Tech

Tech

Photography BY The Author

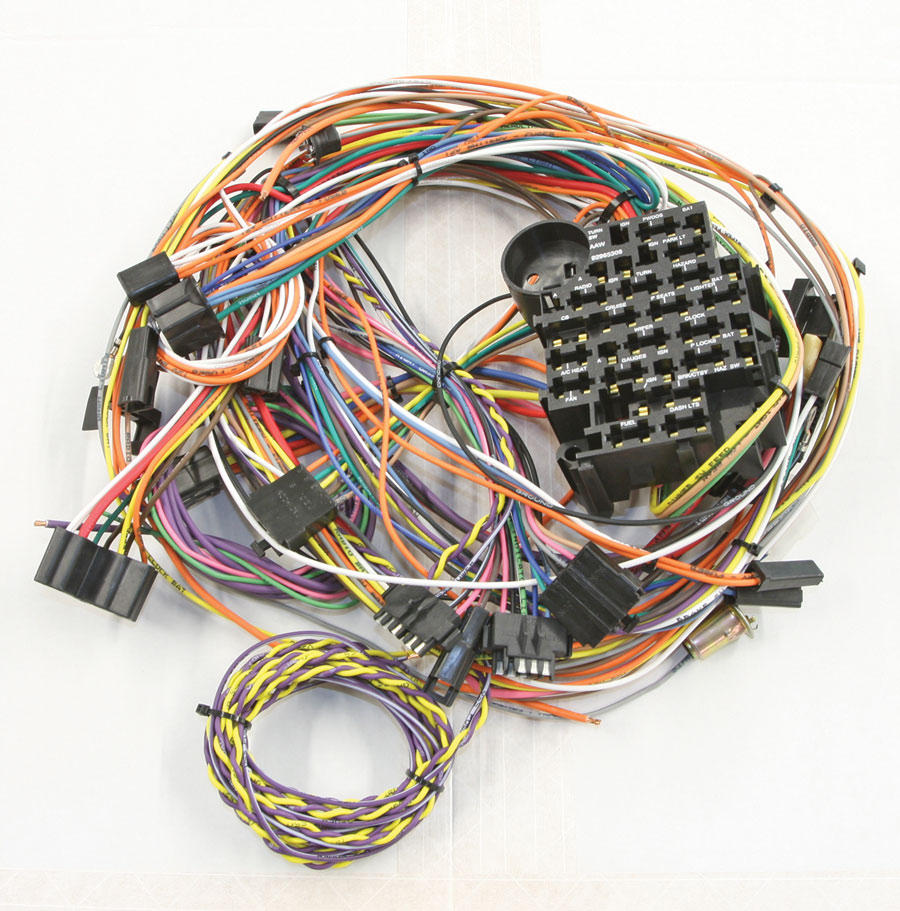

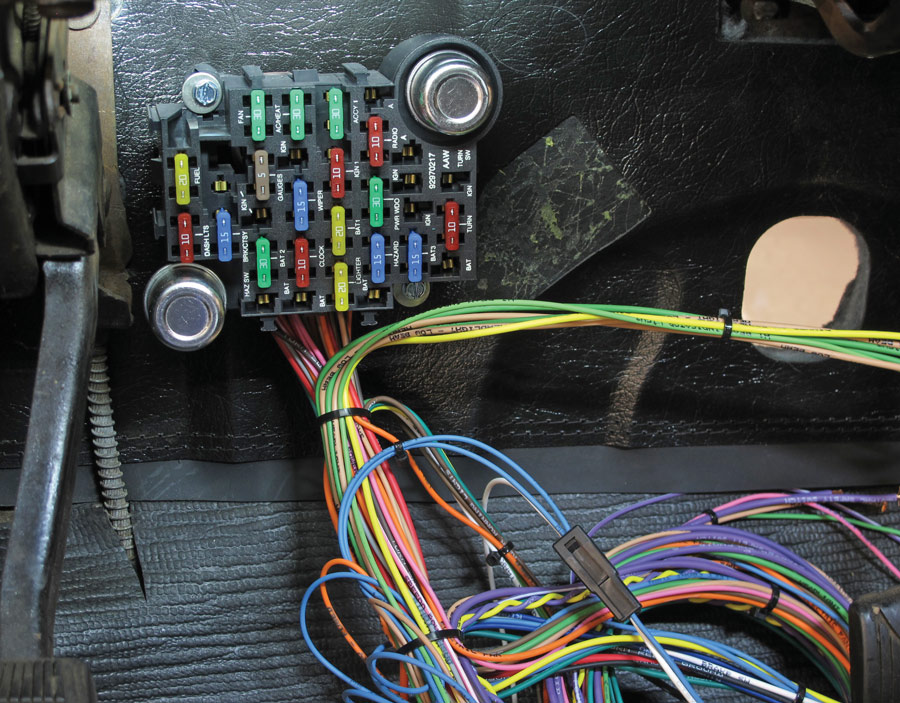

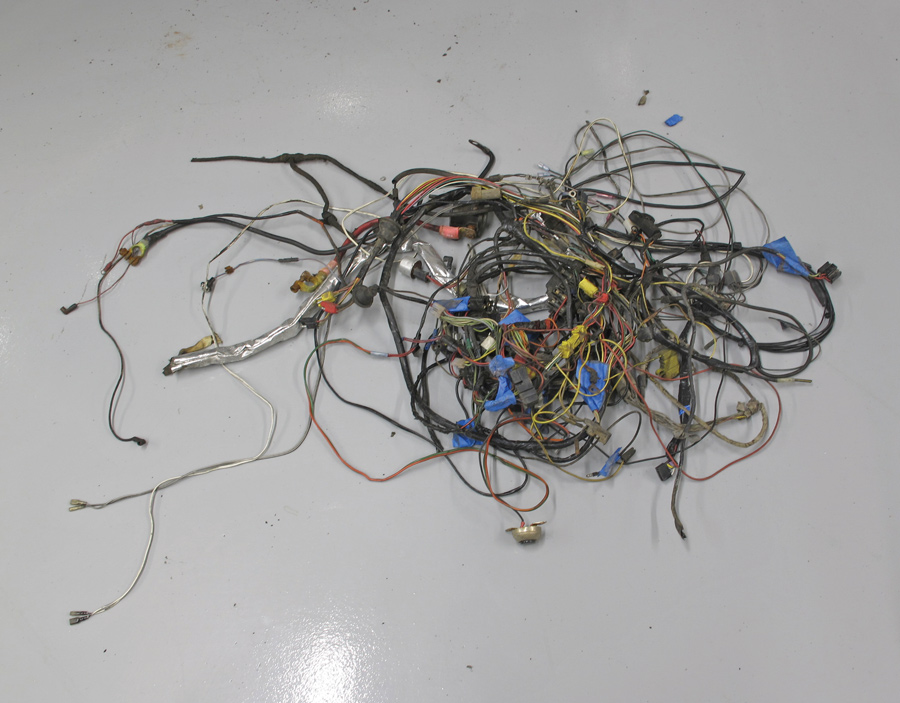

Photography BY The Authoriring a classic truck can be a daunting undertaking at first blush, but it doesn’t have to be. Anyone with a bit of common sense when it comes to automotive electrical systems can successfully run a bit of cable and get that hauler fired up properly. With a wiring harness kit like American Autowire’s Power Plus 20 on hand, a bit of careful study of the various included diagrams, and further inspection of the actual harness can provide a lot of insight to even the biggest luddite when it comes to the routing and wiring of a basic automotive system.

