Tech

Tech

BY Ron Covell Photography By Adam Cecil

Photography By Adam Cecil

he aftermarket provides an abundance of reproduction parts for classic trucks, but there are some parts that are not available. One of these is a bucket seat cab brace for a 1969-1972 Chevrolet C10—and they are virtually impossible to find in wrecking yards.

Adam Cecil is building a C10. Being a person who likes challenges, he hatched the idea of making his own seat brace by utilizing the hammerforming process. A lot of people think that anything shaped with a hammer could be called “hammerformed,” but the specific process we are describing involves making a form of some durable material, holding a piece of metal tightly against it, and then hammering the metal until it takes the shape of the form beneath it. This is distinctly different from the freehand way metal is sometimes shaped with a mallet and sandbag, or with a hammer and handheld dolly.

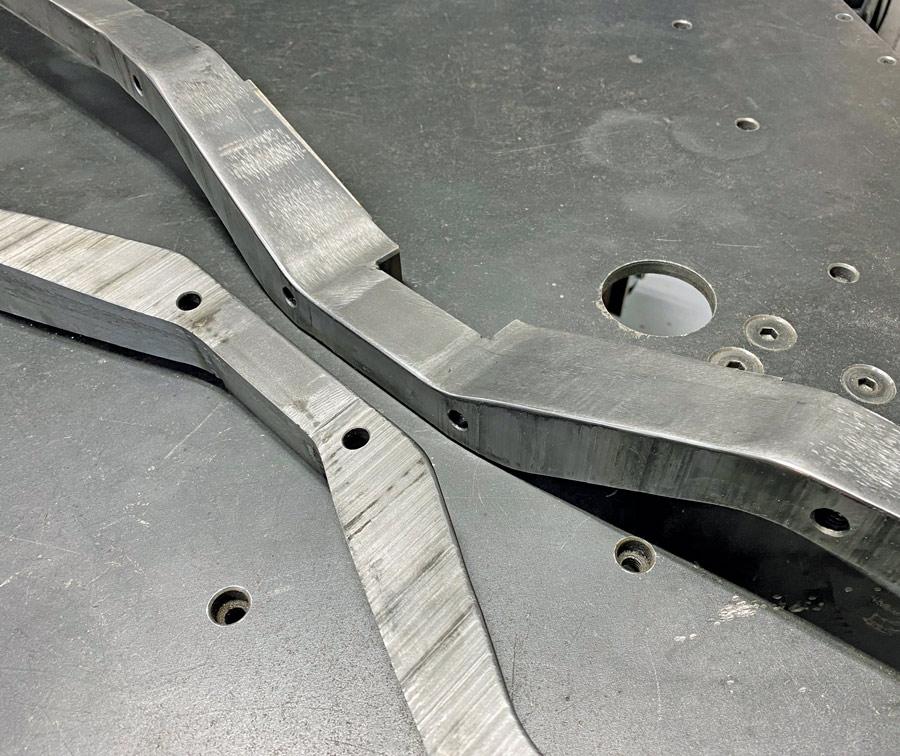

3. Here’s a close-up of one end that shows some of the part’s complexity and the tabs required for mounting to the cab.

4. To start the process, Adam Cecil made an accurate, fullsize drawing of the part. The giant chunk of square cold-rolled steel bar is part of the stock he will use to make the form.

