Tech

Tech

Tech

Tech

Photography BY The Author

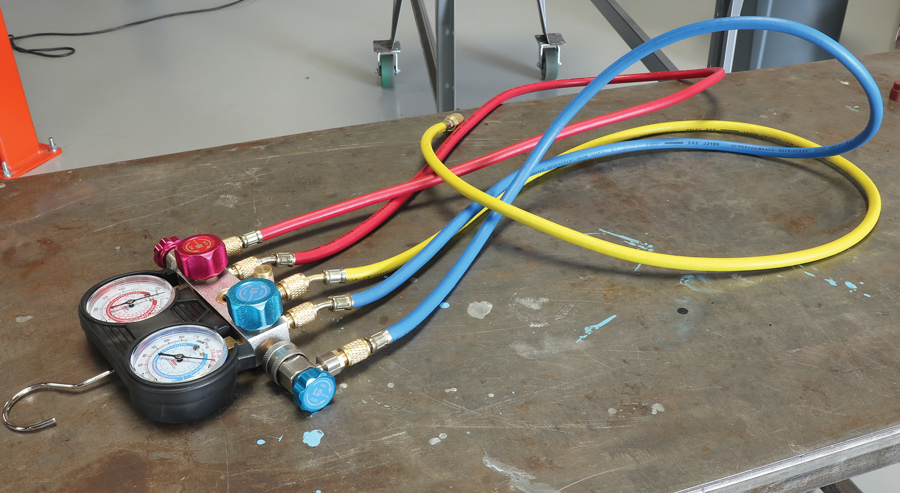

Photography BY The Authorhe great state of Texas is known for having a lot of good things, and that includes plenty of classic trucks. In this article our focus is trained on informing the DIY guy how he can handle every phase of installing an aftermarket A/C system in his truck, including how to charge the system with R-134a for as little money as possible.

