Tech

Tech

BY “Rotten” Rodney Bauman

BY “Rotten” Rodney Baumanall been done before!” Yes, we’ve heard that said, but let’s be open-minded here. Granted, walking through a custom car show won’t likely trigger novel notions, but walking through a wrecking yard still can. For Colten Hart, of Kalispell, Montana’s Vintage Soul Garage, that’s exactly how his custom taillight treatment came to mind—by walking 40 acres of elderly cars and trucks. We’ll circle back around to that, in just a bit or two.

For now, before we go much further, know this about Colten Hart: At age 28, he’s a builder with a full bag of tricks. Custom body- and paintwork are his specialties, and he’s helped a good number of other builders over some humps. Lately, Hart has been assisting Kalispell collector, Bob King, with a restomod-style 1959 Chevy ice cream truck build. At the same time one of his own projects is on the lift in King’s shop. Long story short, Hart has purchased an unfinished 1959 Chevy Stepside shorty that he’ll rethink as necessary, see through, play with, and perhaps peddle one day down the road. (At the time of this typewriting, Hart’s personal pickup project is receiving some needed attention, as he’s pulling off a good save. From here, however, let’s focus only on the aforementioned custom taillight treatment.)

Through the existing white paintjob, the old truck’s Stepside fenders appear to be decent, for used OE parts, anyway. In its current stage of incompletion, the project’s taillights have not yet been thought out. The easy way would be to order up some new reproduction Stepside-type lights from Brothers. For Hart, however, choosing the easy way doesn’t come so natural.

So, back to the boneyard. During a routine visit to Cut Bank, Montana’s Rustless in Montana, Hart came upon the shell of a 1958 Chevy Fleetside pickup. Recognizing shapes, as well as their potential, he then birthed the notion to graft a pair of Fleetside-type taillights to his good-enough, used Stepside fenders.

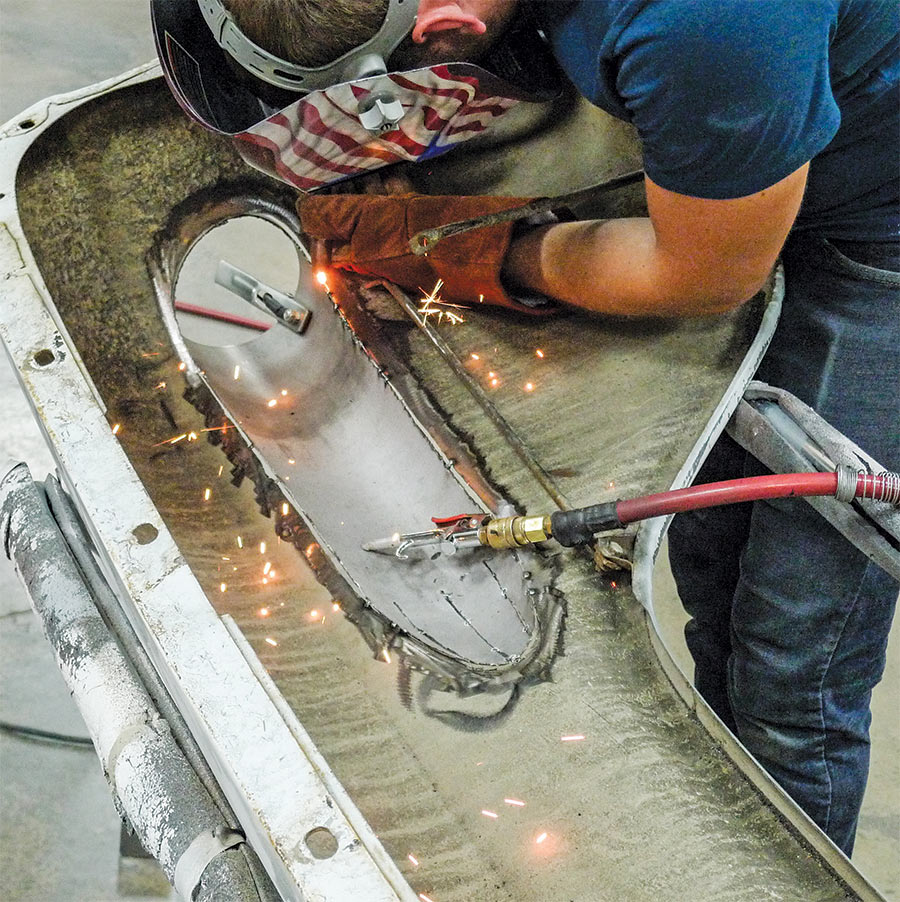

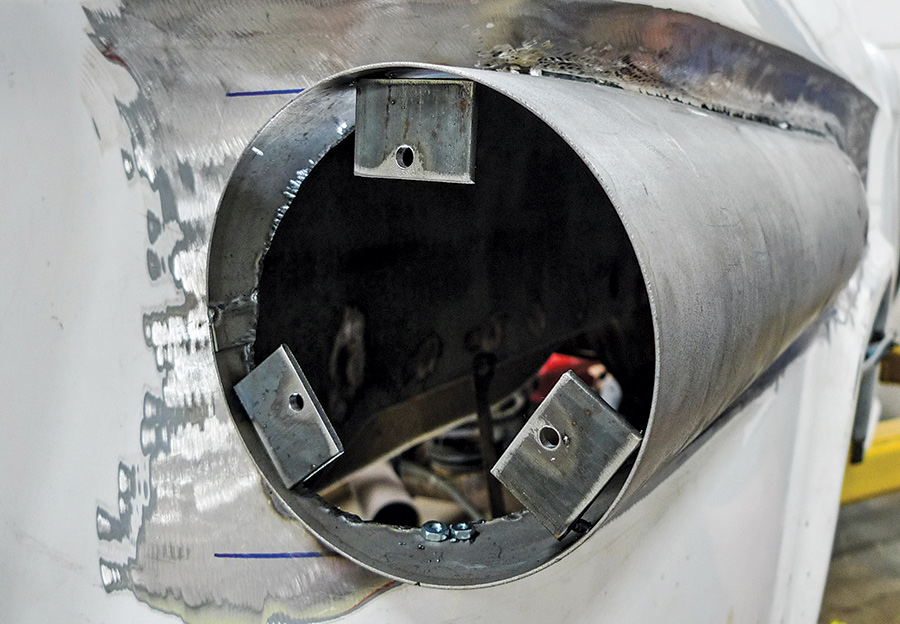

At the shop the next day, it was first things first, as a parts order was placed. From that point on, Hart’s custom body modifications would be based on a shiny new pair of LED taillight assemblies, available through Brothers, which outwardly appear to be exact reproductions of the 1958-1959 Chevy Fleetside units. When those parts arrived, Hart commissioned the local sheetmetal shop to roll out a pair of 18-gauge steel tubular tunnels to match the od of the shiny new taillight bezels.

Skipping ahead, we’ll end up with a one-off custom taillight treatment, all in compatible, same-vintage, Chevy pickup style. On that note, you’re invited to stick around as Hart openly divulges the step-by-step procedure for the replication of his own boneyard brainchild. Somewhere between Stepside’ing Fleetside?! The end result deserves a clever name of its own … we’ll leave that open for suggestions.

SOURCEs

SOURCEs

(800) 977-2767

brotherstrucks.com

Harbor Freight Tools

(800) 423-2567

harborfreight.com

Vintage Soul Garage

vintagesoulgarage@hotmail.com