Tech

Tech

Images by The Author

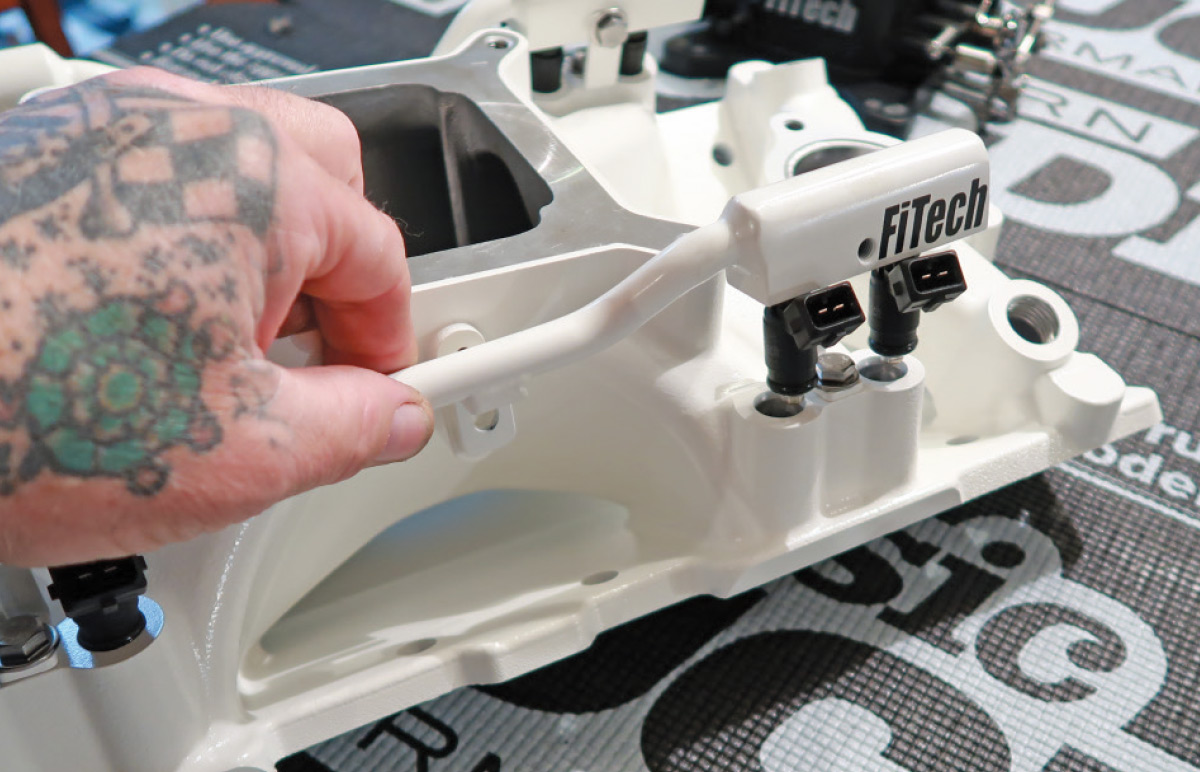

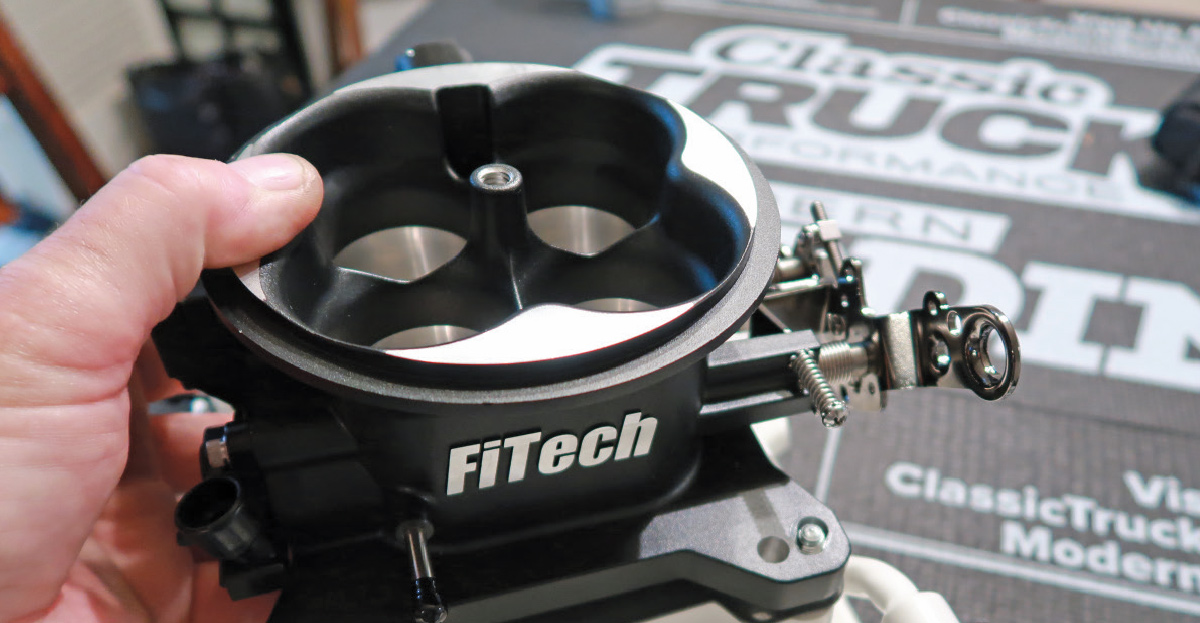

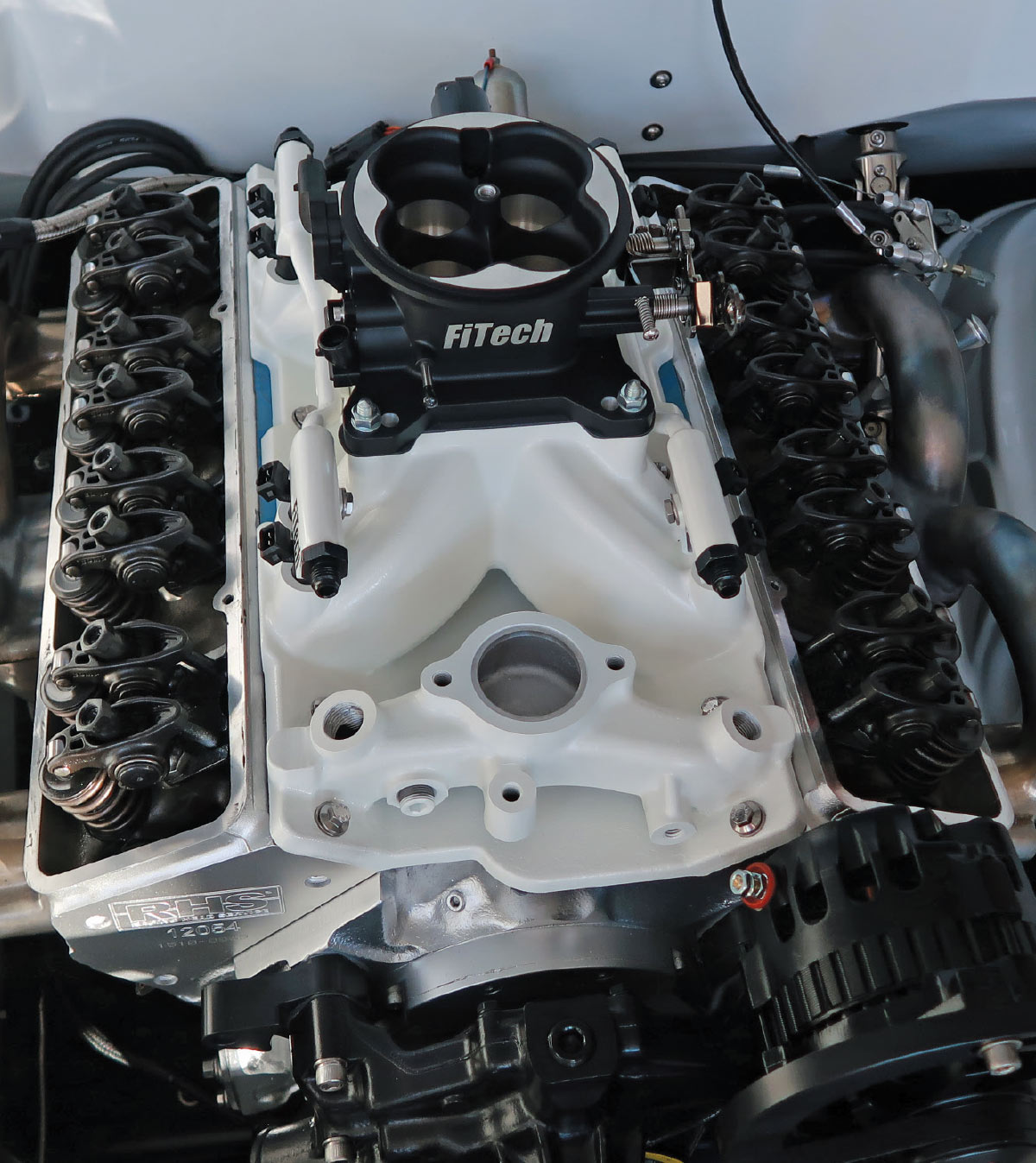

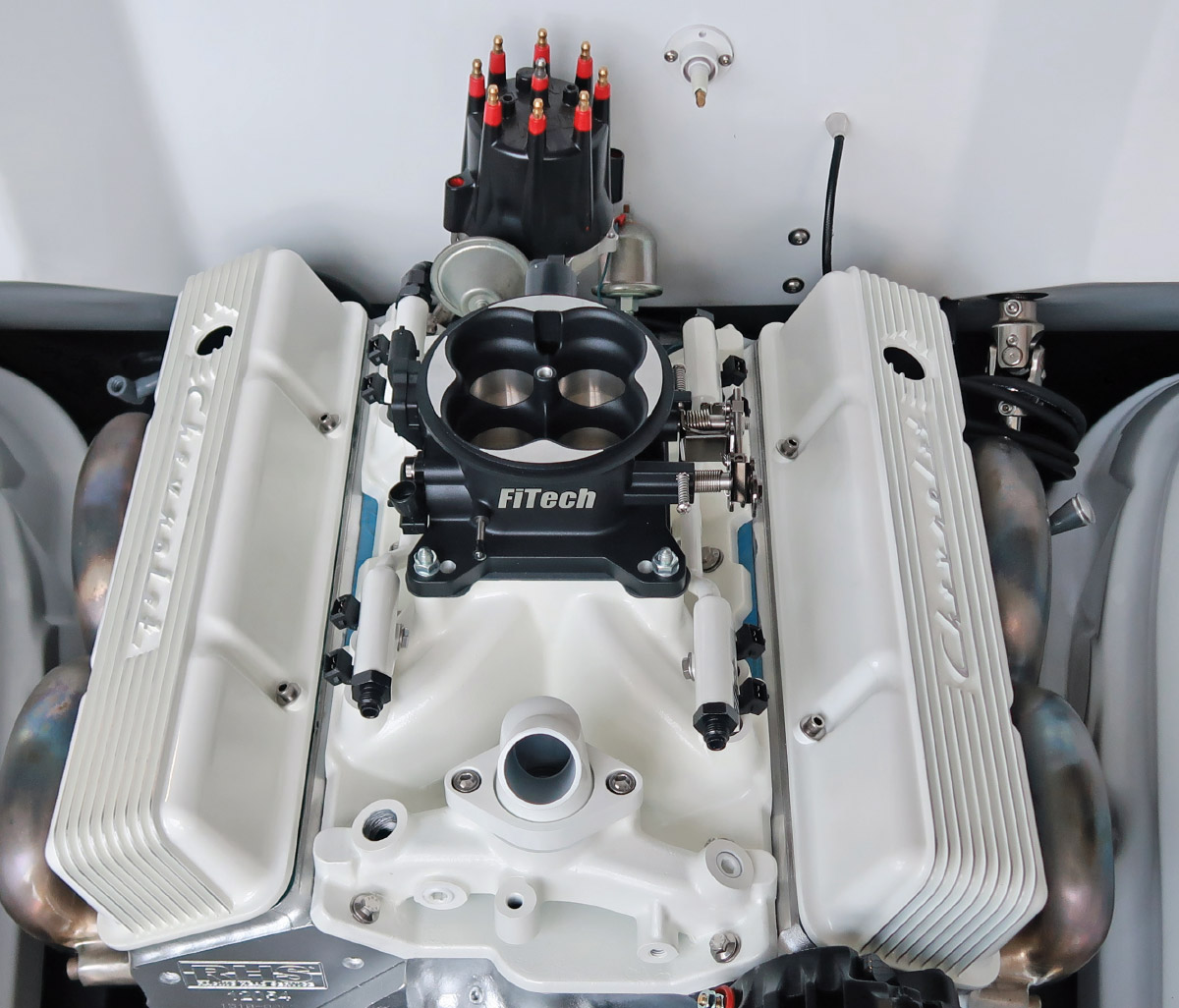

Images by The Authorome of you may be asking, why switch over to EFI? To me, it was an easy choice after doing a little research with our friends over at FiTech Fuel Injection in Riverside, California. Right from the get-go they suggested their new Ultra Port SBC unit for the small-block in my (old) 1949 Chevy three-window.

I’ve owned this 1949 Chevy truck since I was 18 years old. Not to date myself, but that’s been 30-plus years. Originally, the style I was shooting toward was a 1990s street rod. That quickly shifted as I got into the rockabilly scene. There was just something about the music, the style, and the down-and-dirty feel that I fell in love with. Now I had my sights on building a traditional hot rod. After quite some years under my belt driving it around, it was time to hand off the keys to my wife, Randi. While I’d already updated the chassis/brakes, there was one more “modern” thing left for me to do before that happened: make the EFI switch.

