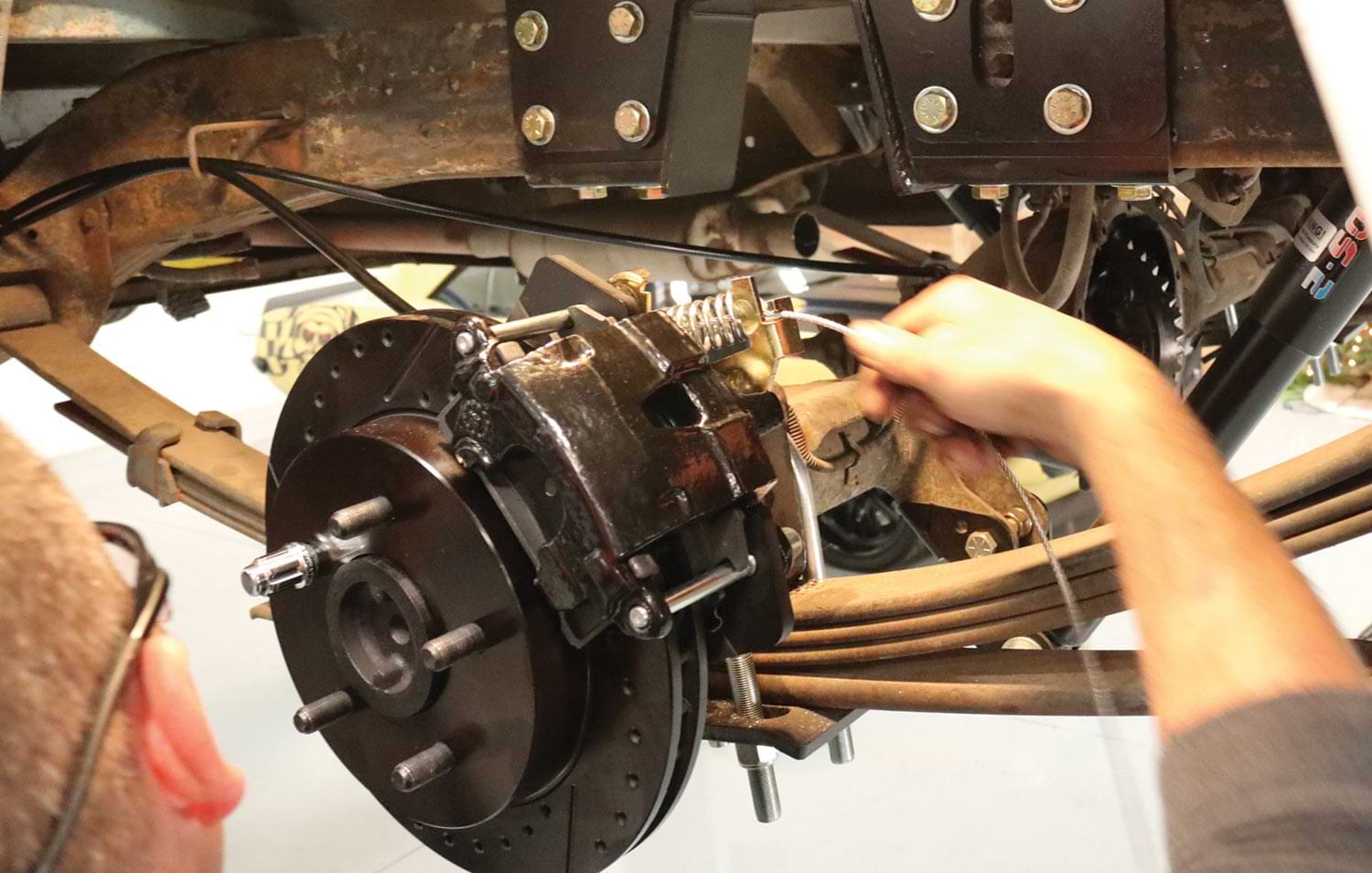

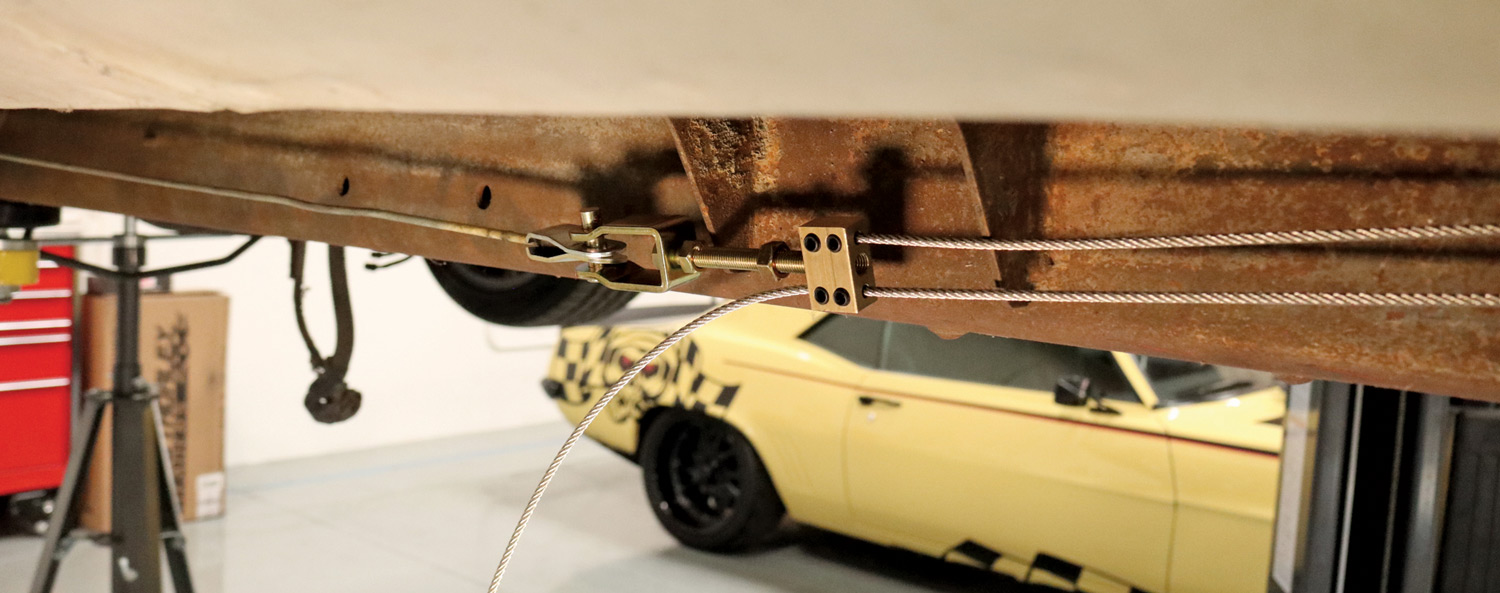

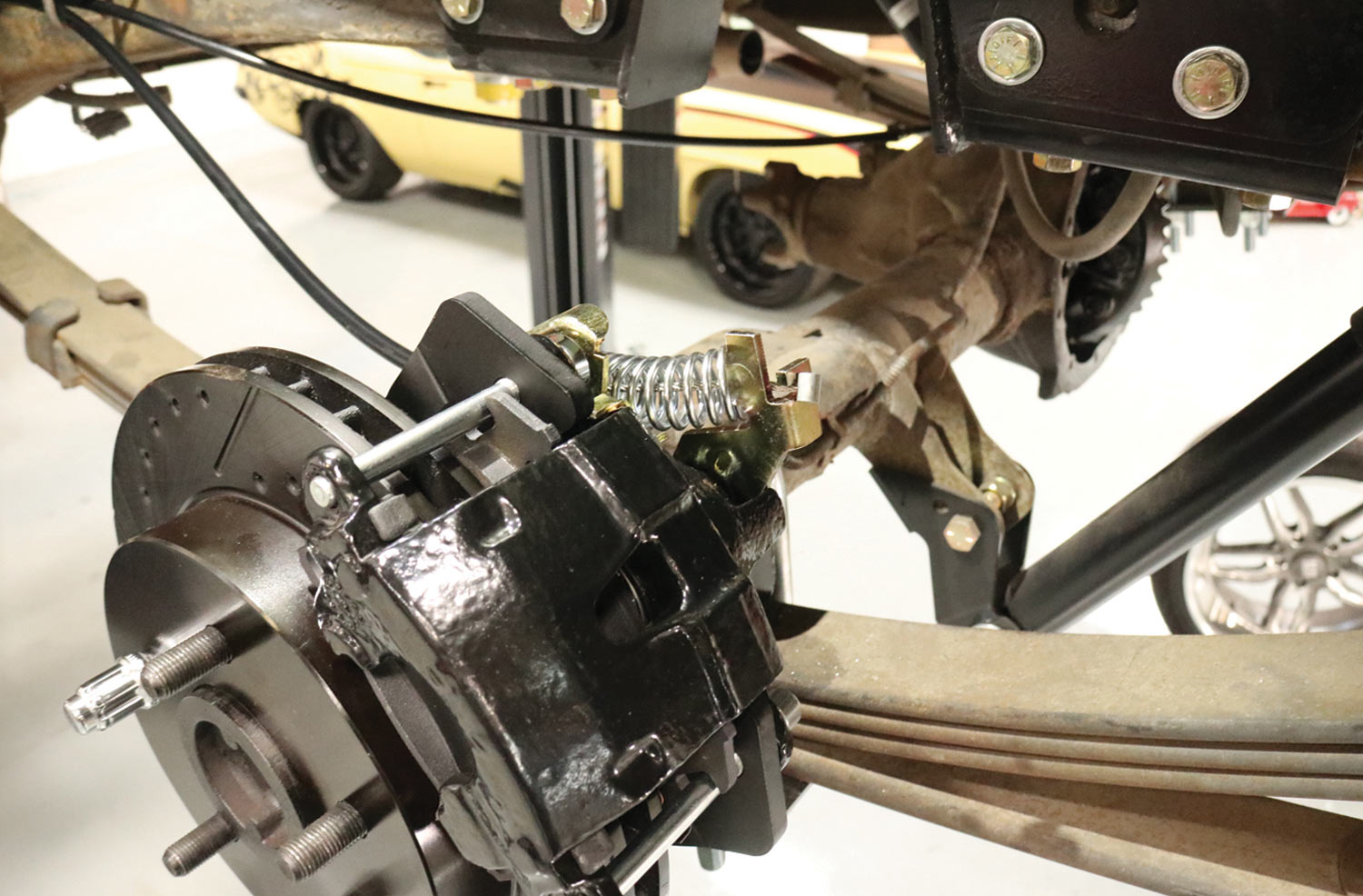

