Tech

Techlowers are not for everyone—nor are they for every engine. They’re cool to look at, they sound bitchin when they whine at high rpm, and they definitely have the ability to exponentially boost performance, no pun intended. But they have their downsides as well: hefty investment and potential to cause unwelcome damage to an underlying reciprocating system (your engine) if not properly prepared for said forced induction.

Positive-displacement superchargers—aka, Roots-style blowers—have been around a long, long time … since the late 1800s to be exact. Originally developed by the Roots Brothers, Francis and Philander, as a means in which to improve air movement in metal-smelting blast furnaces, the idea was actually first implemented for automotive use by Gottlieb Daimler, and subsequently put into production on Mercedes-Benz models by the 1920s. It wasn’t long after that hot rodders began “borrowing” the idea of engine-driven forced induction to help boost performance for street racing, dry lakes racing, and eventually sanctioned drag racing—by scavenging GMC industrial-purpose Roots blowers and facilitating a means in which to forcibly induct mass air into their Flathead V-8s and early OHV engines. Next came the centrifugal superchargers, which effectively served the same purpose, however more efficiently and from within a more compact package.

lowers are not for everyone—nor are they for every engine. They’re cool to look at, they sound bitchin when they whine at high rpm, and they definitely have the ability to exponentially boost performance, no pun intended. But they have their downsides as well: hefty investment and potential to cause unwelcome damage to an underlying reciprocating system (your engine) if not properly prepared for said forced induction.

Positive-displacement superchargers—aka, Roots-style blowers—have been around a long, long time … since the late 1800s to be exact. Originally developed by the Roots Brothers, Francis and Philander, as a means in which to improve air movement in metal-smelting blast furnaces, the idea was actually first implemented for automotive use by Gottlieb Daimler, and subsequently put into production on Mercedes-Benz models by the 1920s. It wasn’t long after that hot rodders began “borrowing” the idea of engine-driven forced induction to help boost performance for street racing, dry lakes racing, and eventually sanctioned drag racing—by scavenging GMC industrial-purpose Roots blowers and facilitating a means in which to forcibly induct mass air into their Flathead V-8s and early OHV engines. Next came the centrifugal superchargers, which effectively served the same purpose, however more efficiently and from within a more compact package.

3. With the ARP head stud kit, pre-soaked hydraulic lifters, and new windage tray installed (as well as the lifter valley freshly coated with Glyptol) …