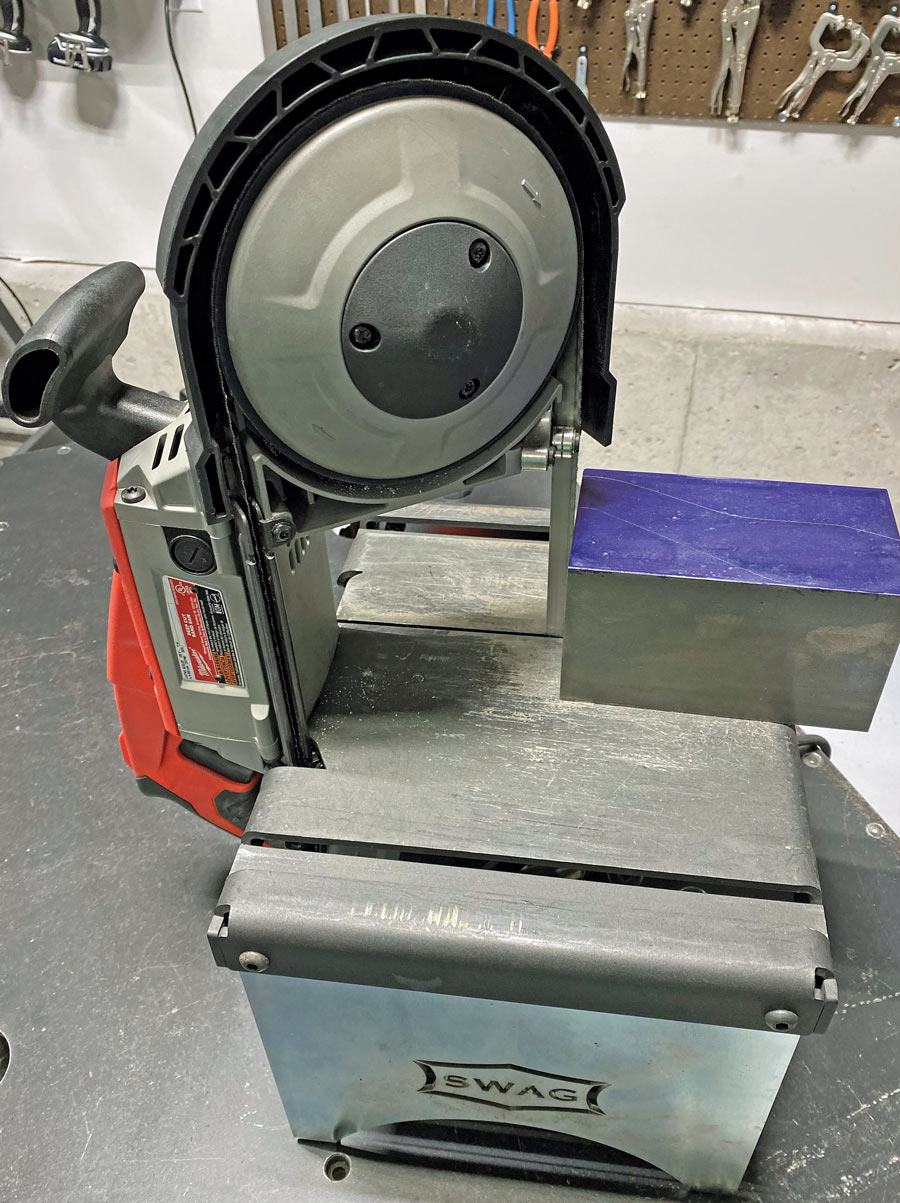

5. Cecil did all of the profile cutting with a simple, handheld bandsaw, supported on an aftermarket base. He said “it took a while” but you’ll see the great results he got.

6. After cutting to size, all of the components are jigged up for tack-welding. The finished parts will only be as accurate as the form, so precision at this stage pays big dividends.