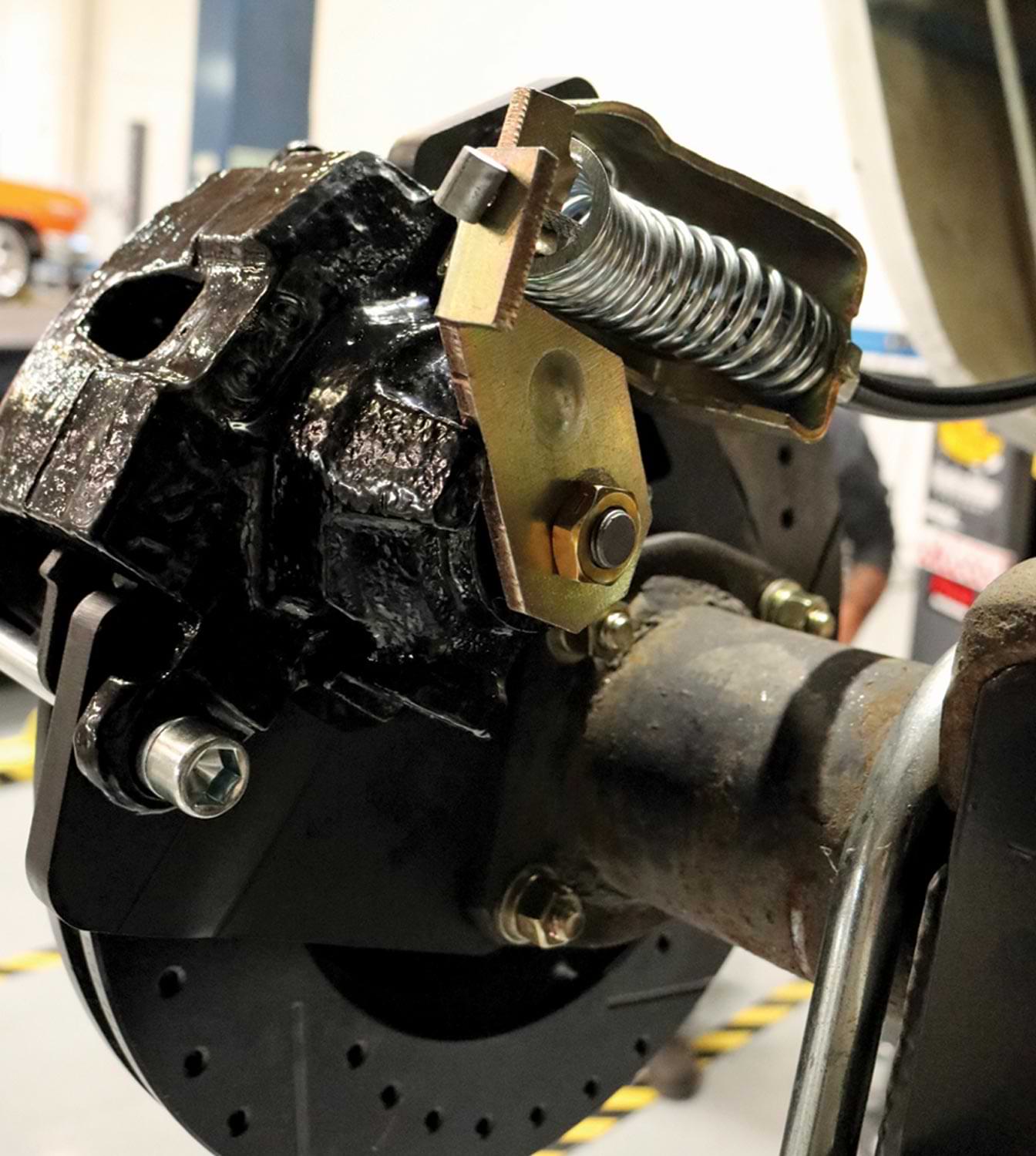

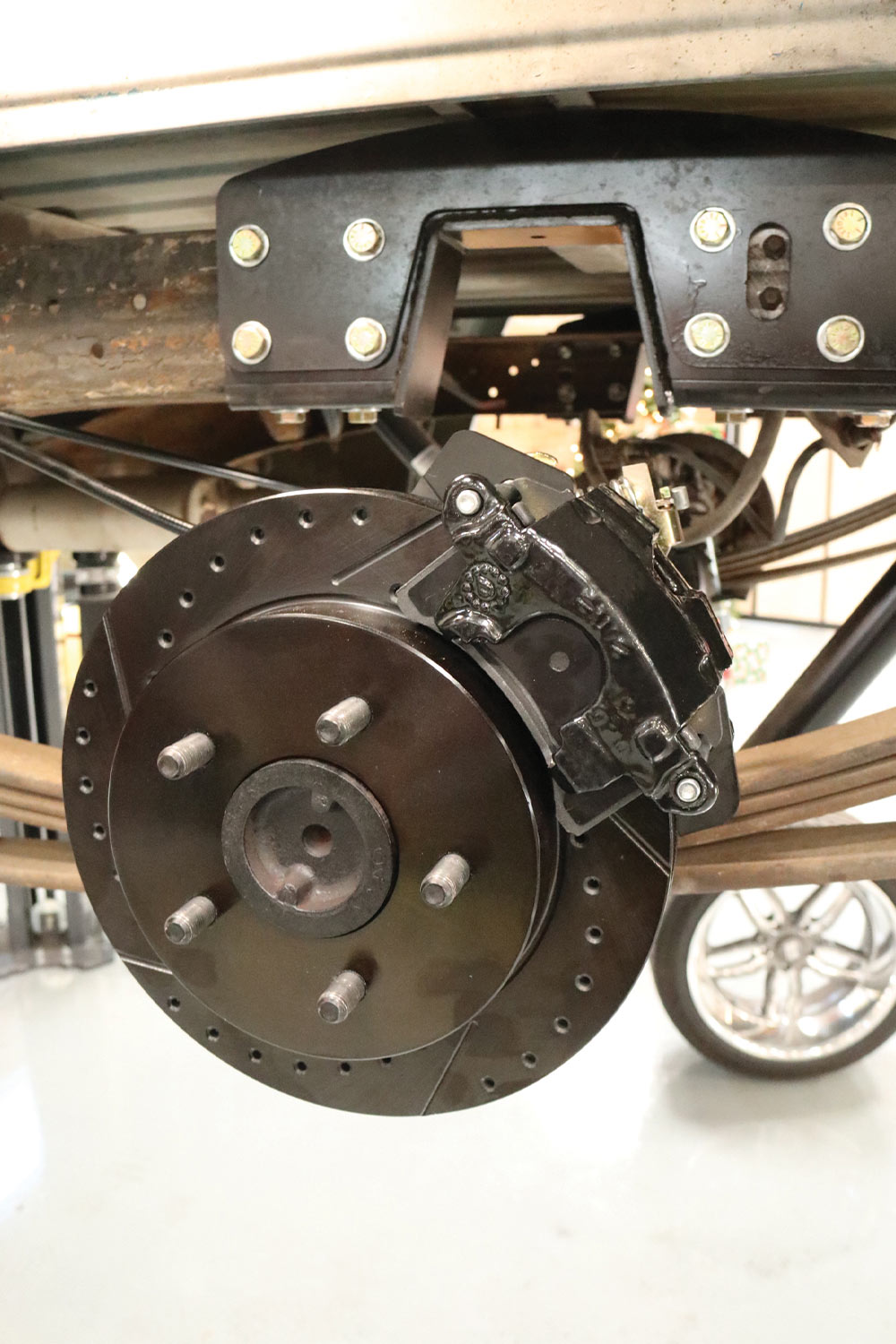

Photography BY THE AUTHORt’s been a minute or few since we last visited Western Chassis’ OBS suspension and brake offerings (Dec. ’20 issue, to be exact!), so we figured it was past due time to take a closer look at their sister company Performance Online’s (POL) Blackout Series of ’88-98 Chevy/GMC 1/2-ton brake kits—11.75-inch rear disc setup for the non-such-equipped OBS 1/2-tons (PN RWB58898).

