Tech

Tech

BY Ron Ceridono

BY Ron Ceridonohere’s no question that the 1967-1972 Chevrolet C10 and GMC C15 pickups are highly sought after by Classic Truck Performance readers. Also extremely popular are the 1973-1987 Squarebody Chevy and GMC trucks. But while there’s a difference in styling of the two series of trucks, the modifications made to them often have the same goals: lower ride height and improved handling. Both these goals can be met with suspension kits from Detroit Speed & Engineering (DSE).

DSE offers two distinct front suspension packages: Speed Kits and SpeedMAX. Entry-level Speed Kits are available in three configurations: Speed Kit 1, 2, and 3. All Speed Kits lower the front of your truck 4-1/2 inches, while handling and steering performance is improved with each level of kit. Each component of the Speed Kits is also sold separately to allow users to fit the build of their truck.

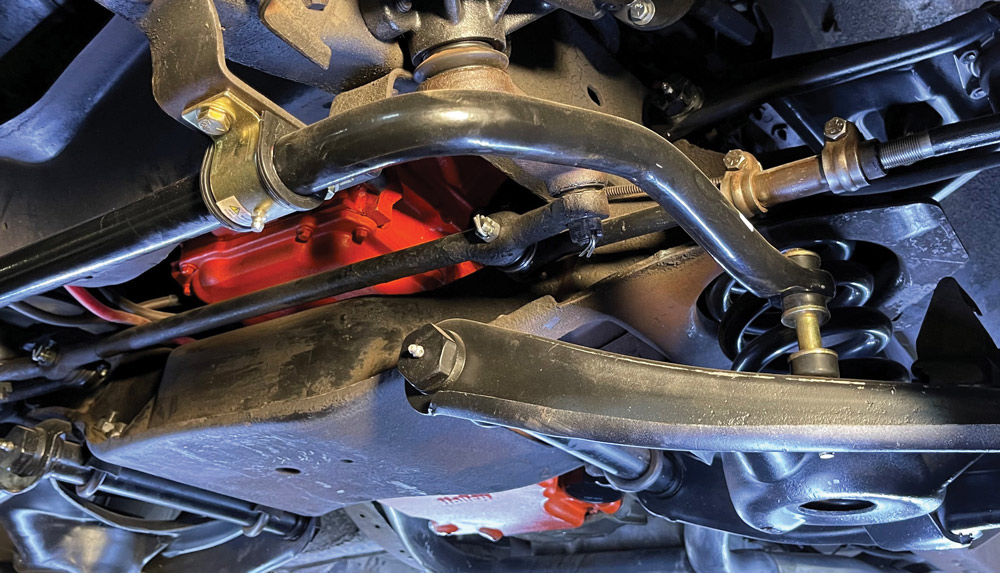

The DSE Speed Kit 2 adds a 1-7/16-inch-diameter sway bar, along with new ball joints and tie-rod ends. The hollow tube design has a wall thickness of 0.188 and is 127 percent stiffer than a factory sway bar.

DSE Speed Kit 3 improves steering performance with DSE’s quick-ratio (12.7:1) power steering box. Not a rebuilt OEM unit, the new DSE power steering box uses “Detroit Tuned” rack-and-pinion valve technology along with a low-friction gear design for improved steering feel. Available for 1968-1986 Chevrolet/GMC C-Series trucks and Suburbans and 1987-1991 Chevrolet/GMC R-Series trucks/Suburbans, a new 3/4-inch x 30-spline rag joint will be required, along with new O-ring power steering hoses. (Note: To install this steering box on a 1967 C-Series truck, frame modifications in the steering box area are necessary.)