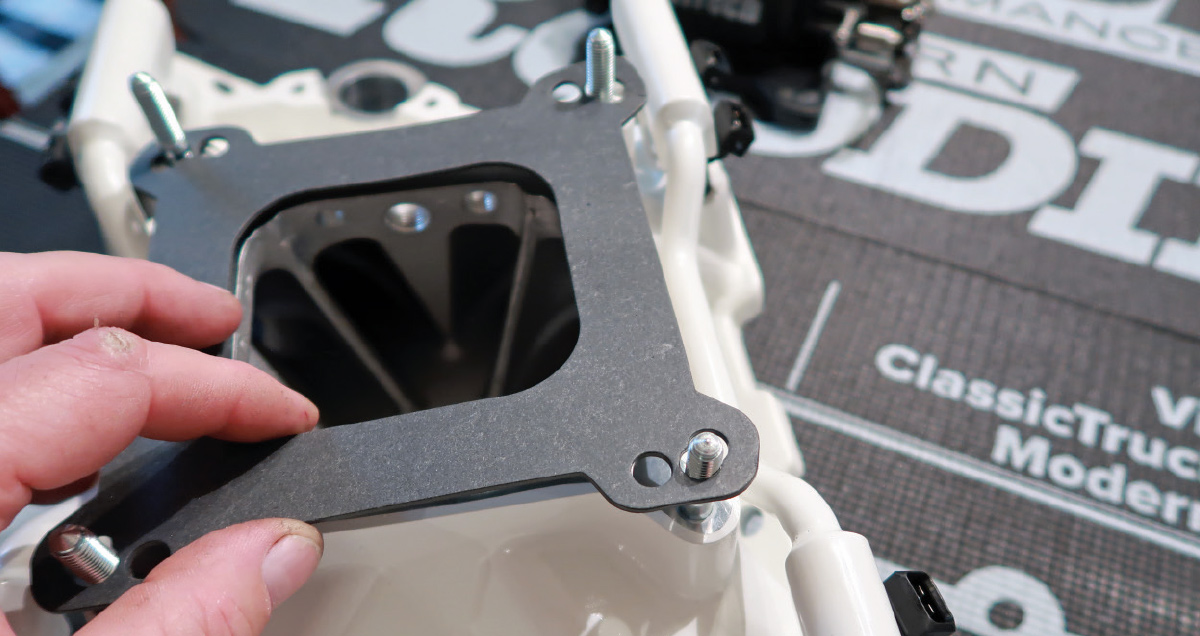

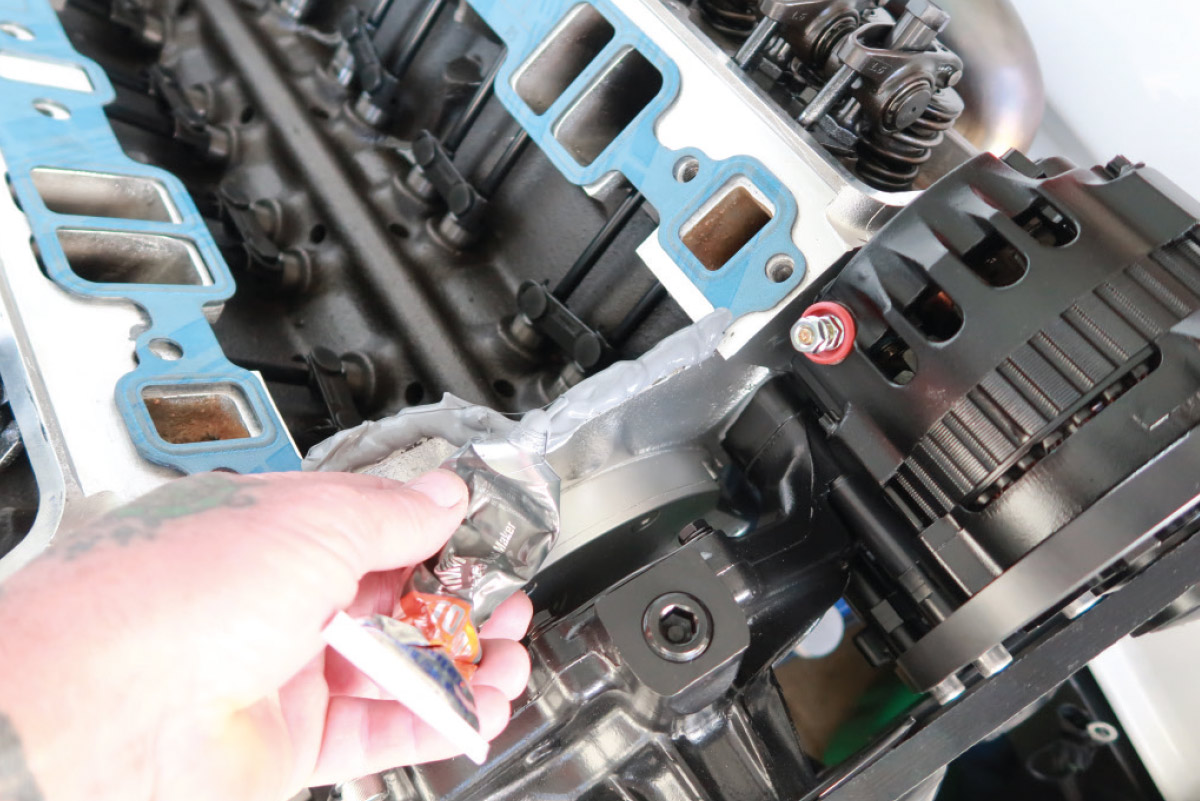

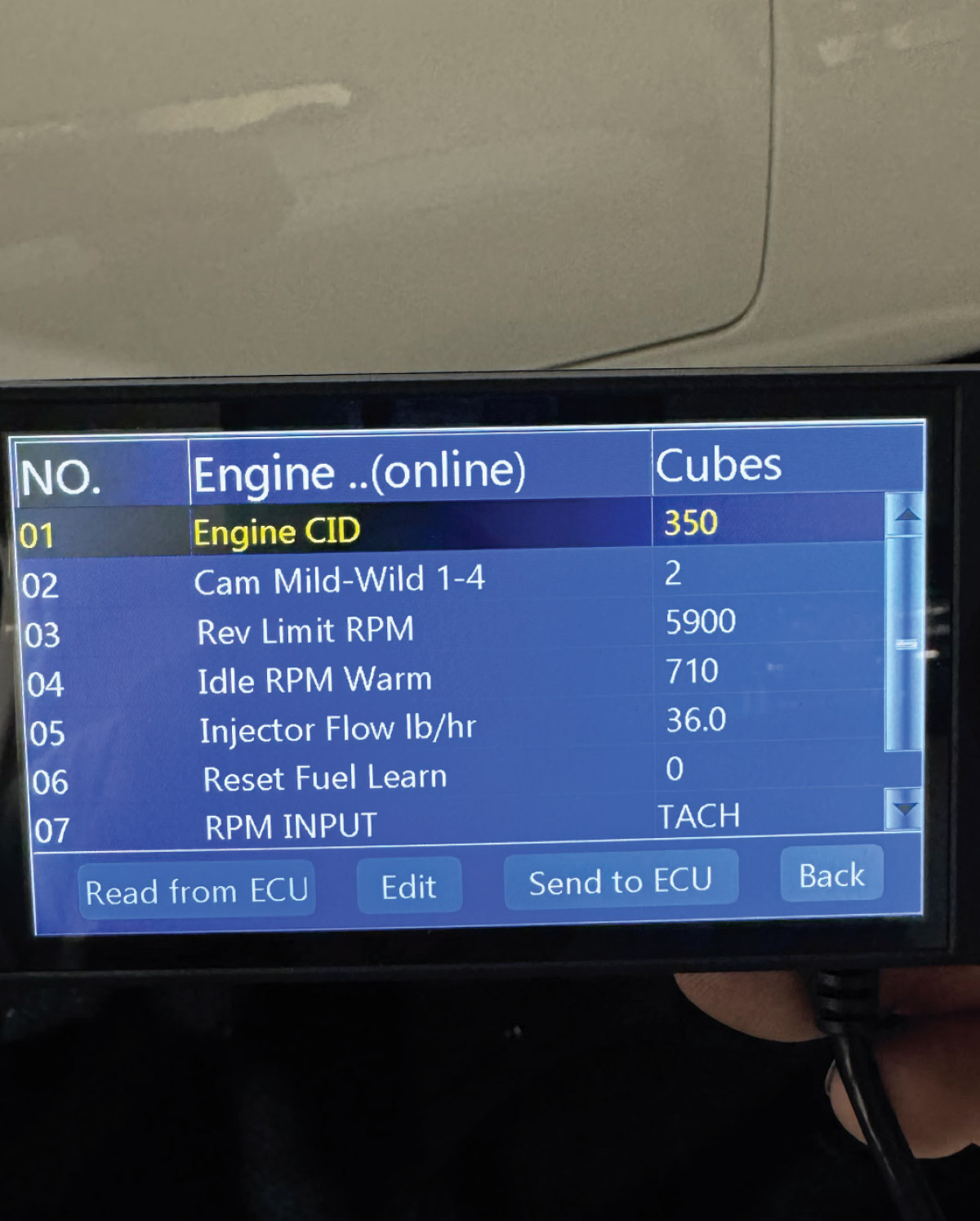

Let’s start off with how easy the installation was. It was a complete bolt-on kit with all-weather pack type connectors, the wiring was simple and straight forward. Once the install was complete, it was time to fire up. With some simple steps with the handheld, I was ready to fire! Now back to why to switch over to EFI. Electronic fuel injection uses pressure to introduce fuel into the engine. This gives the ability of immediate fuel delivery on tip-in of the throttle. This allows for better throttle response over a carburetor. The ECU is always learning, making for an overall reliable and smooth-running truck. When driving on a road trip, say cross country, no reason to worry about elevation changes. Unlike a carburetor, the ECU will make the changes. So if you’re looking for reliability and ability to maximize your miles to the gallon like your daily, but want to look cool doing it, FiTech’s Ultra Port EFI is where it’s at!

To emphasize how simple this swap is, after ripping the carburetor off, about six hours later the truck was up and running. (Note: I’d previously installed an EFI-compatible tank. You will need to factor that into the installation using FiTech’s 50014 Go-Fuel in-tank retrofit kit.) With some adjustments made to the Ultra Port’s stand-alone ECU (via the supplied handheld), the truck was running as smoothly as could be! With all the modern upgrades, I felt my wife could enjoy the truck and have all that reliability.

SOURCES

SOURCES