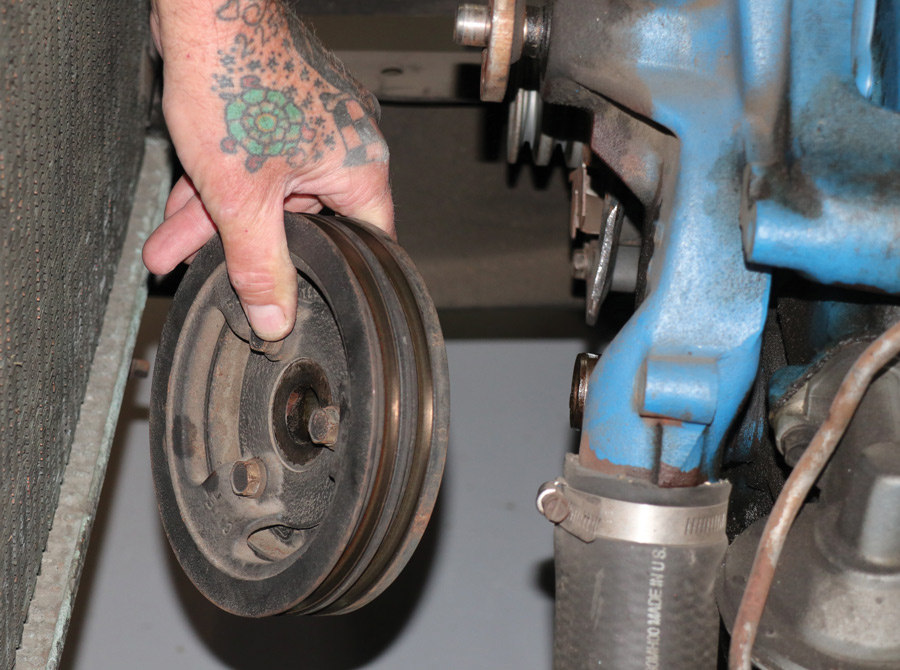

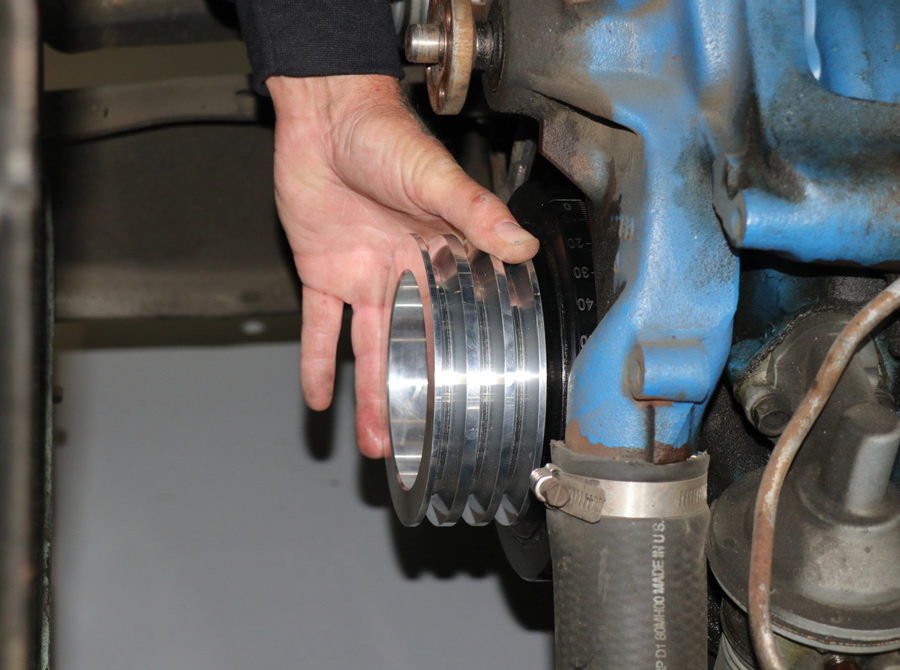

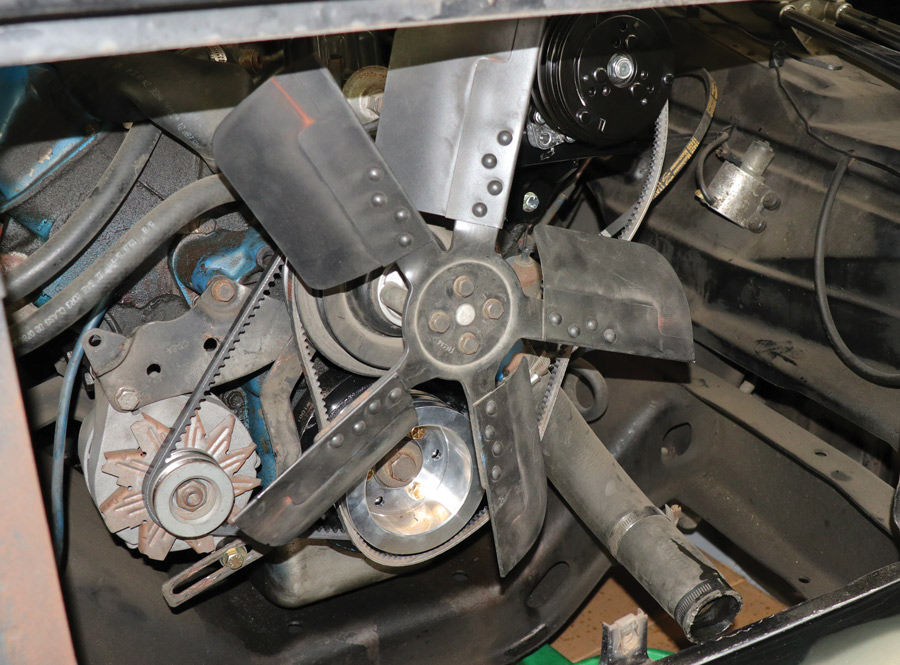

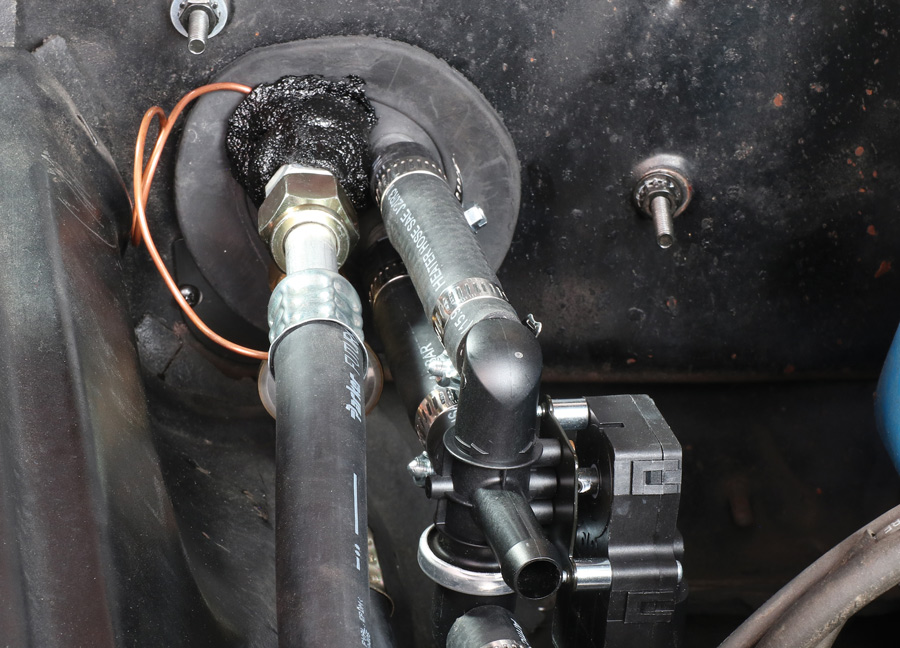

Our subject vehicle is an almost completely stock 1967 Ford F-100 Ranger that came factory equipped with a 352-inch V-8 and three-speed manual transmission. The air conditioning system of choice for this project is Old Air Products’ Hurricane complete system for 1967-1972 Ford trucks (PN CAP-6710H-DS) with a driver side compressor. (It’s the big-block FE engine that dictates a