Tech

Tech

IMAGES BY Joe McGlynn

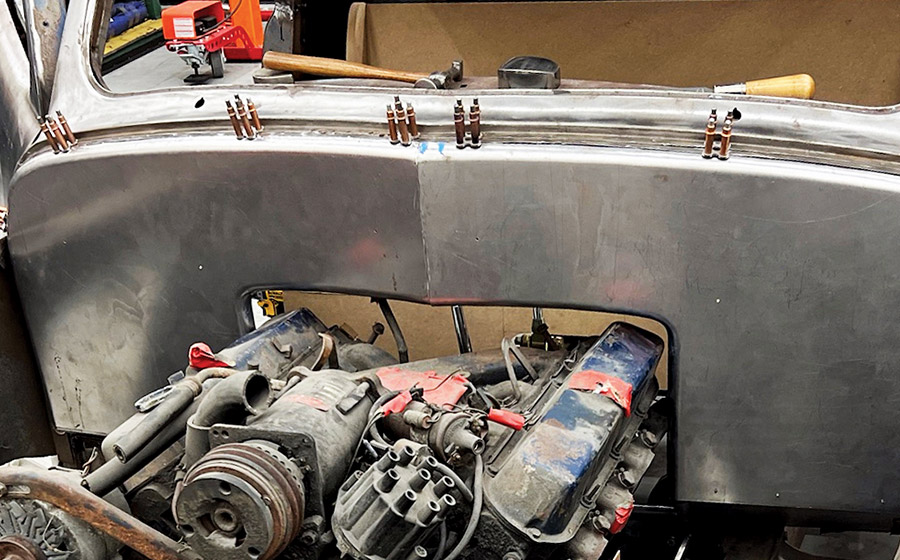

IMAGES BY Joe McGlynne looked at the chassis of Joe McGlynn’s Studebaker pickup project back in the Dec. ’23 issue of Classic Truck Performance. This time we’ll show the great work he has done on the firewall, floor, hood hinges, and some other details. Although McGlynn is a hobbyist who works from his home shop, he has invested in some good-quality tools that speed up the work. He recently purchased a power hammer, which he put to excellent use making the highly complex transmission cover, shaped from 16-gauge steel. Material that thick is a challenge to work with hand tools.

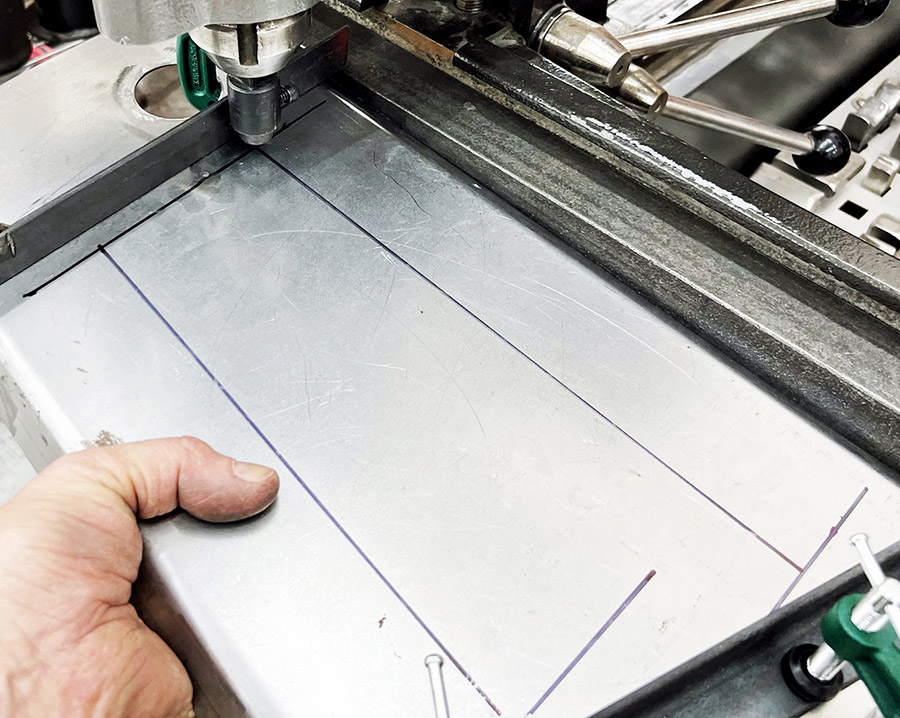

A two-piece pattern for the firewall was made from chipboard, which was then transferred to 16-gauge sheetmetal. The edges of these panels were shaped by hammering over forms made from MDF, which produce a smooth and accurate contour while maintaining the flatness of the panels.