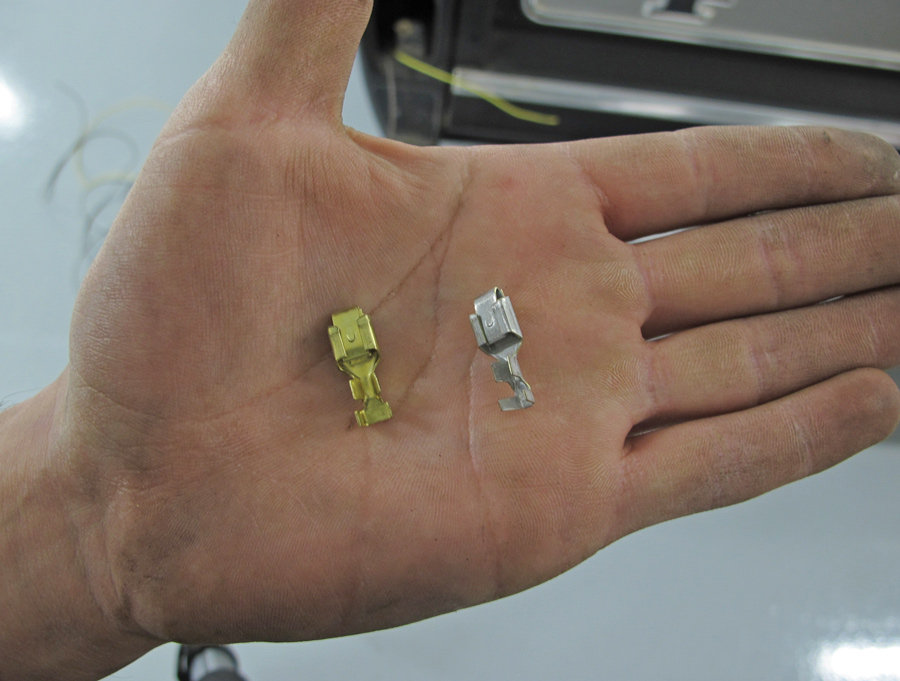

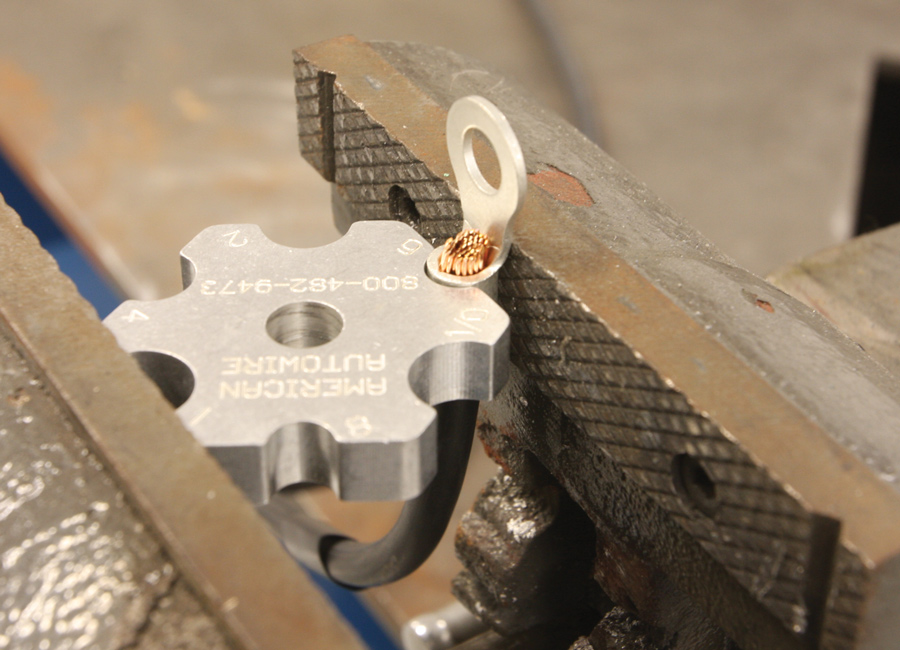

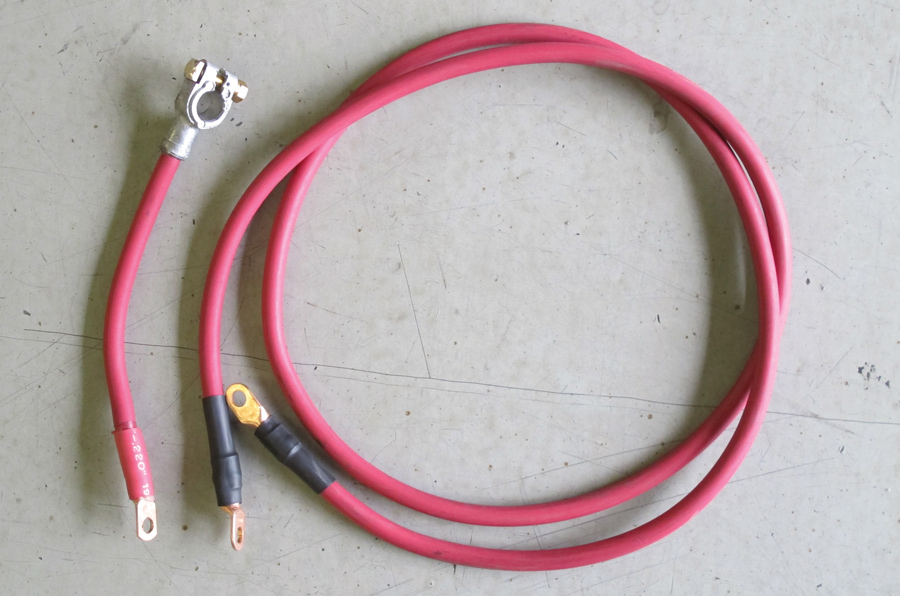

Equipped with a cheap crimper and a set of wire cutters, a guy can be pretty well on his way to providing power to the various accessories, but there are a few tips and tricks that can make the job a little more professional. Making sense of the different circuit harnesses and where to route them in as clean a manner as possible can vary from difficult to daunting, but doing so ensures the installation comes out clean and allows for much easier diagnosis if needed in the future. Electrical tape and zip ties can make quick work of this organization. The addition of braided split loom not only looks good but also helps protect the harness in areas where exposed to the elements. Proper support of the harness is also of utmost importance, provided by a sufficient amount of clamps. Any time wires are routed through a sheetmetal bulkhead, a properly sized grommet or other method to prevent chaffing or rubbing should be used. With a harness like American Autowire’s Power Plus 20, we don’t need to worry about proper protection of the myriad of circuits in the harness as that safety feature is built in, provided one follows the noted fuse size for each circuit. But other aspects of the electrical system might require further protection, such as relays or circuit breakers, depending on that component’s function.

While wiring a classic truck can be overwhelming, it isn’t otherworldly. Basic electrical understanding and a bit of patience can lead to a very rewarding result that further lends itself to being able to diagnose and repair any trouble that may rear its ugly head in the future. As the saying goes, “The more you know …”

![] Fuse panel](https://digital.classictruckperformance.com/wp-content/uploads/2021/12/ctp-jan-22-wiring-1.jpg)