driver side compressor. If you have a 1967-1972 Ford truck with a small-block engine the kit is PN CAP-6710H-PS—the PS at the end indicates passenger side.)

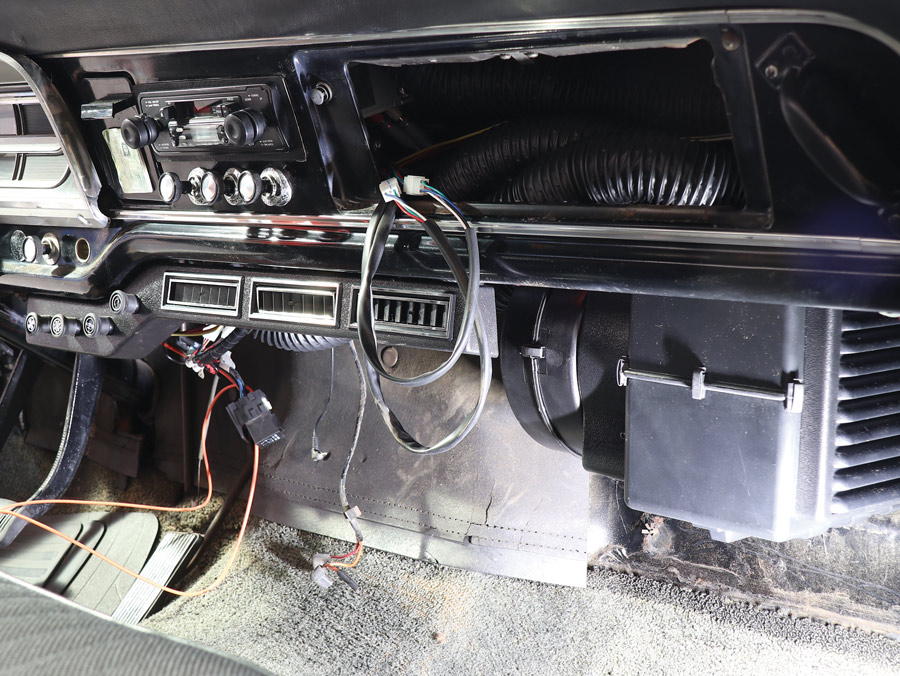

Not only does Old Air’s Hurricane system provide freezing-cold air, it also features a heater and defroster. The added bonus to this type of combined system is the defroster works faster thanks to extracting the moisture out of the windshield fog. Of course having a heater in the wintertime is as nice as having air conditioning in the summertime.