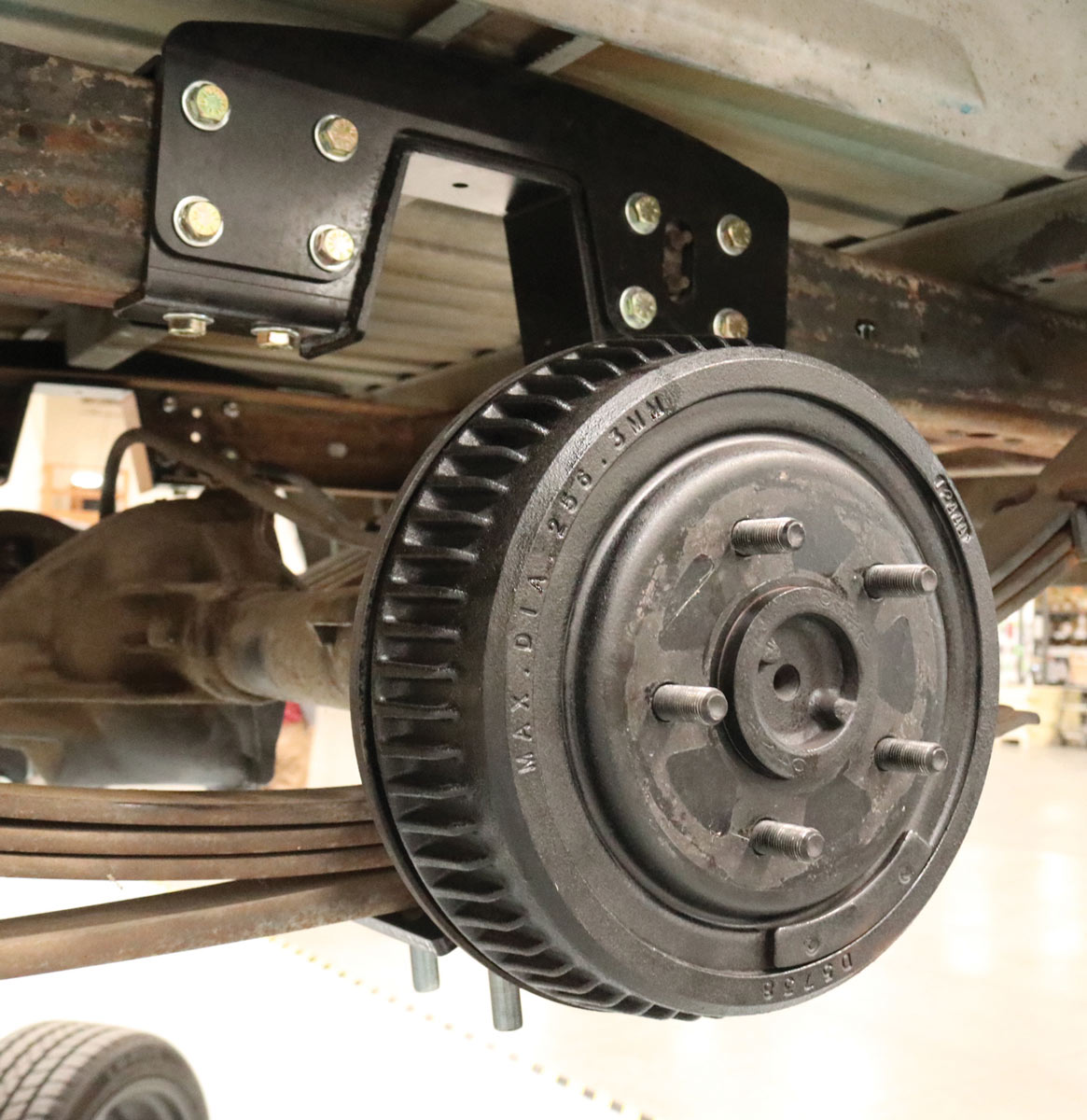

If you’re tired of your C/K 1500/GMT400’s stock 10-inch rear drum brake performance and are looking for a direct bolt-on kit (in lieu of doing the Internet’s favorite backyard mechanic “late-model” swap), Performance Online’s new kit for the Chevy/GMC pickups (as well as the similarly equipped ’92-00 Blazer/Tahoe/Yukon/Suburban) will do the trick … without emptying your wallet.