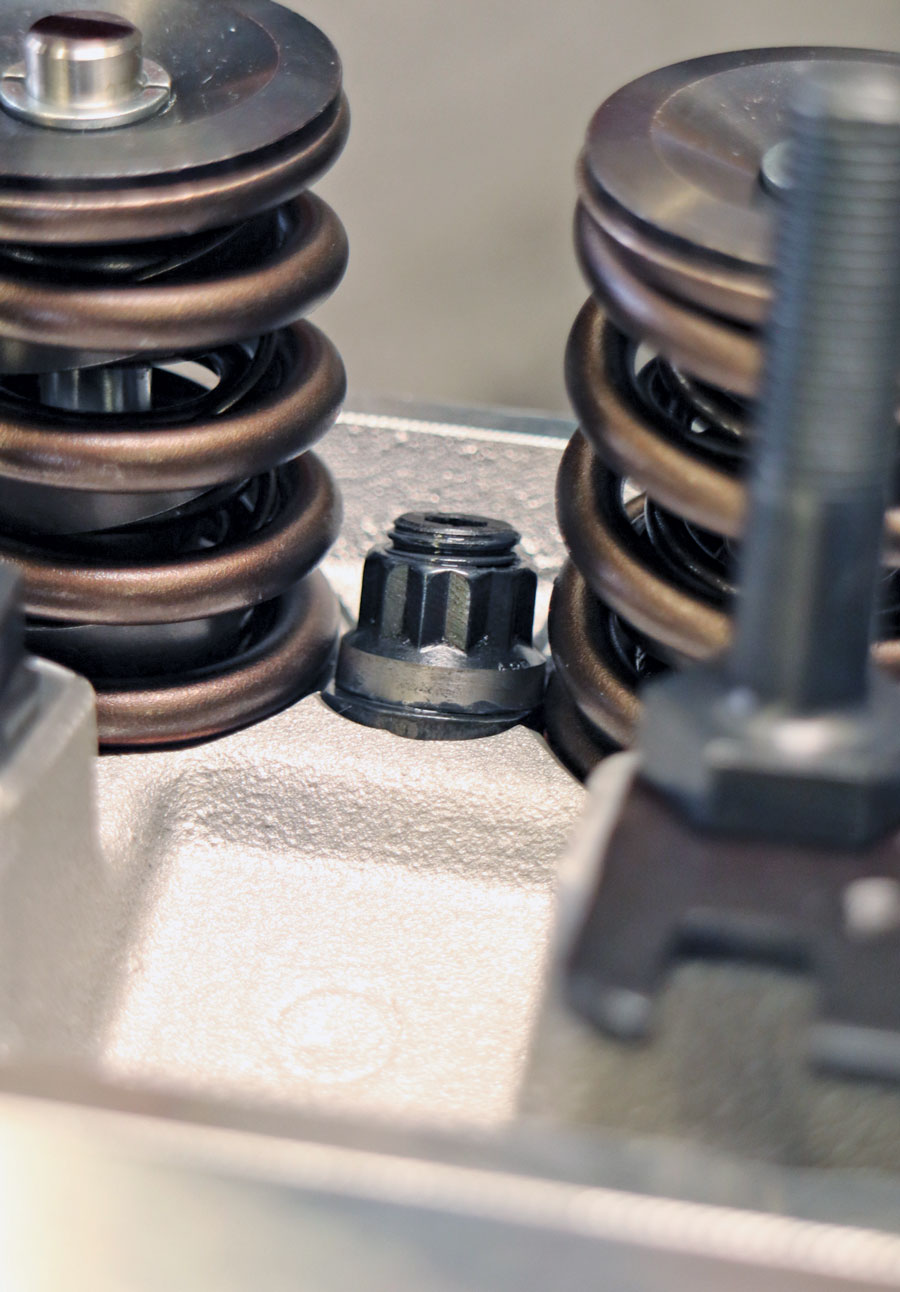

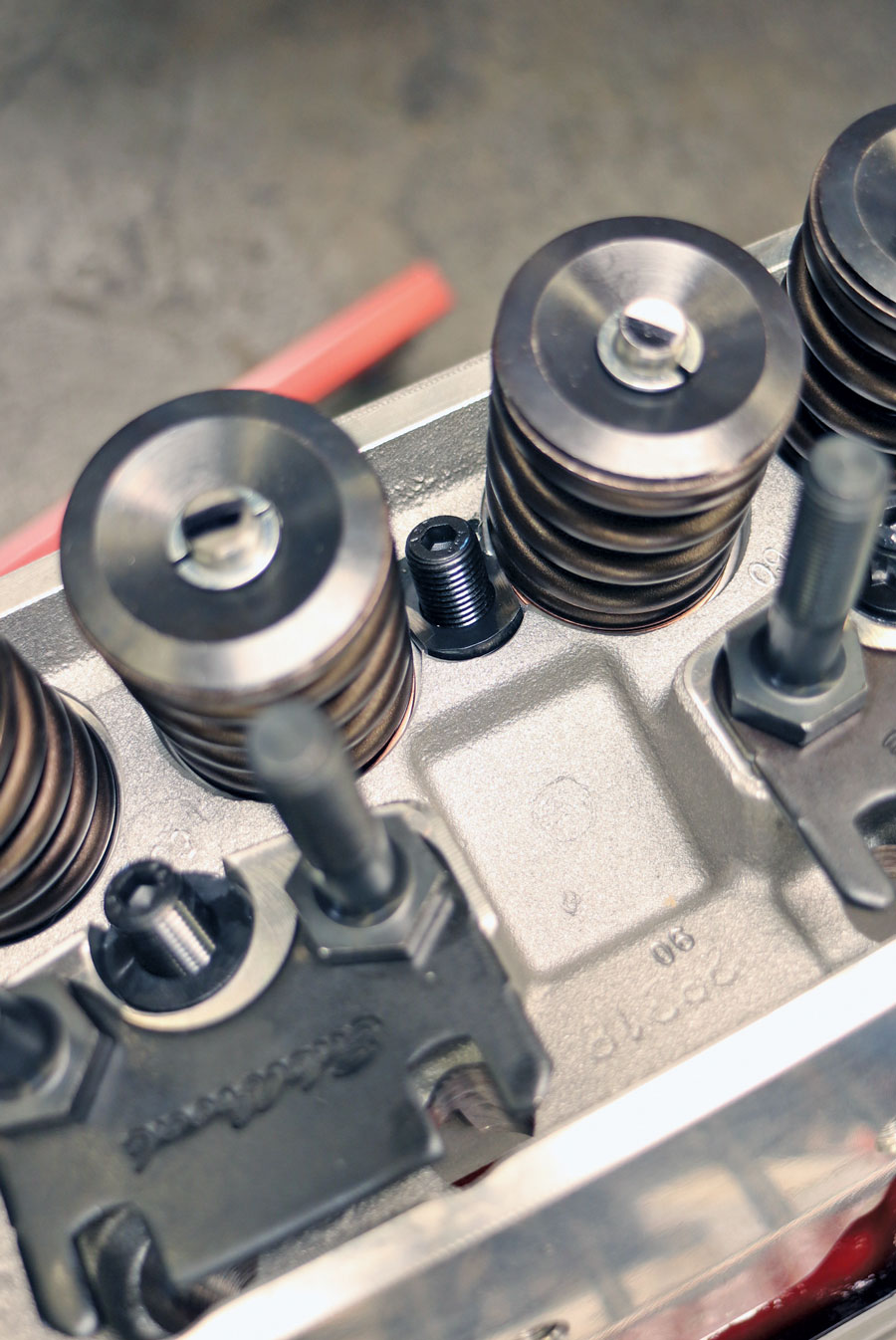

5-7. Due to the larger diameter of the valvesprings it was necessary to “turn down” the shoulder on the ARP 12-point hardware for the outermost studs where space is a bit cramped to begin with.

