Tech

Tech

Photography BY THE AUTHOR

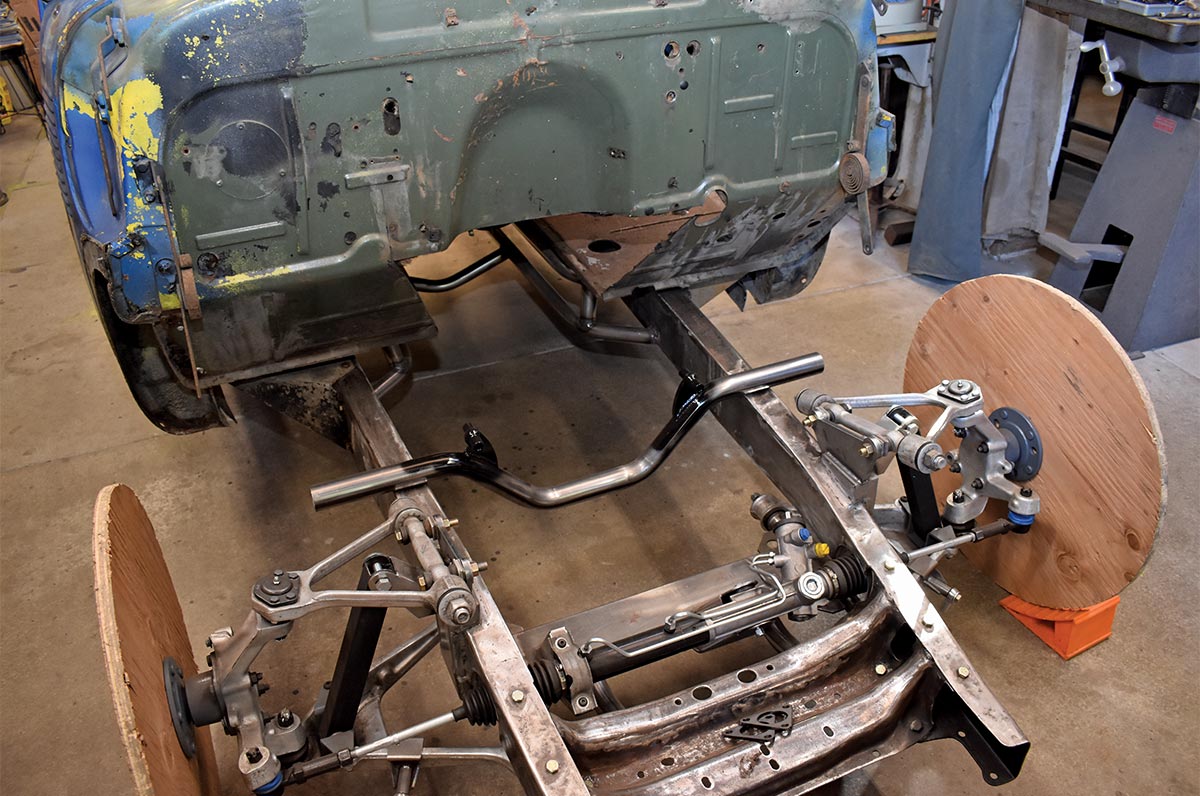

Photography BY THE AUTHORe’ve been following along as Paul Wilson has been in the process of transforming a random pile of parts into a complete ’52 Chevy pickup. So far in the pages of Classic Truck Performance we’ve shown how a mildly tweaked ’55 Chevy pickup frame has been straightened and stepped in the rear. It was then equipped with a C4 Corvette independent front and rear suspension by way of kits from Flat Out Engineering. With a rolling chassis (albeit on wooden mock-up wheels) the next step in this evolutionary process was installing the engine and transmission.