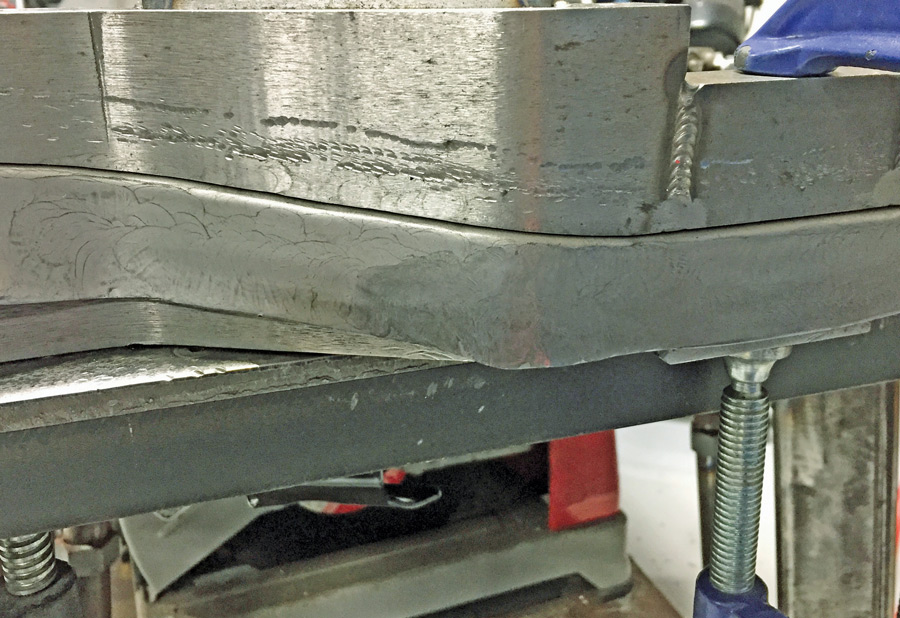

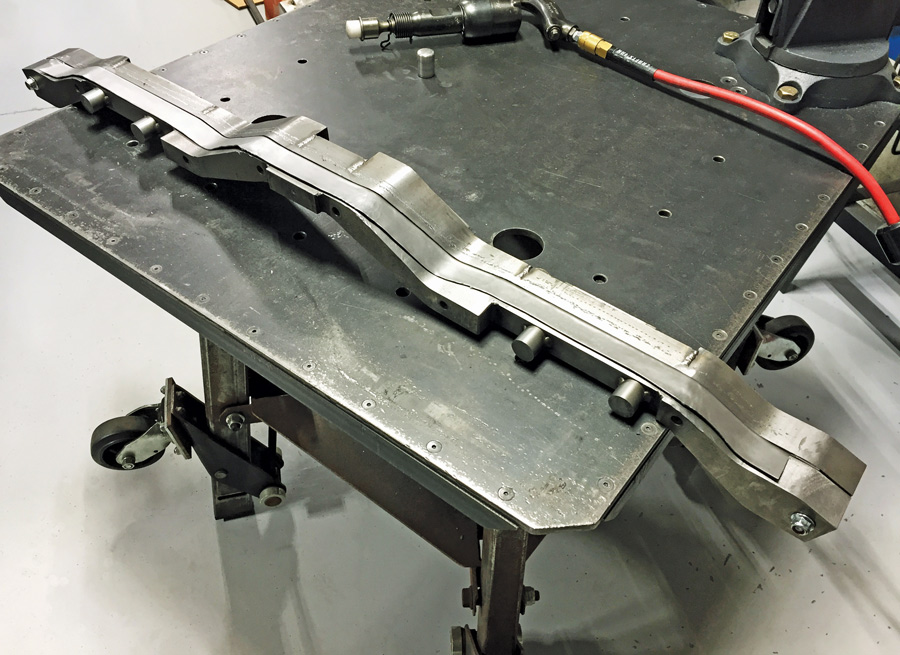

7. Here are the two halves of the form after they were finish welded and sanded to smooth any imperfections.

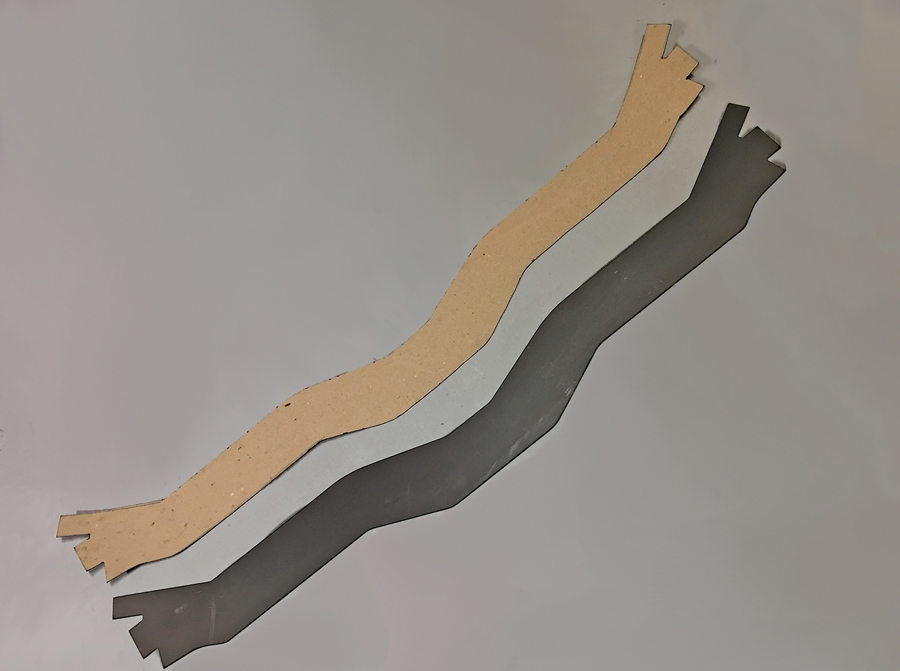

8. At the top is the paper template developed from the drawing. The template was used to cut the blank of 16-gauge cold-rolled steel on the bottom.

The first step is making an accurate, fullsized drawing of the part. This drawing is essential for determining the size and shape for each element of the hammerform, and to develop the pattern for the metal blank to be shaped over the form.