9. Next, our ordered-to-length (long) Comp pushrods were dropped in and the guideplates checked for alignment.

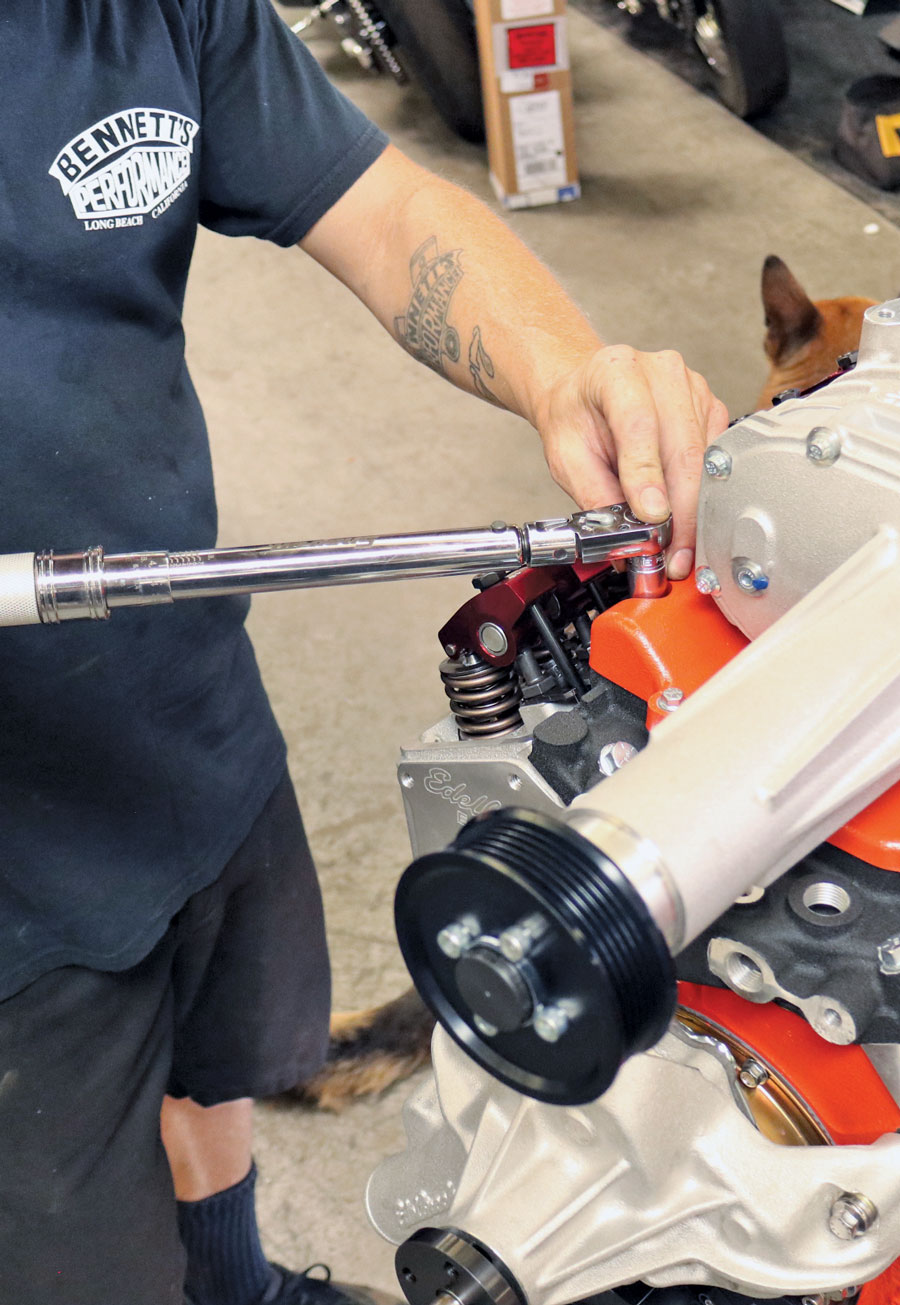

10-11. With the valve tips pre-marked and lubed, our 1.5:1 Red Roller Rocker arms were test-fit to verify proper geometry and clearance (ensuring no interference between pushrods, guideplates, or springs,).

14-15. After initially setting up the valvetrain, Bennett filled the lifter valley with a quart of Mobil-1 10W-30 before priming the new HV Melling oil pump.