While LS engines and overdrive transmissions are all the rage, Wilson decided to take the old-school approach and go with a Gen II 350 Chevy from BluePrint engines coupled to a Turbo 350 transmission. Speaking of the evolutionary process, the engine Wilson chose is virtually all aftermarket with BluePrint’s own cast-iron block, aluminum heads, and internal components. Equipped with a single four-barrel carburetor and roller hydraulic cam the engine dyno showed 341 hp and 371 lb-ft of torque, which will make for a good daily driver. The transmission has been rebuilt and equipped with a mild shift kit and a “tight” stock stall speed torque converter for efficiency.

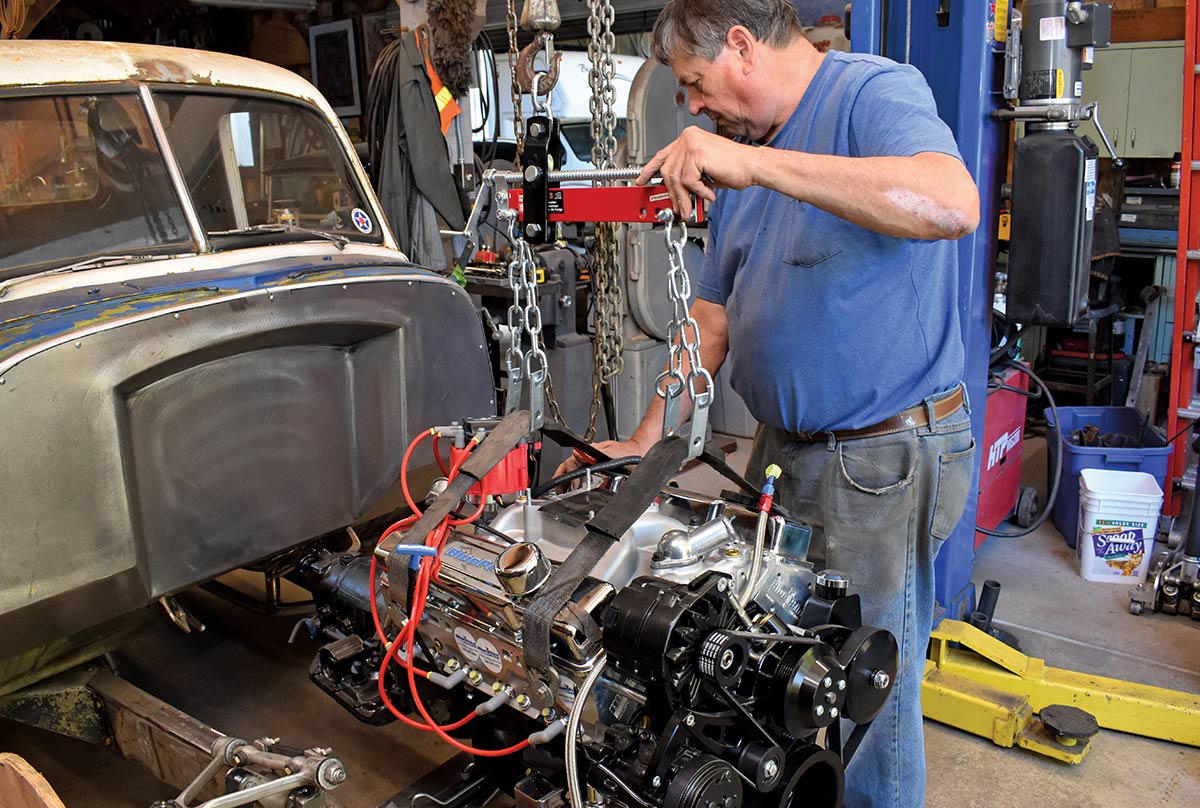

One of the BluePrint engine options that Wilson chose was a serpentine belt drive system that included an A/C compressor, power steering pump, and alternator. As this system includes a “long” water pump with all the accessories hung on the front of the engine, its overall length is considerably greater than an engine with a short water pump and “compact” V-belt driven accessories. This brings up the first rule of engine swaps that is absolutely critical: With the length of the engine determined always start at the radiator and fan with measurements then work to the rear of the vehicle—in our case to make room for those vital components the firewall would have to be modified.