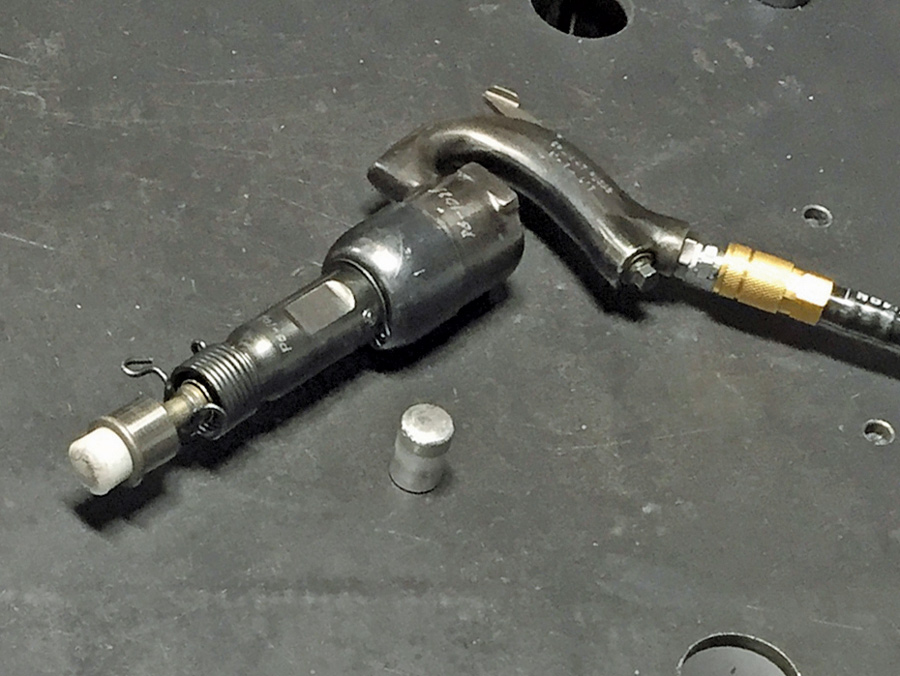

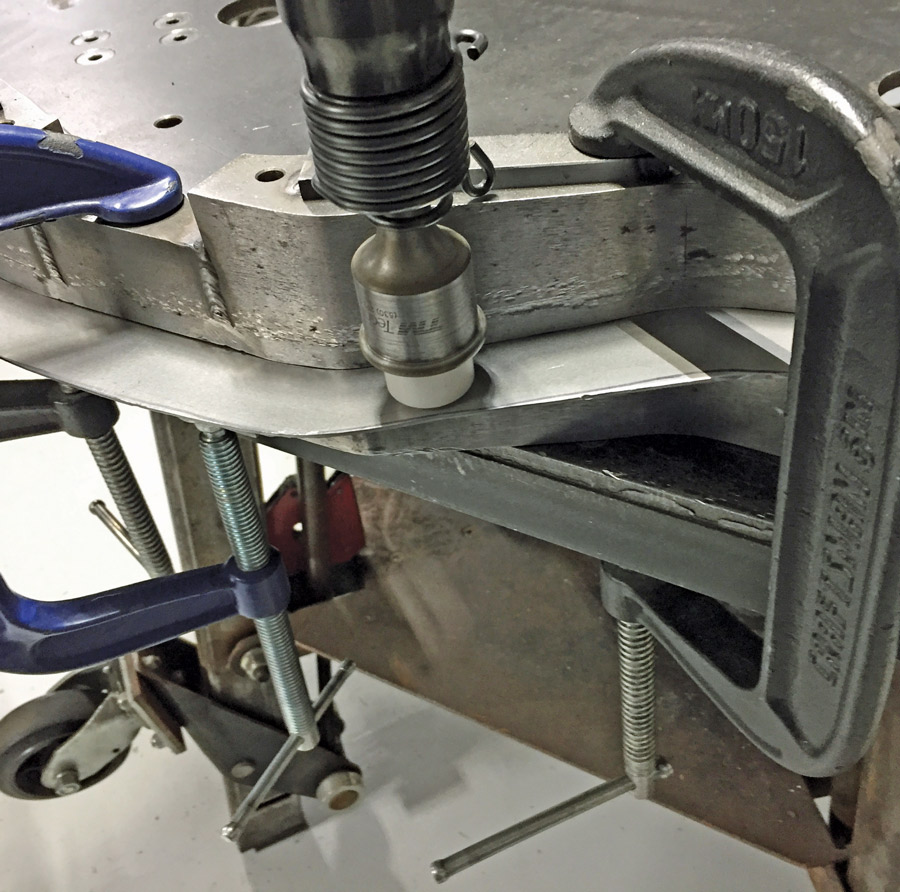

10. The flanges will be formed with a heavy-duty 5X aircraft rivet gun. The nosepiece holds removable inserts. The white insert is Delrin plastic—which is used for the initial forming and the insert on the table is aluminum—used for working out the wrinkles.