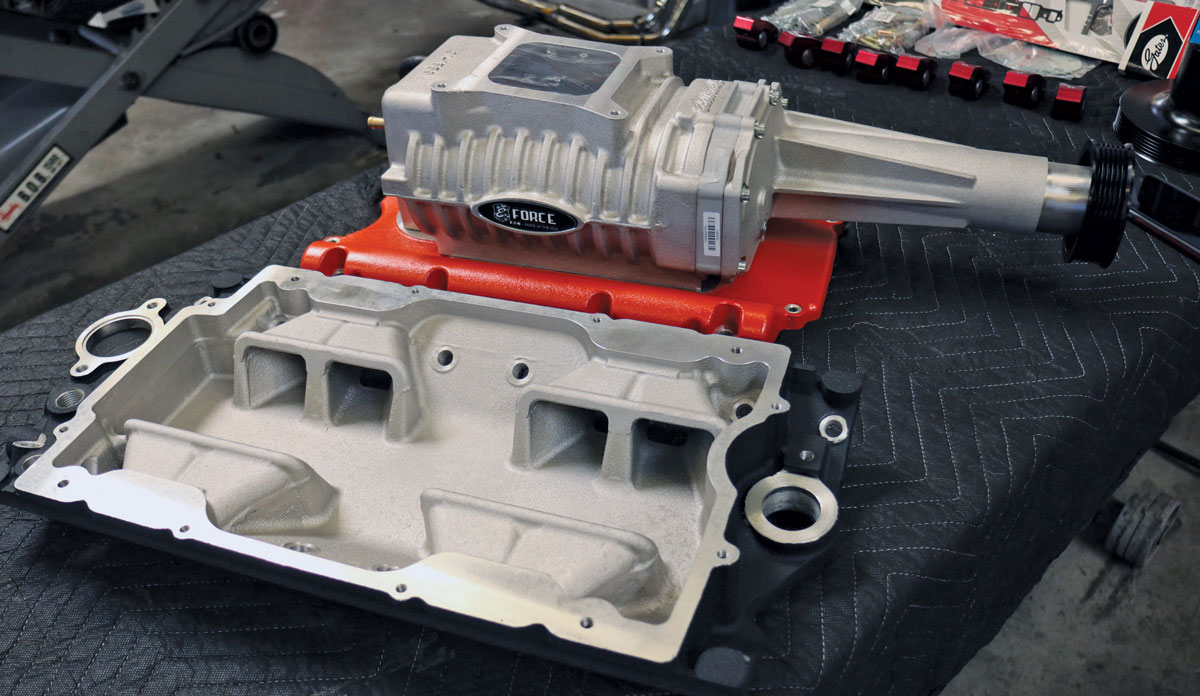

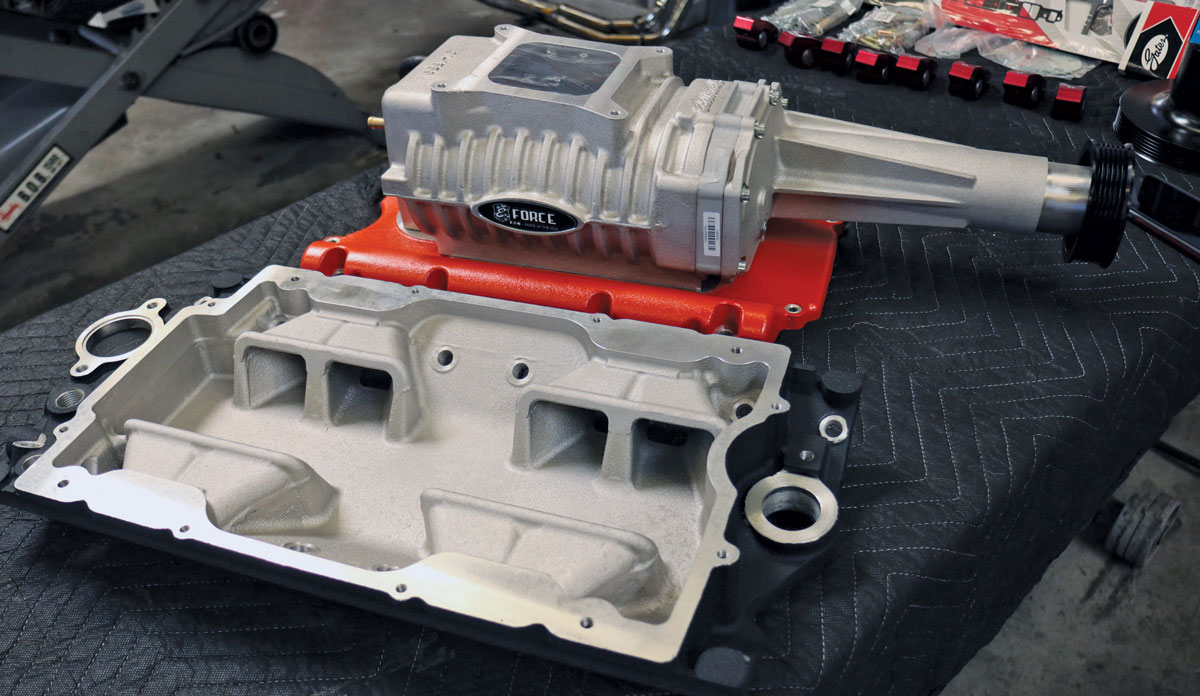

16. Our source of forced induction is, as previously mentioned, Edelbrock’s E-Force 122 positive displacement supercharger, which, according to the manufacturer, is capable of producing over 500 hp “on most applications.” Let’s just hope we fit safely in that category! The kit we obtained from Speedway (PN 1551) is for 1986-earlier standard SBC.

19-20. In lieu of the potential “blow-out” front and rear seals, we opted for the traditional 1/4-inch trowel bead of RTV on each end between the freshly glued intake gaskets, which Edelbrock recommends anyway. (Sealant is also added to the area around the water passages.)

21-22. The blower intake is installed next. Supplied hardware is torqued in specified sequence to 25 lb-ft.