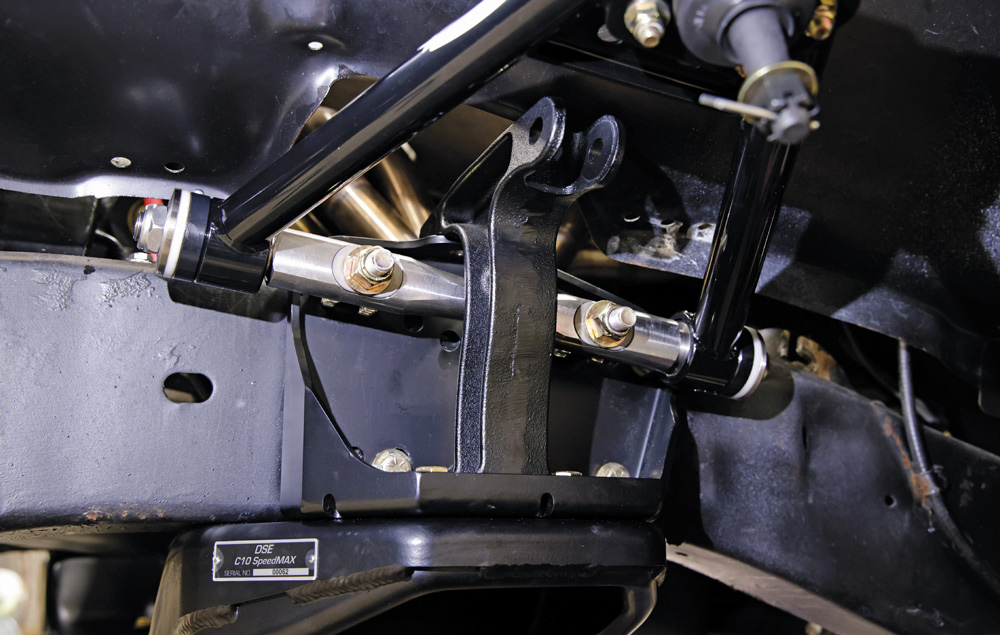

DSE describes SpeedMAX kits as being “designed for sports car–like handling with truck-duty parts.” In addition, DSE’s exclusive suspension geometry is engineered for superior handling and ride quality at a lowered ride height. SpeedMAX kits are a 100 percent bolt-on front suspension system that can be installed with the engine and front sheetmetal in place (some trimming of the inner fender panels is required to clear the coilover mounts).

Included in the SpeedMAX kits is a new stamped crossmember that mounts all the suspension components as well as small-block Chevy engine mounts. The original steering box and linkage is scrapped in favor of DSE’s “Detroit Tuned” GMT800 rack-and-pinion for positive and smooth steering control. The DSE aluminum body coilover shocks replace the factory coil springs and allow for ride height adjustment and spring rate tuning without having to disassemble the control arms and provide for a 4- to 6-inch suspension drop. The DSE shocks are available in non-, single-, and dual-adjustable designs; all come with 550 lb/in springs.

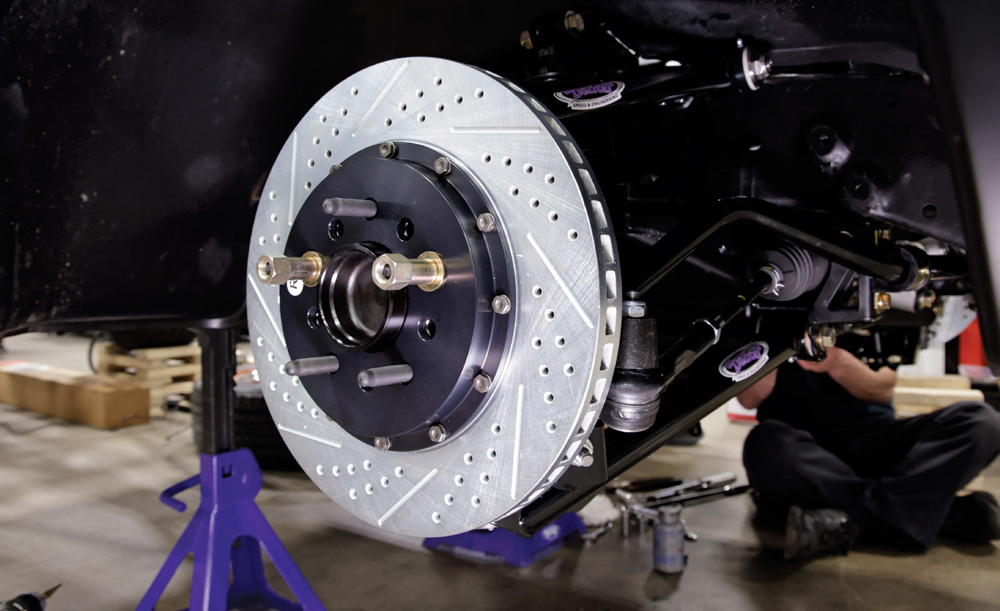

SpeedMAX kits include tubular upper and lower control arms that are both lighter and stronger than the factory stamped steel parts. Using the DSE forged aluminum upright, a DSE SpeedMAX specific steering arm is added to optimize the Ackerman and bumpsteer geometry with the steering rack. The upright features the same dual bolt pattern hub pack and brake options as the Speed Kits. Also included is an improved sway bar specifically designed to work with the SpeedMAX suspension components.

With all DSE Uprights, at least 17-inch wheels with an inside diameter of 16.250 inch must be used. DSE offers 13-inch brake rotors (PN 050403DS) to pair with OE replacement GMT800 calipers. DSE U-joint steering shafts are required for SpeedMAX installations, part numbers available for all year ranges. For the 1967-1972 trucks as shown in this install, DSE steering shaft (PN 092534DS) and Ididit steering column (PN 1120658010) are required.

For a lowered ride height and improved handling, DSE offers their Speed Kits for those looking for a lowered profile; the ultimate in a performance suspension systems are the SpeedMAX kits. Either way, DSE can help get the drop on C10 and C15 pickups.

SOURCE

SOURCE