Classic Truck Performance’s approach to undertaking this particular project was to illustrate to readers the most economical means to install premium-quality air conditioning in a classic truck without compromise. Typically a serpentine pulley system is part of upgrading to air conditioning, but as anyone who has priced a serpentine system realizes it can add over double to the cost.

Part of the motivation to undertake a DIY project is to save money on labor costs and the other half is acquiring tools to be ready for the next time—not to mention the satisfaction of doing it yourself. That’s where shopping at Harbor Freight Tools came in handy. We were able to buy specialized tools for a great price and be equipped to meet the next project.

The history of how an aftermarket manufacturer aimed toward customizing came to be is always an interesting story. In their words: “Old Air Products was established in 1989 with the concept of manufacturing an A/C, heat, and defrost system that would fit any vehicle. We quickly found that with the large variety of vehicles and personal owner preferences we needed to provide a system with variable choices to allow our customers to customize the A/C system to fit both stock and custom vehicles.

“This was the beginning of our Hurricane series systems. When we designed our A/C system we had a few things in mind. Make a system that was compact, modular, easy to service, and easier to install. It was important that the evaporator serve as the backbone for a fully customized installation. What we achieved was the Hurricane system is designed to replace the factory heater and mount up in the space vacated by it. We attained what we set out to accomplish.

“What is amazing is the variety of vehicle applications it fits. There are three variations of the Hurricane, the only difference being where the tubes exit the case and thus go through the firewall. A side-exit fitting design allows for a clean firewall installation. With a wide variety of switching and venting options, one of these systems will fit just about any American-built car from 1928 through the mid ’80s, most foreign cars, as well as later-model vehicles.

“Our next step was to build upon the Hurricane systems by adding custom mounting plates, custom condenser assemblies, and switching packages to make custom kits for many of the more popular vehicles.”

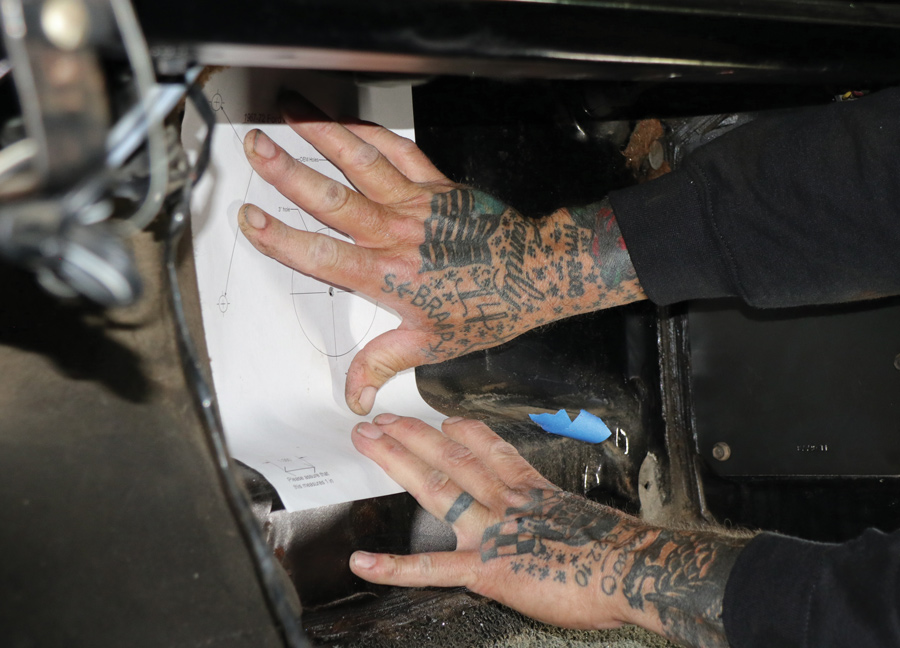

Use the following photos and instructions in conjunction with the installation instructions from Old Air Products that are included with the 1967-1972 Ford pickup kit.

SOURCES

SOURCES