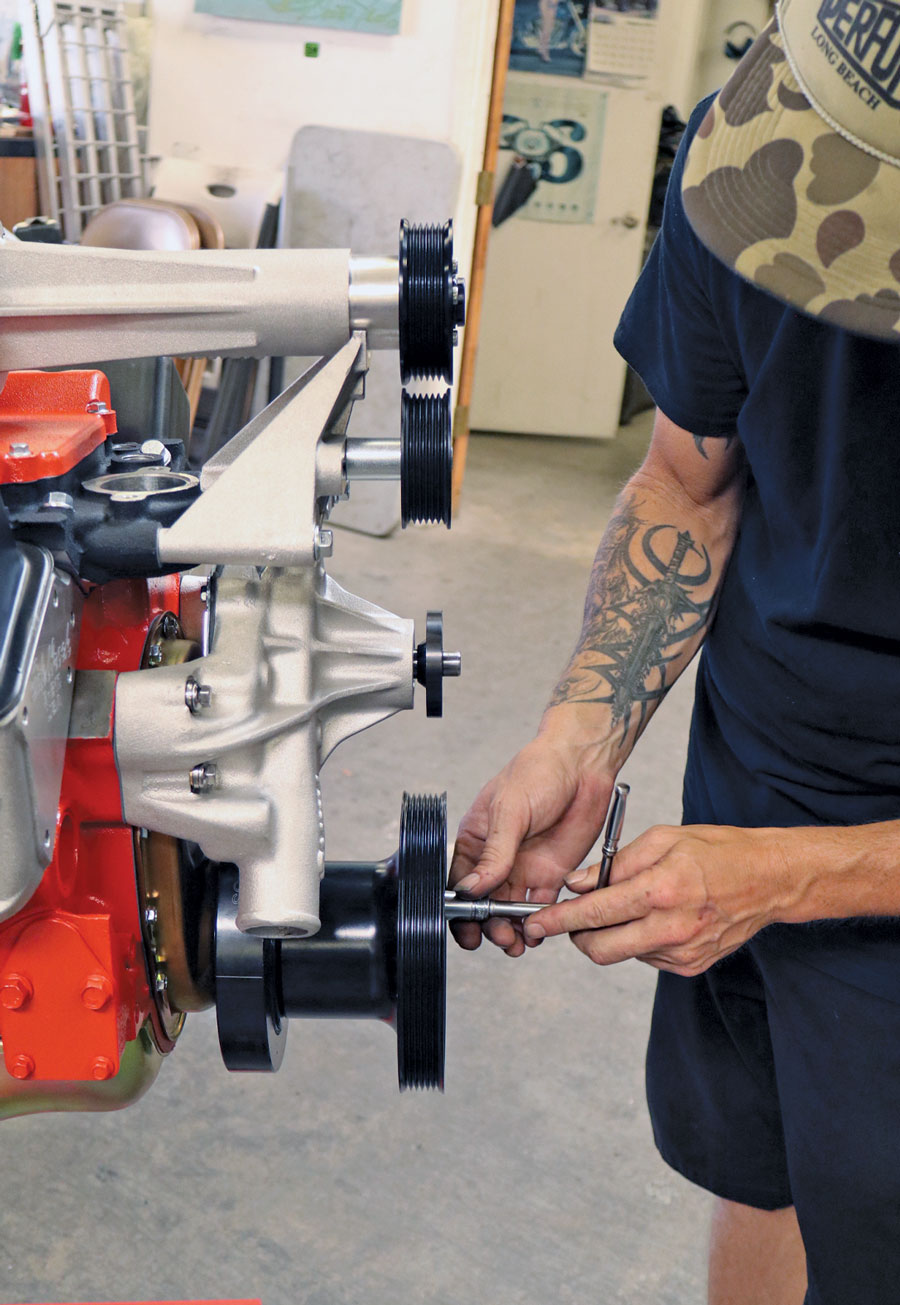

25. Lastly, the primary blower pulley and belt system was installed, and …

26. … save for means of fuel and spark delivery, our street-friendly blower installation is a wrap. As mentioned, ignition timing is important with blower applications—and with that said, we’ll be using the appropriate MSD electronic CD ignition accompanied by their Boost Timing Master. As for fuel supply, that will be handled by a programmable Holley Sniper EFI system.

SOURCEs

SOURCEs