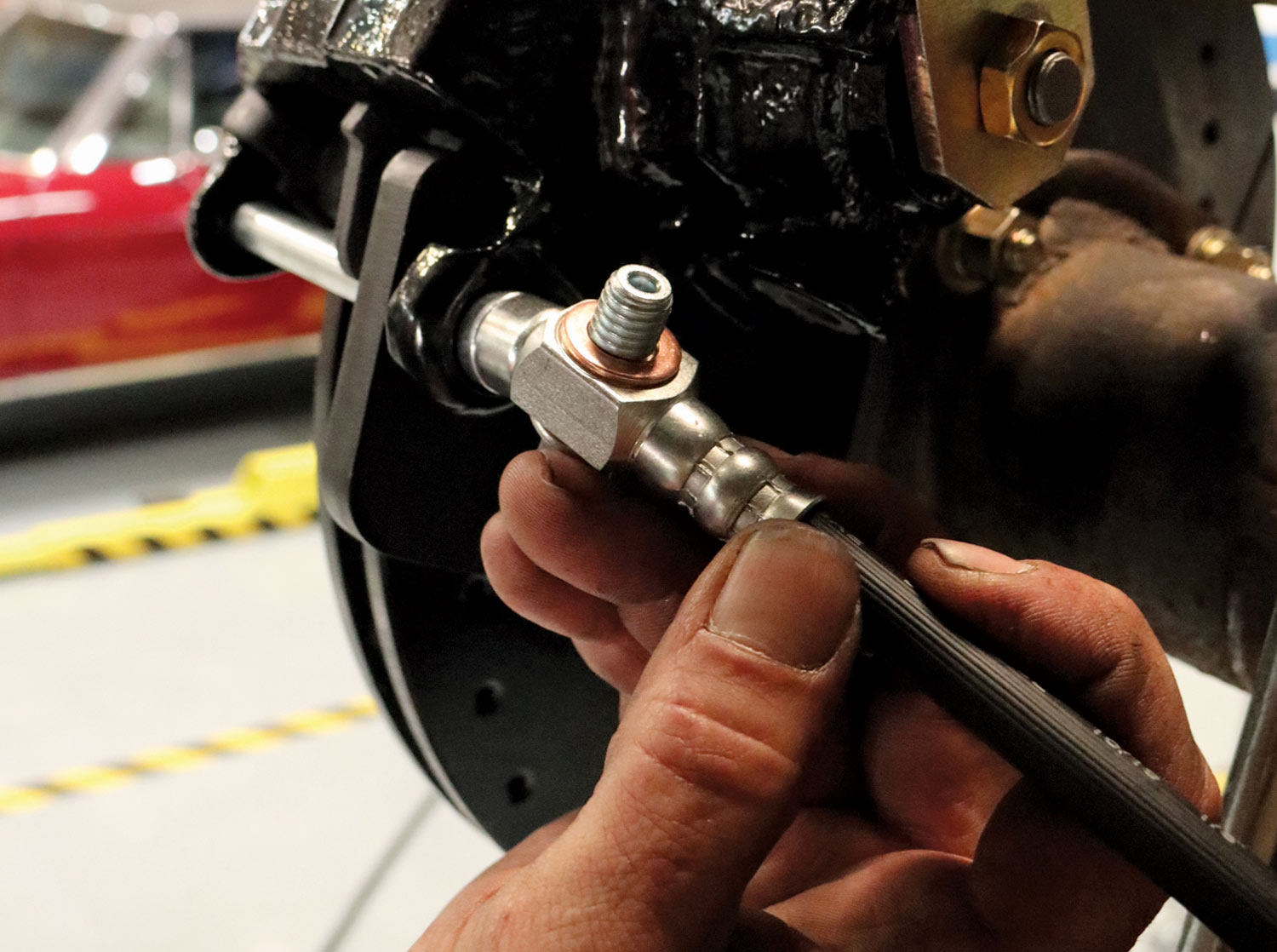

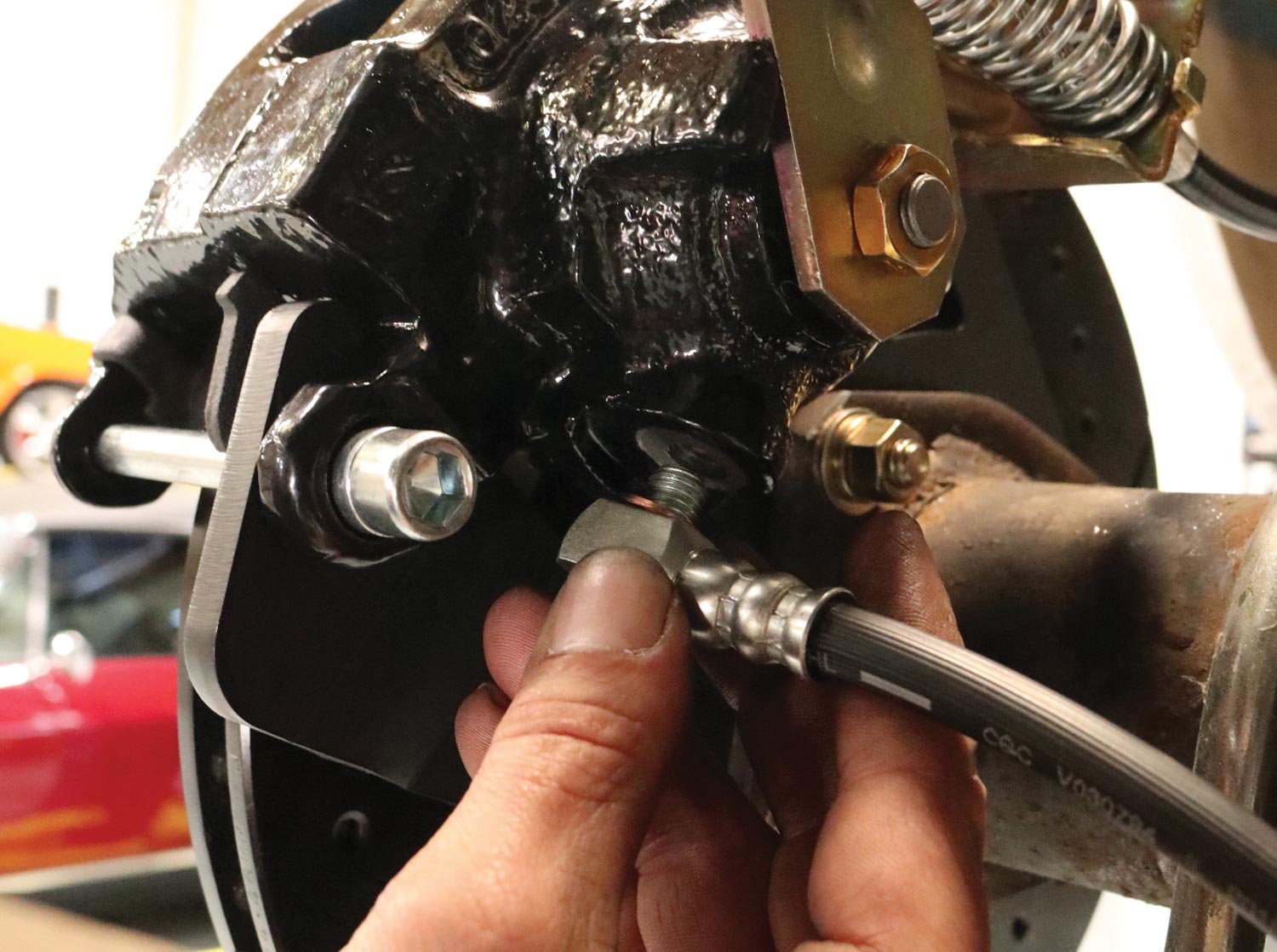

Once Western Chassis had completed the installation of their Super C-Notch and 5-inch drop front spindle and coil kits on the ’93 Silverado test mule and a few miles were put on to let things settle in, as it were, POL took over from there and wrapped up the job with their Blackout Series rear disc upgrade. We just happened to swing by with camera in hand at the right moment to capture the process and share it with you. Enjoy, and use this little tutorial to your benefit when and if the time comes to outfit your OBS accordingly!

(Note: This procedure shows the removal of the axles in order to remove the drum brake backing plates; the alternative is to disassemble the drum brakes and cut the backplate in half using a cutoff wheel.)

27-28. It’s a shame to cover up the newly installed brakes, but in order to take the Silverado out for that aforementioned test we had to do so—at least the 20-inch contrast-cut U.S. Mags five-spokes have large enough windows to see the new brake ware!