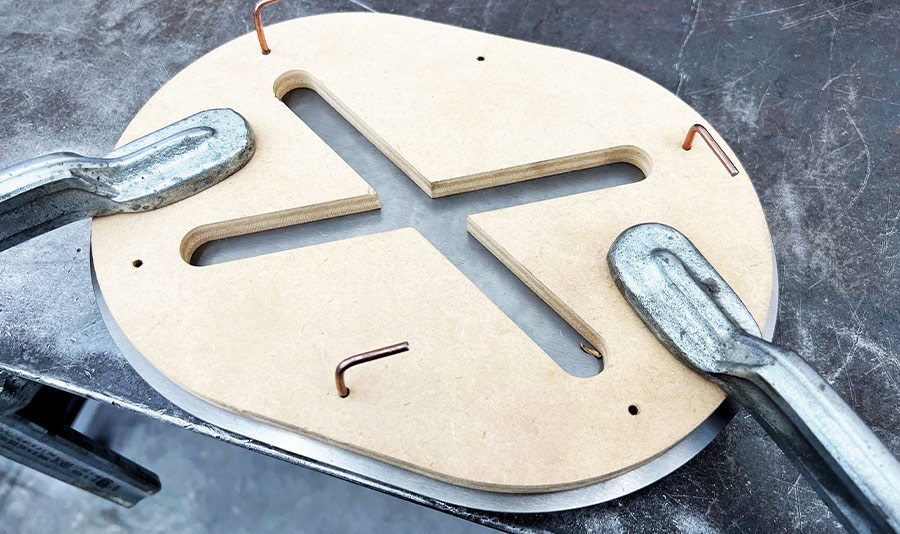

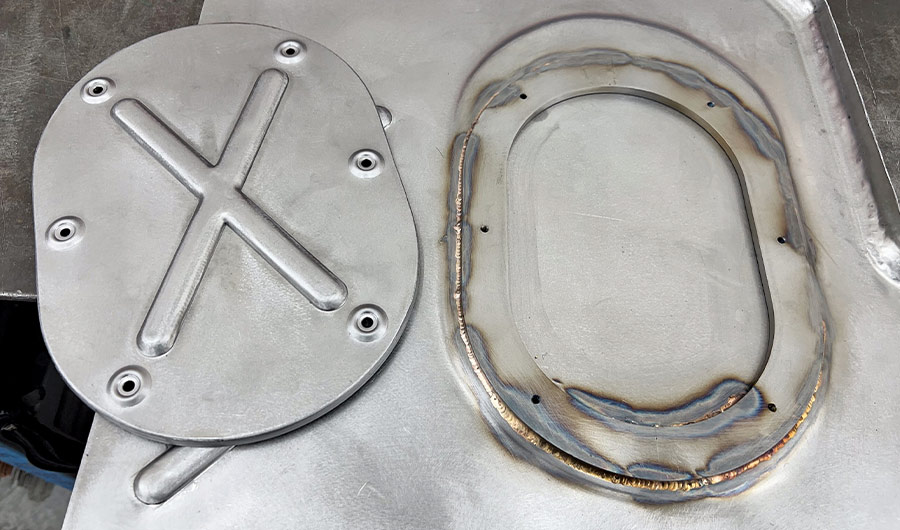

McGlynn designed his own hood hinges with CAD, which incorporate an elegant four-link mechanism. He sent his digital files to a laser-cutting service, and they produced the complex parts quickly and efficiently. The hinges mount to the firewall, which he reinforced with 1/4-inch steel plates.

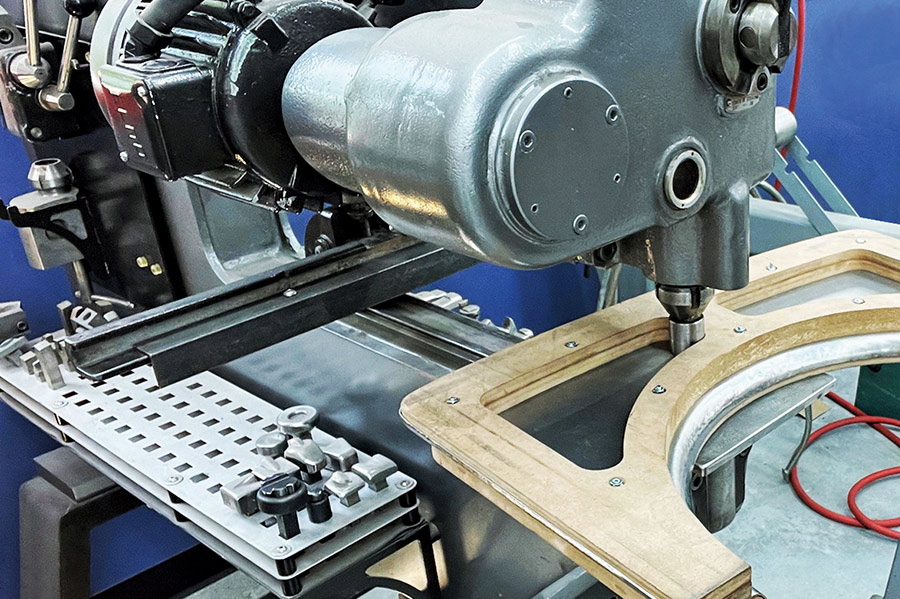

A recess was required in the firewall for the Cadillac engine. McGlynn built this in several pieces. The edges of the largest part were contoured with an MDF hammerform, and windows were put in this same form to guide the piece through a Pullmax machine to emboss kidney-shaped details for strength and style. Once the rear panel for the recess was completed, filler pieces were made to join it to the firewall.

The biggest challenge was the curvy cover for the transmission. McGlynn made an elaborate buck for this, which showed him precisely the shape each piece required. He did the majority of the shaping with a power hammer, and the results are spectacular!

Although McGlynn’s shop is better-equipped than most, all of this work could be done with more basic tools, and the layout and fabrication techniques would be very similar.