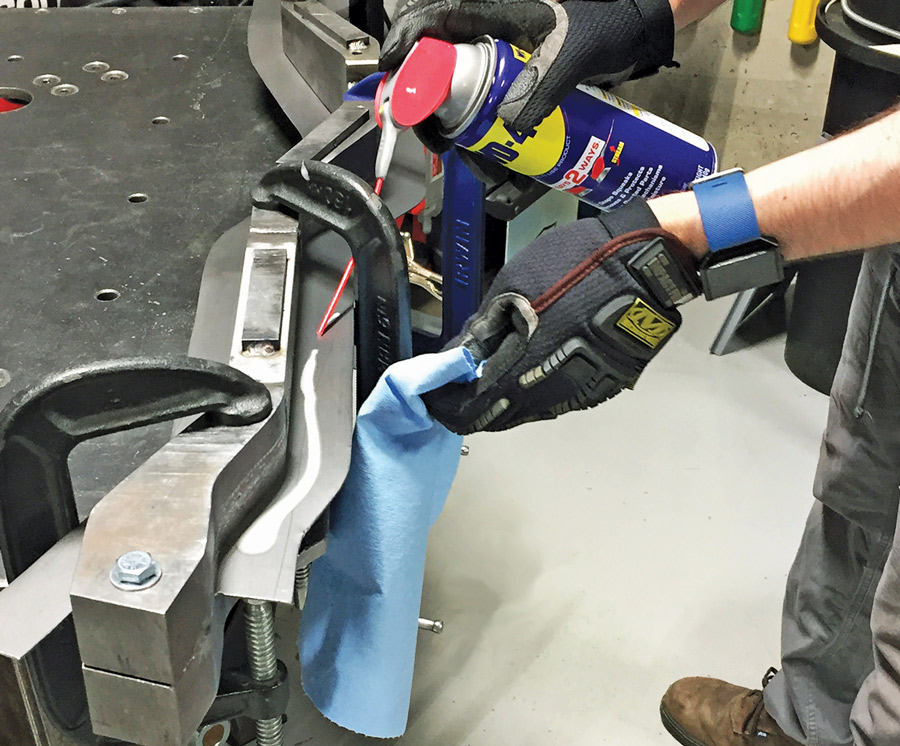

11. A little lubrication helps the dies glide over the metal smoothly.

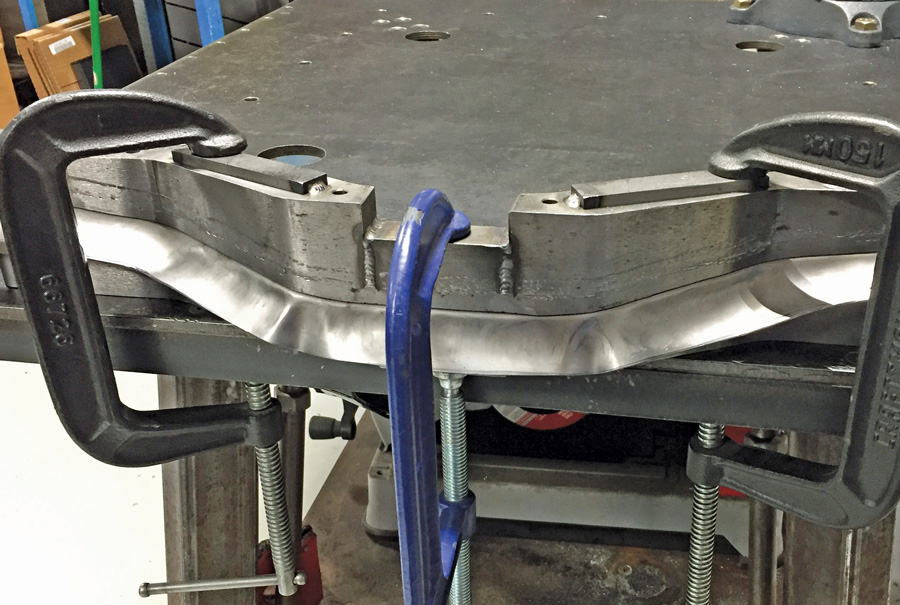

12. Here you can see the flange as it’s just starting to be formed. It’s good to work a large area a little at a time rather than finish one section and then move to another.

13. With the flange formed a little farther, the straight sections are moving nicely, but you can see some wrinkles starting to form on the outside corners.

15. Here the aluminum insert was used in the rivet gun. With the proper technique you can do a surprising amount of cold shrinking and still leave a smooth surface.

16. Here’s the finished flange on the other side of the form, which points in the opposite direction.

18. With both flanges completed, the part can be removed from the form.

19. The flanges were formed oversize to allow trimming to a consistent width. This is a clever adapter for a marker pen that makes a line a uniform distance from the surface it rides on.

The next step was cutting a metal blank, then placing it between the halves of the hammerform, and drawing them together by using C clamps (plus a couple of bolts at the end, which also provided alignment). This formed the blank in one plane.

21. Here’s an operator’s eye view of the edge being cut on a bandsaw. This is a great way to make clean, accurate cuts on metal of nearly any thickness.

22. The finished part.

24. The part is positioned under the cab for a test-fitting.

25. Here’s a close-up of the end of the brace, ready to be plug-welded into place under the cab. The fit is superb, justifying the painstaking process used to reproduce this tricky part.

SOURCES

SOURCESAdam Cecil

adamcecil02@hotmail.com

Swag Off Road

(541) 915-2775

www.swagoffroad.com

TM Technologies

(530) 292-3506

www.tinmantech.com

The photos show all the steps in the process, and I think you’ll agree that Cecil did a superb job. The hammerforming process can be used to make any number of parts from sheetmetal, so let your imagination be your guide as you think about ways to utilize hammerforms for your own projects!