To solve our space issue we turned to Chevs of the 40’s in Vancouver, Washington. With over 800,000 parts in stock and a vast dealer network, if Chevs of the 40’s doesn’t have what you need, they can get it. For our application we selected a 4-inch setback firewall (PN 3693009S54) for ’47-54 Chevy pickups that is suitable for small- and big-block installations.

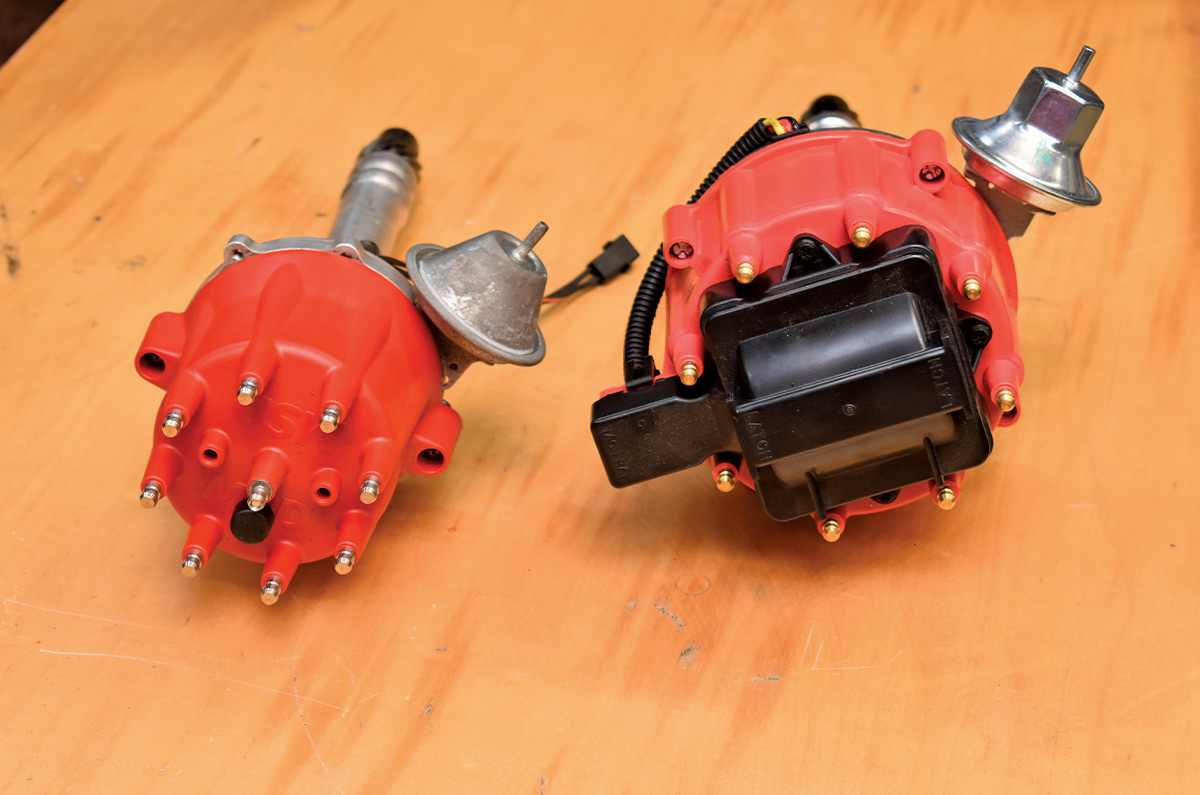

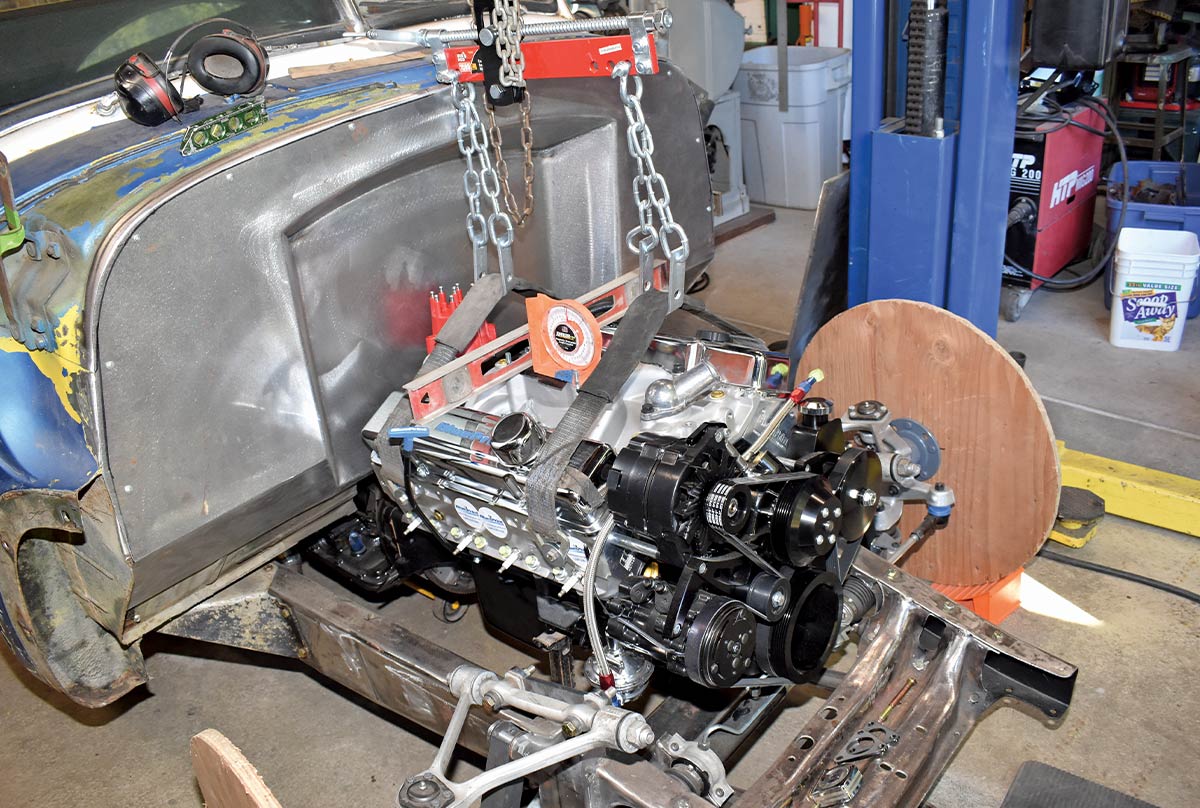

To make absolutely sure we had room for a radiator and fan we cut away the center of the stock firewall to temporarily positioned the replacement. A test-fit of the engine revealed an interference problem with the BluePrint HEI distributor, but that was easy to solve. With a smaller-diameter distributor in place the engine could slide back enough for cooling system clearance, it also allowed it to drop down slightly with the vibration damper and timing cover straddling the rack-and-pinion steering. Which brings us to the second rule of engine swaps. Always have the chassis at ride height and at the intended rake angle (usually around 2 degrees low in front). Then, when locating a carbureted engine, don’t level the valve covers, make sure the carburetor mounting pad is level side to side and front to back so the float(s) will operate correctly. Conventional carburetor intake manifolds have a built in angle for this purpose (with fuel-injected engines this isn’t an issue).

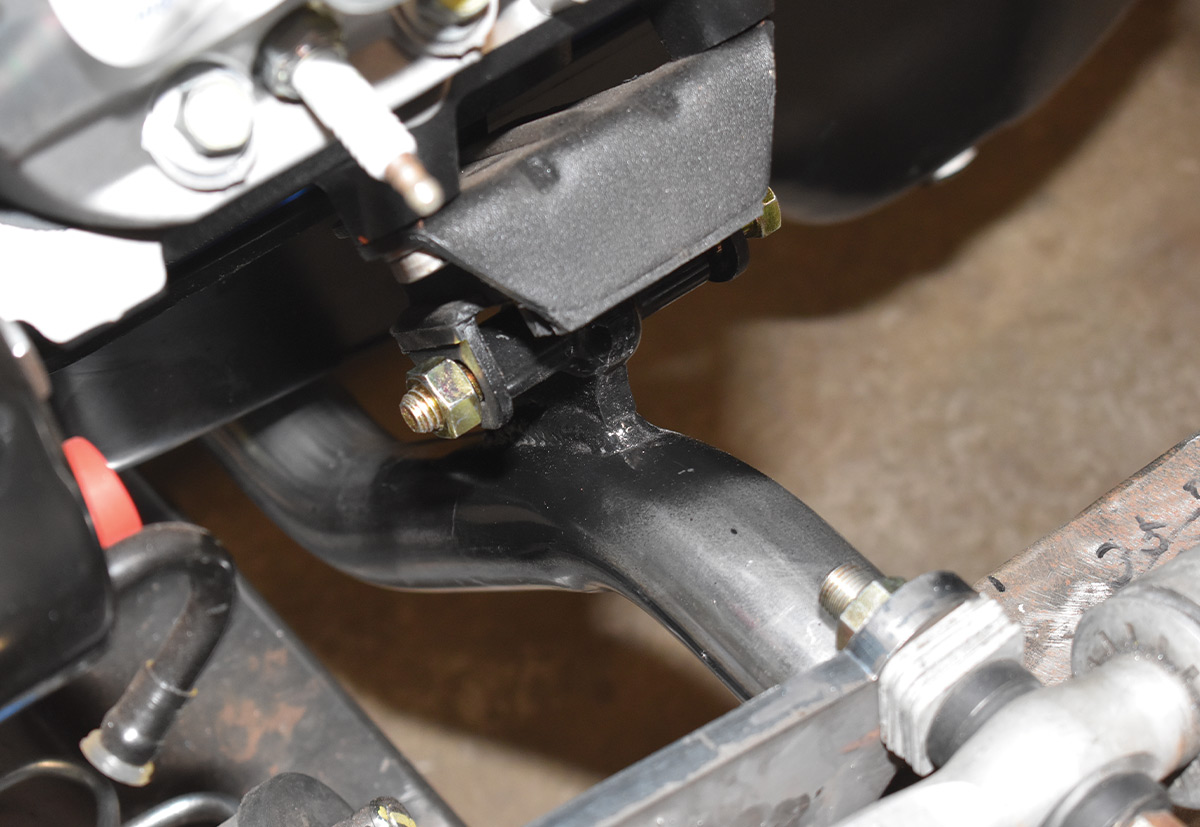

Satisfied with the engine’s position, the original firewall was cut away, leaving only a flange around the edge to weld the replacement to. The recessed firewall was also welded where it joined the original toeboards. With the firewall installation finished, the Speedway Motors tubular engine mount (PN 910182120) was trimmed to fit and welded in place. That brings us to the third rule of engine swaps: Make sure there’s room for steering linkage and exhaust—and we’re happy to report there is (which we’ll show you later).

From the outset Wilson’s goal has been to build an affordable truck that will be a comfortable, reliable driver that can go anywhere with no fuss. With Corvette suspension under both ends and a tried-and-true engine and transmission combination in place, we’d say he’s well on his way to meeting his goal.

6. Self-tapping sheetmetal screws were used to hold the Chevs Of The 40’s firewall in place.

SOURCES

SOURCES